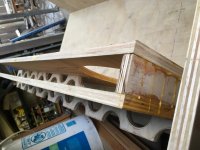

Made about 30 feet of this in a channel shape ~1x3 and tighter 1.5” holes spacing. 14 gage, kinda takes the structural into cosmetic more than otherwise, but the material was rusty (but free) so hard to complain. the 1” and 3” dimensions being opposite the ideal to be a rigid brace, but I’m probably being picky?

Consider curved surfaces...

Yeah - cross-braking does something for thin, flat sheet metal panels, but it's a "cheap fix" at best. Much better inherent stiffness can be achieved by using curved surfaces: cylindrical, conical, etc. I've made some speaker enclosures incorporating surprisingly light-gauge spiral-rolled-seam galvanized steel air duct, and adequate damping of these was readily achievable. You probably have roll-forming capability, but for the purpose at hand, press-brake formed cylinders, cones, or transitions should be equally functional.

https://www.diyaudio.com/forums/attachment.php?attachmentid=885917&stc=1&d=1603173436

Wow - a big steel fabrication shop will be challenging to put intelligible/worthwhile music into! Aren't the staff wearing hearing protection as a matter of course? The only relevant anecdote I can offer is this: some time ago in the previous millenium, I found myself in a certain noisy, cavernous, highly reverberant railway terminal in a large European city, and I recall marveling at the crystal-clear intelligibility of the announcements (low-pitched male announcer voice) on the P.A. system. Unfortunately, I could not ascertain the details of said P.A. system. but if I had to guess: wide, well-balanced frequency response with AMPLE low-frequency output, carefully-located single-source (as opposed to multiple, smaller, speakers in a distributed arrangement), and speaking slowly!🙂 (perhaps an "Industrial" music playlist would work well for your environment...)

Good luck with your project - I look forward to progress updates!

Wilf

Yeah - cross-braking does something for thin, flat sheet metal panels, but it's a "cheap fix" at best. Much better inherent stiffness can be achieved by using curved surfaces: cylindrical, conical, etc. I've made some speaker enclosures incorporating surprisingly light-gauge spiral-rolled-seam galvanized steel air duct, and adequate damping of these was readily achievable. You probably have roll-forming capability, but for the purpose at hand, press-brake formed cylinders, cones, or transitions should be equally functional.

https://www.diyaudio.com/forums/attachment.php?attachmentid=885917&stc=1&d=1603173436

Wow - a big steel fabrication shop will be challenging to put intelligible/worthwhile music into! Aren't the staff wearing hearing protection as a matter of course? The only relevant anecdote I can offer is this: some time ago in the previous millenium, I found myself in a certain noisy, cavernous, highly reverberant railway terminal in a large European city, and I recall marveling at the crystal-clear intelligibility of the announcements (low-pitched male announcer voice) on the P.A. system. Unfortunately, I could not ascertain the details of said P.A. system. but if I had to guess: wide, well-balanced frequency response with AMPLE low-frequency output, carefully-located single-source (as opposed to multiple, smaller, speakers in a distributed arrangement), and speaking slowly!🙂 (perhaps an "Industrial" music playlist would work well for your environment...)

Good luck with your project - I look forward to progress updates!

Wilf

Attachments

Do a pair of ROAR15 in half inch steel plates. 😀 Bend the internal parts in a large press to get some curvature and glue on some bitumen on the inside. I would love to see this built!!!

It really does not take much bitumen to reduce the resonance in the large curved and welded plates down below the background noise level in a large industrial steel fabrication place.

I have a 350 x 350 x 25 mm piece of steel at home and it sure has some nasty resonances when smacked with a hammer. All it takes is my gripping the piece tightly with one hand to lower the resonances to less then half and shorten the decay substantially.

It really does not take much bitumen to reduce the resonance in the large curved and welded plates down below the background noise level in a large industrial steel fabrication place.

I have a 350 x 350 x 25 mm piece of steel at home and it sure has some nasty resonances when smacked with a hammer. All it takes is my gripping the piece tightly with one hand to lower the resonances to less then half and shorten the decay substantially.

