resolution question

Ok..I'm using the 9A62 to get component video into my 1024 x 768 panel. So the panel drops to 640 x 480. But it looks great! Now if I used a Zenark with 480 vertical at the same screen size-The screendoor would be huge since there is so fewer pixels to work with, right?

So even if my 1024x768 panel is in 640x480 mode, I still have a small screendoor affect because of the smaller pixels of the XGA panel?

Ok..I'm using the 9A62 to get component video into my 1024 x 768 panel. So the panel drops to 640 x 480. But it looks great! Now if I used a Zenark with 480 vertical at the same screen size-The screendoor would be huge since there is so fewer pixels to work with, right?

So even if my 1024x768 panel is in 640x480 mode, I still have a small screendoor affect because of the smaller pixels of the XGA panel?

Proto5,

I am not an expert in this but I think that you are correct. Even with 640 x 480 input the image is drawn on a screen with finer pixel size so it would in theory have less screen door effect even at the lower resolution.

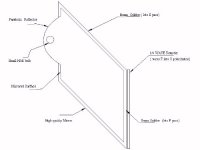

Here is a picture of my polarizing light recyler design. No light can escape except light of the proper polarization. This may not work for OOHP designs with the double fresnel below the LCD (as in most).

Hezz

I am not an expert in this but I think that you are correct. Even with 640 x 480 input the image is drawn on a screen with finer pixel size so it would in theory have less screen door effect even at the lower resolution.

Here is a picture of my polarizing light recyler design. No light can escape except light of the proper polarization. This may not work for OOHP designs with the double fresnel below the LCD (as in most).

Hezz

Attachments

I forgot to mention, the above would be true for a CRT type of screen. With an LCD the image is either reduced in size or some kind of internal circuit has to scale the image.

Still, the edges should be finer even with the LCD. The smaller pixels are closer together.

Hezz

Still, the edges should be finer even with the LCD. The smaller pixels are closer together.

Hezz

Karrock,

Does the Xenarc NTSC model accept the progressive component inputs? That would probably improve the picture. The LCD panel itself could do that if the controller had the support.

I don't have a progressive output DVD player so it makes more sense for me to use a PC since I already have one. With the PC I can scale the iamge to any pixel resolution that the LCD panel can take.

Sure electronic line doubling works well when properly done but I don't have that kind of electronic skill. Plus the PC does a better job. Many of the high end home theaters now are driving data grade projectors with a home theater PC. This seems to work as well as anything but the most outragously priced systems.

Every person who has reviewed one of these systems claims that you have to spend 20-30k for a better line doubler or scaler than the PC.

Because the anamorphic lens squishes the screen vertically with optics you have the same pixel count for the shorter vertical distance. Also with my method there are no wasted pixels. You have the advantage of having internal line doubling on your DVD player but are you getting blackout areas on the top and bottom with widescreen DVD's. If you are you are losing resolution. But if the system looks good it may not matter.

Hezz

Does the Xenarc NTSC model accept the progressive component inputs? That would probably improve the picture. The LCD panel itself could do that if the controller had the support.

I don't have a progressive output DVD player so it makes more sense for me to use a PC since I already have one. With the PC I can scale the iamge to any pixel resolution that the LCD panel can take.

Sure electronic line doubling works well when properly done but I don't have that kind of electronic skill. Plus the PC does a better job. Many of the high end home theaters now are driving data grade projectors with a home theater PC. This seems to work as well as anything but the most outragously priced systems.

Every person who has reviewed one of these systems claims that you have to spend 20-30k for a better line doubler or scaler than the PC.

Because the anamorphic lens squishes the screen vertically with optics you have the same pixel count for the shorter vertical distance. Also with my method there are no wasted pixels. You have the advantage of having internal line doubling on your DVD player but are you getting blackout areas on the top and bottom with widescreen DVD's. If you are you are losing resolution. But if the system looks good it may not matter.

Hezz

Hah, I wish they it had component video in too, but I was banking on the 9A62 to do that particular job in conjunction with the Xenarc 700Y. Kinda pricey as a $560 bundle, so maybe I'll save my pennies and use an XGA monitor panel instead. Projector size just isn't as big a priority for me right now and doesn't outweigh almost double the cost.

