Great project thanks sharing.

If you like to have predictions for floor bounce there is free calculator and other stuff available at Merlijn van Veen website although one need register https://www.merlijnvanveen.nl/index.php/en/calculators.

If you like to have predictions for floor bounce there is free calculator and other stuff available at Merlijn van Veen website although one need register https://www.merlijnvanveen.nl/index.php/en/calculators.

Attachments

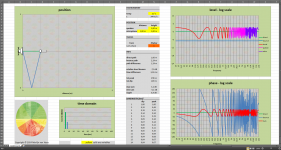

Look now at the measured polars, 4 cycle FDW, 0, 22, 33 & 45 degrees off axis. These angles are little more than eyeballed but sufficient to their purpose.

I expected a cancellation null at 200 Hz based on the geometry. In the 45 degree curve (red) you can see the response diving towards the null already at 157 Hz but the null itself is out at 238 Hz. I narrowed the front panel to just 24" to save on veneer costs, but I think this also widened the bandwidth a little bit.

At the end of the couch in my room, I'll be 22 degrees off axis from the near speaker and 7.3 degrees off axis from the far speaker. The center of the couch is 19 degrees off axis from both. (that being the case, I wonder why I didn't take data at these angles).

At my nominal planned crossover to the synergy mids of 200 Hz, I should be within 2 db across the width of the couch, due to this one effect at any rate.

Jack

I have seen something like this before. Is the back of the speaker on when taking this data (open back mids)? If so, the 330Hz dip may be cancellation from a 20in distance from port to mouth back to rear of cone. Or it may be that you don't have a secondary horn expansion so the mouth abruptly ends from an acoustic impedance standpoint. This can cause a reflection back to port and cancel causing a dip. What is axial distance from port to mouth?

hmmm you quoted a post about the bass bin response but I can see you are talking about the mids on the Synergy horn. let me work up a dimensioned dwg for the horn.

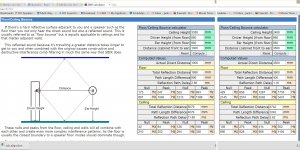

Meanwhile, let me say that I'm pretty sure its a boundary response thing. Allison analyzed a point source against various boundaries, including a corner. Jeff Bagby put his equations in a spreadsheet, which I've spent lots of time with. I expected a floor bounce null and got one. When I added an absorbing pad on the floor, that null, which looks exactly like the one in the Allison paper goes away but I'm left with that response which is about 6 db too low in the region of 100 hz to 400 hz, compared to simulation and what I measure with the mic right at the horn mouth.

Comparing 1pi to 2pi to 4 pi sims, I think I'm lacking side boundary support in that reason - because each sim is 6 db less power than the smaller angle sim. There it is likely sufficiently out of phase not to add constructively. I'm lucky its smooth; it shouldn't be hard to EQ. OTOH, I hate to give up the headroom.

Data from my first gen prototype suggests, doesn't prove, that absorption on the wall immediately adjacent to the horn restores the missing 6 db in the lower half of the synergy mid's pass band. It would be interesting to see if a secondary flare that blended smoothly into the sidewalls had the same effect. I wish I were up to the challenge of simulating it.

Meanwhile, let me say that I'm pretty sure its a boundary response thing. Allison analyzed a point source against various boundaries, including a corner. Jeff Bagby put his equations in a spreadsheet, which I've spent lots of time with. I expected a floor bounce null and got one. When I added an absorbing pad on the floor, that null, which looks exactly like the one in the Allison paper goes away but I'm left with that response which is about 6 db too low in the region of 100 hz to 400 hz, compared to simulation and what I measure with the mic right at the horn mouth.

Comparing 1pi to 2pi to 4 pi sims, I think I'm lacking side boundary support in that reason - because each sim is 6 db less power than the smaller angle sim. There it is likely sufficiently out of phase not to add constructively. I'm lucky its smooth; it shouldn't be hard to EQ. OTOH, I hate to give up the headroom.

Data from my first gen prototype suggests, doesn't prove, that absorption on the wall immediately adjacent to the horn restores the missing 6 db in the lower half of the synergy mid's pass band. It would be interesting to see if a secondary flare that blended smoothly into the sidewalls had the same effect. I wish I were up to the challenge of simulating it.

