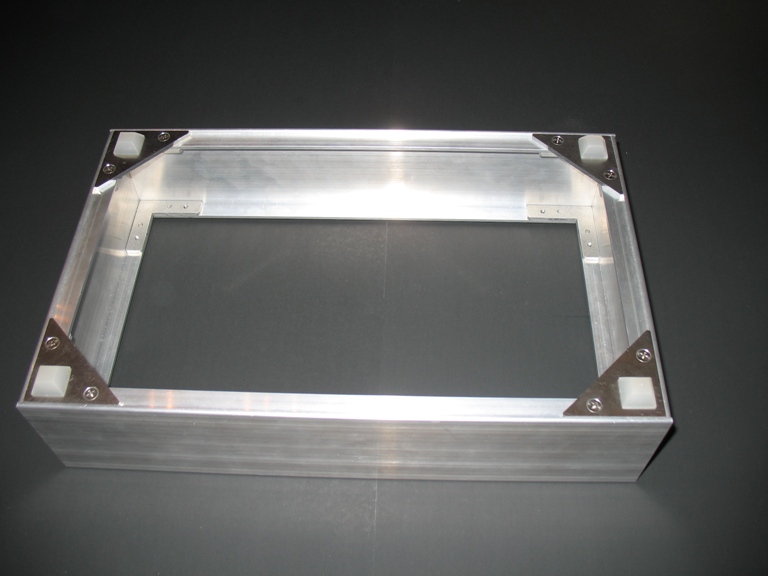

We manufacture custom sized aluminum enclosures for DIY projects. We can currently make enclosures 2.25, 3.25 and 4.25 inches tall. The width and depth are configurable in 1/32 inch increments between 4.5 and 24 inches.

We make each enclosure to order. Let us know if you need something special.

For more information, please visit our website or ask a question here.

http://www.landfallsystems.com

Also, Pete Millett started a thread with some info and pictures of his amps in our chassis:

http://www.diyaudio.com/forums/tubes-valves/229129-new-semi-custom-metal-chassis-manufacturer.html

We've started this thread to support discussions and answer any questions you may have.

We make each enclosure to order. Let us know if you need something special.

For more information, please visit our website or ask a question here.

http://www.landfallsystems.com

Also, Pete Millett started a thread with some info and pictures of his amps in our chassis:

http://www.diyaudio.com/forums/tubes-valves/229129-new-semi-custom-metal-chassis-manufacturer.html

We've started this thread to support discussions and answer any questions you may have.

Last edited:

Hi Dave -

Just wondering if I painted the chassis would I have a problem with assembly. It all looks fine except for the countersuck top plate.

Awesome job and thanks for a Hammond alternative!

Sandy

Just wondering if I painted the chassis would I have a problem with assembly. It all looks fine except for the countersuck top plate.

Awesome job and thanks for a Hammond alternative!

Sandy

Hi Dave -

Just wondering if I painted the chassis would I have a problem with assembly. It all looks fine except for the countersuck top plate.

Awesome job and thanks for a Hammond alternative!

Sandy

Send us an email when you place an order to let us know you want the top and bottom plates cut undersize for painting. We'll cut the lid about 0.010 inch under in each dimension for 0.005 extra clearance on each side. More or less if you prefer. Just let us know.

We realize that we don't have a comment field to use when placing orders so we're adding that to the shipping page. You'll be able to note your preferences there.

Thanks for the quick reply. I'm working on the prototype now and once that gets done I'll get one orderd up.