Proto 5

hey prot its not hard to make a controler u know, all u have to get is the right chip to do what u want, in my system ive got seacan, ntsc4.43 and 3.somthing or rather and 6 tyopes of pal, im going to mod mine to take rgb, i looked up the chips, most of them come from sanyo and wamo i have the pins for rgb and that controler that is on that site wont just work for just that model that he shows but all of them, it depends on the format of the lcd, most are on ntsc so get a chip that will do ntsc, and the chips that do ntsc also do pal, the seacam is another chip. The chips are also fully programable well atleast the one i have, its the same as a computer but smaller and slower and they also have remote function so u could make your screen remote control. The chip u would need is one that can handle your reso and one with 16.7m colours or more, also these chips have all composite in puts, a/v ect and if u want just add a tuner and its a tv, most of this stuff is already tuned so just work out the stuff u need witch they tell u on the data page and build it lol

Trev

hey prot its not hard to make a controler u know, all u have to get is the right chip to do what u want, in my system ive got seacan, ntsc4.43 and 3.somthing or rather and 6 tyopes of pal, im going to mod mine to take rgb, i looked up the chips, most of them come from sanyo and wamo i have the pins for rgb and that controler that is on that site wont just work for just that model that he shows but all of them, it depends on the format of the lcd, most are on ntsc so get a chip that will do ntsc, and the chips that do ntsc also do pal, the seacam is another chip. The chips are also fully programable well atleast the one i have, its the same as a computer but smaller and slower and they also have remote function so u could make your screen remote control. The chip u would need is one that can handle your reso and one with 16.7m colours or more, also these chips have all composite in puts, a/v ect and if u want just add a tuner and its a tv, most of this stuff is already tuned so just work out the stuff u need witch they tell u on the data page and build it lol

Trev

component video

Ace-

I think you are confusing component video (3 separate cables)

with composite video (1 cable)

The controllers are not that easy- believe me I've looked into them!

Most good ones use the 65545 controller which is a wicked fast video processor chip. They also need video memory and alot of glue logic. We're talking 4 layer boards here! Definitely not a home-brew project. EarthLCD seems to have the cheapest LCD controllers I can find- around $250 to drive a 1024x768 panel.

Ace-

I think you are confusing component video (3 separate cables)

with composite video (1 cable)

The controllers are not that easy- believe me I've looked into them!

Most good ones use the 65545 controller which is a wicked fast video processor chip. They also need video memory and alot of glue logic. We're talking 4 layer boards here! Definitely not a home-brew project. EarthLCD seems to have the cheapest LCD controllers I can find- around $250 to drive a 1024x768 panel.

component video

Ace-

I think you are confusing component video (3 separate cables)

with composite video (1 cable) The classes of video are as such:

1: RF (cable tv) =crap

2: composite=bad

3: S-video =fair

4: 480p component video=good

5: 720p or 1080i HDTV=really good

6: high end video projectors-XGA or UXGA=fantastic

The controllers are not that easy- believe me I've looked into them!

Most good ones use the 65545 controller which is a wicked fast video processor chip. They also need video memory and alot of glue logic. We're talking 4 layer boards here! Definitely not a home-brew project. EarthLCD seems to have the cheapest LCD controllers I can find- around $250 to drive a 1024x768 panel.

The only reason I'm interested is a controller is that I'd like to build a smaller projector using a 10.4" panel. Then you don't have to chop up your OHP to get the thing to fit. Or you can make a smaller DIY projector case.

Ace-

I think you are confusing component video (3 separate cables)

with composite video (1 cable) The classes of video are as such:

1: RF (cable tv) =crap

2: composite=bad

3: S-video =fair

4: 480p component video=good

5: 720p or 1080i HDTV=really good

6: high end video projectors-XGA or UXGA=fantastic

The controllers are not that easy- believe me I've looked into them!

Most good ones use the 65545 controller which is a wicked fast video processor chip. They also need video memory and alot of glue logic. We're talking 4 layer boards here! Definitely not a home-brew project. EarthLCD seems to have the cheapest LCD controllers I can find- around $250 to drive a 1024x768 panel.

The only reason I'm interested is a controller is that I'd like to build a smaller projector using a 10.4" panel. Then you don't have to chop up your OHP to get the thing to fit. Or you can make a smaller DIY projector case.

proto5

proto so u got a bare lcd with no boards whats so ever?

if u have good luck to u lol i was talking of what u can make to run through them not to actually control the pixels on the board lol stuff that for a joke, ill post some pics in here soon of my mini projector with a 6inch lcd, still building but not to far from finnished, its about the size of a vcr but 14cm high, and when u see the pics u will see how compact the darn thing is lol also what is the lumens on one of those loa lights things in walmart over there?

Trev

proto so u got a bare lcd with no boards whats so ever?

if u have good luck to u lol i was talking of what u can make to run through them not to actually control the pixels on the board lol stuff that for a joke, ill post some pics in here soon of my mini projector with a 6inch lcd, still building but not to far from finnished, its about the size of a vcr but 14cm high, and when u see the pics u will see how compact the darn thing is lol also what is the lumens on one of those loa lights things in walmart over there?

