That's a great looking build! I'm glad it's finally come together for you. Congratulations on a build well done.

Tom

Tom

My No. 1 advice on the Dissipante is to ensure that you understand which is the front and rear of the bottom panel before tapping & drilling (not an issue if you use the tray however). I asked modushop to put labels on, but they still don't. Do a dry fit first to ensure you have correct orientation.

Other things I consider mandatory on the build: Boot lace ferrules. I picked this up from Tom's video. I'll never use bare wire again, you get a much more secure connection using crimps. There are 'HiFi' versions of crimps as well in pure copper, that aren't that expensive to use in the signal path.

Would be nice if Tom included some retainers within his wiring kit as well (just increase the price a smidge)

Another tip is that Tom puts polarity dots on the PCBs, to help with transformer wiring - no mention of this in the instructions (perhaps to others it's obvious) but it's really useful.

Other things I consider mandatory on the build: Boot lace ferrules. I picked this up from Tom's video. I'll never use bare wire again, you get a much more secure connection using crimps. There are 'HiFi' versions of crimps as well in pure copper, that aren't that expensive to use in the signal path.

Would be nice if Tom included some retainers within his wiring kit as well (just increase the price a smidge)

Another tip is that Tom puts polarity dots on the PCBs, to help with transformer wiring - no mention of this in the instructions (perhaps to others it's obvious) but it's really useful.

+1 on the Dissipante panels. They definitely have a front and back orientation. The first time I used it, I had to extend the holes and use a larger screw head to cover my mistake.My No. 1 advice on the Dissipante is to ensure that you understand which is the front and rear of the bottom panel before tapping & drilling (not an issue if you use the tray however). I asked modushop to put labels on, but they still don't. Do a dry fit first to ensure you have correct orientation.

Other things I consider mandatory on the build: Boot lace ferrules. I picked this up from Tom's video. I'll never use bare wire again, you get a much more secure connection using crimps. There are 'HiFi' versions of crimps as well in pure copper, that aren't that expensive to use in the signal path.

And +1 on the ferrules! I stopped using bare wire connections long ago, as it was too easy for a stray strand of wire to short something.

+1My No. 1 advice on the Dissipante is to ensure that you understand which is the front and rear of the bottom panel before tapping & drilling (not an issue if you use the tray however).

That's thrown ModuShop off also. For my first Modulus-686 Safe-n-Sane build they drilled the panels rotated 180º. They immediately fixed it and overnighted replacements, but still... That was an expensive mistake. The mounting holes are off-centre by the thickness of the rear panel if I recall correctly.

Retainers? The li'l plastic deals that jam into the connectors and hold the wires centred? They're usually out of stock (and were even before the world melted down) but I can certainly place a backorder as long as I meet the minimum order quantity.Would be nice if Tom included some retainers within his wiring kit as well (just increase the price a smidge)

Tom

Retainers? The li'l plastic deals that jam into the connectors and hold the wires centred? They're usually out of stock (and were even before the world melted down) but I can certainly place a backorder as long as I meet the minimum order quantity.

Yep, buy a decent quantity of them and sell them on with your wiring - people will appreciate it