I might be the biggest ROAR fan in the western United States 🙂 but it’s a constant battle with the many ways I can bend and twist that and alternate configurations of it and similar hybrids that seems to be my affliction😀 throat

chambered roar helps some drivers pretend. It starts to dilute the punchy, but still holds on to things much more exciting then without a roar or similar layout.

it’s a guaranteed go to if it was my subwoofer.(38hz, .33 Qts, 22.5Vas and 28 Bl(3.8 Re/4.2Le) But here I’m stuck with someone else’s $ or parts I think, and it’s not my ‘roar’ goto 12”, it’s a bigger Vas (58)and loss of Qes (.51) (26.5 Fs) 17 Bl 3.2re/4.25Le)to put it mildly. car audio piston pump I think. And while I’m familiar with the drivers that’ll get used likely , Rockford Fosgate p3d2 12, it’s isobarik we’re Ive squeezed these into MLTL and had some fun, they choke out in a roar unless I made a throat chamber to help them, or a big chamber transflex pipe to waveguide....?

chambered roar helps some drivers pretend. It starts to dilute the punchy, but still holds on to things much more exciting then without a roar or similar layout.

it’s a guaranteed go to if it was my subwoofer.(38hz, .33 Qts, 22.5Vas and 28 Bl(3.8 Re/4.2Le) But here I’m stuck with someone else’s $ or parts I think, and it’s not my ‘roar’ goto 12”, it’s a bigger Vas (58)and loss of Qes (.51) (26.5 Fs) 17 Bl 3.2re/4.25Le)to put it mildly. car audio piston pump I think. And while I’m familiar with the drivers that’ll get used likely , Rockford Fosgate p3d2 12, it’s isobarik we’re Ive squeezed these into MLTL and had some fun, they choke out in a roar unless I made a throat chamber to help them, or a big chamber transflex pipe to waveguide....?

Attachments

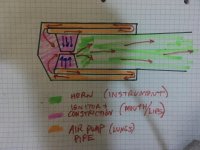

Perhaps considering the MASSIVE space you've got to fill a really big tractrix horn would be best, you could go on the full range section of diyaudio and ask someone to advise/design you one. I thing bitumen coted steel horns have been done. Sorry about the quality of the picture, I had trouble downloading it so I had to do a screenshot,

Perhaps considering the MASSIVE space you've got to fill a really big tractrix horn would be best, you could go on the full range section of diyaudio and ask someone to advise/design you one. I thing bitumen coted steel horns have been done. Sorry about the quality of the picture, I had trouble downloading it so I had to do a screenshot,Yeah - cross-braking does something for thin, flat sheet metal panels, but it's a "cheap fix" at best. Much better inherent stiffness can be achieved by using curved surfaces: cylindrical, conical, etc. I've made some speaker enclosures incorporating surprisingly light-gauge spiral-rolled-seam galvanized steel air duct, and adequate damping of these was readily achievable. You probably have roll-forming capability, but for the purpose at hand, press-brake formed cylinders, cones, or transitions should be equally functional.

https://www.diyaudio.com/forums/att...l-welded-pressbroke-enclosures-10-final-2-jpg

Wow - a big steel fabrication shop will be challenging to put intelligible/worthwhile music into! Aren't the staff wearing hearing protection as a matter of course? The only relevant anecdote I can offer is this: some time ago in the previous millenium, I found myself in a certain noisy, cavernous, highly reverberant railway terminal in a large European city, and I recall marveling at the crystal-clear intelligibility of the announcements (low-pitched male announcer voice) on the P.A. system. Unfortunately, I could not ascertain the details of said P.A. system. but if I had to guess: wide, well-balanced frequency response with AMPLE low-frequency output, carefully-located single-source (as opposed to multiple, smaller, speakers in a distributed arrangement), and speaking slowly!🙂 (perhaps an "Industrial" music playlist would work well for your environment...)

Good luck with your project - I look forward to progress updates!

Wilf

This is an issue, and previously we just have personal equipment on each of our toolboxes grabbing to company WiFi stream.. but that strangely affective beaming or localized of a signal as PA would be nice to deliver to each area!

If Covid would stop interfering with a consistent steady work week.. this might be easy as I am free to ‘dumpster dive ‘ in the recycle bin’ for steeel and hospitals and stairs means lots and lots of pressbrake and 12-16 gage treads and landings! But the drops can be personal projects if not ‘greedy’ or abusing the idea. I have built a lot of things from old steel and scrap from my employer. Not any speakers though(about to change that I think ). Your duct idea is a great one. I have pvc and sonitubr

E that would be great if hvac.!

Attachments

Last edited:

View attachment 885946Perhaps considering the MASSIVE space you've got to fill a really big tractrix horn would be best, you could go on the full range section of diyaudio and ask someone to advise/design you one. I thing bitumen coted steel horns have been done. Sorry about the quality of the picture, I had trouble downloading it so I had to do a screenshot,

You behave!! that can if worms will get me in trouble, 😱 I just cut up the top half of a FLH layout on a sheet of plywood to make something ‘smaller’ instead. I’m chicken.. but I have 4” full range TLs and they’re great, but plastic sewer pipe is kinda getting boring?

