Time will tell. The one that broke in half....I bought it used on this site, guy had several. I think that was early 2000s. Maybe late 90s.

I got my money's worth! We will see if today's modern version comes close.

Russellc

I got my money's worth! We will see if today's modern version comes close.

Russellc

I have been very impressed with my little Hakko even though it is the consumer-grade soldering station as opposed to your more commercial unit. I have two units because I was soldering a ground lead next to a hot on a non-audiophile project and touched the hot. I forgot to unplug the mains  oops...

oops...

I quickly ordered a whole new set as I was working on something. I didn't want to risk just ordering a wand only to find out that the power supply was fried. I tested the wand from the new set on the old power supply. Worked without a hitch. So they are pretty tough to say the least. Not to mentioned, I have dropped it multiple times, had the soldering wand melt it's way into the side of the case, used it in very humid locations (boats), spilled a drink on it, go to reach for something with the wand and pull it off of the table (or the trusty trash can 😬) etc... It really should have died a long time ago but it keeps going for some reason.

oops...

oops...I quickly ordered a whole new set as I was working on something. I didn't want to risk just ordering a wand only to find out that the power supply was fried. I tested the wand from the new set on the old power supply. Worked without a hitch. So they are pretty tough to say the least. Not to mentioned, I have dropped it multiple times, had the soldering wand melt it's way into the side of the case, used it in very humid locations (boats), spilled a drink on it, go to reach for something with the wand and pull it off of the table (or the trusty trash can 😬) etc... It really should have died a long time ago but it keeps going for some reason.

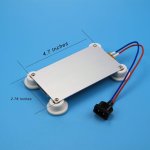

I also have the fore runner of that iron, but in simple square box.

https://hakkousa.com/hakko-936-esd-soldering-station-936-11.html

Still works.

Russellc

https://hakkousa.com/hakko-936-esd-soldering-station-936-11.html

Still works.

Russellc

I still use an old Weller Magnastat iron but with a Danish transformer. The station is from around 1980 or so. They used this type where my father worked as electronic technician where he repaired "stuff". Probably this configuration was cheaper (and better) than the original light blue Weller transformer. They liked the easy access to "earth" via the black banana connector at the front of the transformer when soldering ESD sensitive "stuff" (I was told). I still have a lot of unused tips and they can still be purchased. I usually use tips with no. 8 (which is approx. 425 C (800 F)). I even have a spare and a spare heating element.

Attachments

That is even a still good old fashioned handle on that Magnastat! The double ring type was introduced as the type on the picture tended to break.

Don't be tempted to turn the white plastic screw.

Don't be tempted to turn the white plastic screw.

Yes, there is a white nylon screw at the top "locking" the wire.

Often plastic can get a bit "brittle" over time.......

The long white wire to the iron.......the insulation feels like silicone......soft and flexible.

Often plastic can get a bit "brittle" over time.......

The long white wire to the iron.......the insulation feels like silicone......soft and flexible.

What are the large vise type arms holding the completed board you show in the second picture? I don't see them on Panavise's website as a compatible accessory.

They have many accessories.

https://www.panavise.com/index.html?pageID=1&page=full&--eqskudatarq=25

Zenmod, is this Baku 936D+ pretty much the same soldering station that you use?

yup

as I wrote before - find trusty place and buy set of Quick tips

one of golden rules for soldering - always use biggest tip you can do job with

that way results are simply ....... best

meaning - with biggest tip (possible to use) thermal inertia is biggest; that's what's ensuring steady soldering process, not sheer heater power

that always remind me of situation with spanners - you have normal ones made for universal work, and then you have those mainly for unscrewing work - they're longer, 25-40%

Last edited:

That looks to be a Hakko 936 clone, which is what I have used for the past 15 years or so, still going strong (the Hakko). A Metcal/Pace would be nice, but too much money generally. I also have the Panavise as in a previous post, but only with the circuit board holder; none of the other toys for it. And agree with ZM, biggest tip you can get away with. I use the 3.2mm chisel tip quite a bit on stuff you wouldn't think it would work on. Its a lifesaver trying to solder 0805 SMDs where one end is on a ground plane.

......Cardas RCA jacks.....

<Cough> ... As if you haven't already helped me so much...

I have two pair of those ... and I am about put them through the wall. I have a nice iron... a big fat soldering tip with the thermal mass of a hippo, and what I thought was a decent amount of patience. I thought the Cardas speaker terminals were bad. At least I could mechanically hold the wire in place while the joint heated to the temperature of a white dwarf.

I don't have any other RCAs that use the same hole diameter or they'd be long gone. Any tips for the pre-heating? I've got a decent hot air station. The tip portion isn't too big a deal b/c there is actually a solder cup, but there is no 'tab' for the ground. I gave up...

Attachments

for these, I'm using older direct mains soldering iron, 60W with 10mm wide chisel tip

but stub of tip is also 10mm Dia and longish

means, plenty of hot copper on disposal

but stub of tip is also 10mm Dia and longish

means, plenty of hot copper on disposal

As far as exact temps, time, technique, and so on... not sure.. Experience will be your teacher. Steps= "real good and warm" with the hot air pre-heat, beast chisel tip, cranked station knob, and I always use a bit of flux with any of my soldering with one of those flux pens. Some pre-heating will really help with the "but I had to hold my soldering tip on there forever...." thing.

I like my Thermaltronics TMT-9000s, designed by the same guy who started Metcal. Caveat: the power supply doesn't like being in direct sunlight and overheats on a warm day. It complained only once, I moved it away from the window, no problems since. Eventually I might retrofit a more happening fan on the thing.

For a moment, I thought that you might be soldering outside. A friend of mine told me that he tried to solder a connection on a security system in Wyoming in the winter. Yah, wait till spring.

My Hakko 888 has lasted pretty long I guess, but if I do decide to replace it, I will spend some coin for reliability. Same with a desoldering device.

My Hakko 888 has lasted pretty long I guess, but if I do decide to replace it, I will spend some coin for reliability. Same with a desoldering device.

I agree, So then these tips made for a Hakko 936 may work well? A friend is looking for a starter setup and I thought this soldering station was nice and inexpensive. I like the stackable feature. The link I shared with you doesn't have a ton of info on the soldering station.yup

as I wrote before - find trusty place and buy set of Quick tips

one of golden rules for soldering - always use biggest tip you can do job with

that way results are simply ....... best

meaning - with biggest tip (possible to use) thermal inertia is biggest; that's what's ensuring steady soldering process, not sheer heater power

that always remind me of situation with spanners - you have normal ones made for universal work, and then you have those mainly for unscrewing work - they're longer, 25-40%

Thank you again for taking the time to share your soldering setup. It actually looks like a pretty great value.

- Home

- Amplifiers

- Pass Labs

- New Solder Rig day!