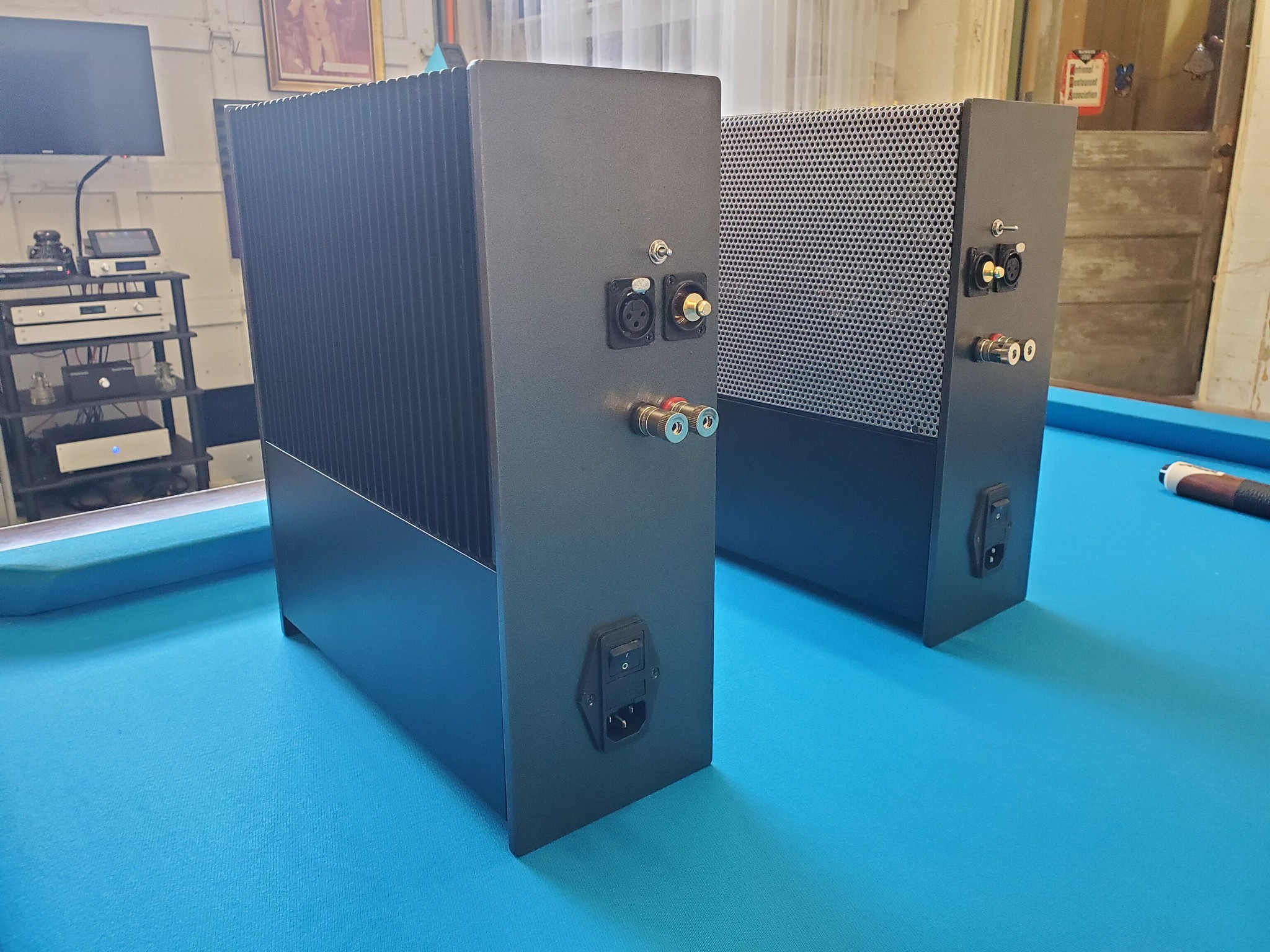

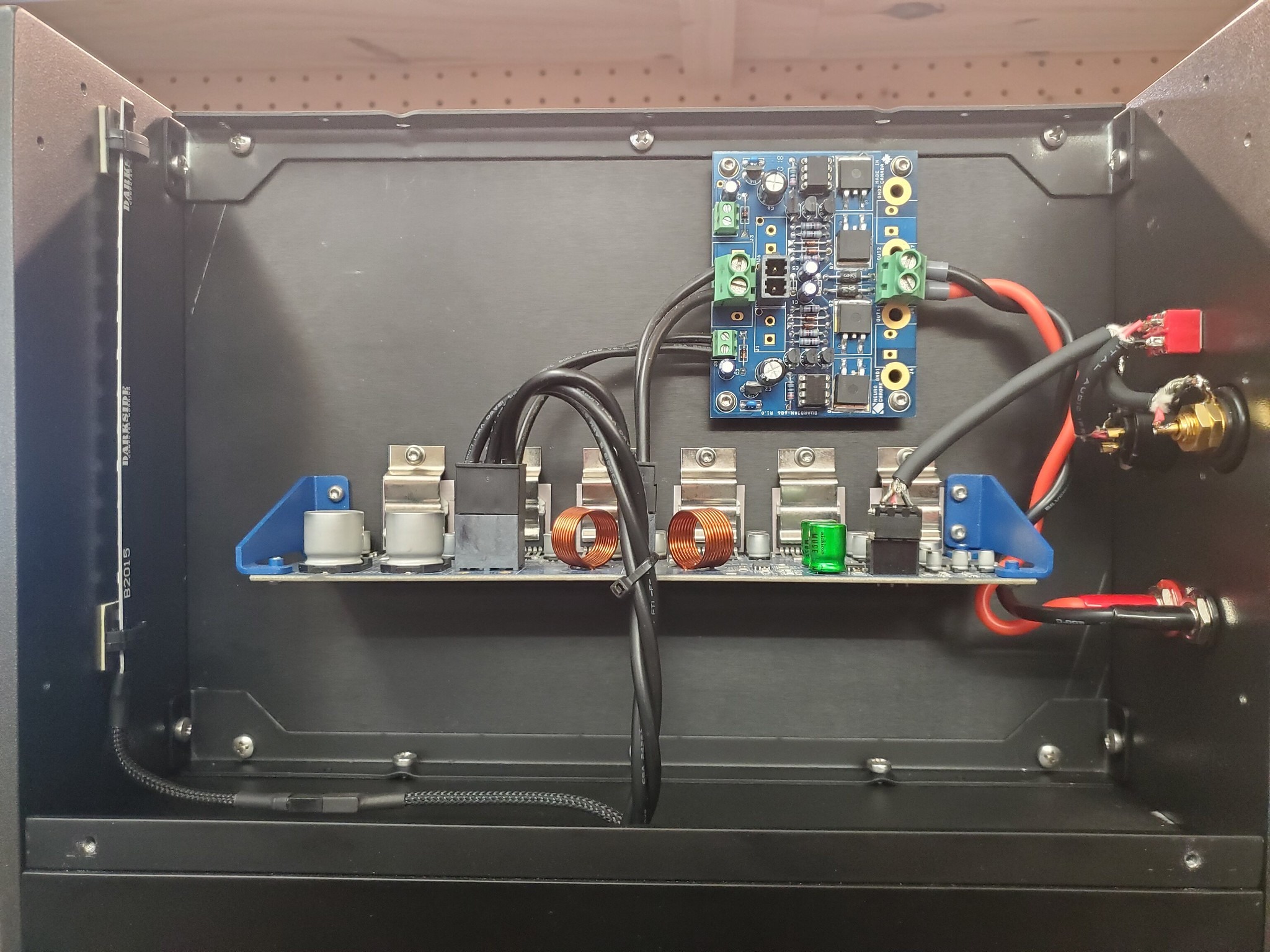

After 2 1/2 years, my v1 Mod 686 "Modulus Monoliths" have reached their final form. I used a DIY powder coat kit and toaster oven to coat the raw aluminum. I upgraded the cover plates from aluminum to stainless steel with a finer hole pattern, and added some blue LED strips powered from the Mean Well fan headers for a subtle illumination of the inside circuitry. I think they came out great, and they sound fantastic.

Tell us more about the DIY powder coat! Did you build the chassis yourself too?After 2 1/2 years, my v1 Mod 686 "Modulus Monoliths" have reached their final form. I used a DIY powder coat kit and toaster oven to coat the raw aluminum. I upgraded the cover plates from aluminum to stainless steel with a finer hole pattern, and added some blue LED strips powered from the Mean Well fan headers for a subtle illumination of the inside circuitry. I think they came out great, and they sound fantastic.

View attachment 1091667

View attachment 1091666View attachment 1091668

Thanks everyone for the positive comments. The chassis was designed and built by me out of aluminum I bought on eBay (and obviously the heatsink & brackets from the DIY Audio Store.) The bottom piece that houses the power supplies and Mean Well Control board are made of 5" x 5" aluminum square tubing. The front and back panels are 5" x 14" x 1/4" aluminum bar. More info on this build and enclosure design details (venting etc) can be found in this thread from January 2020, Page 60 & 61 if you use the default page size.

