Hi Loren42, Nice. Magnificent in fact. Do you have a thread or website describing this project? What circuit is used?

Hi SGregory, the KT88 spec says to keep the tubes 4" apart on centers. But I can't say I've ever seen that occur in the real world. I dug up my B.V.A. book so I'll study this topic over the next few days. I'll also check your Opus thread to see what you've done for a layout. It's been quite a while (too long) since I've tuned into your thread (or any thread for that matter).

..Todd

Hi SGregory, the KT88 spec says to keep the tubes 4" apart on centers. But I can't say I've ever seen that occur in the real world. I dug up my B.V.A. book so I'll study this topic over the next few days. I'll also check your Opus thread to see what you've done for a layout. It's been quite a while (too long) since I've tuned into your thread (or any thread for that matter).

..Todd

Hi Loren42, Nice. Magnificent in fact. Do you have a thread or website describing this project? What circuit is used?

Hi SGregory, the KT88 spec says to keep the tubes 4" apart on centers. But I can't say I've ever seen that occur in the real world. I dug up my B.V.A. book so I'll study this topic over the next few days. I'll also check your Opus thread to see what you've done for a layout. It's been quite a while (too long) since I've tuned into your thread (or any thread for that matter).

..Todd

Thank you very much. This is a Williamson circuit. Grounding is a Star ground. I don't have a build web site for it.

The chassis is quite custom. I have a Bridgeport mill and a lathe in my garage that I use for my business, so I took full advantage of those resources.

I've read the same thing about the 4" center to center distance, but never seen anyone actually obey that. Mine are 3.25".

Pins 4 and 8 should be aligned as well. IIRC, MJ's book talks about the placement of the tube with respect to the corners of the transformers to minimize interaction.

In reality it is like everything else, it is a carefull compromise.

In reality it is like everything else, it is a carefull compromise.

Loren42

Any competent transformer company uses a minimum class (UL 130 class B) NEMA 155 C insulation system. Edcor is quite competent. That 130 C rating is for 300 k hours of expected MTBF. That is running at 90C in a 40C ambient. So, hot as boiling water on the hottest day you don't want to experience, for 300 k hours as it's average life time under those conditions. Even if you can only hold your hand on it for just long enough to hurt, you are still well beneath what the transformer can handle.

The current draw is less than their ratings, but they do get pretty warm. This has nothing to do with the layout, but is inherent with the transformers. Edcor states that they are operating within their limits.

Any competent transformer company uses a minimum class (UL 130 class B) NEMA 155 C insulation system. Edcor is quite competent. That 130 C rating is for 300 k hours of expected MTBF. That is running at 90C in a 40C ambient. So, hot as boiling water on the hottest day you don't want to experience, for 300 k hours as it's average life time under those conditions. Even if you can only hold your hand on it for just long enough to hurt, you are still well beneath what the transformer can handle.

Hi Taj!

It's been a while since I have checked in, and i'm happily surprised to see this thread active again. I got derailed with some other priorities, but they're now done, and I'm going to go ahead with this project. I have just found out that my previous fustration about how to do a professional looking job has been solved by Hammond! I'm going to order 3 of those lovely walnut amp chassis' from them tomorrow. (I'm getting an extra for a matching 12B4 preamp).

I'll be following your layout progress with much interest! Keeps me informes of your other part decisions. I have my Edcor, and Electraprints in hand, but have not purchased anyting else yet. Multible order are about to go out!

It's been a while since I have checked in, and i'm happily surprised to see this thread active again. I got derailed with some other priorities, but they're now done, and I'm going to go ahead with this project. I have just found out that my previous fustration about how to do a professional looking job has been solved by Hammond! I'm going to order 3 of those lovely walnut amp chassis' from them tomorrow. (I'm getting an extra for a matching 12B4 preamp).

I'll be following your layout progress with much interest! Keeps me informes of your other part decisions. I have my Edcor, and Electraprints in hand, but have not purchased anyting else yet. Multible order are about to go out!

Last edited:

Glad to see you back in the saddle again, TubeMack. Summer is short and sweet here so I've been spending as much time outdoors as possible, but I am starting to prepare for the upcoming 9 months of chilly clouds, rain and indoor activities. I will be ordering a pair of OPTs from BudP as soon as my wife isn't looking. ...probably soon if I'm planning to be living in the doghouse while the weather is still nice.

I got a real confusing collection of feedback here about the chassis layout though. I'm not sure how best to lay it out. I don't have enough experience to proceed without more direction from the more-capable-multitudes here.

I also noticed the new woodies from Hammond and I'll check their size for compatibility sake.

..Todd

I got a real confusing collection of feedback here about the chassis layout though. I'm not sure how best to lay it out. I don't have enough experience to proceed without more direction from the more-capable-multitudes here.

