If i use only one flared end, then the length will be 2.9" with the connecting ring. Will the lack of a flared end on the inside affect anything?

sure you can

just cut off the inner flare with enough distance from flare to have a small piece of straight tube on it

then cut off another small piece of the actual tube

slice it, and put it on the outside

and glue when you have the port length you like

may be worth to note that port lenth and tuning interacts closely with box size

have you tried to use a box calculator ?

heck 🙄

you could also do the obvious thing, and use tape 😛

Please stick to the subject of the original thread. I have moved the JBL related posts to a new thread.

Please stick to the subject of the original thread. I have moved the JBL related posts to a new thread.Here: http://www.diyaudio.com/forums/multi-way/195463-deja-vu-box-design-jbl-2235h.html

Further OT posts will be deleted...

According to the vent tuning options, the port needs to be modified to 3" from the default of 4.75". But i see no way to do that if both flared ends need to be used. If i use only one flared end, then the length will be 2.9" with the connecting ring. Will the lack of a flared end on the inside affect anything?

No biggie as you have flared on the outside which should slow the velocity enough on exit. Just give it a try and see what you think with the higher Fb.

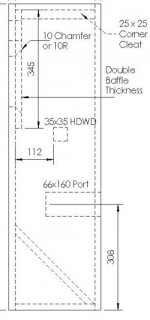

It's been mentioned by others before, that shelf brace arrangement can be a problem. I'm not fussed on the grouping especially directly above the port. If you remove shelf braces you can add cross bracing and corner cleats to sort out panel resonances.

I'm not saying to do what I have in the pic, but I've found this arrangement good in tall slender boxes. The hardwood cross brace attaches to driver cut outs to help with side panel resonances and the lower angled section forms a tapered section to help with box pipe resonances. You can add more cross bracing to suit taller boxes. The baffle has braces above and below the mid woofer as shown by the cross pieces. The pic is before corner cleats are added. This complete arrangement allows damping to hang like a curtain in the middle of the box (not blocking airflow to the port) which is a good method for vented designs and is more effective than damping applied to walls (ref Ralph Waters, Vance Dickason). Further damping is used on the top and in the tapered section.

Another thing to check is the rear of the woofer cut out being chamfered to assist in air flow as well as the entry to the port has a minimum of 75mm clearance to the back of the box and any damping.

I'm not saying to do what I have in the pic, but I've found this arrangement good in tall slender boxes. The hardwood cross brace attaches to driver cut outs to help with side panel resonances and the lower angled section forms a tapered section to help with box pipe resonances. You can add more cross bracing to suit taller boxes. The baffle has braces above and below the mid woofer as shown by the cross pieces. The pic is before corner cleats are added. This complete arrangement allows damping to hang like a curtain in the middle of the box (not blocking airflow to the port) which is a good method for vented designs and is more effective than damping applied to walls (ref Ralph Waters, Vance Dickason). Further damping is used on the top and in the tapered section.

Another thing to check is the rear of the woofer cut out being chamfered to assist in air flow as well as the entry to the port has a minimum of 75mm clearance to the back of the box and any damping.

Attachments

Last edited:

Thank you all for the advice, especially rabbitz. Might you happen to have a 3/4 picture view of the bracing? Somehow my mind cannot visualize how the bracing arrangement looks like.

It will be quite a challenge to modify the current bracing, because they are all glued in place and it will be a real pain to get them out. I will definitely take those ideas into consideration for my next project!

I finally got down to setting up both speakers and listening in stereo. I can say now, objectively, that they sound absolutely amazing, even if i wasn't the one who built them. The low end extension is pretty good. No, make that damn good for a 6.5" woofer. Though with that said, i will still experiment with different port tunings. Any more suggestions would be welcomed

It will be quite a challenge to modify the current bracing, because they are all glued in place and it will be a real pain to get them out. I will definitely take those ideas into consideration for my next project!

I finally got down to setting up both speakers and listening in stereo. I can say now, objectively, that they sound absolutely amazing, even if i wasn't the one who built them. The low end extension is pretty good. No, make that damn good for a 6.5" woofer. Though with that said, i will still experiment with different port tunings. Any more suggestions would be welcomed

I finally got down to setting up both speakers and listening in stereo. I can say now, objectively, that they sound absolutely amazing..

Aha! Yes, always fully assemble both speakers and place them in your listening area before you make any judgments about their performance!

I finally got down to setting up both speakers and listening in stereo. I can say now, objectively, that they sound absolutely amazing, even if i wasn't the one who built them. The low end extension is pretty good.

does this mean you actually never listened to the speakers, properly

😕

does this mean you actually never listened to the speakers, properly

😕

Apparently... 😛

Not that it would invalidate what was being said mind you, it's just that with two loudspeakers in a room you're going to have less issues with room modes.