The powder coat kit came from Harbor Freight and the toaster oven was from Jegs. I spray painted some DIY aluminum enclosures before and decided that I am not a painter. The powder coat applied evenly, looks great, feels great, and is nice and durable. This amp sits on the floor, so the extra durability is appreciated. I also went with a textured color (silver vein for the front and rear panels, matte black for the PSU enclosures) to hide any surface imperfections.

Here's a glow picture. I indulged my inner PC Mod kid with the "Neurochrome blue" LED strip. The camera doesn't capture it, but you can see the amp board if you line yourself up with the holes in the stainless perforated cover.

The powder coat kit came from Harbor Freight and the toaster oven was from Jegs. I spray painted some DIY aluminum enclosures before and decided that I am not a painter. The powder coat applied evenly, looks great, feels great, and is nice and durable. This amp sits on the floor, so the extra durability is appreciated. I also went with a textured color (silver vein for the front and rear panels, matte black for the PSU enclosures) to hide any surface imperfections.

Here's a glow picture. I indulged my inner PC Mod kid with the "Neurochrome blue" LED strip. The camera doesn't capture it, but you can see the amp board if you line yourself up with the holes in the stainless perforated cover.

That is absolutely gorgeous. I love the use of perf plate. It looks like a timeless classic amp design.

Now, of course, I need to come up with a custom perf plate design that has the Neurochrome logo embedded in the hole pattern somehow. 🙂

Tom

Now, of course, I need to come up with a custom perf plate design that has the Neurochrome logo embedded in the hole pattern somehow. 🙂