If I put a ‘horn’ on an existing TL and the tapped entry creates a second squirt mid path to the new exit.... the results are rediculous if the motorforce is there! pipe dream, but not day dream, it’s simmed in a bunch of ways

Last edited:

Lol! I like your style! This approach is affective. Just go home sick after a bunch of galvanized and send a message before the horn shaped excuse !

Just let the management think that it's a fume extractor, whenever you see them stop the music and play a fan sound effect. " beast in metal " is one cool name, if I saw that on an album cover I'd buy it!

Lord Flashheart, I have a bit of a beard...

Lord Flashheart, I have a bit of a beard...

beast in metal, lmao

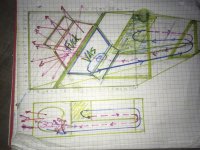

this might need to be shrimaged with a pair of tangband w5s. i dunno how far i can stretch the ferrous material in the 2.1 segment and lightweight or convenient enough? but i didnt anticipate the simple acceptance of steel sheetplate so much. this is kinda hard to not see what i can get goin? bit hyst for a crazy huge monster bass bin at work , but right here and now for myself shop or bedroom/office whatever..

might be an exocageand structure over plywood, or shared with

? anything i suppose. but i think this sounds funner than not, so ill try to come up with a few sketches

tangband w51138s paired up in a tapped qw pipe

this might need to be shrimaged with a pair of tangband w5s. i dunno how far i can stretch the ferrous material in the 2.1 segment and lightweight or convenient enough? but i didnt anticipate the simple acceptance of steel sheetplate so much. this is kinda hard to not see what i can get goin? bit hyst for a crazy huge monster bass bin at work , but right here and now for myself shop or bedroom/office whatever..

might be an exocageand structure over plywood, or shared with

? anything i suppose. but i think this sounds funner than not, so ill try to come up with a few sketches

tangband w51138s paired up in a tapped qw pipe

Last edited:

That bracing looks cool as h3ll! I bet you could sell those beams to the SPL crowd in car audio.

Two very influential people in my little world!

MMJ and Anders Martensonn(sp)!!

I think I’ve read and absorbed and processed even more of those then MJK Who got me hooked.

MMJ and Anders Martensonn(sp)!!

I think I’ve read and absorbed and processed even more of those then MJK Who got me hooked.

Last edited:

That bracing looks cool as h3ll! I bet you could sell those beams to the SPL crowd in car audio.

I wish I could find just a few on

Pinterest or anywhere to

Get a little kick in the butt if inspiration to consider ? There’s nothing to see in ‘metal ‘. some cool speaker stands and a few aluminum

Machined billet chunks or similar? But I’m coming up pretty dry on the well of ideas if searching ?

WORSE case scenario stuck with car audio 12s. I have already done a version of this (tockfordfosgste p3d212)and I would just need to adapt the shape from

an existing restaurant trash can looking hideaway OSB/ plywood Covid time killer project that turned out to be kinda hilarious but in a good way?

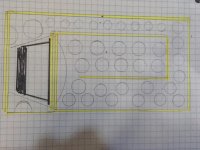

Better scenario if it became a choice in drivers I could get more going on but as a not nearly so LOW in a roar/tham/paraflex type of approach. I’m stuck to simming and obviously can’t just guess on ringing or panels resonances by design. but the next pic is bracing I do as wood normally.

As metal exocage instead? Blue is the closed end side of the isobaric bisected rectangle box shape, purple is the open sides path so that zigzag makes sense? There nothing drawn to show the other sides path or panels and both ends are fine if they match atb45 liters, and 250-300cm2 ‘port’ around 24hz tuning.

an existing restaurant trash can looking hideaway OSB/ plywood Covid time killer project that turned out to be kinda hilarious but in a good way?

Better scenario if it became a choice in drivers I could get more going on but as a not nearly so LOW in a roar/tham/paraflex type of approach. I’m stuck to simming and obviously can’t just guess on ringing or panels resonances by design. but the next pic is bracing I do as wood normally.

As metal exocage instead? Blue is the closed end side of the isobaric bisected rectangle box shape, purple is the open sides path so that zigzag makes sense? There nothing drawn to show the other sides path or panels and both ends are fine if they match atb45 liters, and 250-300cm2 ‘port’ around 24hz tuning.

Attachments

Last edited:

I like the "F Vas" comment! I remember having 4 MTX Road Thunder Two 15's in an isobaric BP4 in a 1983 Grand Marquis. That bad boy talked to whales!

- Home

- Loudspeakers

- Subwoofers

- Mild steel welded and pressbroke enclosures