Trev

bare lcd

Yea, I found a Sharp 10.4" XGA panel cheap. The controller will cost me alot more than the panel.

The LOA lites aren't worth your time- you need a point source of lite - metal halide is best, but many people use halogen projector lamps. I wanna know how the high end LCD projectors are able to shove so many lumens through their LCDs w/o melting them.

My 1545v routinely sees 130 degrees F with my Elmo 7000 lumen OHP. And that heat isn't rising from the OHP, it's from the lite hitting the panel and heating it!

Yea, I found a Sharp 10.4" XGA panel cheap. The controller will cost me alot more than the panel.

The LOA lites aren't worth your time- you need a point source of lite - metal halide is best, but many people use halogen projector lamps. I wanna know how the high end LCD projectors are able to shove so many lumens through their LCDs w/o melting them.

My 1545v routinely sees 130 degrees F with my Elmo 7000 lumen OHP. And that heat isn't rising from the OHP, it's from the lite hitting the panel and heating it!

The high end LCD projectors use a few methods to keep the Lumens up.

1) First LCD's must have polarized light to work and any non polarized light does not pass through the LCD so there is a method to polarized and recycle the light. If you don't do this you are losing about 50% or more of your light up front.

2) Second they use three monochrome LCD and shine a different color light through each of them and then recombine the total picture. This has two effects were light output is concerned. It allows three LCD to pass the light so more total light can be put through the system. And monochrome LCDs do not filter out as much light as full color ones do because they have fewer transistors blocking the light. They are also disigned for a narrower angle of view which allows more light to be passed straight through the LCD at perpendicular angles. With a computer monitor LCD they are designed to dispurse the light more so that the screen can be viewed over a wider viewing angle.

About the heat. Of course it naturally rises and the OHP design requires alrge and noisy fans to cool it becasue the design traps hot ait by nature.

Your LCD will get over heated if you do not pre polarizr the light before it goes through the LCD panel. Since non plarized light is absorbed by the LCD's polarizer you should use another reflective polarizing film to reflect back the non polarized light into the reflector. This film will take most of the heat build up instead of your LCD.

Obviously hot air trapped will also build up heat. You have to deal with that somehow.

Hezz

1) First LCD's must have polarized light to work and any non polarized light does not pass through the LCD so there is a method to polarized and recycle the light. If you don't do this you are losing about 50% or more of your light up front.

2) Second they use three monochrome LCD and shine a different color light through each of them and then recombine the total picture. This has two effects were light output is concerned. It allows three LCD to pass the light so more total light can be put through the system. And monochrome LCDs do not filter out as much light as full color ones do because they have fewer transistors blocking the light. They are also disigned for a narrower angle of view which allows more light to be passed straight through the LCD at perpendicular angles. With a computer monitor LCD they are designed to dispurse the light more so that the screen can be viewed over a wider viewing angle.

About the heat. Of course it naturally rises and the OHP design requires alrge and noisy fans to cool it becasue the design traps hot ait by nature.

Your LCD will get over heated if you do not pre polarizr the light before it goes through the LCD panel. Since non plarized light is absorbed by the LCD's polarizer you should use another reflective polarizing film to reflect back the non polarized light into the reflector. This film will take most of the heat build up instead of your LCD.

Obviously hot air trapped will also build up heat. You have to deal with that somehow.

Hezz

Another small panel possibility

Fujitsu makes a notebook computer P-1120 which has a 8.9 inch wide screen SXGA TFT touch screen. I wonder if it's there own LCD. I don't know and who needs touch screen but the specs look good for resolution. I don't know about other thinks like speed and contrast ratio.

Hezz

Fujitsu makes a notebook computer P-1120 which has a 8.9 inch wide screen SXGA TFT touch screen. I wonder if it's there own LCD. I don't know and who needs touch screen but the specs look good for resolution. I don't know about other thinks like speed and contrast ratio.

Hezz

polarizer

Hezz:

Talk to me more about this repolarizer thing...If we could use more of that 50% wasted light it'd make all our projectors more efficient.....Any ideas on how to do it in a standard OHP/LCD setup?

Hezz:

Talk to me more about this repolarizer thing...If we could use more of that 50% wasted light it'd make all our projectors more efficient.....Any ideas on how to do it in a standard OHP/LCD setup?

talk about high end

here's an expensive solution:Polarcor™ Linear Polarizers

79% transmission.

further googling uncovered the Proflux Polarizer by Moxtek, which apparently is available in a 90%+ transmission version. dunno how expensive it is though.