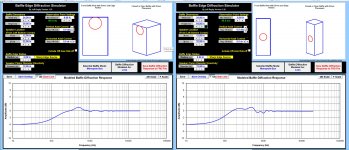

Here is what Allison wouldd predict for a point source centered in my horn mouth - a 330 Hz dip, albeit a deeper one. I created this with the JeffB spreadsheet. The depth and location of the null varies with either the distance from the floor or a sidewall which implies the sidewall reflection is involved with me. Recall that I had absorption on the floor for my measurement so the effect I see is due to the sidewalls.

Here is what Allison wouldd predict for a point source centered in my horn mouth - a 330 Hz dip, albeit a deeper one. I created this with the JeffB spreadsheet. The depth and location of the null varies with either the distance from the floor or a sidewall which implies the sidewall reflection is involved with me. Recall that I had absorption on the floor for my measurement so the effect I see is due to the sidewalls.

Last edited:

Are you mids rear cone isolated from front horn radiation? 11.55in X 2 = 23.1in that would be 290Hz cancellation for 1/2 wave.

Yes my mids are sealed and yes that was my first thought as I had done some preliminary measurements open back

Great project thanks sharing.

If you like to have predictions for floor bounce there is free calculator and other stuff available at Merlijn van Veen website although one need register https://www.merlijnvanveen.nl/index.php/en/calculators.

Thanks Byrtt. I did go to Merlin's site but I ended up using the calculator linked below because it shows both floor and ceiling bounce. SBIR calculator

Here is the results for both 1m where I measured in my garage with 11' ceiling and 3.5m where I will listen. I see the delta path goes down the further away you listen, making it easier to absorb.

Attachments

"6dB too low"..... reminds of baffle step, no?

Your horn's directivity is going away about there, so it won't help with a change toward 4pi - that's the horizontal directivity, the vertical directivity is long gone down at those frequencies already.

Your horn's directivity is going away about there, so it won't help with a change toward 4pi - that's the horizontal directivity, the vertical directivity is long gone down at those frequencies already.

Last edited:

"6dB too low"..... reminds of baffle step, no?

Your horn's directivity is going away about there, so it won't help with a change toward 4pi - that's the horizontal directivity, the vertical directivity is long gone down at those frequencies already.

Right. pattern control was something like 386 horizontally and up around 800 hz vertically.

re' 6 db low - I suspect using a floor absorber as I did - 6" of poly and two layers of old throw rugs cost me the floor support.

correction

checked the spreadsheet

Horizontal pattern coverage is down to 328.3 Hz

pretty close to the null frequency but not quite low enough

I should experiment with cardboard or foam secondary flares to see if that helps

checked the spreadsheet

Horizontal pattern coverage is down to 328.3 Hz

pretty close to the null frequency but not quite low enough

I should experiment with cardboard or foam secondary flares to see if that helps

.....I ended up using the calculator linked below because it shows both floor and ceiling bounce. SBIR calculator.....

Thanks link looks a nice tool.

Simulation experience regarding nulls the time i spent into JB spreadsheets as soon as two boundary's gets near same numbers we get some trouble and if its three boundary's with same numbers it accelerate in very bad direction, therefor just for test but in live situation wonder if you raise speaker height just a bit will reveal anything.

since you don't have secondary flares now, you should be getting a little 'help' from the waistbanding down near the lower end of the horn so that should be mitigating things. Extending what you have with further flare shjould move the control frequency down.

But I imagine it behaves pretty much like a driver on a baffle in the vertical there, so there will still be some of a drop from the step from that. (by the way, you can find the vertical control frequency by swapping horizontal and vertical angles in my spreadsheet and adjusting the frequency to get the same physical dimensions).

But I imagine it behaves pretty much like a driver on a baffle in the vertical there, so there will still be some of a drop from the step from that. (by the way, you can find the vertical control frequency by swapping horizontal and vertical angles in my spreadsheet and adjusting the frequency to get the same physical dimensions).

Good point. Waistbanding is pattern narrowing just before the horn loses control, which would indeed help keep the sound off the walls. As you say, a secondary flare would extend control lower, also helping keep sound off the walls.

If I model a 12" dia. piston on a 24" wide baffle, then I do see baffle step, which would get stronger when I stack a 2nd bass bin on top of the horn.

If I model a 12" dia. piston on a 24" wide baffle, then I do see baffle step, which would get stronger when I stack a 2nd bass bin on top of the horn.

