The maximum diameter at the central wire for a 5-7mm diameter cable is AWG16 (1.3mm). 5m of cable will have a cumulative resistance (round + return) of about 0.13Ω, which for an 8Ω speaker is a lot. To the high resistance of the cable is added the enormous capacity, which leads to instability for the amplifier.Coaxial cable for speakers?!? One of the worst ideas ever.

I suggested a test a few days ago but was completely ignored. It seems that if I don't give audiophile suggestions, no one listens.

When I lay a PCB out I always do the output stage power transistor traces (V+, V-, output rail, 0V and decoupling) first. After that the feedback resistor and gain resistor plus HBR then after that, everything else.

@sesebe, it's not because I don't give feedback to your post that I didn't read it! It's just that I don't have these kind of ferrite core in stock for the moment.I suggested a test a few days ago but was completely ignored. It seems that if I don't give audiophile suggestions, no one listens.

I bet I am one of the guy here who read everything!

Well noted!When I lay a PCB out I always do the output stage power transistor traces (V+, V-, output rail, 0V and decoupling) first. After that the feedback resistor and gain resistor plus HBR then after that, everything else.

You should observe how much it is crowd.

Maybe some components could go to the PSU board, such as C603/C503 and R605/505 (which could be from a separate bridge anyway), and some earths could perhaps be merged, the DC servo takes some space too, but not sure there's any better place to put it, the +/- 15V could perhaps be off board too, but maybe they need to be super quiet..

.. of course theres a temptation to combine a PSU and amplifier board, I certainly would - but that makes it bigger, then it would have to perhaps be edge on to the heatsinks - lots of options !

Anyway, I'd have a listen to it for a few days, in my experience time always gives new ideas 🙂

Three - four turns made of a ferrite tor with the signal input cable solved much more serious problems than the ones you encountered here.@sesebe, it's not because I don't give feedback to your post that I didn't read it! It's just that I don't have these kind of ferrite core in stock for the moment.

I bet I am one of the guy here who read everything!

Well, I guess my design isn't as bad as it look's like after all. I don't say it cannot benefit more from what has been said but, I followed suggestions that I could already done without breaking anything.

