Oh, bonus -- I see Canadian Tire has 'em for $11.99! Pennies. The cost of this project is going down all the time.

;-)

;-)

there's no substitute for the old reliable Pony pipe clamps

So true.

You can also sometimes get the clamps only and then do your own pipes, more work but this is a DIY forum😀

Another alternative is straps (not strap ons😉 - I kill me with humor and its not yet Friday).

You can get the ratcheting types that are used often to tie down loads in trucks, make some corner blocks at 90 degrees, line same with wax paper and Bob's your Uncle!

Otherwise, use a couple finishing nails to locate the panels so they will not shift and then use the tie downs.

Masking tape makes a fine "clamp". As long as the wood is properly cut, you really do not need much pressure to make a good joint (wood joint)

I better get back to work before I get the corny joke award.

'Tis true, Andrew. A story as old as the hills is the tale of the misdirected strap-on, and how it leads to the joint being put in the wrong place. Best be careful where I'm laying my pipe while I'm at it.

But I think I'll just put a clamp on it there, and encourage you no further!

But I think I'll just put a clamp on it there, and encourage you no further!

A lot of the claps from Harbor Freight are questionable. I broke the fulcrum on one of the squeeze style clamps; fixed it...and it's never worked better. There are some Irwin clamps my friend has that are unreal. HUGE surface area and like 2000lbs of clamp force. I'm always tempted to hold onto them when I borrow them from him.

My down fall is I don't know anyone with tools.

Someone's gotta be the first guy on the block to by a dozen clamps. Guess it's me!

Someone's gotta be the first guy on the block to by a dozen clamps. Guess it's me!

I have to say, could there be a more satisfying woodworking micro skill as using a decent quality plane with adequate technique?

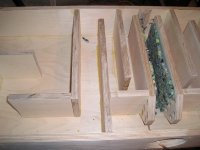

Less than 45 minutes with a plane, and everything is flat. Some of the internal bits are a bit short, but we're talking less than 1 mm.

Sides'll go on tomorrow, boys.

Well, one tomorrow after work, one Saturday morning.

Sanding and varathane on Sunday.

I'm excited!

Dave of Bass, you out there m8? You know what I'm feelin'!

Less than 45 minutes with a plane, and everything is flat. Some of the internal bits are a bit short, but we're talking less than 1 mm.

Sides'll go on tomorrow, boys.

Well, one tomorrow after work, one Saturday morning.

Sanding and varathane on Sunday.

I'm excited!

Dave of Bass, you out there m8? You know what I'm feelin'!

^I was thinking the same thing. I'd hate for him to have to go through the ordeal I'm completing with my build. The fleece cloth sold for most craft projects is pretty decent as well. Two layers of that attached to the walls is very effective.

Less than 45 minutes with a plane, and everything is flat.

Looks good from here! Nice work.

Thanks for the feedback, guys.

Dave, thanks for the correction on that. I misunderstood your earlier email explaining how to deploy that foam!

I'll take your suggestion and get the wool product.

Glad I didn't seal that box last night without checking in here!

Dave, thanks for the correction on that. I misunderstood your earlier email explaining how to deploy that foam!

I'll take your suggestion and get the wool product.

Glad I didn't seal that box last night without checking in here!

Dave: The blue colored felt type material (I got from you) is the best stuffing I've seen.

What's it called, and where d'you get it?

Wha'DIYa know: Looking good! Do you have a finish in mind?

Don

What's it called, and where d'you get it?

Wha'DIYa know: Looking good! Do you have a finish in mind?

Don

Dave: The blue colored felt type material (I got from you) is the best stuffing I've seen.

What's it called, and where d'you get it?

Don

I believe the blue felt material you're referring to is UltraTouch insulation that you can get from here Creative Sound - Product Details

Regards,

Ewan

^That stuff is the bomb. If I remember correctly it's made from recycled blue jeans. Great performance AND eco friendly, can't beat that! I always forget to get it from Bob in advance and I usually end up getting the felt stuff locally as a decent compromise.

Thanks, Ewan, thats the "stuff"!

It's the best stuffing material I've used.

Don

I third and forth that motion, sir

actually I think the virtues of this product have been sung elsewhere, ad nauseam

Door man, is that an LP12 you have there in your avatar? Looks like mine, and in similar finish. I was thinking to finish the speakers with a glossy varathane type product, and hoping to get it close to the colour of my turn-table finish.

But since you're in the business, you won't mind my asking you for suggestions, tips, advice -- I'd like the speakers to look nice when I'm done with 'em.

If you can offer any suggestions, please don't be modest!

Brenton

But since you're in the business, you won't mind my asking you for suggestions, tips, advice -- I'd like the speakers to look nice when I'm done with 'em.

If you can offer any suggestions, please don't be modest!

Brenton

Hi Brenton: No, it's a Heybrook TT2, (w/Ittok LVll) It was said when students left design school, those who went to Linn turned right, Heybrook bound turned left!Door man, is that an LP12 you have there in your avatar? Looks like mine, and in similar finish. I was thinking to finish the speakers with a glossy varathane type product, and hoping to get it close to the colour of my turn-table finish.

But since you're in the business, you won't mind my asking you for suggestions, tips, advice -- I'd like the speakers to look nice when I'm done with 'em.

If you can offer any suggestions, please don't be modest!

Brenton

As far as finishes go, I've built 5-6 pairs of speakers,but am no expert re: finishing. (Chrisby has done lots, and would have more info than moi!)

My latest speakers, Fonken 167 "EnABled" floorstanders are cherry veneered, tung oiled with a Benjamin Mooore product, "clear view" IIRC. over top.

Best, Don

Door man, is that an LP12 you have there in your avatar? Looks like mine, and in similar finish. I was thinking to finish the speakers with a glossy varathane type product, and hoping to get it close to the colour of my turn-table finish.

But since you're in the business, you won't mind my asking you for suggestions, tips, advice -- I'd like the speakers to look nice when I'm done with 'em.

If you can offer any suggestions, please don't be modest!

Brenton

Don and others will make their own suggestions, but my own choice for top coat would generally be a sprayed nitrocellulose lacquer (to each his own - I'm just not a fan of the look of , or maintenance required for oil & wax finish). Of course I have access to a small commercial spray booth and the right equipment.

While there are several OTC lacquers available in spray bomb form (my own personal favorite is the Mohawk M102-0412 Satin Pre-Cat clear), that work very well on small projects, the time & cost to finish a pair of Saburos with those would be silly. ( you could probably get finished by a commercial shop for less)

No doubt you'll get lots of other advice as well, but the only thing I would suggest you avoid would be any of the "one step" stain and varnish products, particularly on a project of this size.

If this was a piece of furniture likely to get a lot of traffic / wear ( dining /coffee / side table or dresser, etc) a more rugged finish like conversion varnish, etc., might make sense - but the most abuse a 72" tall speaker box should see is during the install/set up, which is generally when you'll treat with kid gloves 🙂 (n'est-ca pas?)

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- New Saburo Build thread