Does the front baffle gets lined with wool felt, or just the back, top, and sides???

If you're referencing the little microFonken design, our approach is to line as much of all internal panels as possible without blocking any internal vent apertures, as well as leaving some margin of breathing room around the driver.

On the uFonken?

all sides including baffle & the bottom. Do not obstruct the vent entrances

dave

edit: Chris beat me to the punch

all sides including baffle & the bottom. Do not obstruct the vent entrances

dave

edit: Chris beat me to the punch

If you're referencing the little microFonken design, our approach is to line as much of all internal panels as possible without blocking any internal vent apertures, as well as leaving some margin of breathing room around the driver.

On the uFonken?

all sides including baffle & the bottom. Do not obstruct the vent entrances

dave

edit: Chris beat me to the punch

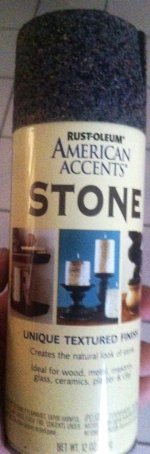

Thanks! They are lined allright...Front, back, top, bottom, and sides. Vents are not obstructed. Made a foam core model, then will build 12 mm baboon plywood cabinets. It was quite a learning experience working with foam core, hadn't done that since my college years (1987 - 1992). Not having a good pulse didn't make for really straight cuts, the first enclosure had some gaps larger than the usual hairline; sealed with epoxy. The second was much better, there are some hairline gaps, but will also seal with epoxy. In order to cover the imperfections I will prime and paint with a stone textured spray paint. Here is a picture of the pair.

Attachments

Here are pictures of the finished enclosures. 2-Part Epoxy was used to seal a few hairline and not so hairline cracks in between panels. Let's say my pulse is not the same as many years ago (need to buy a cutting wheel). After the Epoxy cured, in order to cover the marks left by Epoxy and cutting, I applied Primer then painted with textured stone paint. For the first time I will say that is not that bad.

Attachments

- Status

- Not open for further replies.