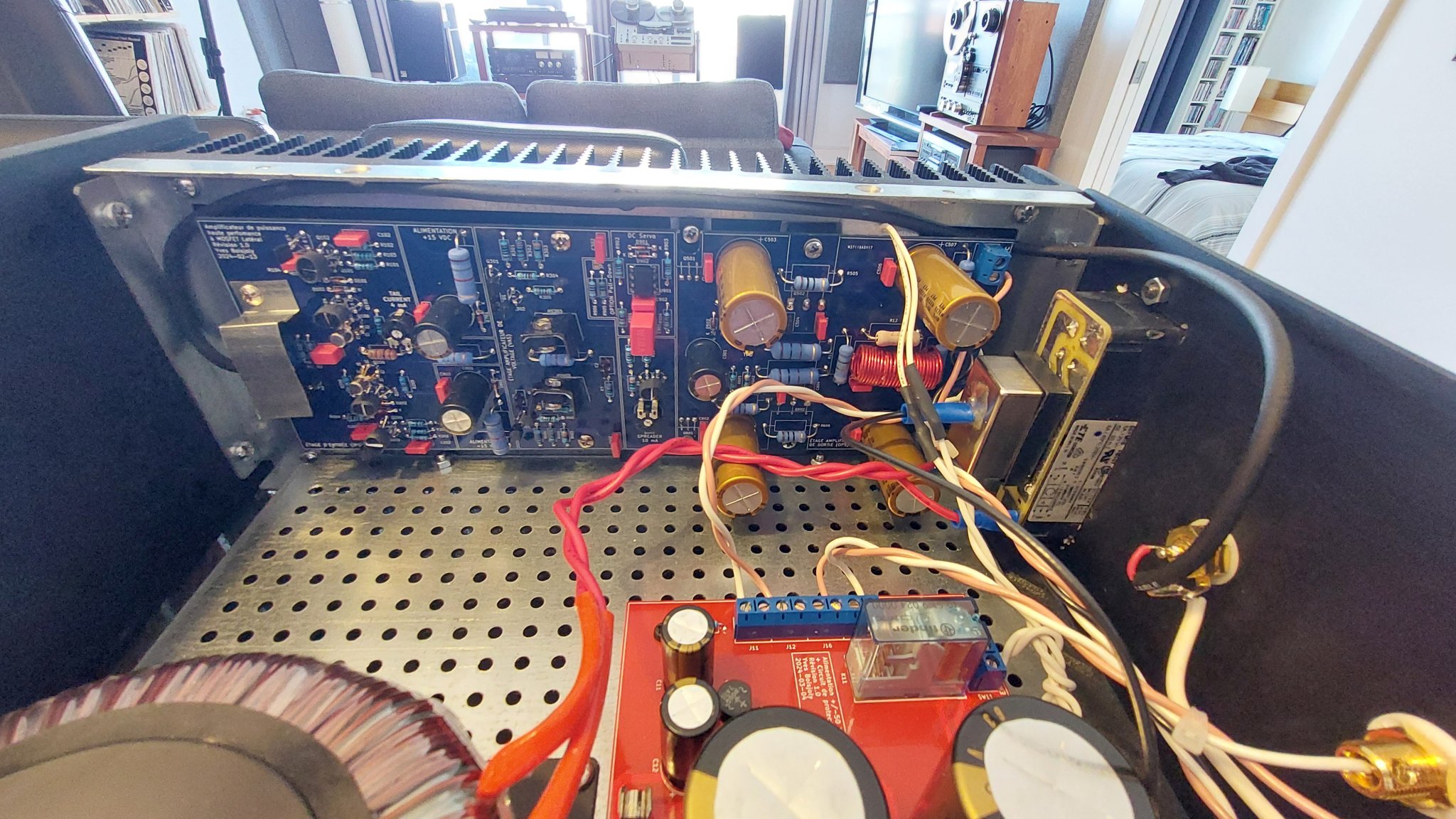

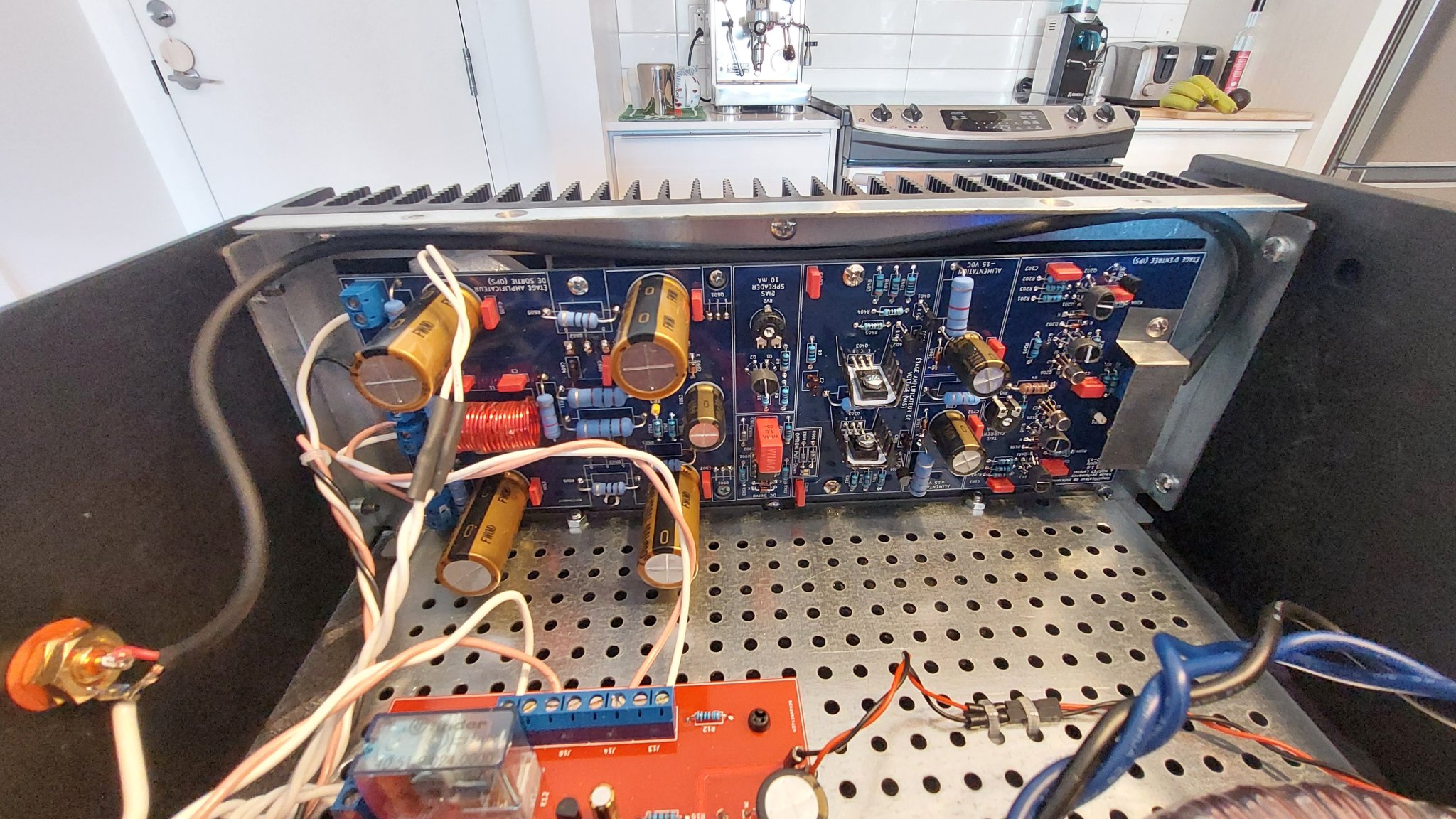

First I modified the path of the input cables as Bonsai suggested, above the top of the PCB module and without going trough the bottom plate, for both sides. I also cut the tie-wrap of the Primary cables to put them far from the bottom plate.

