Typically, more plies the better.

Yes, easier to work on it (routing/cutting) and doesn't bend as much with temperature or moisture change. If the edges are visible or even rounded or beveled the number of plies might be an argument design wise.

I looked up recycled plastic 18mm 8x4ft sheets but they seem to be around €110. it's a pity they are not cost competitive as one would think that they have ideal properties.

Our living room speakers are made out of pine boards. Seem to be holding up nicely after several years of abuse.

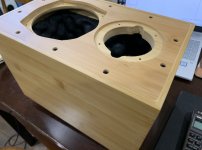

It was a "how much can I dumd it down?" type of build, 1st order 700hz filter, Seas FU10RB and double 6,5" closed.

Sounds great.

Almost anything is possible to use if you just "do it right".

FYI 2x2cm square spruce sticks are usually more than adequate for bracing even quite large boxes, very stiff and light.

It was a "how much can I dumd it down?" type of build, 1st order 700hz filter, Seas FU10RB and double 6,5" closed.

Sounds great.

Almost anything is possible to use if you just "do it right".

FYI 2x2cm square spruce sticks are usually more than adequate for bracing even quite large boxes, very stiff and light.

Attachments

Poplar seems to be rather good also i hear from many. Never tried it, so that is second hand info. I got my projects on hold for the moment untill the wood prices go back to normal. Now it's like 400% of what it was 2 years ago down here...

Poplar is rather soft and light weight and it stinks, literally.

I love Plyboo. 🙂

Attachments

Last edited:

I personally don't want E1 (formaldehyde glue) wood products in my apartment.........I don't use MDF anymore.

My generation having spent a life in a formaldehyde environment hasn't proven to be any real health risk, at least compared to other toxins, though in a modern, well insulated environment I imagine if one can smell it, then better to avoid it if the air handling system isn't designed to filter it out.

Good plan......with my lifelong chronic sinus problems I've never used the various particle boards beyond bonding other's scraps to mass load panels, filling voids, etc., that don't require cutting and don't help folks that do.

Hi X,

I must admit that I also like the look of bamboo. Still trying to find a source of it here in down south.

Kevin

I must admit that I also like the look of bamboo. Still trying to find a source of it here in down south.

Kevin

Twenty or so years ago before Baltic became the default choice , Lowther Medalion back loaded horn builders used apple ply.

Still trying to find a source of it here in down south.

Make your own! 😉 At the end of our N.E. Atlanta neighborhood there's enough to start a business that's still there after the power, etc.., companies 'top'/mow down/control since apparently there's no safe way to kill it in an urban environment.

back loaded horn builders used apple ply.

Right, it's one of several I recommend, but [still] the best of them all is the no void marine grade I used way back when, though in more recent decades I've been told by suppliers it's not aways pure no void, but plugged like other premium plywoods unless special ordered in bulk.

Pass DIY Addict

Joined 2000

Paid Member

Thanks for all of the great suggestions, everyone! I really like the look of the bamboo ply, that's pretty sweet.

KaffiMann - those look like nice speakers!

I also remember reading a few articles about using apply ply - I had forgotten about this material.

Given the feedback and what I can get locally, I'm thinking I'll aim for the 9-ply lauan for now.

KaffiMann - those look like nice speakers!

I also remember reading a few articles about using apply ply - I had forgotten about this material.

Given the feedback and what I can get locally, I'm thinking I'll aim for the 9-ply lauan for now.

Twenty or so years ago before Baltic became the default choice , Lowther Medalion back loaded horn builders used apple ply.

Apple ply, at least as sold on the west coast of Canada is a trade name for a Baltic Birch core “platform”; most usually sourced from Europe, and faced with very thin decorative veneers of various select species. The more exotic of “architectural” choices could easily double or even triple the sheet cost , and can make for very pretty furniture and speaker enclosures, but with no improvement in acoustic performance.

If you want to get really crazy, investigate the likes of Panzerholz. An internet rumour I just started suggests that it’s the default cabinet core material used in the cabinetry and helicopter landing decks of Jeff Bezos’ latest yachts. I’ve seen salesman’s samples and the stuff truly does look almost bulletproof, but I never built with it, and I’d imagine you’d need to be ready to invest bigly on cutting tools.

The only Meranti plywood I personally encountered was a very low quality product from “the east”. We had more cases of defects with this type than any other sheet goods: delaminations of ply once cut; very high numbers of unpatched voids in interior plies; substantial variations in thickness across the 32sq ft surface; and most disturbingly and expensively the occurrence of foreign materials such gravel and, honest to god, machine nuts within the core. The wood itself is much softer than birch, and I’d not personally use it for speakers. Plus the splinters are a bitch.

I have cabinets made of "Arauco" (pine) plywood - its decent - dings rather easily compared to BB but a steam iron and damp rag can remove most dents.

It would be good to stock up online with BB as is sometimes about as cheap as crap OSB.

It would be good to stock up online with BB as is sometimes about as cheap as crap OSB.

those look like nice speakers!

Thank you. While pine boards in general really should be avoided, it Is possible to use just about anything and get away with it.

Most kinds of ply are great, birch is a hard wood often with nice patterns, but as long as it's void free and lots of layers the kind of wood is less important IME.

OSB works very well, but it's a pain to make it look good.

OSB works very well, but it's a pain to make it look good.

That's why you put in the big 15 inch tricone fullrange drivers. It distracts from the OSB. 😀

Marine plywood

Void free, waterproof glue, multiple piles

My local HD had some couple months ago

98.00 for a 4x8 sheet

Void free, waterproof glue, multiple piles

My local HD had some couple months ago

98.00 for a 4x8 sheet

Thank you. While pine boards in general really should be avoided, it Is possible to use just about anything and get away with it..

My dad built a big enclosure for a large 12" University Speakers coaxial driver (monaural Dynaco MKIV etc system) out of white pine in the very early 1960s sort of out of a stubborn effort based on everyone telling him it couldn't possibly work to use white pine. It is reinforced on the inside with cleats screwed in place with wax paper between the cabinet sides and the cleats, and the countersinking of the screws in the cleats is slightly oval-ized to allow for expansion and contraction. It was glued together with some non-premium ordinary adhesive. After my dad went 2-channel, he gave it to my cousins, several of whom carted it around as a musical instrument speaker to various gigs and basically gave it no mercy, in handling or in driving it to the limit with any amplifier they could get ahold of. Then it came back to me as a teen and I carted it around all through college, also giving it un-gentle treatment. And I still have it, and both the enclosure and the 12" driver still work great.

- Home

- Loudspeakers

- Full Range

- Next best wood after Baltic Birch?