If I did want an extra reflex port... I'm not sure what I'd do with it; it might require the cone to be longer/bigger, or to be pointed out the back, which aren't really very appealing options. TBH I'm just hoping not to go there.

I'm not sure the ports really need to be in an exact position.

On the MF driver baffle side, 4 of.

You'd have to have a rear cab enclosure tuned to suit.

I found that out - volume matters.

Enclosure adds weight and size though.

My SH50 rear enclosures are almost as heavy as the horns and flares!

Esp suitably damped with bitumen sheeting.

Could be removeable for transportability though.

All said you might be just fine with taps and subs that run higher - horses for courses.

Really cool project.

Wow, you are doing exactly what I've not had the courage to do yet, a SM-60 coax style.experiment with pro coax in the style of Danley patent fig 7 and renkuz-Heinz coentrant driver and it’s a really nice way to get the midrange taps close to the tweeter and potentially make it as compact as possible.

This is also really cool!

I will follow with excited anticipation.

Go for it, the 6” is cheap, they even provide a cad model on their site https://www.redcatt.net/cx6f-140f.html

https://redcatt.de/REDCATT-CX601X8

https://redcatt.de/REDCATT-CX601X8

Wow, that is a good price.Go for it, the 6” is cheap, they even provide a cad model on their site https://www.redcatt.net/cx6f-140f.html

https://redcatt.de/REDCATT-CX601X8

Thank you for your posts and ideas. I'd run across suggestions and examples of different types of coentrant and coaxial drivers (as well as the more common coaxial ring compression drivers), but your work is particularly impressive; very neat indeed.Not going in to details here...

It is wonderful what can be done with 3d printing, combined with clever design, these days. I'm still clinging to the idea of making my horn/waveguide without printing (I'm intending to only make two, and then stop). But I do wonder how long it will be before I weaken and save up for a printer.

I also think the cardioid approach is quite interesting for directivity control, and I like your design. I would probably need something bigger than your example but it would indeed still be much smaller than a <500hz horn. In my case though I can simply use sufficiently large horns, so on balance I happen to prefer this route; they just need a little inventiveness, to allow them to pack down smaller for occasional storage and transport etc.

A printer is such a nice addition in the arsenal of tools. I only wish I had a bigger printer..

More inspiration for leaking midrange.

https://www.instagram.com/s/aGlnaGx...3099086584270671090&igsh=MW42MzlnaDkzOW56bA==

More inspiration for leaking midrange.

https://www.instagram.com/s/aGlnaGx...3099086584270671090&igsh=MW42MzlnaDkzOW56bA==

Attachments

That does seem to be a common theme. Almost everyone who has a 3d printer (wrt horns) would like a bigger one. Maybe one day I'll get or make one.

On a different note, another common theme with MEHs is that many DIYers who make one seem to later try different/improved versions. Sometimes multiple times. So, in spite of my initial ideas, which are getting quite narrow, I'm starting to think that my best route would be to buy drivers that are known to work in many/most MEH designs. I'm not rich enough to simply cast them out if/when I try a different mkII.

On a different note, another common theme with MEHs is that many DIYers who make one seem to later try different/improved versions. Sometimes multiple times. So, in spite of my initial ideas, which are getting quite narrow, I'm starting to think that my best route would be to buy drivers that are known to work in many/most MEH designs. I'm not rich enough to simply cast them out if/when I try a different mkII.

So, in spite of my initial ideas, which are getting quite narrow, I'm starting to think that my best route would be to buy drivers that are known to work in many/most MEH designs. I'm not rich enough to simply cast them out if/when I try a different mkII.

In the above picture, I can make out the B&C label, and they appear to be the 4DNF34 from the rear magnetic structure. I use these, Mark100 and Weltersys use these as well.

In my multiple entry horn use case, a modified 18 Sound XT1464, they cross to a 3" diaphragm compression driver at just under 1khz. If the 4NDF34 is a bit expensive for your budget, the Celestion closed back 4" and 5" midrange drivers have been used before as well.

Yes, the 4NDF drivers seem a pretty safe bet. Taller than e.g. the faital 3" but in the scheme of things, perhaps not massively so.

I might also consider stepping up to 10" for the bass drivers, there seems more choice with suitable perameters, and more common usage (in MEHs) than 8". 8" is only midrange territory for some people - e.g. if using with a big direct radiator for bass. 10" is only a small increase, whereas 12" starts to become more significant; width-wise as well as in depth.

I might also consider stepping up to 10" for the bass drivers, there seems more choice with suitable perameters, and more common usage (in MEHs) than 8". 8" is only midrange territory for some people - e.g. if using with a big direct radiator for bass. 10" is only a small increase, whereas 12" starts to become more significant; width-wise as well as in depth.