Might you happen to have a 3/4 picture view of the bracing? Somehow my mind cannot visualize how the bracing arrangement looks like.

These pics may help. Both are different speakers to the previous pic.

Attachments

Thank you for the detailed drawings, rabbitz! It is extremely helpful, i've saved the pictures for my future projects

Thank you to everyone who helped in one way or another, i really appreciate it!

Couple of quick updates:

I modified the port tuning higher to 35 Hz. The bass is really tight now and full now, no complains at all.

The only 'problem' left now is i'm not 100% satisfied with how drum toms sound and in general, rock songs lack some body, for lack of a better word. There's definitely much stronger (< 80 Hz) with the new speakers, but i suspect i'm lacking that midbass punch.

So.. i'm wondering if it's because of the reduced BSC (2.0 mH) i went with that was recommended for my near field usage, throwing off the tonal balance and making the speakers a bit too forward and mid-centric.

Or is it because i have too much mineral wool lining?

I'm using this particular rockwool type

The sound absorption data is as follows:

The back wall is lined with 2" roxul rockwool, side walls lined with 1" and top 2". There is no stuffing at all. I understand fiberglass wool is generally more effective at killing frequencies than acoustic foam/fill, so i don't know if i'm using too much. While googling around i found other people who reported that fiberglass wool killed off the sound too much so maybe i'm in a similar situation?

At the same time, i don't see how i can minimize the lining even more. Maybe reduce the back lining to 1"? But then i'm worried about not attenuating the backwaves enough.

I did change the lining thickness quite a lot but it didn't seem to make much of a difference, this being the bare minimum i thought was necessary. I guess i could continue tweaking the amount of stuffing but if it's a BSC problem then i guess i should be changing that instead?

Thank you to everyone who helped in one way or another, i really appreciate it!

Couple of quick updates:

I modified the port tuning higher to 35 Hz. The bass is really tight now and full now, no complains at all.

The only 'problem' left now is i'm not 100% satisfied with how drum toms sound and in general, rock songs lack some body, for lack of a better word. There's definitely much stronger (< 80 Hz) with the new speakers, but i suspect i'm lacking that midbass punch.

So.. i'm wondering if it's because of the reduced BSC (2.0 mH) i went with that was recommended for my near field usage, throwing off the tonal balance and making the speakers a bit too forward and mid-centric.

Or is it because i have too much mineral wool lining?

I'm using this particular rockwool type

The sound absorption data is as follows:

The back wall is lined with 2" roxul rockwool, side walls lined with 1" and top 2". There is no stuffing at all. I understand fiberglass wool is generally more effective at killing frequencies than acoustic foam/fill, so i don't know if i'm using too much. While googling around i found other people who reported that fiberglass wool killed off the sound too much so maybe i'm in a similar situation?

At the same time, i don't see how i can minimize the lining even more. Maybe reduce the back lining to 1"? But then i'm worried about not attenuating the backwaves enough.

I did change the lining thickness quite a lot but it didn't seem to make much of a difference, this being the bare minimum i thought was necessary. I guess i could continue tweaking the amount of stuffing but if it's a BSC problem then i guess i should be changing that instead?

Be worthwhile trying the higher BSC as that was the default. Not being familiar with the xo design, there may be other changes required besides the 2.7mH inductor.

You may want to try 3mH parallel with 47 ohms (10-20 watts). I'm using this in my Seas ER18 to get some mid-bass kick.

The other components are all for contouring. There's no crossover. My speakers are active bi-amped with 18dB/oct electronic crossover.

The other components are all for contouring. There's no crossover. My speakers are active bi-amped with 18dB/oct electronic crossover.

Attachments

re:'My speakers are active' - then wouldn't it be better to do all this 'contouring' at line level?

It all depends on what you're after. For some, there's nothing wrong with tone controls and equalizers but I don't use them because they degrade the sound. Take electronic crossovers. It took me many, many years to develop one that I can live with. Right now, it's incorporated in my Synergy Bi-amp Kit. My crossover is transparent, invisible. I can't hear it. I compared it with my Starling passive crossover and I could hear the passive one. There's this very slight veil in the music.

re:'My speakers are active' - then wouldn't it be better to do all this 'contouring' at line level?

Yes. It will eliminate the worst offender in a passive crossover; the inductor. It also uses smaller sized capacitors, which is a benefit.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- no bass from vented + floorstander 18w-8531- port problems?