I have worked somewhat with EQ og XO, some adjustments were necessary...

The midrange falls off quite a lot below 300 Hz, so I had to move the XO point to the woofer up to 250 Hz. The 21" does not have obvious problems with that. Also, I found that the tweeter could be crossed over at 1200 Hz.

Bass extends to 25 Hz with my current EQ... which is very good for a dipole speaker of this size.

Graphs will come, I promise!

The midrange falls off quite a lot below 300 Hz, so I had to move the XO point to the woofer up to 250 Hz. The 21" does not have obvious problems with that. Also, I found that the tweeter could be crossed over at 1200 Hz.

Bass extends to 25 Hz with my current EQ... which is very good for a dipole speaker of this size.

Graphs will come, I promise!

StigErik said:

Graphs will come, I promise!

I'm particularly interested in your midrange graph, because i think that the reflections on the woofer u-frame top will have some impact.

In order to see whether the U-frame creates any problems for the midrange, we would have to measure it with and without the frame... which I cant do.

The midrange is very far from flat, I will present a graph later. The main problems are very steep roll-off below 300 Hz, and an 11 dB peak around 520 Hz.

The main problem with the tweeter is a peak at 9 kHz, which is caused by removing the rear damper pad (there is a felt pad glued to the rear side of the driver). Apart from that, it behaves well in the open baffle.

The woofer behaves well! No significant resonance peak either.

After some listening tests, I found that 1500 Hz XO is better than 1200 Hz. It just sound better, and it was also easier to make the mid and tweeter sum flat at the XO point.

The midrange is very far from flat, I will present a graph later. The main problems are very steep roll-off below 300 Hz, and an 11 dB peak around 520 Hz.

The main problem with the tweeter is a peak at 9 kHz, which is caused by removing the rear damper pad (there is a felt pad glued to the rear side of the driver). Apart from that, it behaves well in the open baffle.

The woofer behaves well! No significant resonance peak either.

After some listening tests, I found that 1500 Hz XO is better than 1200 Hz. It just sound better, and it was also easier to make the mid and tweeter sum flat at the XO point.

Are you going to equalize actively or passively?

the midrange resonace can be simulated (very roughy) in edge! putting the driver close to the floor, that is considering the U top as the floor.

if the resoannce frequency matches, that's the case. if not, it's more complicated.

the midrange resonace can be simulated (very roughy) in edge! putting the driver close to the floor, that is considering the U top as the floor.

if the resoannce frequency matches, that's the case. if not, it's more complicated.

We had the same resonance on our first tryout, which was just a square board with no wings. We had a wider baffle, and the resonance was lower in frequency. I think this is just the main dipole resonance, caused by the rear wave combining with the front wave. 11 dB peak is more than expected, but I think we have a combination of the peak and the fact that the driver's response falls off above 1.2 kHz, and below 300 Hz.

All EQ and XO is active, running digitally in my computer. To (try to) do this passively is - in my opinion - not a brilliant idea.

All EQ and XO is active, running digitally in my computer. To (try to) do this passively is - in my opinion - not a brilliant idea.

Since this definitely is NO resonance, we should not call it a resonance either. For the midrange this goes without saying. For the U frame things are a little bit more complicated. There should be a quarter-wavelength resonance of the frame depth. But it is overlaid by the peaks and dips of the dipole comb(in)ing at almost the same frequencies. IMHO it can be very misleading to call any peaks and dips in the dipole response "resonance".StigErik said:We had the same resonance on our first tryout, which was just a square board with no wings. We had a wider baffle, and the resonance was lower in frequency. I think this is just the main dipole resonance, caused by the rear wave combining with the front wave.

StigErik said:

All EQ and XO is active, running digitally in my computer. To (try to) do this passively is - in my opinion - not a brilliant idea.

Cool. I plan to do the same. Which software and soundcard combo are you using for the task?

OK, we'll call it frequency response peak then....

My XO setup is quite simple on the software side - Console for running the XO and EQ plugins, Waves LinEQ for XO and Waves Paragraphic for EQ. I also use Voxengo SampleDelay for time alignment.

The hardware side is a bit more complicated. I use a laptop computer, because its small and low-noise. There are not many good alternatives for multichannel soundcards with laptops, at least if you want to avoid USB. I have an RME Fireface 800, which is a fabulous box. From there I go through an RME ADI-4 DD format converter to get AES3 interface (the Fireface has only ADAT). And then we end up in the DAC, which is a 8-channel DAD (Digital Audio Denmark) AX-24.