Tom

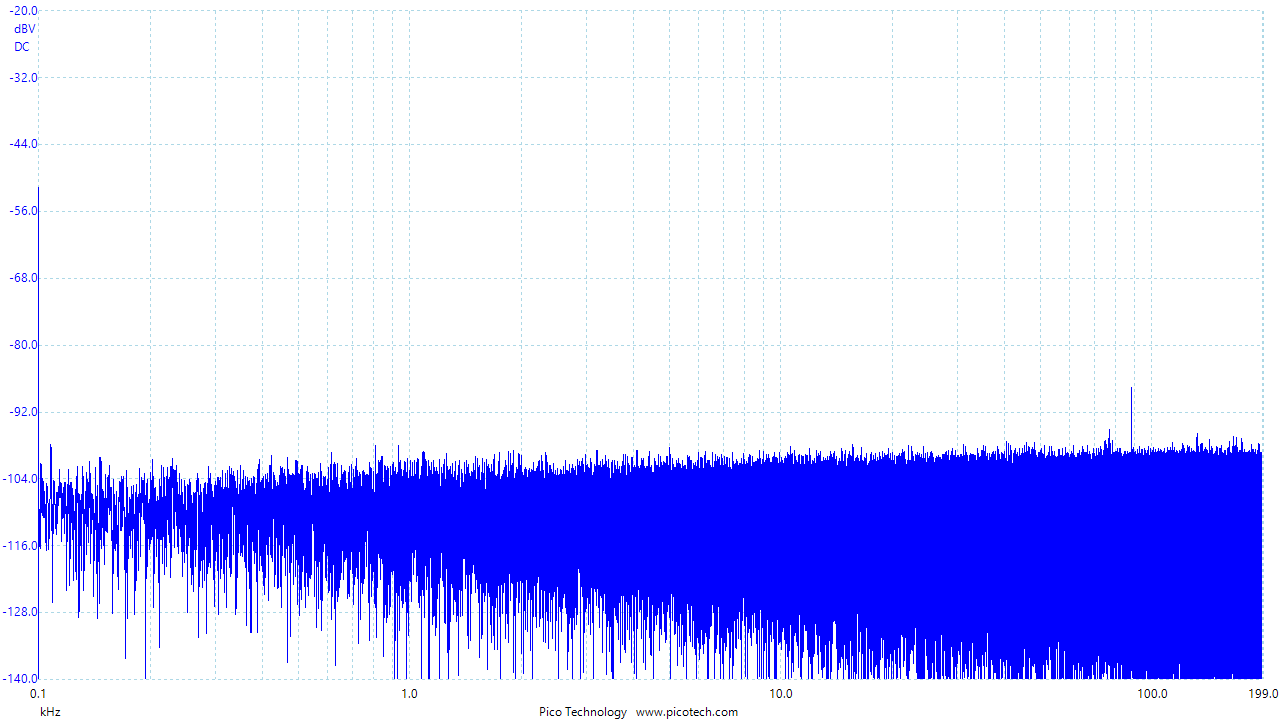

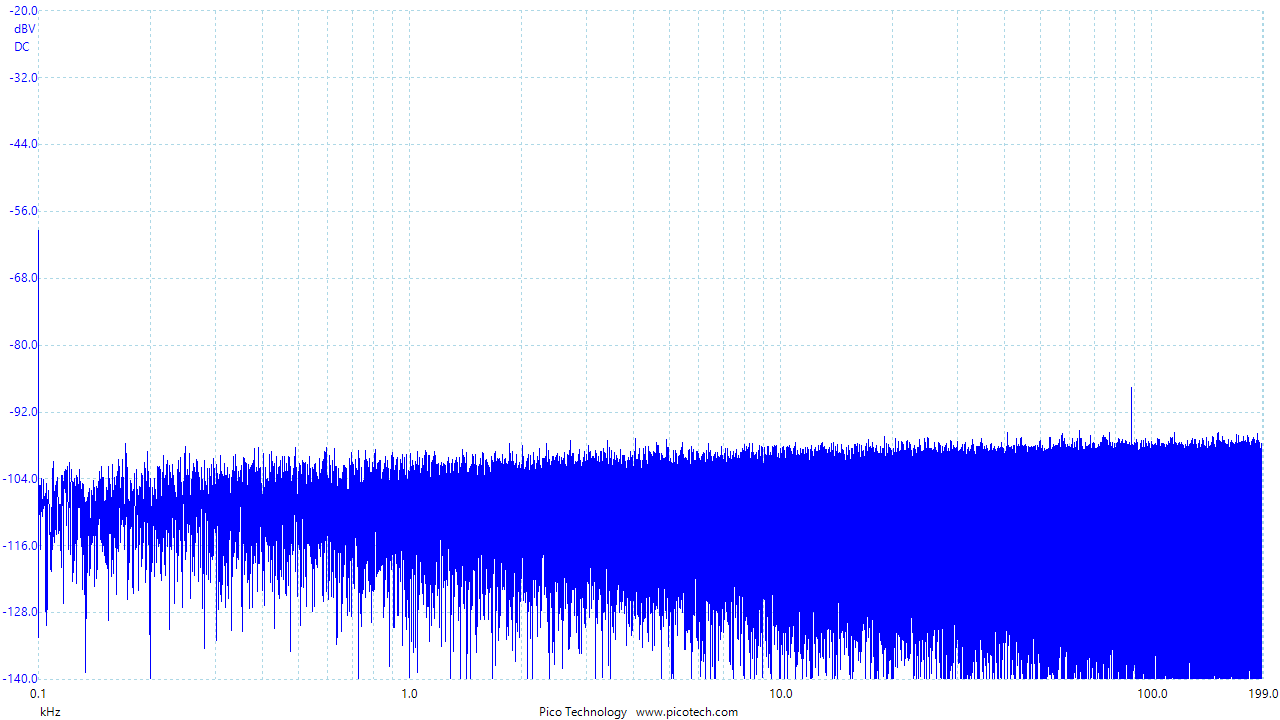

Small update on my Modulus-686 + MeanWell UHP-750 build.

Everything still works great. Out of curiousity, I tried to do a noise floor measurement with a PicoScope 5000 series (hooked up to a laptop running on battery as a risky poor-man's differential scope), but the noise floor is below what the scope can measure.

I do see a tiny bit of 88 kHz noise coming through at like -85 dB, and this is right around the PFC frequency (90 kHz) of the power supplies according to their datasheet. Luckily, I'm not a bat so I can't hear 88 kHz.

The actual switching frequency of the power supplies is 55 kHz and I see absolutely none of that on the output of the amp, nor do I see any 60 Hz mains noise.