Attachments

Thanks link looks a nice tool.

Simulation experience regarding nulls the time i spent into JB spreadsheets as soon as two boundary's gets near same numbers we get some trouble and if its three boundary's with same numbers it accelerate in very bad direction, therefor just for test but in live situation wonder if you raise speaker height just a bit will reveal anything.

I've seen the same thing in simulation. What I need to do is carry the horn outside and place it on the railing of my deck where it will be about 7' off the ground. But my back might not be up to that challenge (I've got a note from the doctor.)

I'm also kicking myself for throwing out those old fiberglass panels that were shedding all over the place. Now I can't readily repeat the measurement with wall absorption. I will find a way in a day or two.

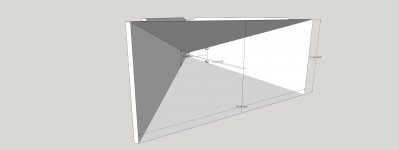

Veneering a front panel

The panic of the day was laminating a piece of 6 mm plywood with PSA veneer attached to the front of my first 2nd cabinet. It turned into a panic as I couldn't get it lined up perfectly before the glue started to grab. The first cabinet has the plywood lamination done already so I will have to apply the veneer to it in place. That should be easier because I won't have to deal with all these clamps which were indispensable for dealing with the front of the triangular cabinet but tend to shift a little as they are tightened.

The panic of the day was laminating a piece of 6 mm plywood with PSA veneer attached to the front of my first 2nd cabinet. It turned into a panic as I couldn't get it lined up perfectly before the glue started to grab. The first cabinet has the plywood lamination done already so I will have to apply the veneer to it in place. That should be easier because I won't have to deal with all these clamps which were indispensable for dealing with the front of the triangular cabinet but tend to shift a little as they are tightened.

Attachments

vertical coverage angle

Keele has a simple formulat for that - the vertical pattern control frequency is approximately equal to the horizontal frequency times the square of the ratio of the coverage angles.

For my horn that is 328*4 = 1312 Hz, which I should have expected based on its 12" height.

(by the way, you can find the vertical control frequency by swapping horizontal and vertical angles in my spreadsheet and adjusting the frequency to get the same physical dimensions).

Keele has a simple formulat for that - the vertical pattern control frequency is approximately equal to the horizontal frequency times the square of the ratio of the coverage angles.

For my horn that is 328*4 = 1312 Hz, which I should have expected based on its 12" height.

Attachments

Got a coat of finish one one front panel

I got the veneer - Khaya or African Mahogany - stuck down to the first front panel and one coat of Watco Natural Danish Oil applied. The plan is 3 coats, one per day.

I also fabricated the first metal grill for the slides; you can seeing it just laying in place along the top edge of the cabinet. Clearly, I need to paint the inside of the horn black. This is perforated aluminum with 1/8" holes on a 60 degree stagger for 41% open-ness; ordered from Home Depot on line; not available in stores. Other sources were 3x the cost although they did offer smaller holes. It comes already painted black.

The metal grill is easily cut with tin snips. I bought a 30" metal bending brake from Harbor Freight. When I saw they would ship it for only $6.99, I didn't bother driving the 20 mi. to the store. The thing weights about 40 lbs. There is a slight bow in the hinged part of the mechanism, about 1/32" or so, but its good enough for what I am doing.

I got the veneer - Khaya or African Mahogany - stuck down to the first front panel and one coat of Watco Natural Danish Oil applied. The plan is 3 coats, one per day.

I also fabricated the first metal grill for the slides; you can seeing it just laying in place along the top edge of the cabinet. Clearly, I need to paint the inside of the horn black. This is perforated aluminum with 1/8" holes on a 60 degree stagger for 41% open-ness; ordered from Home Depot on line; not available in stores. Other sources were 3x the cost although they did offer smaller holes. It comes already painted black.

The metal grill is easily cut with tin snips. I bought a 30" metal bending brake from Harbor Freight. When I saw they would ship it for only $6.99, I didn't bother driving the 20 mi. to the store. The thing weights about 40 lbs. There is a slight bow in the hinged part of the mechanism, about 1/32" or so, but its good enough for what I am doing.

Attachments

- Home

- Loudspeakers

- Multi-Way

- My Synergy Corner Horn and Bass Bins