Yeah I have to confess that it’s not my first time dabbling with MEH’s. My first was a classic approach with BMS 4550, 3fe25 and four sica 6”.On a different note, another common theme with MEHs is that many DIYers who make one seem to later try different/improved versions. Sometimes multiple times. So, in spite of my initial ideas, which are getting quite narrow, I'm starting to think that my best route would be to buy drivers that are known to work in many/most MEH designs. I'm not rich enough to simply cast them out if/when I try a different mkII.

But they are not allowed in the house..

And the journey, experiments and fiddling is my goal rather than a finished product.

I want to thank you again for this, Mark. It also sent me looking back at some of your previous versions, to see why you reached these particular choices. The syn7 version also has a lot of interest, even to the extent of having removable flares. I see the use of foam flares didn't work out so well, which is valuable information, as the concept is something I'm quite keen on attempting so I'll need to look at different materials.I share your objective of as large a horn as reasonably works. And portability has also been one of my main priorities.

The best compromise I've come up with is the build i call syn-10. https://www.diyaudio.com/community/threads/syn-10.383607/

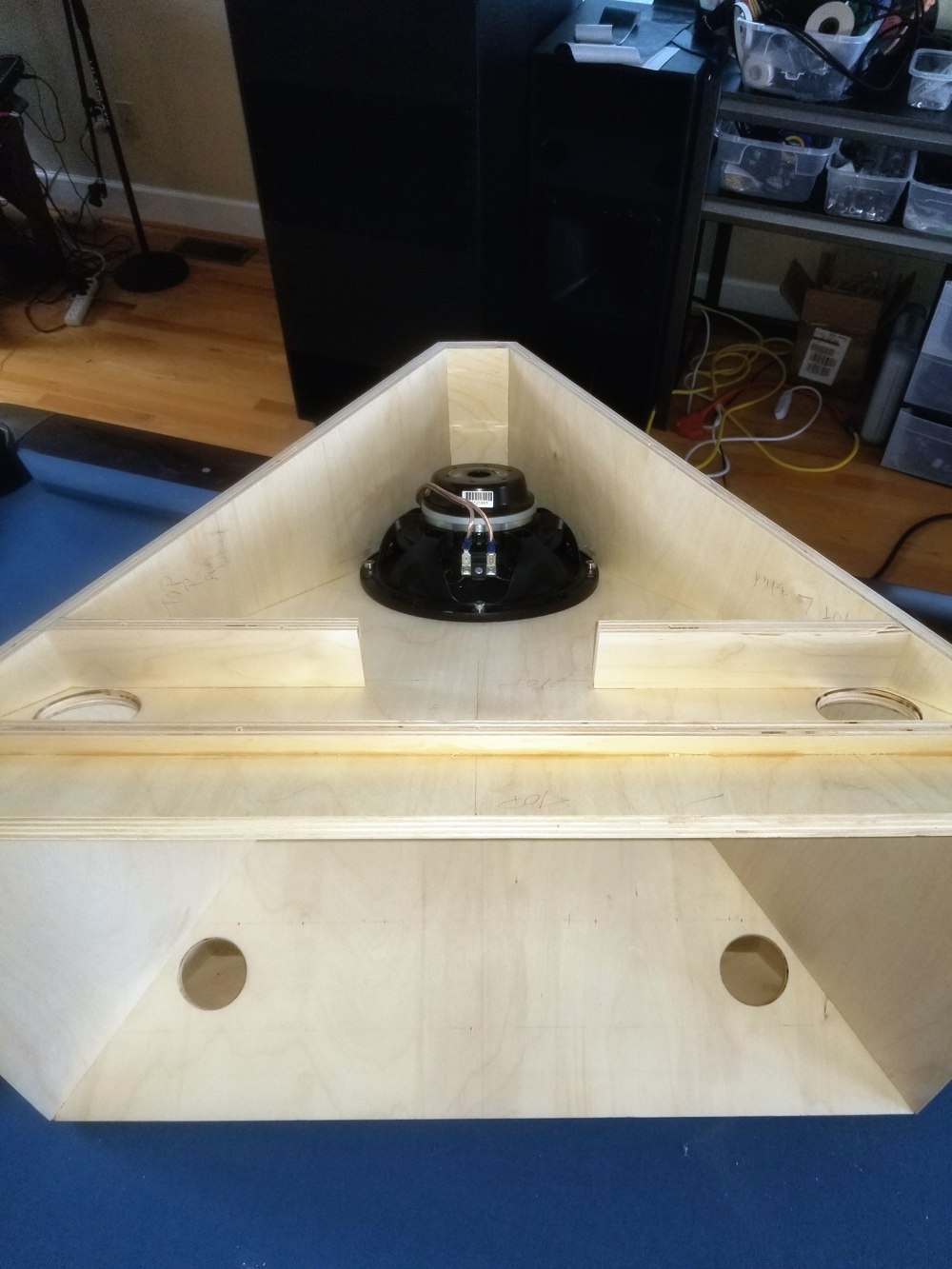

It's a 90x60, 36" wide x 22" tall x 22" deep. Uses two 12"s, four 4"s, and a coax CD.

