Hi

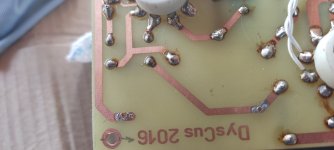

So I just disoldered 2 capacitors from my tube amplifier. I think I made a bit a mess, there is still solder residue on the copper traces of the PCB. The pump doesn't remove it.

Is there some trick?

Can I just solder the new capacitor anyway for the time being or?

So I just disoldered 2 capacitors from my tube amplifier. I think I made a bit a mess, there is still solder residue on the copper traces of the PCB. The pump doesn't remove it.

Is there some trick?

Can I just solder the new capacitor anyway for the time being or?

Attachments

If the solder wick doesn't pick up the solder well, which seems to happen when there is little to no flux left, a dab of paste flux will help it. To remove the flux residue, acetone and a Q-tip works very well.

So without going through the hole? It was a capacitor.Just install the new part and solder the leads to the traces.

In face the new cap has thicker leads and doesn't fit through the hole

Use a watchmaker's pin vice with a 0.8 mm bit to make the hole bigger, go from track side.

Other side may push foil off the board.

I use Iso propyl alcohol and stiff fiberglass brush or tooth brush to clean off flux.

Big pieces to be removed with a fine tweezers or miniature screw driver.

Other side may push foil off the board.

I use Iso propyl alcohol and stiff fiberglass brush or tooth brush to clean off flux.

Big pieces to be removed with a fine tweezers or miniature screw driver.

So without going through the hole? It was a capacitor.

In face the new cap has thicker leads and doesn't fit through the hole

On a single sided board with no solder mask, like this one, carefully drill out the hole just enough

for the lead clearance. But don't damage the pad's integrity if there is not enough room.

The lead going through the hole to the other side of the board makes a stronger mounting for the part.

Take care not to lift traces.

Solder wick can if you allow the solder to solidify as you are pulling it away - easily done.

The important thing is to clear the hole and a steel needle can help to poke a hole through the molten solder - steel doesn't easily stick to solder.

Having a coating of solder on the trace is actually a good thing - it is called tinning.

You can be confident that the joint will take and not subject to oxidation as with a bare trace.

With the amount of free space on that board, you could even drill a lead hole immediately alongside the trace though I imagine the component lead is not going to be so big as to create a problem opening the existing holes a bit.

Solder wick can if you allow the solder to solidify as you are pulling it away - easily done.

The important thing is to clear the hole and a steel needle can help to poke a hole through the molten solder - steel doesn't easily stick to solder.

Having a coating of solder on the trace is actually a good thing - it is called tinning.

You can be confident that the joint will take and not subject to oxidation as with a bare trace.

With the amount of free space on that board, you could even drill a lead hole immediately alongside the trace though I imagine the component lead is not going to be so big as to create a problem opening the existing holes a bit.

If you are planning to remove lots of solder spots in the future, invest in solder sucker.

https://www.stewmac.com/luthier-too...es-for-electric-guitar/solomon-solder-sucker/

https://www.stewmac.com/luthier-too...es-for-electric-guitar/solomon-solder-sucker/

Or even better version...

https://www.amazon.com/YIHUA-Electr...cphy=1018598&hvtargid=pla-1392525875694&psc=1

https://www.amazon.com/YIHUA-Electr...cphy=1018598&hvtargid=pla-1392525875694&psc=1

Drilling would be my last option.

If your pump can't remove solder from a through-hole it is usually remedied by adding a little fresh solder to allow the solder in the via to become fluid.

If you have a way to clamp the board into a vertical position you can put the tip of the pump on one side of the hole and heat the solder on the other.

I don't know what else is on your board but one very simple way to remove solder is to add a little , make sure the whole mass has liquified and then while the solder is still hot and fluid (!) tap the board against the bench (or heel of your palm or if you're sitting, your knee ) to make the board's travel abruptly stop and flick the solder out - of course aligning the board and its trajectory so you don't get hot solder on your hand, or the cat, or your lunch, etc. . (If there are tubes on the board pull them first. )

If your pump can't remove solder from a through-hole it is usually remedied by adding a little fresh solder to allow the solder in the via to become fluid.

If you have a way to clamp the board into a vertical position you can put the tip of the pump on one side of the hole and heat the solder on the other.

I don't know what else is on your board but one very simple way to remove solder is to add a little , make sure the whole mass has liquified and then while the solder is still hot and fluid (!) tap the board against the bench (or heel of your palm or if you're sitting, your knee ) to make the board's travel abruptly stop and flick the solder out - of course aligning the board and its trajectory so you don't get hot solder on your hand, or the cat, or your lunch, etc. . (If there are tubes on the board pull them first. )

You can always enlarge the hole with a round file ( small diameter for fine work ) before drilling.

That would have been the smartest idea, idk why I didn't think about it.You can always enlarge the hole with a round file ( small diameter for fine work ) before drilling.

I've never seen a file small enough (except maybe at a watchmakers' tool shop in Vienna), and if it exists it would be extremely breakable. The fluted portion of steel twist drills can be (ab)used as a rasp to enlarge holes. Hold the bit by both ends and draw it back and forth.

Dentists use teeny tiny little files for doing root canals. They come in sizes from almost hair-like up to fairly substantial. My dentist gave me a selection of them. Various ones of those are easily small enough to fit in pc board holes for reaming. And they are not dainty. I am sure I could break one, but I'd have to try to do it.

And while I'd never give up my Pace desoldering station, I used the metal tube spring loaded **** it and push the button solder suckers for years. They work really well. But one thing I see a lot of novices do is pull the iron off and then quick stick the sucker down on the joint. Of course in that fraction of a second, the solder hardens. You heat the joint with your iron, then put the sucker tip right on the joint and solder iron tip and trigger it. You then suck the moltn solder right out.

And while I'd never give up my Pace desoldering station, I used the metal tube spring loaded **** it and push the button solder suckers for years. They work really well. But one thing I see a lot of novices do is pull the iron off and then quick stick the sucker down on the joint. Of course in that fraction of a second, the solder hardens. You heat the joint with your iron, then put the sucker tip right on the joint and solder iron tip and trigger it. You then suck the moltn solder right out.

That was a detail you didn't share or I missed. 😀 Through the hole of course, you will need to enlarge the holes with a drill. Use a bit just slightly larger than needed. I have never used a dental root canal file to enlarge holes in a PCB although I have had them used for the stated purpose. I would suggest drilling from the bottom side as this will not lift the trace.So without going through the hole? It was a capacitor.

In face the new cap has thicker leads and doesn't fit through the hole

Last edited:

This is very handy, called a pin vice.

0.8 mm drill bit is less than 20 cents here, the vice is about $2.50.

It allows you do do delicate stuff by hand, dental drills are very high speed (the machines), for them to get enough cutting speed (feet per minute).

This is easier to control, and a tiny drill may snap off in a power tool or bench press if slightly out of true.

Here you have a pilot hole in the form of the old hole, go gently, takes a couple of minutes for a hole.

I have a 19 mm bench drill, and a 10 mm hammer drill, and I have broken small bits using them.

So my advice comes from experience...

- Home

- Design & Build

- Construction Tips

- New to soldering - how do I remove solder residue from PCB traces?