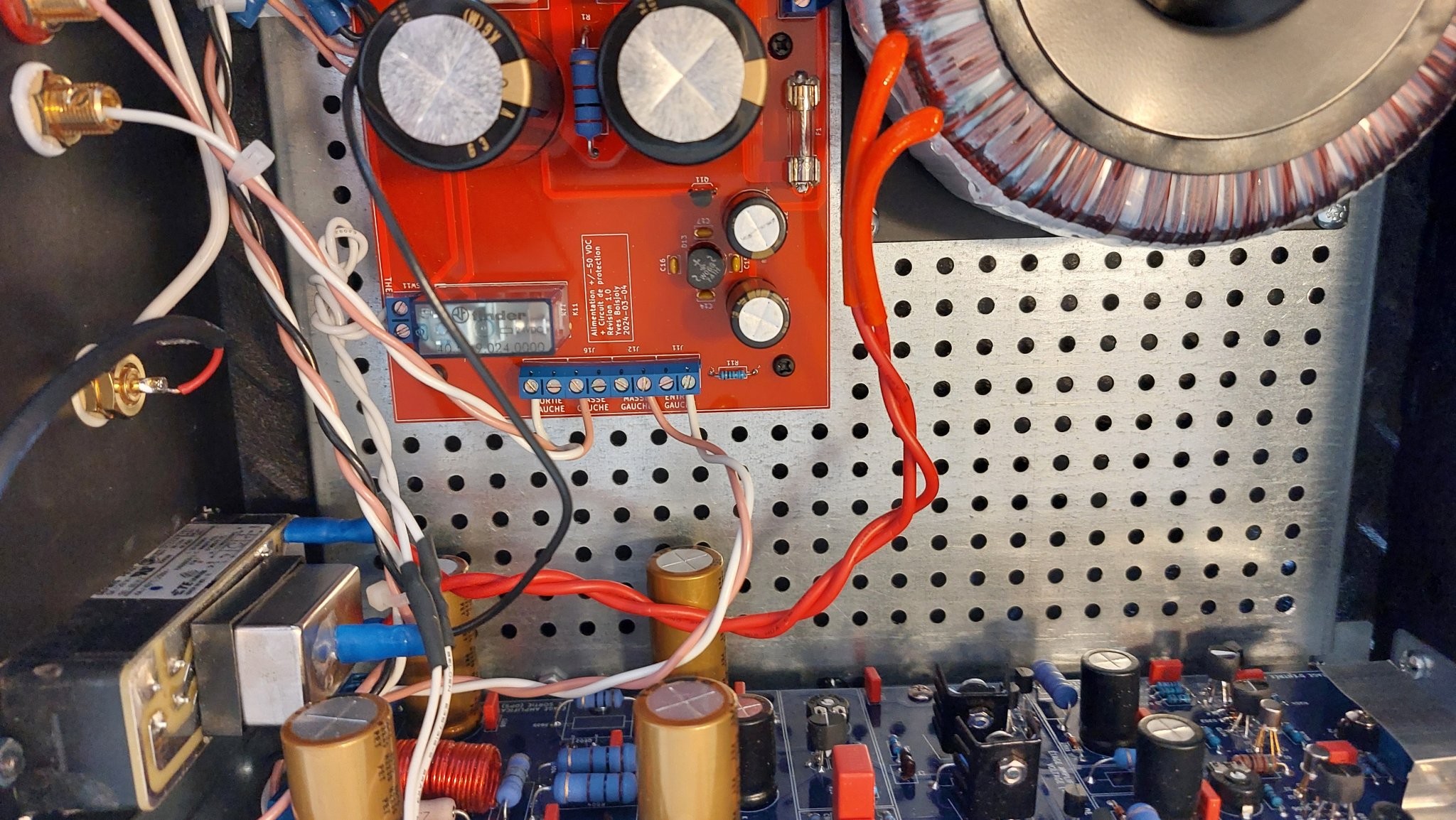

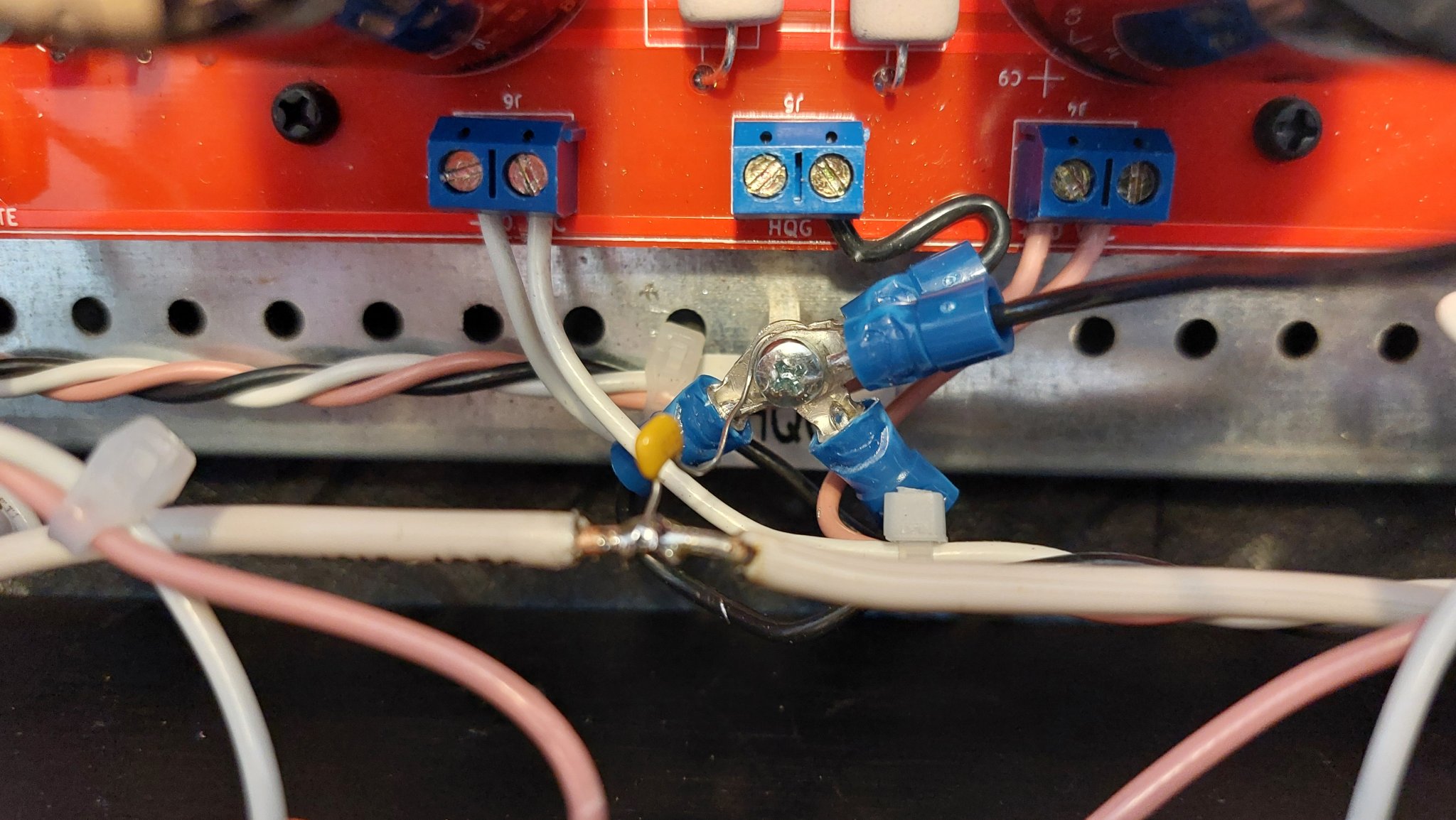

This as lower the noise at the headphone. Then I removed the lug from the Input RCA connector to HQG to remove the ground loop with the PCB module ground. With this last modification, there was no more difference with and without the RCA Looback! There was a pretty good noise before when I was connecting the RCA Loopback. I then add a 100nF Ceramic capacitor between the center of the white ground cable that join the two RCA Input ground connector together and the HQG lugs. Also I have turn again the transformer for lower noise.

Now are you all well sit?

Absolutely no noise in both channel with nothing connected.

Absolutely no noise in both channel with RCA Loop-back connected.

Absolutely no noise in left channel with the gears connected. Before this channel was the tiny noisy.

The most low noise I ever reach on the right channel compared to the all preceding tests with noise on the left one. It's like the noise moved from one channel to the other, but much lower!

That's no so bad after all!

First I modified the path of the input cables as Bonsai suggested, above the top of the PCB module and without going trough the bottom plate, for both sides. I also cut the tie-wrap of the Primary cables to put them far from the bottom plate.

This as lower the noise at the headphone. Then I removed the lug from the Input RCA connector to HQG to remove the ground loop with the PCB module ground. With this last modification, there was no more difference with and without the RCA Looback! There was a pretty good noise before when I was connecting the RCA Loopback. I then add a 100nF Ceramic capacitor between the center of the white ground cable that join the two RCA Input ground connector together and the HQG lugs. Also I have turn again the transformer for lower noise.

Now are you all well sit?

Absolutely no noise in both channel with nothing connected.

Absolutely no noise in both channel with RCA Loop-back connected.

Absolutely no noise in left channel with the gears connected. Before this channel was the tiny noisy.

The most low noise I ever reach on the right channel compared to the all preceding tests with noise on the left one. It's like the noise moved from one channel to the other, but much lower!

That's no so bad after all!