Left:

Right:

Everything still works great. Out of curiousity, I tried to do a noise floor measurement with a PicoScope 5000 series (hooked up to a laptop running on battery as a risky poor-man's differential scope), but the noise floor is below what the scope can measure.

I do see a tiny bit of 88 kHz noise coming through at like -85 dB, and this is right around the PFC frequency (90 kHz) of the power supplies according to their datasheet. Luckily, I'm not a bat so I can't hear 88 kHz.

The actual switching frequency of the power supplies is 55 kHz and I see absolutely none of that on the output of the amp, nor do I see any 60 Hz mains noise.

Left:

Right:

Have you verified that it is indeed the amp/supply that causes that 88 kHz component? It seems plausible, but it's equally plausible that it's another switcher that gets in via the cabling in your test setup. I've seen that more than once.

Tom

Tom

I've tried to verify this to the best of my ability, but I can't say for sure. I've moved my test setup into my basement away from all other electronics and the results are the same. For all tests, I have the input shorted with a dummy shielded Neutrik connector.Have you verified that it is indeed the amp/supply that causes that 88 kHz component? It seems plausible, but it's equally plausible that it's another switcher that gets in via the cabling in your test setup. I've seen that more than once.

Tom

Do you think it's even worth looking into this any further? The noise seems to be around -82 dBV, so like 79 microvolts. This aligns with what I measure with my regular AC RMS multimeter (~80-100 uV). The frequency is so far outside audible that I'm not concerned about audio quality, but I'm wondering if it will result in extra heat or anything. I think it's really a battle with my OCD at this point. The speakers I'm using have a sensitivity of 88.5 and are 8 ohms so it works out to like 5 dB SPL assuming the speakers are flat to 88 kHz...🤣

I've also noticed that the 88 kHz noise is actually reduced if I remove the top cover of the chassis (but then I pick up other EMI). That's very odd to me. I've also ensured that all panels of the chassis are bonded to ground (used star washers on all panels). Isolating the entire amp from ground also makes no difference. I'm wondering if it's a magnetic field issue, like, the transformers used for the PFC circuit are leaking and pushing some currents around in the chassis panels?

I'm inclined to believe that the noise is somehow getting coupled into the input stage of the amp rather than leaking in through the power supply side since these SMPS have like 8 smaller electrolytic caps in parallel and the Mod-686 has such good PSRR. Then again, IDK if the Mod-686 even has enough response at that high of a frequency for it to end up on the speaker output if it's coming in through the input.

I considered trying a ferrite bead on wires from the SMPS to the Mod-686, but I don't know if they would be effective at 88 kHz and I don't want to risk creating some type of LC circuit by accident.

I wonder how many amps have noise at these levels but no one is even aware of it since they don't usually measure that high.

That's a really good start. What you can then try is to unplug the scope from the amp and short the input to the scope. Leave everything else the same (so the amp still powered up with input shorted). If that noise blip goes away, it's from the amp. But if it remains, it's from the cabling (or scope).I've tried to verify this to the best of my ability, but I can't say for sure. I've moved my test setup into my basement away from all other electronics and the results are the same. For all tests, I have the input shorted with a dummy shielded Neutrik connector.

Do you have a speaker connected or are you using a load resistor? Or is the amp output just floating? I've seen speakers and speaker cables act as antennae as well. I'd terminate the amp in 8 Ω (or anything in the 3.9-10 Ω range). It doesn't have to be a power resistor. A plain 0.25 W type will work just fine as long as the input to the amp is shorted.

Not really. I'm asking mostly out of academic interest and also because at the levels of precision that my circuits operate it's common for cable-induced noise/EMI to show up, so this seemed like a good teaching opportunity.Do you think it's even worth looking into this any further?

Nah. 3.7 nW dissipated in the Zobel resistor. Nothing to worry about.[...] I'm wondering if it will result in extra heat or anything.

That leads me further in the direction of "cable issue" then. Or maybe coupling directly into the scope. Does it change when you move the scope further away from the amp?I've also noticed that the 88 kHz noise is actually reduced if I remove the top cover of the chassis (but then I pick up other EMI).

