You're welcome!

Yes, there's more than one way to do it and I'm always for using up as much scrap as practical.

Right, cavities can 'boom', so filling them up was a massive material is best. FWIW, I use kitty litter/oil dry as a weight compromise. If sand is used, make sure it's sterile. The top one can have expanding foam as an acceptable trade-off between acoustic efficiency and weight, just be careful not to use too much as it can rupture seams.

GM

Yes, there's more than one way to do it and I'm always for using up as much scrap as practical.

Right, cavities can 'boom', so filling them up was a massive material is best. FWIW, I use kitty litter/oil dry as a weight compromise. If sand is used, make sure it's sterile. The top one can have expanding foam as an acceptable trade-off between acoustic efficiency and weight, just be careful not to use too much as it can rupture seams.

GM

You mean Siporex maybe?

I think he means styrofoam. Kitty litter would work better.

Personally i'd just leave it vestigal and not have a void at all.

dave

GM, about sterile sand... boil it?

Should the cavity be just filled with sand or maybe a layer of glue (or something) should be used on inner walls of the cavity?

Should the cavity be just filled with sand or maybe a layer of glue (or something) should be used on inner walls of the cavity?

Vestigial? Looked it up but I'm not sure I've got it right... 🙂

Something like this?

That's it.

dave

Normally you would bake at a few hundred degrees F, but if you can buy decent sandbox or fish tank sand it's sterile enough, though the latter is usually just sandbox sand at a much higher price: Ash Grove Play Sand AG 50# - 361.50.AG at The Home Depot

No glue needed, just pour in a little, tap the box with a rubber mallet or hammer and wood block to settle it, repeat as necessary until filled, then plug the hole.

GM

No glue needed, just pour in a little, tap the box with a rubber mallet or hammer and wood block to settle it, repeat as necessary until filled, then plug the hole.

GM

Tnx. I'll rather sterilize some sand myself, all in a frugal spirit!

Dave, some external brace on the back wouldn't hurt? I'll try to make some drawings about possible modifications later on...

I just hope Scott don't mind me making a Frankenstein out of his Chang... 😉

Dave, some external brace on the back wouldn't hurt? I'll try to make some drawings about possible modifications later on...

I just hope Scott don't mind me making a Frankenstein out of his Chang... 😉

Dave, some external brace on the back wouldn't hurt? I'll try to make some drawings about possible modifications later on...

I just hope Scott don't mind me making a Frankenstein out of his Chang...

🙂

When we get around to doing one of the Chang^2 it will be in the spirit of the image i posted earlier.

dave

😱 kitty litter ?I think he means styrofoam. Kitty litter would work better.

Dave , Vann got it right . Stiroflex or any name ,the material is that. I did also made a powder from it and mix with plaster ,to cover some dead woofer's cone,resulting a good waveguide, also useful to lesser the volume of a box with a light material as that is ...

Styrofoam also is good but doesn't have the "inertial mass"of porous concrete.

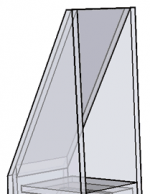

Pico, I've decided to go without the upper corner.

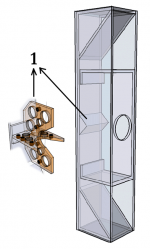

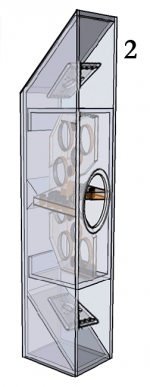

Dave, I've made the rough sketch of the mods we talked about (attached bellow). Mind answering few questions (illustrated in pics attached)?

1. Should I keep the original deflectors (the ones behind the driver) and make a blend with bracers as shown in your pic earlier? Link

Should braces go side to side in internal box? Changs internal box is kinda longer than the one in Maiko...?

2. Braces in the vent openings... yes or no? I guess they will improve strength of the cabinets but what will they do sound-wise?

3. Cabinet rotating for a few degrees so it faces a bit more upward, is this a good thing?

Dave, I've made the rough sketch of the mods we talked about (attached bellow). Mind answering few questions (illustrated in pics attached)?

1. Should I keep the original deflectors (the ones behind the driver) and make a blend with bracers as shown in your pic earlier? Link

Should braces go side to side in internal box? Changs internal box is kinda longer than the one in Maiko...?

2. Braces in the vent openings... yes or no? I guess they will improve strength of the cabinets but what will they do sound-wise?

3. Cabinet rotating for a few degrees so it faces a bit more upward, is this a good thing?

Attachments

. Should I keep the original deflectors (the ones behind the driver) and make a blend with bracers as shown in your pic earlier?

The purpose of that isn't deflector, but to give some isolation to the 2 vents. If you have the full width cross-brace it can serve that purpose.

Should braces go side to side in internal box? Changs internal box is kinda longer than the one in Maiko...?

They should reach all the way to the box sides (with holes). As the Changs have a longer cab, i'd also add some braces parallel to the baffle above and below the drivers (similar to the ones in the Fonken167 pictured above)

2. Braces in the vent openings... yes or no? I guess they will improve strength of the cabinets but what will they do sound-wise?

They can be left out and added after the fact if needed.

dave

It seems I have found a supplier for 3/4" plywood... but he's not sure how much he's got in supply so I'll drop in a day or 2 to check quantity and quality...

Any tips on quality check methods, besides obvious air gaps in edges of the sheets?

Also I'm about to draw the cut (jig) plans, I thought I'd better be ready to ask for cutting at the shop (it's quite far). That is if I like the plywood quality.

Does somebody have ready made cut plans in some vector file format? (CAD, Inkscape, Coreldraw, anything...)

I'm told those CNC machines love being fed in those file formats...

Any tips on quality check methods, besides obvious air gaps in edges of the sheets?

Also I'm about to draw the cut (jig) plans, I thought I'd better be ready to ask for cutting at the shop (it's quite far). That is if I like the plywood quality.

Does somebody have ready made cut plans in some vector file format? (CAD, Inkscape, Coreldraw, anything...)

I'm told those CNC machines love being fed in those file formats...

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- Need suggestions and advice for stereo/HT setup