And weighs only 51 lbs. Part of the catch with weight though, is the horn has no back....the CD and mid drivers are exposed off the back of the horn.

It has a handle on the top, and I can get it thru doors, up/down stairs, etc easily enough. That said, it is a bit awkward just because it's a big triangle/pyramid, but if this 71 yr old can move it around, can't be too bad 🙂

If I had to move it to a difficult location, the CD comes off with 2 screws, which knocks 6+ lbs and 4" of depth off the tab.

When it come to the smallest, lightest, version I've built that i think worked....it was another 90x60 31" wide x 19" high.

It used two 10"s.

I really don't think that getting below 30" wide is going to allow anything other than small lows, and like you said, doesn't get to 500Hz pattern control.

I've also built versions that had 36" wide primaries, and detachable flares that expanded them to 48-49" wide.

Detachables work, but are a PIA to make, imo. Art Welter might have them best solution there.

I've had trouble with resonances at cranking SPL.....bass energy from subs want's to turn the flares into energy grabbers i think.

Anyway, just some random thoughts/experiences...hope they help...

I'd already thought about putting the midbass woofers towards the back of the horn on top and bottom faces, so I'm very encouraged to see that you achieved this with such a small sealed rear chamber, and from what I can see not much of a front chamber either.

The central tap/port is also something of a revelation, too. It flies in the face of theories that I've read but your results make me quite relaxed about doing it, at least for the bass ports which aren't very close to the compression driver.

Other things too, like the open backed midranges on syn10; it seems like a few of the 'rules' are more fexible than one might imagine. I have concluded that I do want a 3-way with small mids, after what you, Art and a few others have said but your example shows that they needn't add much size or weight to the design. I might get some of the B&Cs since they're so well regarded, though I've already got some faitalpro 4FE35s whose parameters also seem not to need tiny enclosures. (EDIT: the coaxial that Nissep mentioned is still an option, but perhaps harder to implement without a printer, and I already have compression drivers that I would like to use).

All very useful stuff; thanks hugely for sharing your progress down this route - the things that did and didn't work are extremely valuable to read about.

Kev

Last edited:

I can second the weight difference of no back / driver chamber.

It roughly doubles the weight of my SH50s!

They go from being tiny without the mouth flare to pretty big with..

Then add the backs and they are heavy!

How to get that lovely reflex bass without though?

Make the back easily removeable? But the multiple bolting up provides resonance control as well as fixing.

Be interesting to see what you come up with.

It roughly doubles the weight of my SH50s!

They go from being tiny without the mouth flare to pretty big with..

Then add the backs and they are heavy!

How to get that lovely reflex bass without though?

Make the back easily removeable? But the multiple bolting up provides resonance control as well as fixing.

Be interesting to see what you come up with.

Yes, doubling up the whole cone for an enclosure would seem to add a lot of material (especially if done strongly to avoid hearing it vibrate etc). If I understand correctly Mark just has chambers on two of the sides for the 10" woofers (I may not, have been reading many threads and sometimes get them confused!). IIRC they're sealed rather than reflex, and perhaps that (along with DSP) is one reason they can be smaller. If for some reason I did need a chamber for the midranges then probably cups or a small box just around those would suffice; I'd need something to protect them when moving them about, in any case.

In fact, that rear chamber size for the woofers is likely to prove a key issue for me. I've found various ways to make the main part of the MEH only slightly bigger than the bass woofers themselves. But it seems likely that I'll need to make the thing bigger in order to give them a reasonable rear chamber size, unless I want to use masses of power and EQ. I don't think I could go open baffle with those, partly for reasons of wanting 80hz from a small speaker and partly because I want them to be as unaffected by different rooms and positions as possible.

Either my new SSD was DOA or the laptop is broken, so I've still not started trying to learn hornsrep. It'll just be a matter of time, though.

Either my new SSD was DOA or the laptop is broken, so I've still not started trying to learn hornsrep. It'll just be a matter of time, though.

Hi Kev, thanks for the kind words...and very glad my builds have helped give ideas.