That is also possible. The CMRR is pretty high (80-100 dB if memory serves) at lower frequencies but decreases on a 20 dB/dec slope at higher frequencies so it will be lower at 80 kHz than it is within the audio band. The PSRR is more complicated. There's considerable decoupling on the PCB, both in the form of two 1000 uF bulk capacitors but also local decoupling at each LM3886 (33 uF || 1.0 uF X7R). Getting 80 kHz to disturb the supply voltage much will be a challenge.I'm inclined to believe that the noise is somehow getting coupled into the input stage of the amp rather than leaking in through the power supply side since these SMPS have like 8 smaller electrolytic caps in parallel and the Mod-686 has such good PSRR. Then again, IDK if the Mod-686 even has enough response at that high of a frequency for it to end up on the speaker output if it's coming in through the input.

I'm assuming you're running the supply wires pretty tightly bundled. You could try one of those clamp-on ferrite deals. I doubt it'll do much either way.I considered trying a ferrite bead on wires from the SMPS to the Mod-686, but I don't know if they would be effective at 88 kHz and I don't want to risk creating some type of LC circuit by accident.

Probably quite a few. Even if the manufacturer did measure, they could have concluded that it wasn't worth pursuing because it's such low level, well outside the audio band, and doesn't hurt the amp (or speaker) any.I wonder how many amps have noise at these levels but no one is even aware of it since they don't usually measure that high.

Tom

I chased my tail when measuring an active crossover and getting tens of kHz of what looked like oscillation. Looked all through the circuit trying to find the opamp that was hooting. Fiddled with that for more hours than I can own up to.

I was measuring the output using a compact Tektronix digital scope. TDS2004B. For no real logical reason I turned the scope on its side, and the oscillation disappeared.

The switched mode supply in the scope was coupling to the audio!

Craig

I was measuring the output using a compact Tektronix digital scope. TDS2004B. For no real logical reason I turned the scope on its side, and the oscillation disappeared.

The switched mode supply in the scope was coupling to the audio!

Craig

Oh, that's special! 🙂 Yeah... Gotta love life at precision levels.

My favourite is when I spent hours and hours chasing down some 60 Hz mains hum that registered at -130 dBV (256k FFT, 44.1 kHz sampling). That's pretty low levels. Definitely below audible but it doesn't look pretty in the plot. I also wanted to know the root cause of it. I tried everything. I wrapped the circuit in grounded aluminum foil, changed cables, turned the lights off, etc. I built star quad XLR cables for the measurement. No dice! I think I even tried battery operation. I could not make that hum go away. I wanted to take this up with Audio Precision and needed a screen shot. Now the hum was gone!! I finally retraced my steps from earlier in the day and found that the hum was present when the HP 34401A bench top multimeter that sits on top of the APx555 was turned on. I guess there's enough leakage field from the power transformer in the meter to disturb the frontend of the AP (which is right below the meter).

I'm a bit disappointed that AP didn't include a mu metal shield so that their box would play nice with others. But whatever... A sheet of mu metal is not that expensive at Bezos' Bookstore or that auction site.

Tom

My favourite is when I spent hours and hours chasing down some 60 Hz mains hum that registered at -130 dBV (256k FFT, 44.1 kHz sampling). That's pretty low levels. Definitely below audible but it doesn't look pretty in the plot. I also wanted to know the root cause of it. I tried everything. I wrapped the circuit in grounded aluminum foil, changed cables, turned the lights off, etc. I built star quad XLR cables for the measurement. No dice! I think I even tried battery operation. I could not make that hum go away. I wanted to take this up with Audio Precision and needed a screen shot. Now the hum was gone!! I finally retraced my steps from earlier in the day and found that the hum was present when the HP 34401A bench top multimeter that sits on top of the APx555 was turned on. I guess there's enough leakage field from the power transformer in the meter to disturb the frontend of the AP (which is right below the meter).

I'm a bit disappointed that AP didn't include a mu metal shield so that their box would play nice with others. But whatever... A sheet of mu metal is not that expensive at Bezos' Bookstore or that auction site.

Tom

You guys were right. It turned out to be a false alarm - or rather, at least not caused by the amp itself.

