Dear Gianluca, do you have same picture about the heatsink of 3U Dissipante box as well?There you go 🙂

Question here about "Heat-spreader" (1 or 2 pr. chassis) made by 10mm aluminium to connect the two heatsinks thermically.

I prefer a "Heat-spreader" that is close to max. dimensions the inner measurements of the chassis allow. Then I will mount everything on "Heat-spreader". Drill some holes for mounting. Cut some threads in heatsink for mounting the "spreader" (or maybe make holes all the way through).

For my project with SIT-follower I don't need the standard thread-holes in heatsinks (but of course the holes for mounting the heatsinks to chassis I need).

If possible, how to order such an "add one"?

I prefer a "Heat-spreader" that is close to max. dimensions the inner measurements of the chassis allow. Then I will mount everything on "Heat-spreader". Drill some holes for mounting. Cut some threads in heatsink for mounting the "spreader" (or maybe make holes all the way through).

For my project with SIT-follower I don't need the standard thread-holes in heatsinks (but of course the holes for mounting the heatsinks to chassis I need).

If possible, how to order such an "add one"?

Extruded heatsinks most times have a slight wiggle/warp to them. Be prepared to work them for flatness so the heat spreader makes full contact without air gaps between heatsinks and spreader.

Question here about "Heat-spreader" (1 or 2 pr. chassis) made by 10mm aluminium to connect the two heatsinks thermically.

I prefer a "Heat-spreader" that is close to max. dimensions the inner measurements of the chassis allow. Then I will mount everything on "Heat-spreader". Drill some holes for mounting. Cut some threads in heatsink for mounting the "spreader" (or maybe make holes all the way through).

For my project with SIT-follower I don't need the standard thread-holes in heatsinks (but of course the holes for mounting the heatsinks to chassis I need).

If possible, how to order such an "add one"?

So if I get this right you would need some small 10mm thick panels which are going to be "the middleman" between the heatsinks and your components?

@Vunce

battery of M4 screws will take care of that

from experience - MEPER mentioned going through-hole with screws; yes, best approach - M4 Allen screws, head goes between fins, if you file/grind it from two sides , to make it narrower

once you have case on bench, it'll clear as day

appropriate details here, post #4

battery of M4 screws will take care of that

from experience - MEPER mentioned going through-hole with screws; yes, best approach - M4 Allen screws, head goes between fins, if you file/grind it from two sides , to make it narrower

once you have case on bench, it'll clear as day

appropriate details here, post #4

Hi GianlucaSo if I get this right you would need some small 10mm thick panels which are going to be "the middleman" between the heatsinks and your components?

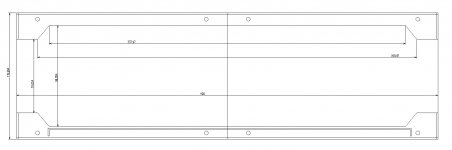

Yes, 10mm thick but large 🙂 ....so it covers as much of the heatsinks inside the chassis as possible. It will be less than 400 x 160 mm but how much less I don't know. Maybe you can see what is possible so alu panel does not interfere with internal mechanics?

This was my idea.

Recent first hand experience with with this.Extruded heatsinks most times have a slight wiggle/warp to them.

I wanted to increase the mass/surface dissipation of a chassis I built with some 4U/300 heatsinks I was try to pump some more current through.

Needless to say, both pieces of heatsink had some warp which was pronounced by trying to bolt them back to back.

Be prepared to have to use some real force if you are going to try and flatten a full size 4U heatsink. I propped both ends on some blocks and tried standing and bouncing on it to no avail.

I got lucky that the smaller piece of heatsink responded and I was able to reverse its warp to match the 4U piece. I bolted them together with stainless 8-32 (m4 equivalent).

Trying to pull it in place with M4 through bolts may work, it will shift as you flatten it so give the holes some clearance if you can.

Attachments

Last edited:

Fine, and the heat-paste will help the heat transfer also.

Modushop heatsinks are high quality and very flat 🙂

Modushop heatsinks are high quality and very flat 🙂

Using this picture as reference, considering there's about 15mm of space used by the brackets on top/bottom edges of the heatsink and about 20mm of space used by the brackets on left/right edges of the heatsinks I would leave some extra mm of tolerance to make these panels, what do you think?

Attachments

I think this would be perfect to subtract few more mm than 15 / 20 mm for the alu panels. E.g. 20 / 25 mm ?Using this picture as reference, considering there's about 15mm of space used by the brackets on top/bottom edges of the heatsink and about 20mm of space used by the brackets on left/right edges of the heatsinks I would leave some extra mm of tolerance to make these panels, what do you think?

