I'm reading that soy oil is becoming popular in electrical transformers.

Dave G., I appreciate your suggestion to use an oil bath, and you need not think you lead me down a wayward path with regards to safety. I consider it my responsibility to explore and use the correct product.

Life is good.

Dave G., I appreciate your suggestion to use an oil bath, and you need not think you lead me down a wayward path with regards to safety. I consider it my responsibility to explore and use the correct product.

Life is good.

Hello carpenter, I thank you for your humbleness and nobility, but I still worry. I would hate to think I had a hand in a catastrophe, especially if I wasn't directly involved!😉 Too many people today seem to want to just go for it without researching things first, I see it everyday at my work place. I am just a drafting technician (mostly mechanical) with an associates in EET, but it amazes me how often I am cleaning up others messes because they didn't take the time to learn about the specific subject and parts before going at things. And they rarely ask the end user if the documents they create are any good.

Peace and good luck,

Dave

P.S. you could always put the transformer and chokes in separate enclosures, away from the electronics, that way you could have even bigger oil baths!

Peace and good luck,

Dave

P.S. you could always put the transformer and chokes in separate enclosures, away from the electronics, that way you could have even bigger oil baths!

Don't encourage him. This thing is going to end being so big it will need to become a structural member of the house😀

I really like the idea of sinking the power transformers in oil. Nice way to save on copper and make up for it with a bit of labor.

I really like the idea of sinking the power transformers in oil. Nice way to save on copper and make up for it with a bit of labor.

OOOOOHHHH!!!!! I like that idea. Build the power supply so that it adds structural integrity to the house. As opposed to just putting a huge amount of weight onto the framing and stressing it out.😉

Peace,

Dave

Peace,

Dave

I think the follow up to that is a chip amp to run in the summer and a nice 150 watt class a full balanced setup for those chilly winter months. Why pay for heat when you spend that much powering an amp?

I did once consider building a concrete stereo rack that started in the basement and ended in the living room. Now my setup is in the basement. Not to bad getting things down there, but a real PIA getting them back up.🙂

I did once consider building a concrete stereo rack that started in the basement and ended in the living room. Now my setup is in the basement. Not to bad getting things down there, but a real PIA getting them back up.🙂

I have considered creating two, side by side, heat sinks with a common shaft coupling the pair together. The wire would be in physical contact and, thus, transfer heat out the sides.

Hello carpenter, the weather here in Vermont does weird things to the brain. Either you go with the comedy, or go with insanity. Sometimes a combination of both!

I still like the idea of a big old power supply in the basement of your place with the various oil cooled transformers and chokes located there.

Hey DaveM, interesting idea about the concrete stereo cabinet to the basement, but I don't think my tenant below would care for a big pillar of concrete going through her living room.😀

While getting equipment out of the basement is a PITA, there are benefits. Reduced vibrations for your equipment(although not upstairs), and it's usually a more stable temperature.

Peace,

Dave

I still like the idea of a big old power supply in the basement of your place with the various oil cooled transformers and chokes located there.

Hey DaveM, interesting idea about the concrete stereo cabinet to the basement, but I don't think my tenant below would care for a big pillar of concrete going through her living room.😀

While getting equipment out of the basement is a PITA, there are benefits. Reduced vibrations for your equipment(although not upstairs), and it's usually a more stable temperature.

Peace,

Dave

One could always run PEX under their floors (preferably tile) and transfer the heat to the floor via a liquid medium. The floor becomes the heat sink. Great in the winter!

Wow, good idea. Now if you figure out how to create the power for the system from the decomposing corpses of gnats that died of natural causes (no swatting allowed) and the greenies will love you!

Peace,

Dave

Peace,

Dave

Gnats and just about everything else: Run a long tube to the deeper parts of the ocean and start sucking up that methane nitrate. Burn it under a boiler and use the steam to operate a generator.

Simple aye? 😀 😀 😀

edit: come to think of it, you could use the surplus heat from your amplifier to gasify the frozen methane. Place a tent above the underwater project and collect the gases released. Easier to pump a gas than a frozen solid. Yes?

Simple aye? 😀 😀 😀

edit: come to think of it, you could use the surplus heat from your amplifier to gasify the frozen methane. Place a tent above the underwater project and collect the gases released. Easier to pump a gas than a frozen solid. Yes?

Indeed gases require less energy to pump than fluids, not always as easy to control. However releasing methane from the ground is pulling up all of the dead dinosaurs, that's a no-no. By using the heat and methane given off by natural decomposition of creatures here already (not long buried) you maintain the cycle, thus neutrality.😉

I'm kind of in favor of a stirling engine to generate the power myself.

😀 😎

Peace,

Dave

I'm kind of in favor of a stirling engine to generate the power myself.