Sandy

Sandy

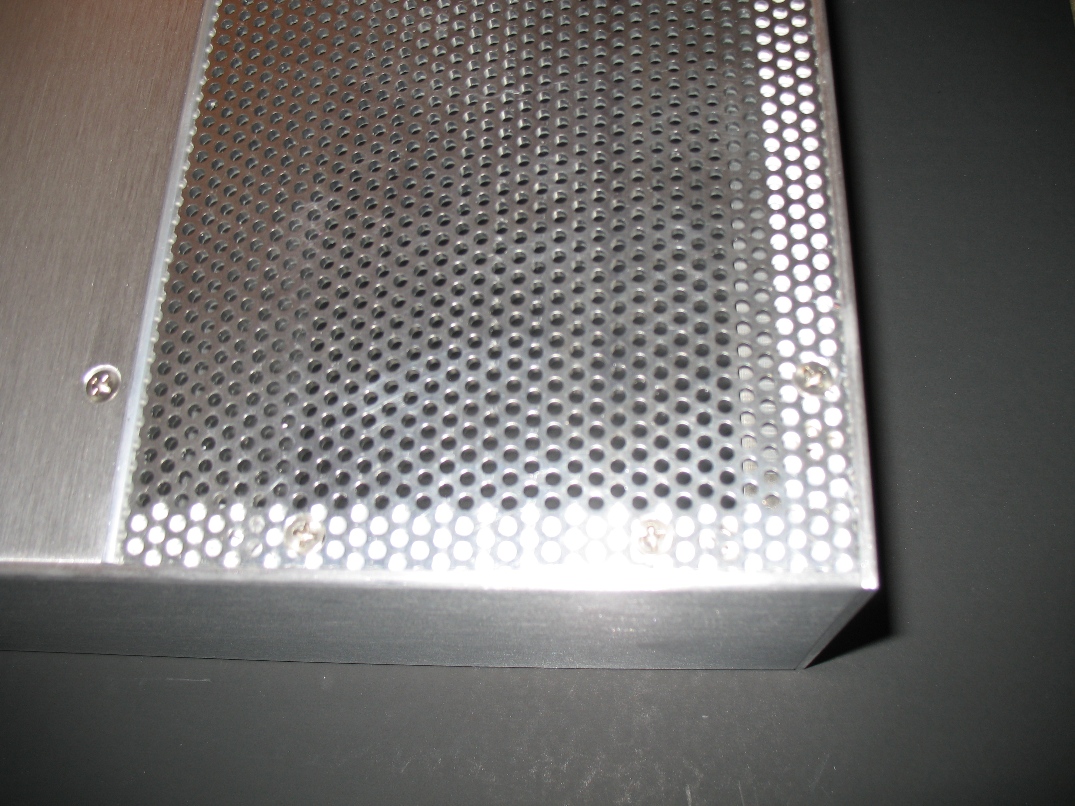

We now have perforated sheet and can provide it as a top and/or bottom for any of our enclosures. It's 1/8" thick like our other top/bottom plate material. Holes are 1/8" on 3/16" centers in a staggered pattern. This gives an open area of 40% for some good ventilation.

The perforated material is aluminum alloy 3003-H14. The extrusion and plate we use are aluminum alloy 6061-T6. The two will look a bit different when anodized so you may want to leave the perforated sheet as is. It has a nice smooth finish on one side.

The perforated material is aluminum alloy 3003-H14. The extrusion and plate we use are aluminum alloy 6061-T6. The two will look a bit different when anodized so you may want to leave the perforated sheet as is. It has a nice smooth finish on one side.

Excellent. I was thinking about the bottom cover for the perferated sheet. I'm slow at finishing the design, but working on it.

Now just figure out how to make some transformer covers and you have it all!

Sandy

Now just figure out how to make some transformer covers and you have it all!

Sandy

Another option for bottom ventilation is to use our corner plates. Granted these don't provide any protection from harmful voltages that may be present inside, so be sure your design is safe enough to use them.

As for transformer covers, we can make enclosures as small as 4.25" x 4.25" and as tall as 4.25". Might be a bit pricey for the use, but it's doable. Just pick your size 🙂

Nice website Sandy. Lots of cool stuff.

As for transformer covers, we can make enclosures as small as 4.25" x 4.25" and as tall as 4.25". Might be a bit pricey for the use, but it's doable. Just pick your size 🙂

Nice website Sandy. Lots of cool stuff.

The open bottom is not an option as I have kids 😉

But I Have been looking at some interesting ways to make a box for the transformer covers. I'll come up with something as I really like your chassis flexibility and pretty sure you could come up with something simple that would match.

One quick question what is the size of the top/bottom edge/flange on the chassis? Getting close to a fixed PCB size and want to allow for the edge so I could lift out the top plate as a complete unit.

Sandy

But I Have been looking at some interesting ways to make a box for the transformer covers. I'll come up with something as I really like your chassis flexibility and pretty sure you could come up with something simple that would match.

One quick question what is the size of the top/bottom edge/flange on the chassis? Getting close to a fixed PCB size and want to allow for the edge so I could lift out the top plate as a complete unit.

Sandy

Sandy,

The flange is 1/2" wide. I just realized that we don't have that dimension on our detailed drawings. We'll add it.

Thanks

The flange is 1/2" wide. I just realized that we don't have that dimension on our detailed drawings. We'll add it.

Thanks

I am the new owner of the shiney metal box shown in post #5. Dave at Landfall Systems worked with me to get this designed, and acquired the perforated aluminum to create a rather unique rack or cabinet mountable tube amp design. Plans are underway to create similar chassis for the SSE and TSE.