If I could order 4 of these panels for two mono blocks, I will be happy.

@Gianluca - If you're willing to publish, what is your max allowable deviation across a panel for "flatness". Is there any guidance you could provide re: what to generally expect?Fine, and the heat-paste will help the heat transfer also.

Modushop heatsinks are high quality and very flat 🙂

The reason I ask, is that over the 6 chassis (20 separate heatsinks ... 4x4 and 2x2) I have, all of them are wonderful and are perfectly suitable for the task at hand. I love them. Admittedly, it took a few tries for me to learn to assemble them properly 😉. However, I've never personally needed nor expected a "flat" heatsink. All my amplifiers (with the exception of the VFET amp) have the devices mounted directly onto the heatsinks, so I've never needed to mate two 'flat' surfaces together or use a sizable heat spreader. With that said, when I've put some of my sinks against a 'flat' glass table, there are noticeable gaps. I wouldn't call any of them "flat". It doesn't matter to me, but I thought I'd ask for the sake of discussion, and also for a future amp I'm considering similar to what MEPER is doing.

not replying instead of Gianluca, but I've told you from experience that there is no need to worry, as long you're using M4 (or same Yank size), moderate (adequate) number of screws

whatever you'r going to mate with Modus ( or any other decent ) heatsink, it'll comply (whatever is less firm it'll comply - either spreader or Modu hsink)

warping is just longitudinal - across depth ( as in case depth), while vertically is perfect - no warping

that's just result of physical form

and one can expect no significant warping (cold state and also due to temp increase) only starting with base thickness of 10mm or so ...... but that's already hop in all different money game

whatever you'r going to mate with Modus ( or any other decent ) heatsink, it'll comply (whatever is less firm it'll comply - either spreader or Modu hsink)

warping is just longitudinal - across depth ( as in case depth), while vertically is perfect - no warping

that's just result of physical form

and one can expect no significant warping (cold state and also due to temp increase) only starting with base thickness of 10mm or so ...... but that's already hop in all different money game

^ 100% agree with you. As mentioned, I've never had an issue. I was just curious as to whether there was a spec to reference for the Modushop sinks. When they're available, I prefer measurements vs. general observations. We all could have a different expectation for 'flat'. I'd certainly not call any of my sinks, 'flat', but they're perfectly/wonderfully suitable. I don't disagree with Max at all, and he may have gotten sinks with less deviation than I. My guess is that we just have different definitions of 'flat'.

I've seen people go to what I'd consider great lengths to grind some sinks to achieve a level of 'flatness' that I personally don't need, but to each their own.

Again, I was more curious than anything.

I've seen people go to what I'd consider great lengths to grind some sinks to achieve a level of 'flatness' that I personally don't need, but to each their own.

Again, I was more curious than anything.

To note…I think it’s pretty obvious I was not working with Modushop heatsinks from the picture I posted…they were sourced from Heatsink USA.

This was a project where I was endeavoring to create something unique for myself as I felt that was really the only thing I could contribute to it.

I have long since given up on the idea that I could save money taking this route (if anything it probably cost me more than a equivalent professionally manufactured product) or that I could improve on a professionally engineered product such as those offered by Modushop.

Playing engineer to try and improve on something is often just that…playing. I have spent more time trying to fix my “good ideas” than anything else.

I think what is a relevant piece of information is that when trying to mate surfaces in an attempt to improve heat transfer between them what is considered an acceptable tolerance regarding gap(s) that we can hope thermal grease will help improve transfer. It is minute (.001?) and can’t address issues like heatsink warp.

This was a project where I was endeavoring to create something unique for myself as I felt that was really the only thing I could contribute to it.

I have long since given up on the idea that I could save money taking this route (if anything it probably cost me more than a equivalent professionally manufactured product) or that I could improve on a professionally engineered product such as those offered by Modushop.

Playing engineer to try and improve on something is often just that…playing. I have spent more time trying to fix my “good ideas” than anything else.

I think what is a relevant piece of information is that when trying to mate surfaces in an attempt to improve heat transfer between them what is considered an acceptable tolerance regarding gap(s) that we can hope thermal grease will help improve transfer. It is minute (.001?) and can’t address issues like heatsink warp.

Last edited:

- Home

- Amplifiers

- Pass Labs

- New Monoblock chassis (sets!!!) from Modushop