Is the 100nF cap joining the signal ground to the PSU/ chassis ground? I can't quite see exactly what the opposite end is attached to. Should the signal ground not be entirely isolated?(actually connected back at the pre amp)

As this is a Modushop chassis why not remove each side heatsink with the amp attached and swap them over?

The 100nF is connected between the Input RCA ground lugs via the white #14 gauge wire, and the screw of the bottom panel HQG ground. This bottom panel HQG is the star point of both Amplifier modules HQG (on each pcb) and the HQG of the Power Supply PCB.Is the 100nF cap joining the signal ground to the PSU/ chassis ground? I can't quite see exactly what the opposite end is attached to. Should the signal ground not be entirely isolated?(actually connected back at the pre amp)

Following comments saying that both RCA should be as close to each others as they can, and seeing that my back panel is already cut, I choose to solder this white wire to have their ground lugs electrically close connected as possible. Then the 100nF capacitor is in the middle of the white wire. I could have put two capacitors, one to each RCA ground lug, but their other side would have a long path to reach the HQG screw.

As this is a Modushop chassis why not remove each side heatsink with the amp attached and swap them over?

This was the original setup, but the Input connector of the right PCB was to close to the AC socket and was picking noise. Again, I am stuck with a back panel with all holes already cut that limit mechanical modifications setup.

In a future I have the solution to have a brand new back panel with better holes positions. But seeing that I have achieved a setup which I don't hear any noise with the gears connected, I don't see the benefit to modify it.

Instead, I decided to make a better upgrade and I am presently studying a new PCB layout based on Bonsai hands schematic of post #88.

Question... Where did you read something about coaxial cable for speaker in this threads? I can't find it.Coaxial cable for speakers?!? One of the worst ideas ever.

In your layout, you show a central ground track going to the input circuit. This is the correct way to do it, with the following caveats. This signal ground track must run under the feedback and gain setting resistors - again, to keep the loop arwea as small as possible. The gain setting resistor is returned to the signal ground trace through the HBR and the input signal; ground connects to the other side (ie not the signal ground trace side) of the HBR. Again, keep the input circuit loop areas as small as possible. Do not connect any other components to this signal ground trace. If you put your decoupling capacitor returns, you will cause excess noise.

This signal ground track must run under the feedback and gain setting resistors

By "under", do you mean that the trace should physically pass on the opposite side of the PCB or do you mean below the feedback and gain setting resistors?

The gain setting resistor is returned to the signal ground trace through the HBR and the input signal; ground connects to the other side (ie not the signal ground trace side) of the HBR.

This is not clear. I read it again and again and cannot picture it lol

My gain setting resistor is R4 and my feedback resistors are R5 and R6 below. Did I understood well connecting my HBR resistor, R14 as below?

Attachments

Question... Where did you read something about coaxial cable for speaker in this threads? I can't find it.

I can also interpret pictures, it doesn't have to be explicitly written somewhere.

"Speaker" is written there...I can also interpret pictures, it doesn't have to be explicitly written somewhere.

https://mogamicable.com/category/bulk/speaker_cable/pure_sound/

It doesn't matter what it says on it, it's still one of the worst ideas. 253pF/m

I really can't understand where all these crazy ideas come from and especially how the world accepts them. It's just audiophile nonsense.

I really can't understand where all these crazy ideas come from and especially how the world accepts them. It's just audiophile nonsense.

Any cables suggestions?it's still one of the worst ideas. 253pF/m

I use cables and wiring from a company called "Sommercable". Mostly used for RCA and XLR. To connect my Speakers i have used "thesssnake". A little bit cheaper. You can have a look https://www.thomann.de/de/lautsprecherkabel_meterware.html

Sommercable sells worldwide. I do not like Voodoo and the prices, importent to me is OFC.

Greets

Peter

Sommercable sells worldwide. I do not like Voodoo and the prices, importent to me is OFC.

Greets

Peter

- Home

- Amplifiers

- Solid State

- My DIY Amplifier has a small sizzling sound