/andrew - likes to google for fun sometimes.

here's an expensive solution:Polarcor™ Linear Polarizers

79% transmission.

further googling uncovered the Proflux Polarizer by Moxtek, which apparently is available in a 90%+ transmission version. dunno how expensive it is though.

/andrew - likes to google for fun sometimes.

polarisers

another place we could try is a big photographic shop, im sure they would have one of these for some effects for photos or for taking pro night shots or even astro photography

might be cheaper

Trev

another place we could try is a big photographic shop, im sure they would have one of these for some effects for photos or for taking pro night shots or even astro photography

might be cheaper

Trev

More on polarizers

Proto5,

Hope things are going well and your most exellent image is still shining on the wall.

If you look back at my big momma design you'll notice among other things that it has a long folded horn like structure which makes the box very big. The purpose of this is to straighten out the light paths as much as possible so that you don't need a point source of light as in the traditional OHP design.

This design uses only one fresnel instead of two fixed together becasue the light is already coming from a relatively perpendicular path. With this set up the above polarizer should work because it is not so dependent on point source light.

With the doulbe fresnel approach which most OHP's use they have two light cones and for proper focusing they need a small light source at the focal point of the lower fresnel.

I have not given much thought to designing a point source polarizing recycler but you still can use a reflective polarizing film near the lower fresnel. This will decrease light output slightly but give better contrast and definition. It will also help cool down your LCD panel by taking much of the light heat buildup.

The above diagram which I proposed could be built very inexpensively maybe 25-40USD depending on where you got your parts.

You could still use it with a OHP design if you got the focal point right but as the fresnel refracts a lot of non focused light it may or may not increase light output. You would have to try it.

I will have to give this more thought.

Hezz

Faustion,

The Moxtek polarizers are very high quality high intensity cabable polarizers but they cost about 200-300 USD for a few square inches. To expensive for me to experiment with and probably way more than we would need. They can take multiple kilowatts of light output without harm.

Standard beam splitters on glass substrates I have seen for 8-15 USD in 8 inch sqaure sizes.

You would need a glass cutter and some high temperature glue to mount them together.

Hezz

Proto5,

Hope things are going well and your most exellent image is still shining on the wall.

If you look back at my big momma design you'll notice among other things that it has a long folded horn like structure which makes the box very big. The purpose of this is to straighten out the light paths as much as possible so that you don't need a point source of light as in the traditional OHP design.

This design uses only one fresnel instead of two fixed together becasue the light is already coming from a relatively perpendicular path. With this set up the above polarizer should work because it is not so dependent on point source light.

With the doulbe fresnel approach which most OHP's use they have two light cones and for proper focusing they need a small light source at the focal point of the lower fresnel.

I have not given much thought to designing a point source polarizing recycler but you still can use a reflective polarizing film near the lower fresnel. This will decrease light output slightly but give better contrast and definition. It will also help cool down your LCD panel by taking much of the light heat buildup.

The above diagram which I proposed could be built very inexpensively maybe 25-40USD depending on where you got your parts.

You could still use it with a OHP design if you got the focal point right but as the fresnel refracts a lot of non focused light it may or may not increase light output. You would have to try it.

I will have to give this more thought.

Hezz

Faustion,

The Moxtek polarizers are very high quality high intensity cabable polarizers but they cost about 200-300 USD for a few square inches. To expensive for me to experiment with and probably way more than we would need. They can take multiple kilowatts of light output without harm.

Standard beam splitters on glass substrates I have seen for 8-15 USD in 8 inch sqaure sizes.

You would need a glass cutter and some high temperature glue to mount them together.

Hezz

Inexpensive polarizer films

You guys should check out the 3M vikitu film polarizer site. They make a wide range of inexpensive fims for enhancing LCD images.

I plan on using three of their products if I can find a supplier who sells them in small quantity.

1) Refective polarizer 2) Brightness enhancemnt film 3) ESR reflective film to line the light pipe or reflector with.

If we combine these films with glass panels which can disipate and block heat we should have success.

Hezz

You guys should check out the 3M vikitu film polarizer site. They make a wide range of inexpensive fims for enhancing LCD images.

I plan on using three of their products if I can find a supplier who sells them in small quantity.

1) Refective polarizer 2) Brightness enhancemnt film 3) ESR reflective film to line the light pipe or reflector with.

If we combine these films with glass panels which can disipate and block heat we should have success.

Hezz

- Status

- Not open for further replies.

- Home

- General Interest

- Everything Else

- The Moving Image

- DIY Projectors

- New High end 7" LCD projector design proposal