😀 😎

Peace,

Dave

Yeah, you probably should. And it would be wise to hide the audio equipment you show on your site.😀

On second thought, you're safe, transporting all that monstrous iron across country would be a royal PITA!😉

On second thought, you're safe, transporting all that monstrous iron across country would be a royal PITA!😉

Thoughts to get this thread back on the original topic and to continue carpenters design. Why not integrate Magura's design right into the case and mount the caster directly to the bottom of the amp enclosure. Add a pull up handle similar to those seen on suitcases and traveling toolboxes, and voila, you have an amp that is relatively easy to move around.

Peace,

Dave

Peace,

Dave

Oh, that was the original intent of this thread, yes? There's a 1/4" aluminum bottom plate on this chassis; I could mount casters directly to it. This thing is so heavy and large, I don't see how it will fit on a shelf. The floor is probably a good place for it to live.

I'm fabricating this big, bad fellow for a friend; my wife took one look at it, smiled and asked why we don't have one--reminds me of the story of the shoe maker's kids.

I told her that my past endeavors have always focused on the electrical aspects of the project. Only now, after years of playing, have I the capacity to consider physical beauty an element of my design.

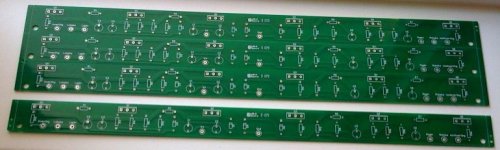

I've ordered pcbs for the new third (output) stage. It's going to be interesting in that there's a built-in voltage regulator. This should assist the CLC filter tremendously--not to mention, I've added a bit of circuitry to allow me to modulate it, which allows me to shift it out of the way and allow the output voltage to climb above the power supply voltage.

This is relevant because the primary mosfet (IRFP044N) only sees 6 volts and that isn't much room to swing a signal. This being a low wattage amp, I can get away with a low voltage swing.

Though it doesn't move a lot of voltage, it does swing amperage. The sim shows it capable of driving a 1 ohm load without the power curve getting too ugly.

The open baffle bass/midbass section of my test speaker system is loaded with 8--16ohm drivers configured for an 8 ohm load. It sounds terrific. This little amp drives them with authority in my little lab.

I have iTunes on my computer and have the computer connected the the amplifier. I downloaded Bass Mechanic's test tones. The speakers play fairly even down to 30hz. I haven't taken the speakers any lower for fear of damaging them. I should mention that I boosted the EQ a smidge in the bass region. Still, it's impressive considering I'm use a bifilar choke with only 41mH inductance. This is too small a value, but it works. I'm going to follow Magura's lead and have it bumped to 80+ mH.

Fun stuff.

I'm fabricating this big, bad fellow for a friend; my wife took one look at it, smiled and asked why we don't have one--reminds me of the story of the shoe maker's kids.

I told her that my past endeavors have always focused on the electrical aspects of the project. Only now, after years of playing, have I the capacity to consider physical beauty an element of my design.

I've ordered pcbs for the new third (output) stage. It's going to be interesting in that there's a built-in voltage regulator. This should assist the CLC filter tremendously--not to mention, I've added a bit of circuitry to allow me to modulate it, which allows me to shift it out of the way and allow the output voltage to climb above the power supply voltage.

This is relevant because the primary mosfet (IRFP044N) only sees 6 volts and that isn't much room to swing a signal. This being a low wattage amp, I can get away with a low voltage swing.

Though it doesn't move a lot of voltage, it does swing amperage. The sim shows it capable of driving a 1 ohm load without the power curve getting too ugly.

The open baffle bass/midbass section of my test speaker system is loaded with 8--16ohm drivers configured for an 8 ohm load. It sounds terrific. This little amp drives them with authority in my little lab.

I have iTunes on my computer and have the computer connected the the amplifier. I downloaded Bass Mechanic's test tones. The speakers play fairly even down to 30hz. I haven't taken the speakers any lower for fear of damaging them. I should mention that I boosted the EQ a smidge in the bass region. Still, it's impressive considering I'm use a bifilar choke with only 41mH inductance. This is too small a value, but it works. I'm going to follow Magura's lead and have it bumped to 80+ mH.

Fun stuff.

dave_gerecke said:Yeah, you probably should. And it would be wise to hide the audio equipment you show on your site.😀

On second thought, you're safe, transporting all that monstrous iron across country would be a royal PITA!😉

I have some spare transformers if you're ever in the market to play with my design. Judging from their core, they're probably 1800 watt units. Output taps are 2 x 0/14/28 volts

Hello John, Thank you for the offer, but at this point I already have way to many projects brewing in my head. And I don't think I could afford the shipping on those monsters!😱

Peace,

Dave

Peace,

Dave

- Status

- Not open for further replies.

- Home

- Amplifiers

- Pass Labs

- No more aching back