My XO setup is quite simple on the software side - Console for running the XO and EQ plugins, Waves LinEQ for XO and Waves Paragraphic for EQ. I also use Voxengo SampleDelay for time alignment.

The hardware side is a bit more complicated. I use a laptop computer, because its small and low-noise. There are not many good alternatives for multichannel soundcards with laptops, at least if you want to avoid USB. I have an RME Fireface 800, which is a fabulous box. From there I go through an RME ADI-4 DD format converter to get AES3 interface (the Fireface has only ADAT). And then we end up in the DAC, which is a 8-channel DAD (Digital Audio Denmark) AX-24.

Updates:

The baffle we build works great for the woofer and tweeter. The mid however, does not have a very good on-axis frequency response and the extension below 300 Hz could be better. We did have better measured performance on our previous prototype. The main difference was that we had "wings" for the midrange as well.

An other thing is that the baffle still vibrates too much, and its the lower midrange thats the problem now. We are going to try this:

1. Add "wings" around the midrange, this will stiffen the baffle.

2. Add damping - heavy bitumen (asphalt) damping sheets.

3. If this is not enough - mount the driver without contact with the baffle, like Linkwitz did in Orion+.

Regarding point 3.... Linkwitz mounted the midrange driver on a bracket attached to the magnet, with the driver not having direct contact with the baffle. This will still transfer vibrations through the bracket, although not directly to the baffle.

We would like to go a bit further. We are thinking of using foam seal around the driver, just like Orion+. The "new" idea is to suspend the drivers rear side with rubber bands or maybe steel springs to avoid any vibration transfer. Anyone tried something like this before?

The baffle we build works great for the woofer and tweeter. The mid however, does not have a very good on-axis frequency response and the extension below 300 Hz could be better. We did have better measured performance on our previous prototype. The main difference was that we had "wings" for the midrange as well.

An other thing is that the baffle still vibrates too much, and its the lower midrange thats the problem now. We are going to try this:

1. Add "wings" around the midrange, this will stiffen the baffle.

2. Add damping - heavy bitumen (asphalt) damping sheets.

3. If this is not enough - mount the driver without contact with the baffle, like Linkwitz did in Orion+.

Regarding point 3.... Linkwitz mounted the midrange driver on a bracket attached to the magnet, with the driver not having direct contact with the baffle. This will still transfer vibrations through the bracket, although not directly to the baffle.

We would like to go a bit further. We are thinking of using foam seal around the driver, just like Orion+. The "new" idea is to suspend the drivers rear side with rubber bands or maybe steel springs to avoid any vibration transfer. Anyone tried something like this before?

StigErik said:Updates:

The mid however, does not have a very good on-axis frequency response and the extension below 300 Hz could be better.

hI

Thats why I have concerns whether to buy 6" PHL or 8" PHL

Or maybe loose the midrange top and go for 10" PHL

Most of those PRO mids roll of in the midbass

Woofer will probably be Faital 18FH500 😀

....

We would like to go a bit further. We are thinking of using foam seal around the driver, just like Orion+. The "new" idea is to suspend the drivers rear side with rubber bands or maybe steel springs to avoid any vibration transfer. Anyone tried something like this before? [/B]

There is no "solution" to your problem IMO - but maybe some ideas from my page you may find inspiring:

http://members.aon.at/kinotechnik/diyaudio/diy_audio/CIC/Introducing_CIC.htm

Michael

We tried out one thing here. We attached small rubber pads to the driver frame (the rear side..), and held the driver in place by hand. Almost all vibration in the baffle disappeared, so its quite obvious that isolating the driver from the baffle has a dramatic effect.

We then fastened the driver loosely with two screws. The effect was gone, vibration was transfered through the screws.

Isolating the driver frame from the baffle is simple - just use rubber or foam seal. The problem is how to hold the driver in place without transfering too much energy.

The best solution would be to suspend the entire driver. How to do this is the challenge here, so any ideas are appreciated.

We then fastened the driver loosely with two screws. The effect was gone, vibration was transfered through the screws.

Isolating the driver frame from the baffle is simple - just use rubber or foam seal. The problem is how to hold the driver in place without transfering too much energy.

The best solution would be to suspend the entire driver. How to do this is the challenge here, so any ideas are appreciated.