I also noticed the new woodies from Hammond and I'll check their size for compatibility sake.

..Todd

Taj: If you're worried about layout and hum, then breadboard everything on a piece of plywood first. I've found that the amps tend to have less hum once rebuilt into a real chassis from the breadboard. So if the breadboard is quiet, odds are good that the finished amp will be quiet. I wouldn't stress too much about the layout.

Use small coax for the signal wires and keep them away from the filament wiring and the PS wiring, and use a star grounding scheme. Use solid wire for the filaments and tuck them into the edges and corners of the chassis, allowing them to poke out to the tube sockets only where req'd. Refer to MJ BVA about how to properly wire the filament wires at the tubes sockets. My EL34 PP monoblocks have the centerlines of the power trans and the output trans offset by about 3/4" (bad practice but had no room) and it has no perceptible hum on my 90db speakers. The two projects that I to spend time chasing hum away on both had volume pots, but they are also hum-free on my speakers.

I would also not try to cram too much iron and components into a tiny chassis, as it becomes a real pain to troubleshoot/rework/modify. A little extra room under the hood doesn't hurt. Of course, if you really want a compact chassis, then getting everything dialed in on the breadboard first is desirable, then clean up and transplant into the final chassis.

This past weekend was spent helping a friend get a EL34 SE amp breadboarded; we used the chassis and iron from an old console. It's a two chassis layout with the PS on a separate chassis and the (twisted) filament wires sitting right next to the B+ wire in the umbilical between the chassis. The amp chassis is presently a rat's nest of wires, etc. and it is dead quiet in my main system.

After 800+ posts, somebody's gotta build one of these!

Use small coax for the signal wires and keep them away from the filament wiring and the PS wiring, and use a star grounding scheme. Use solid wire for the filaments and tuck them into the edges and corners of the chassis, allowing them to poke out to the tube sockets only where req'd. Refer to MJ BVA about how to properly wire the filament wires at the tubes sockets. My EL34 PP monoblocks have the centerlines of the power trans and the output trans offset by about 3/4" (bad practice but had no room) and it has no perceptible hum on my 90db speakers. The two projects that I to spend time chasing hum away on both had volume pots, but they are also hum-free on my speakers.

I would also not try to cram too much iron and components into a tiny chassis, as it becomes a real pain to troubleshoot/rework/modify. A little extra room under the hood doesn't hurt. Of course, if you really want a compact chassis, then getting everything dialed in on the breadboard first is desirable, then clean up and transplant into the final chassis.

This past weekend was spent helping a friend get a EL34 SE amp breadboarded; we used the chassis and iron from an old console. It's a two chassis layout with the PS on a separate chassis and the (twisted) filament wires sitting right next to the B+ wire in the umbilical between the chassis. The amp chassis is presently a rat's nest of wires, etc. and it is dead quiet in my main system.

After 800+ posts, somebody's gotta build one of these!

Last edited:

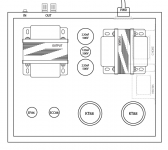

Okay, I read the appropriate section of BVA. Not sure I applied all of it, or even understood some of it, but here's my 3rd kick at the can. Any comments? It's 10 x 12".

..Todd

Your layout looks fine to me, although it may get a little busy under the deck, based on the dimensions. You could also flip the input tubes and the output tubes locations, but it's a trade. Right now you have the input jack far away from the PS (good) and it can run along the side of the chassis to the input tubes, but the wiring from the output tubes to the transformer will be diagonal across the center of the chassis.

Having the output tubes in front of the output transformers makes for short easy wiring, but then you'll have to re-think the input wiring a little. I'd probably go with the way that you have it drawn.

Another alternative is arranging the phase splitter and the output tubes in a triangular pattern, that can make for clean, short, symmetrical wiring of the coupling caps etc between the stages.

What are you planning on using for a choke? That also has to go somewhere. Do you need a volume control or are these strictly power amps?

Last edited:

What are you planning on using for a choke? That also has to go somewhere. Do you need a volume control or are these strictly power amps?

Hi boywonder,

I'm not planning to add volume controls to the amps.

The choke will fit underneath assuming a 3" chassis height. I did that because the choke is ugly.

I'm working on a paper wiring diagram. I don't have the iron to breadboard it, and won't be getting it for a while yet, so I'll do it on paper first. No rush. 🙂

..Todd

After 800+ posts, somebody's gotta build one of these!

I agree. I was just hoping it would be someone with more experience than I have first. But I will eventually get er done once I have all the parts accumulated. I'm looking forward to that day, but it's a few months away.

