Great work! I was looking into this and noticed this PIC designed for PWM motor control.

Digi-Key - DSPIC30F3011-30IP-ND (Manufacturer - DSPIC30F3011-30I/P)

Not sure if the timing would work, but it looks like it could implement most everything by using the PIC and a few buffers and maybe detectors for the driver phase inputs. The PIC looks like it has the features to do everything else in software! Timers to allow implementation of the speed selection. A/Ds to read detected phase inputs. Ability to trigger a counter off of the tach input. By implementing the speed control in software, and multiplying the phase inputs by the gain to control the 3 PWM outputs, the DC speed control can be implemented in software. Wow, this chip has some significant compute power.

Digi-Key - DSPIC30F3011-30IP-ND (Manufacturer - DSPIC30F3011-30I/P)

Not sure if the timing would work, but it looks like it could implement most everything by using the PIC and a few buffers and maybe detectors for the driver phase inputs. The PIC looks like it has the features to do everything else in software! Timers to allow implementation of the speed selection. A/Ds to read detected phase inputs. Ability to trigger a counter off of the tach input. By implementing the speed control in software, and multiplying the phase inputs by the gain to control the 3 PWM outputs, the DC speed control can be implemented in software. Wow, this chip has some significant compute power.

Change of plan: I think i will be putting the crystal on my current PC board. That way, IF it works, it's a complete basic system and nothing else needs to be built or added.

The PIC DSP chips certainly can do this kind of thing, but then you have the same situation as with the original Technics LSI chips: it it goes wrong, you can't fix it with a generic component made by 10 different semiconductor manufacturers and available ex-stock in every city. I'm deliberately avoiding any component that isn't easily going to be available for a long time.

I will bend that rule a little and use a low capacity 'generic' microprocessor, that does no speific functions other than controlling logic and provide timing. That will be easy to substitute if necesary.

I was looking into this and noticed this PIC designed for PWM motor control.

The PIC DSP chips certainly can do this kind of thing, but then you have the same situation as with the original Technics LSI chips: it it goes wrong, you can't fix it with a generic component made by 10 different semiconductor manufacturers and available ex-stock in every city. I'm deliberately avoiding any component that isn't easily going to be available for a long time.

I will bend that rule a little and use a low capacity 'generic' microprocessor, that does no speific functions other than controlling logic and provide timing. That will be easy to substitute if necesary.

...

The PIC DSP chips certainly can do this kind of thing, but then you have the same situation as with the original Technics LSI chips: it it goes wrong, you can't fix it with a generic component made by 10 different semiconductor manufacturers and available ex-stock in every city. I'm deliberately avoiding any component that isn't easily going to be available for a long time.

I will bend that rule a little and use a low capacity 'generic' microprocessor, that does no speific functions other than controlling logic and provide timing. That will be easy to substitute if necessary.

I like your philosophy! But nearly a minimal chip count solution is tempting. I would think that PICs with these types of features will be around awhile. However, if one picks the wrong chip and it disappears, then one my be forced to write new code and modify the design.

Change of plan: I think i will be putting the crystal on my current PC board.

PCB layout revision to accommodate above capriciousness:

link: Phase/frequency detector + PWM board layout GIF image

Yes, that's Tango for DOS in action.Are you using Tango?

I've just opened a new pack of Press-'n'-Peel (the blue iron-on emulsion film). It's thinner than the previous PnP I had, and seems to be easier to use. It irons onto the board more easily, peels off more easily, but produces slightly more ragged edges.

One thing that occured to me now - that I should have put on that board - is a connection for the strobe illumination. It can go on the next revision, or can just be a flying lead soldered to the appropriate IC pin - which is a bit ugly, but works as well.

Last edited:

Half a pound of twopenny rice...

Half a pound of treacle

That's the way the money goes

Pop goes the RC4136

All along I've been doing my PCB layouts with the LM324, 348 & TL074 pinout in mind, thinking I will just plug in an RC4136.

I'm about to test the PLL with an RC4136 installed... power on... and it explodes quite spectacularly.