StigErik said:

The best solution would be to suspend the entire driver. How to do this is the challenge here, so any ideas are appreciated.

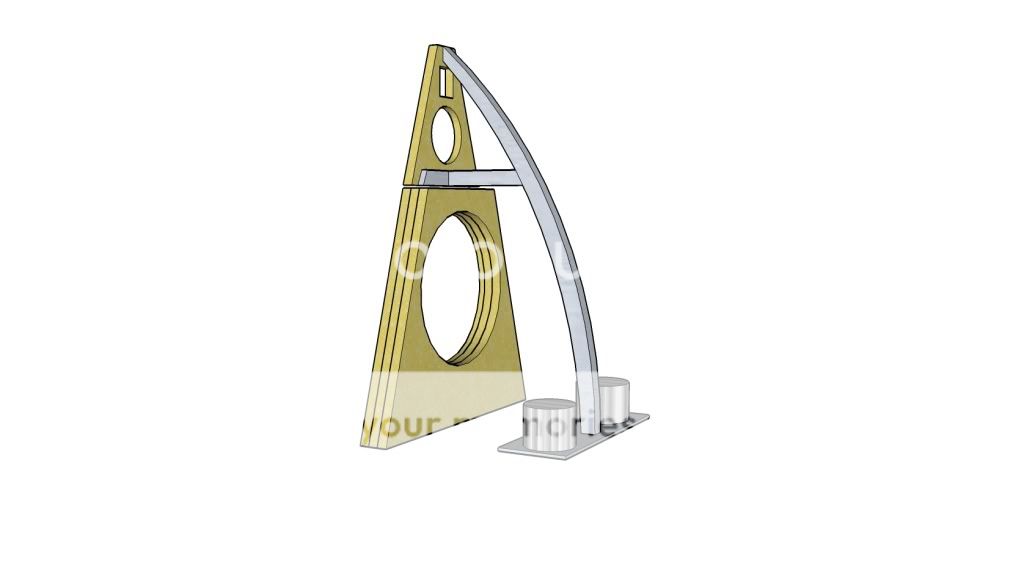

I would try to make two completely seperate cabinets. One for the 21" and one for the rest. Then make a cool steel stand for the mid/high box.

Naim, in some models, mount the mid and tweeter on separate sub-baffles, and then de-couple these from the box with radially arranged leaf springs. Low resonant freq of only a few Hz.

David

David

Lindells proposition looks very elegant. Before going to such expense, you could try to divide the main baffle along the red line (same as Lindell does) and mount it again with the green triangles. The joint between the H frame sides should be really vibration free.

If you feel any vibration at that point, it probably is due to the whole construction rocking back and forth. Did you recognise that you don't prop up the baffle against forward movement at all?

If you feel any vibration at that point, it probably is due to the whole construction rocking back and forth. Did you recognise that you don't prop up the baffle against forward movement at all?

Attachments

Lindell said:

I would try to make two completely seperate cabinets. One for the 21" and one for the rest. Then make a cool steel stand for the mid/high box.

That will not solve the problem, the midrange will still make the baffle vibrate.

The bass is not the problem here. I have strong vibrations in the upper part of the baffle even with the bass driver turned off.

StigErik said:

That will not solve the problem, the midrange will still make the baffle vibrate.

The bass is not the problem here. I have strong vibrations in the upper part of the baffle even with the bass driver turned off.

Not nearly comparable to the vibration of a woofer, esp a 21" one.

Maybe you can try with a second layer of wood/mdf?

Here's what I will try - just let the woofer H-frame wings continue all the way up. It should add some stiffness. Next is to add damping to the rear side of the baffle.

This will only *reduce* the problem, not remove it...

I've had success with the brute-force method in sealed boxes - a lot of bracing and a lot of sand for damping and mass. Sadly, thats not so easy to do here. The baffle is already two layers of 30 mm MDF.

An externally hosted image should be here but it was not working when we last tested it.

This will only *reduce* the problem, not remove it...

I've had success with the brute-force method in sealed boxes - a lot of bracing and a lot of sand for damping and mass. Sadly, thats not so easy to do here. The baffle is already two layers of 30 mm MDF.

Driver mouting ... I will try this:

(it should reduce the coupling between the driver frame and baffle)

(it should reduce the coupling between the driver frame and baffle)

An externally hosted image should be here but it was not working when we last tested it.

- Home

- Loudspeakers

- Multi-Way

- My open baffle dipole with Beyma TPL-150