..Todd

I'm finding that it's harder to layout a monoblock, and have it be, symetrical, functional, and still look look "pretty". Especially since my Pow, and OP transformers vary greatly in size. A stereo amp just seems easier. I think i'll be doing some mock ups this weekend. I want to see if a 17"x10" chassis is going to look too bare?

Hi boywonder,

The choke will fit underneath assuming a 3" chassis height. I did that because the choke is ugly.

..Todd

For open frame chokes that have a sufficient current rating, there are only a couple readily available off-the-shelf. Back when the post count was still in the double digits Eli suggested the Triad C-17x (1.5H, 300 ma). The Hammond 159T (2.5H, 300 ma) is the other easy choice. To get more Henries than those (and less B+ ripple), you need a enclosed Hammond 193 series choke or equivalent. These need some real estate above the deck, and they cost more. For the Hammond 193 series, you can easily get 5H or 10H 300ma rated chokes.

The open-framed ones get a little large for this current rating, but is appears that they will fit a 3" tall case.

Keep in mind that more henries=less ripple=less hum. Also remember that you need to add the ripple current to the B+ current to get the current rating for the choke.

The Hammond 159T (2.5H, 300 ma) is the other easy choice. To get more Henries than those (and less B+ ripple), you need a enclosed Hammond 193 series choke or equivalent. These need some real estate above the deck, and they cost more. For the Hammond 193 series, you can easily get 5H or 10H 300ma rated chokes.

The open-framed ones get a little large for this current rating, but is appears that they will fit a 3" tall case.

I don't recall which choke is in my layout drawing, but it's the Hammond one from the BoM we made up earlier, and it fits in 3" tall space, but that height is a bit unsightly itself.

The bigger ones with end bells, mounted on top, might be a good idea to simplify layout and wiring underneath and increase visual wow factor (to tube geeks at least), at the expense of budget of course. The caps can go underneath instead. It's worth considering.

..Todd

I'm finding that it's harder to layout a monoblock, and have it be, symetrical, functional, and still look look "pretty". Especially since my Pow, and OP transformers vary greatly in size. A stereo amp just seems easier.

Yup, symmetry is easy when there's two of everything. When you consider two monoblocks as a whole, in the same room, the symmetry returns, you just have to stand back further to appreciate it. 😉

..Todd

Last edited:

Small hint regarding chokes:

Remember that somewhere there is an air-gap, in the proximity of which there can be quite strong magnetic fields. Careful with these close to an input stage, even in power amplifiers. Should a choke-input filter be used (I don't think that is the case here), it is almost impossible to fit such a choke on a small chassis without some magnetic influence, even with the usual stray field precautions. A pity.

Remember that somewhere there is an air-gap, in the proximity of which there can be quite strong magnetic fields. Careful with these close to an input stage, even in power amplifiers. Should a choke-input filter be used (I don't think that is the case here), it is almost impossible to fit such a choke on a small chassis without some magnetic influence, even with the usual stray field precautions. A pity.

If you position the power transformer with one side of the coil fitted into a rectangular hole in the chassis and mount an output transformer on endbells with feet, with the long side of the core touching the chassis but oriented as the cross bar in a capitol T, you can mount a choke between these two objects and most stray flux from the gap will be attracted to the core of both. This will not cause noise and can be quite useful. The choke should also be mounted like the OPT, with reference to the power transformer. Obviously, two OPT's can be mounted to form a capital H configuration.

Just wondering...what happened to this project. Did any of the respondents actually build the "Soloist 88"? I thought this might be good as my next project.

I'm still collecting parts as the budget allows. I'm saving up for higher-end output transformers, and I'm not in any particular hurry. My man-cave is almost finished, and when it finally is, I'll be raising the priority of this project. My Gold Lion KT88s are starting to complain about the cold.

Go ahead and be first! But you'll need to do some finalizing and tweaking and possibly debugging since it's not proven yet.

Neon, where are you located? Vancouver, Victoria ... Spuzzum ... ??

..Todd

Go ahead and be first! But you'll need to do some finalizing and tweaking and possibly debugging since it's not proven yet.

Neon, where are you located? Vancouver, Victoria ... Spuzzum ... ??

..Todd

Last edited:

I'm saving up for higher-end output transformers, and I'm not in any particular hurry.

..Todd

I've been sitting on a pair of Hashimoto 60W 5K PP transformers and I'll either build Sgregory's Opus (which is an evolution of this thread incorporating MOSFET followers), or Triode Dick's Mono Bill II.

I'm finally finishing my Tubelab SE which has also been on the shelf for quite a while..............then one of the above, and perhaps the 6V6 version of Poindexter's Music Machine, and I almost forgot, I've got a half built pair of Half Changs waiting in the garage........good thing winter is coming.

- Home

- Amplifiers

- Tubes / Valves

- Mullard 5-20 KT88 PP blocks!