Turns out the 4136 - electrically similar - is not pin compatible. Who knew?? I should have!

The happy news is with an LM324 the basics work - not yet tested fully with quartz reference.

Half a pound of treacle

That's the way the money goes

Pop goes the RC4136

All along I've been doing my PCB layouts with the LM324, 348 & TL074 pinout in mind, thinking I will just plug in an RC4136.

I'm about to test the PLL with an RC4136 installed... power on... and it explodes quite spectacularly.

Turns out the 4136 - electrically similar - is not pin compatible. Who knew?? I should have!

The happy news is with an LM324 the basics work - not yet tested fully with quartz reference.

Attachments

I've discovered now that this motor - unlike a 'normal' 3-phase motor - does not reverse direction just by swapping two phases.

Two ways I found to make it reverse: (1) invert each phase drive, and (2) advance the phase sequence by 120 degrees.

(1) is electrically complicated, (2) doesn't produce as much torque, and makes a faint droning noise.

I cannot think of any realistic need to run the motor in reverse - other than for a fraction of a second to bring it to standstill, so I'll be going with (2).

Two ways I found to make it reverse: (1) invert each phase drive, and (2) advance the phase sequence by 120 degrees.

(1) is electrically complicated, (2) doesn't produce as much torque, and makes a faint droning noise.

I cannot think of any realistic need to run the motor in reverse - other than for a fraction of a second to bring it to standstill, so I'll be going with (2).

Wow...great progress Steerpike!

I've been gone awhile and just checking to see how things are going and it looks promising!

Very much appreciated!

Rick

I've been gone awhile and just checking to see how things are going and it looks promising!

Very much appreciated!

Rick

Reversing

Steerpike, I agree. I can see no practical reason to reverse a turntable.

Thanks for your excellent efforts

Steerpike, I agree. I can see no practical reason to reverse a turntable.

Thanks for your excellent efforts

Hm...but without reverse how are we going to hear the sublime messages recorded on old Beatles records?😀

Rick

Rick

Hm...but without reverse how are we going to hear the sublime messages recorded on old Beatles records?

This IS Do-It-Yourself audio: so now that I've told you how to make the motor run backwards, you can create your own drive circuit to do exactly that 😛

It's actually not that difficult, just unnecessary switching & signal handling that I can't see anyone ever using. Playing long sections backwards is not going to do the stylus any good at all - unless you have two arms that are stereoisomers of each other.

Frankly anyone who wants to abuse a turntable with the potential of an SP10 by running it in reverse for any purpose other than braking is an absolute idiot. Anyway the turntable with all brakes removed - incl. mechanical, stops very easily by applying drag with your fingertip to the platter edge......that is if you really have to rush!!

Steerpike....

You are doing well - I had to have my PS rebuilt by Vantage here in the UK as it is my primary TT. But I have a spare and will try your circuit once you have finished it. It will be an interesting comparison!

Steerpike....

You are doing well - I had to have my PS rebuilt by Vantage here in the UK as it is my primary TT. But I have a spare and will try your circuit once you have finished it. It will be an interesting comparison!

Frankly anyone who wants to abuse a turntable with the potential of an SP10 by running it in reverse for any purpose other than braking is an absolute idiot. Anyway the turntable with all brakes removed - incl. mechanical, stops very easily by applying drag with your fingertip to the platter edge......that is if you really have to rush!!

Steerpike....

You are doing well - I had to have my PS rebuilt by Vantage here in the UK as it is my primary TT. But I have a spare and will try your circuit once you have finished it. It will be an interesting comparison!

Thanks for the kind words...

Obviously I was joking as I have no use for reverse myself...but there are many modders that add reverse to the Technics SL1200 series turntables for "mixers" and those that are using reverse music for their work.

There are also "pro" tables built from the factory with reverse for whatever reason...The EMT 950 and other Studio tables had Reverse for cuing records.

I think "idiot" is a harsh response for something that you may not need, but others might have a use for. I suggest a little restraint with the name calling and maybe you will learn something.

Now back to the project!

