Can we use this thread to post information about how to mount DHT tubes horizontally?

A lot of them have orientation restrictions. I've been doing a search and found this so far.

"Directly Heated Rectifiers

The type 80 rectifier, vertical is preferred, but if mounted horizontally, pins 1 and 4 must be either at the top or at the bottom. 5Y3 vertical is preferred, but if mounted horizontally, pins 2 and 8 must be in a horizontal plane. Most modern data sheets do not list the orientation restrictions. Franks tube data pages have lots of old data sheets, mixed in with the new data sheets."

I don't know if this applies to other directly heated rectifiers.

I particularly want to know about 2P29L, if anyone has experience or details. But other common DHTs too like 2a3, 6B4G, 300b, 10Y, 26, 4P1L etc.

A lot of them have orientation restrictions. I've been doing a search and found this so far.

"Directly Heated Rectifiers

The type 80 rectifier, vertical is preferred, but if mounted horizontally, pins 1 and 4 must be either at the top or at the bottom. 5Y3 vertical is preferred, but if mounted horizontally, pins 2 and 8 must be in a horizontal plane. Most modern data sheets do not list the orientation restrictions. Franks tube data pages have lots of old data sheets, mixed in with the new data sheets."

I don't know if this applies to other directly heated rectifiers.

I particularly want to know about 2P29L, if anyone has experience or details. But other common DHTs too like 2a3, 6B4G, 300b, 10Y, 26, 4P1L etc.

Western Electric 300B Datasheet lists the required correct rotation for Horizontal Tube operation.

That way, the beginning and end of the filament is Vertically aligned.

(Pins 1 and 2 must be in a Vertical plane).

Other manufacturers 300B may, or may not, be rotationally constructed the same.

So, just line them up with the beginning and ending of the filaments in a north (high), and south (low) Vertical filament orientation.

This works for most similar mono-plate DHTs.

The principal of what to avoid is:

If a Horizontally mounted tube is rotated with the filament ends in an east - west orientation, that is wrong. The horizonatlly aligned filament can sag, and touch the grid that is 'below' it, or in the case of a Directly Heated Rectifier, an incorrect rotation can make the filament sag and touch the plate.

The below WE 300B link has a statement about the correct rotation, and also has a lot of additional helpful information too.

Link:

https://frank.pocnet.net/sheets/084/3/300B.pdf

Enjoy your DHTs

That way, the beginning and end of the filament is Vertically aligned.

(Pins 1 and 2 must be in a Vertical plane).

Other manufacturers 300B may, or may not, be rotationally constructed the same.

So, just line them up with the beginning and ending of the filaments in a north (high), and south (low) Vertical filament orientation.

This works for most similar mono-plate DHTs.

The principal of what to avoid is:

If a Horizontally mounted tube is rotated with the filament ends in an east - west orientation, that is wrong. The horizonatlly aligned filament can sag, and touch the grid that is 'below' it, or in the case of a Directly Heated Rectifier, an incorrect rotation can make the filament sag and touch the plate.

The below WE 300B link has a statement about the correct rotation, and also has a lot of additional helpful information too.

Link:

https://frank.pocnet.net/sheets/084/3/300B.pdf

Enjoy your DHTs

Last edited:

Before filament touching the grid the tube would probably not meet its characteristics.The horizontally aligned filament can sag, and touch the grid that is 'below' it, or in the case of a Directly Heated Rectifier, an incorrect rotation can make the filament sag and touch the plate.

An example of properly vertically mounted 300B tubes, that went wrong.

Horizontal mounting could have made it even worse, and caused more failed tubes.

Years ago, a number of us in a local vacuum tube club, had some really great performing 300B tubes from one manufacturer.

But a rather large number of those 300B tubes could not work with DC filaments.

The filament and grid would short.

Apparently, the filament and grid structure were spaced nearer to one side of the plate versus the other side of the plate.

DC on a filament wire Attracts the wire to a steel plate, more force to the closest side of the plate, and less force to the farer side of the plate. Therefore, the sum of the attractive forces is toward one side of the plate. The bad spacing does not have to be real bad, the force is proportional to 1/distance squared.

If there is a 10% spacing error, 1.1 squared = 1.21; 0.9 squared = 0.81. The effective direction of the force is 1.21 / 0.81 = 1.49.

As the hot filament was attracted to one side of the plate, it moved to the grid and shorted to the grid.

But proper spacing cancels those forces, resulting in 0 movement.

Horizontal mounting could have made it even worse, and caused more failed tubes.

Years ago, a number of us in a local vacuum tube club, had some really great performing 300B tubes from one manufacturer.

But a rather large number of those 300B tubes could not work with DC filaments.

The filament and grid would short.

Apparently, the filament and grid structure were spaced nearer to one side of the plate versus the other side of the plate.

DC on a filament wire Attracts the wire to a steel plate, more force to the closest side of the plate, and less force to the farer side of the plate. Therefore, the sum of the attractive forces is toward one side of the plate. The bad spacing does not have to be real bad, the force is proportional to 1/distance squared.

If there is a 10% spacing error, 1.1 squared = 1.21; 0.9 squared = 0.81. The effective direction of the force is 1.21 / 0.81 = 1.49.

As the hot filament was attracted to one side of the plate, it moved to the grid and shorted to the grid.

But proper spacing cancels those forces, resulting in 0 movement.

I'm very interested to hear about this. I've already gone through the design and build of this horizontal mounting assembly for my planned 4P1L preamp.

When evaluating the socket and position of the pins from what I can tell 4P1L filament pins 1 and 7 will be relatively vertical in orientation. So heating occurring from the side. My logic was also based on an understanding these were robust military tubes designed for radio and other circuits which would have been portable or at least seen more precarious mounting than would say a bigger DHT power tube like the 300B.

I need to get some design feedback for a B+ supply but hopefully this project will come together more over the next few months then we will know for sure.

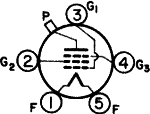

307A datasheet specific the way to mount horizontally the tubes, if mounted in a horizontal position the plane of the filament, wich is indicated in fig. 2 should be vertical, wich one of the photo the left side or the right side?

Attachments

Not necessarily so dramatic, but loctal Russian tubes were all designed for use in portable military radio stations.Any vacuum tube that is used on a Russian Mig fighter can probably be mounted in any position.

Think about it . . . upside down, slicing through the air with the right wing pointing to the earth, etc.

Not a success story as we learned from recent happenings..Not necessarily so dramatic, but loctal Russian tubes were all designed for use in portable military radio stations.

- Home

- Amplifiers

- Tubes / Valves

- Mounting DHT tubes horizontal