For a bass-reflex idea you might want to look at what I called syn8. It's the only reflex i tried (other than the huge syn11 with 18"s that was a clear reflex failure.) Syn8 reflex worked...got the 8" down to 80Hz. https://www.diyaudio.com/community/threads/a-somewhat-easier-to-build-synergy.362087/

It ended up with removable wood flares...straight ones, not curved. As I recall, initially i liked it's 75x50 pattern over previous 90x60, but ended up going back to 90x60. No real answer there...

Oh, and ime, 4fe35's work fine as small mids. They are a bit of a pain to mount, but other than that all good.

Oh, and ime 4fe35's

For a bass-reflex idea you might want to look at what I called syn8. It's the only reflex i tried (other than the huge syn11 with 18"s that was a clear reflex failure.) Syn8 reflex worked...got the 8" down to 80Hz. https://www.diyaudio.com/community/threads/a-somewhat-easier-to-build-synergy.362087/

It ended up with removable wood flares...straight ones, not curved. As I recall, initially i liked it's 75x50 pattern over previous 90x60, but ended up going back to 90x60. No real answer there...

Oh, and ime, 4fe35's work fine as small mids. They are a bit of a pain to mount, but other than that all good.

Oh, and ime 4fe35's

Yow. If that data sheet is accurate, that looks like just the thing for a small synergyish horn. Kinda wish I was still building such things.Go for it, the 6” is cheap, they even provide a cad model on their site https://www.redcatt.net/cx6f-140f.html

https://redcatt.de/REDCATT-CX601X8

https://hifi-selbstbau.de/index.php/hsb-datenblaetter/koaxialchassis/redcatt-cx6f140fx8

Unfortunately redcatt’s data sheets are a little off.

And the model isn’t as accurate as I hoped.

A perfect fitting back chamber in the virtual world vs printed on the driver.

But it’s still a nice one.

Unfortunately redcatt’s data sheets are a little off.

And the model isn’t as accurate as I hoped.

A perfect fitting back chamber in the virtual world vs printed on the driver.

But it’s still a nice one.

Attachments

That is indeed unfortunate. I suppose they don't specify a tolerance on their dimensions, but that amount of difference looks more like a mistake (or unpublished design change) than a reasonable deviation. I agree that it remains a very interesting driver, though; especially for compact designs.

For the current build, I will probably use a more conventional combo of compression driver and separate midranges. I already have some high quality compression drivers that I really like, and they would also be smaller at the pointy end of the horn (for cases where the speaker might be fitted into a corner). But I thank you for posting about these redcatt drivers, as I can already think of a few other projects where they would be quite useful, and I hope that your own experiments with them bring a fruitful outcome.

Kev

For the current build, I will probably use a more conventional combo of compression driver and separate midranges. I already have some high quality compression drivers that I really like, and they would also be smaller at the pointy end of the horn (for cases where the speaker might be fitted into a corner). But I thank you for posting about these redcatt drivers, as I can already think of a few other projects where they would be quite useful, and I hope that your own experiments with them bring a fruitful outcome.

Kev

For the current build, I will probably use a more conventional combo of compression driver and separate midranges. I already have some high quality compression drivers that I really like

That's about where I am on the SM60F build I'm considering / working on.

Too many difficulties (for me) getting a coaxial cone 5" mid sound into the horn.

Too risky buying 2 more drivers $$$, I don't know the sound of.

Esp B&C dcx464 price.

I love the sound of the compression driver I use and the 2 X Celestion 5" mids work so well, they just do what they should and sound great.

This is enough for me to go with the same compression driver and 2 smaller mids and then the 8" LFs.

It will fits nicely too.

Sounds good. I'm slowly working my way through re-reading that enormous 'suitable midrange' thread, since (in spite of the narrow title) there is a great deal of information about many aspects of MEH design. It is clear that there are numerous valid ways to achieve a MEH 'provided' one can achieve suitable geometry for whichever approach is chosen. Personally I'm coming to favour the 3-way approach for my first attempt, even though a 2-way (or 3-way using a coax) might be made a bit smaller.

EDIT: I might go up a size or two for the bass woofers though; the midranges make this easy and bigger bass drivers might work better especially sealed 4th-order. Though I'm not too concerned about using 6th-order/reflex now, since further research has suggested the rear chamber port location isn't very critical after all; it doesn't play a part in the whole synergy equasion-juggling and could even be outside the horn. So my choice will likely depend more on what chamber sizes are required.

EDIT: I might go up a size or two for the bass woofers though; the midranges make this easy and bigger bass drivers might work better especially sealed 4th-order. Though I'm not too concerned about using 6th-order/reflex now, since further research has suggested the rear chamber port location isn't very critical after all; it doesn't play a part in the whole synergy equasion-juggling and could even be outside the horn. So my choice will likely depend more on what chamber sizes are required.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Multiple Entry Horn with removable mouth?