Rick

Last edited:

This IS Do-It-Yourself audio: so now that I've told you how to make the motor run backwards, you can create your own drive circuit to do exactly that 😛

It's actually not that difficult, just unnecessary switching & signal handling that I can't see anyone ever using. Playing long sections backwards is not going to do the stylus any good at all - unless you have two arms that are stereoisomers of each other.

As I explained in my post above, I was only joking 😀...but obviously there is a use for reverse as many pro and studio tables have reverse controls... including the BBC Technics SP10 MKIIP.

Rick

Brian Colin

to diyAudio

show details 23:41 (0 minutes ago)

I am NOT saying that there is no use for reverse rotation: I am simply saying that the SP10 is NOT (in my opinion) the TT to convert for that purpose. There is I am sure an adequate choice of TTs - made with this facility. The broadcast decks which have such facilities are for specialised use. The SP WAS a broadcast deck which almost all broadcasters made redundant many years ago. Odd ones do creep out of the BBC when they are found but I am confident that they are simply not used for broadcast purposes any longer. I have had a couple which were in BBC pop station guise with exceptionally accurate cuing....but a BBC DJ friend told me that they were adjusted by hand - not through the motor.

Rich121:

It was not a remark directed at you🙂......it was directed at anyone who seriously intended to have such a function on an SP10!!

Good luck,

Brian

to diyAudio

show details 23:41 (0 minutes ago)

I am NOT saying that there is no use for reverse rotation: I am simply saying that the SP10 is NOT (in my opinion) the TT to convert for that purpose. There is I am sure an adequate choice of TTs - made with this facility. The broadcast decks which have such facilities are for specialised use. The SP WAS a broadcast deck which almost all broadcasters made redundant many years ago. Odd ones do creep out of the BBC when they are found but I am confident that they are simply not used for broadcast purposes any longer. I have had a couple which were in BBC pop station guise with exceptionally accurate cuing....but a BBC DJ friend told me that they were adjusted by hand - not through the motor.

Rich121:

It was not a remark directed at you🙂......it was directed at anyone who seriously intended to have such a function on an SP10!!

Good luck,

Brian

I think anyone doing reversing of long sections would now do it with a non-linear editor. My controller will do reverse, but not with the same high performance as forward. So if yu need to do remote reverse cue, it's possible still, just not suggested for many minutes on end.

Anyway, now that I know the workings of the motor better, full-spec reverse play MAY appear on the "Reviosion 2" version.

Anyway, now that I know the workings of the motor better, full-spec reverse play MAY appear on the "Reviosion 2" version.

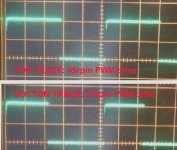

This thing is being retarded! The 3-section power amplifier that worked fine is now playing up. It's oscillating at a few megahertz - all three channels.

If I disconnect the power partially so as to power only one, it is stable.

Adding decoupling caps from V+ to Gnd, and V- to Gnd, seems to make it worse in fact.

(I had this trouble on a 4-way headphone amp some years ago - the chip amps worked OK on their own, but all 4 on together would interact & oscillate, & I never got it totally stable.)

Has anyone lse had any experience of such instability when multiple amps share a power supply?

If I disconnect the power partially so as to power only one, it is stable.

Adding decoupling caps from V+ to Gnd, and V- to Gnd, seems to make it worse in fact.

(I had this trouble on a 4-way headphone amp some years ago - the chip amps worked OK on their own, but all 4 on together would interact & oscillate, & I never got it totally stable.)

Has anyone lse had any experience of such instability when multiple amps share a power supply?

SP, try using a series/shunt R/C per amplifier stage after the initial filter C and see if that isolates them enough to stop oscillation. I would use the largest R and C I could that didn't affect operation in other ways.

Just OTTOMG Sat AM suggestion. Maybe also ask in the Chip Amp forum here and see if the more experienced users of these beasties can offer solutions.

Just OTTOMG Sat AM suggestion. Maybe also ask in the Chip Amp forum here and see if the more experienced users of these beasties can offer solutions.

- Home

- Source & Line

- Analogue Source

- New Technics SP10 motor controller specification