The noise is still there even if I unplug everything from the amp (including the mains), so that rules out basically everything inside the box. I am using a 4 ohm load resistor for all these tests.

It's not there if I short the scope though. My guess is the chassis itself is picking the noise up somehow.

Even though it's still there, as weird as this sounds, it psychologically doesn't bother me now knowing that it's not some interference from the supply. I was really concerned about the amps picking up noise from being close to the SMPS but I can't see any of the SMPS switching frequency on the output at all. Zero.

I actually went down the MuMetal path recently. I was planning on making shields for the SMPS if this became an issue (before I even did any measurements). It's really hard to get ahold of the stuff. I contacted the main MuMetal company directly and ordered a sheet from them, as well as some company in Europe. I spent a couple hundred on sheets of the stuff, but now I guess I'll have to save it for my next project. I think you're also supposed to re-anneal it each time you machine it. It's kind of hard to work with.

I also have MuMetal wire sheathing conduit. I think I got that from Mouser or something.

The noise is still there even if I unplug everything from the amp (including the mains), so that rules out basically everything inside the box. I am using a 4 ohm load resistor for all these tests.

It's not there if I short the scope though. My guess is the chassis itself is picking the noise up somehow.

Even though it's still there, as weird as this sounds, it psychologically doesn't bother me now knowing that it's not some interference from the supply. I was really concerned about the amps picking up noise from being close to the SMPS but I can't see any of the SMPS switching frequency on the output at all. Zero.

A sheet of mu metal is not that expensive at Bezos' Bookstore or that auction site.

I actually went down the MuMetal path recently. I was planning on making shields for the SMPS if this became an issue (before I even did any measurements). It's really hard to get ahold of the stuff. I contacted the main MuMetal company directly and ordered a sheet from them, as well as some company in Europe. I spent a couple hundred on sheets of the stuff, but now I guess I'll have to save it for my next project. I think you're also supposed to re-anneal it each time you machine it. It's kind of hard to work with.

I also have MuMetal wire sheathing conduit. I think I got that from Mouser or something.

Odd with the mu metal shortage. Last I checked (probably 12-18 months ago) there was plenty. Oh, well. Life in the New Paranormal.

An amp that's just sitting there floating will be an excellent antenna. It'll pick up something. If you really want to chase this down I'd start with everything that switches. So SMPSes, LED/CFL light bulbs, etc. I won't blame you if you'd rather listen to music, though. 🙂 It's good to know whatever that 88 kHz component is, it's not coming from the active circuitry in the amp.

Before I bought my Keysight DSXO1102 60 MHz digital scope I used a 400 MHz Tektronix 2465B. I still have it. It's a great scope. Just not so convenient if you want pictures out of it. Anyway. That scope spent the vast majority of the time with the bandwidth limiter on. That turns the 400 MHz scope into a 20 MHz scope. The reason being that I live in the city and have plenty of FM radio to listen to. My scope likes to listen too... I can usually get a few, maybe ten, mV of fuzz on the trace picked up by the probe grounding lead. No big deal, but doesn't look pretty if you're presenting the data.

Tom

An amp that's just sitting there floating will be an excellent antenna. It'll pick up something. If you really want to chase this down I'd start with everything that switches. So SMPSes, LED/CFL light bulbs, etc. I won't blame you if you'd rather listen to music, though. 🙂 It's good to know whatever that 88 kHz component is, it's not coming from the active circuitry in the amp.

Before I bought my Keysight DSXO1102 60 MHz digital scope I used a 400 MHz Tektronix 2465B. I still have it. It's a great scope. Just not so convenient if you want pictures out of it. Anyway. That scope spent the vast majority of the time with the bandwidth limiter on. That turns the 400 MHz scope into a 20 MHz scope. The reason being that I live in the city and have plenty of FM radio to listen to. My scope likes to listen too... I can usually get a few, maybe ten, mV of fuzz on the trace picked up by the probe grounding lead. No big deal, but doesn't look pretty if you're presenting the data.

Tom

- Home

- Vendor's Bazaar

- Modulus-686: 380W (4Ω); 220W (8Ω) Balanced Composite Power Amp with extremely low THD