I did a mock-up of the completed amp to make sure my thinking was correct. Pictures are in post #23 of this thread.

http://www.diyaudio.com/forums/tubes-valves/229129-new-semi-custom-metal-chassis-manufacturer.html

Once all the parts have arrived a new thread will be opened in the Tubes forum to follow the build. The Edcor OPT's are several weeks away. They were just ordered.

I did a mock-up of the completed amp to make sure my thinking was correct. Pictures are in post #23 of this thread.

http://www.diyaudio.com/forums/tubes-valves/229129-new-semi-custom-metal-chassis-manufacturer.html

Once all the parts have arrived a new thread will be opened in the Tubes forum to follow the build. The Edcor OPT's are several weeks away. They were just ordered.

Since we've received a few questions regarding the strength of our enclosures, we decided to do a little experiment. I've also posted this information here:

http://www.diyaudio.com/forums/tubes-valves/229129-new-semi-custom-metal-chassis-manufacturer.html

The video and images below are of a small 6 x 10 inch enclosure we affectionately call "the brick," and Saer's Raptor. Thinking you could pretty much drive over the thing, we thought we'd see what would happen setting a wheel on it.

Landfall Systems, Simple Single weight test, Part 1 - YouTube

Lanfall Systems, Simple Single weight test, Part 2 - YouTube

Curb weight of the truck is about 6,000 lbs. Figure there's somewhere in the range of 1,500 lbs on the box.

The last two images are of both sides of the box after the experiment.

http://www.diyaudio.com/forums/tubes-valves/229129-new-semi-custom-metal-chassis-manufacturer.html

The video and images below are of a small 6 x 10 inch enclosure we affectionately call "the brick," and Saer's Raptor. Thinking you could pretty much drive over the thing, we thought we'd see what would happen setting a wheel on it.

Landfall Systems, Simple Single weight test, Part 1 - YouTube

Lanfall Systems, Simple Single weight test, Part 2 - YouTube

Curb weight of the truck is about 6,000 lbs. Figure there's somewhere in the range of 1,500 lbs on the box.

The last two images are of both sides of the box after the experiment.

Attachments

Notice: the batch level for black anodizing is over 60%. If you're interested in purchasing a black enclosure, now is a good time. We'll be taking enclosures over to the anodizing shop in the near future.

Dave

Dave

Notice update: We're taking a batch of enclosures to the shop on Monday for black anodizing. If you want a quick turn around on a black enclosure, now is a good time to order. Order by Friday night and we'll get it in to the anodize shop on Monday. Saturday orders MIGHT make it also.

Notice: Lone Star Audio Fest is this weekend! May 3rd, 4th and 5th. Anyone near the Dallas area should stop in and say hi. We'll be setup in one of the exhibitor rooms along with Apex Audio and CablePro. Just look for the red Landfall Systems sign.

Obviously, we'll be enjoying all the goodies at the show, so any orders received before Monday will be delayed a few days.

Hope to see y'all there.

Obviously, we'll be enjoying all the goodies at the show, so any orders received before Monday will be delayed a few days.

Hope to see y'all there.

Hi, it has been awhile on this thread but I was wondering if their is any update to the features available on these enclosures.

Also, Tubelab, where are you at with your prototype?

Also, Tubelab, where are you at with your prototype?

I have built 2 amps with them and they are fantastic. I think the only feature I could think of would be covers for the chassis or transformers 🙂

I had one last Hammond chassis that I just built an amp in and I remember why I hate them so much, cheep, expensive and always the wrong size.

They do have nice covers however 🙂

Sandy

I had one last Hammond chassis that I just built an amp in and I remember why I hate them so much, cheep, expensive and always the wrong size.

They do have nice covers however 🙂

Sandy

Hi, it has been awhile on this thread but I was wondering if their is any update to the features available on these enclosures.

Well, we've been hesitant to say too much as we're still getting things sorted out. But, we now have 5.20" (3U) extrusion in stock and will soon be setup to make enclosures with it and will add it to the website. So, there's one more size to choose from.

Also, we've built a CNC router and have been making pretty nice holes with it. We don't yet have the details worked out for selling this service, but that will be coming in the not-too-distant future.

More details to come as we work things out.

Thanks for your interest!

Dave -

Please don't make it too easy to make project chassis, their won't be anything else left for me to do when I get the box 😉

Sandy

Please don't make it too easy to make project chassis, their won't be anything else left for me to do when I get the box 😉

Sandy

Dave -

Please don't make it too easy to make project chassis, their won't be anything else left for me to do when I get the box 😉

Sandy

Well, that's kinda the idea

...but we won't do your wiring

- Status

- Not open for further replies.

- Home

- Vendor's Bazaar

- New enclosures for DIY