Why not pour some lead, it's near acoustically dead at room temperature.

Of course you would have to put some massive wheels under it. 😀

Of course you would have to put some massive wheels under it. 😀

bart, lead is very soft at room temp, it would look like a Salvador Dali painting in short order 😉

Thank you Bob Brines for your comments. They clarified what I was getting at.😎

I would be a little hesitant to use Steel, Iron or any other high Iron content alloy. Being that Ferrous materials are magnetic, it may screw up the behavior of the magnetic field for the driver(s). Of course this is just speculation, and I may be completely wrong about this thought.

Peace,

Dave

I would be a little hesitant to use Steel, Iron or any other high Iron content alloy. Being that Ferrous materials are magnetic, it may screw up the behavior of the magnetic field for the driver(s). Of course this is just speculation, and I may be completely wrong about this thought.

Peace,

Dave

I think the Metrenome in iron or aluminum would be cool. It's a fairly easy shape to mold although getting it hollow might be a challenge supporting the core. The bottom plate and port would be cast separately. The internal core might be supported by the print out the driver opening.

Kudos to Bob for bringing some science to the discussion. I was starting to think this forum should be renamed "The Church of Mdf".

Not that it directly correlates, but another case in point for cast gray iron is that it is almost universally used for machine ways and bases, and just as in the example of the piano, it is not about strength, there are much better materials for that property. Cast iron dissipates 10x the vibration energy of steel. Any amount of natural harmonic resonance would be bad for a precision machine tool, or piano for that matter, at least within the audible range.

I think cast aluminum might be interesting as well (minimus 7?). As cast aluminum has a coarse grain structure, and tends to be more brittle, more like cast (gray) iron. It might tend to be more rigid than grain refined plate material.

Aluminum is roughly 30% the density of cast iron. I don't have the comparison to wood handy, but there's no doubt 1/2" of Al is more rigid than 3/4 ply, maybe 1" is equivalent? Point being the enclosure panels don't need to be nearly as thick (again minimus 7, I remember opening one up in high school) or clumsily braced. I think my Thiels are solid mdf. It is fairly trivial to cast in stiffening ribs, baffles, etc.

Kudos to Bob for bringing some science to the discussion. I was starting to think this forum should be renamed "The Church of Mdf".

Not that it directly correlates, but another case in point for cast gray iron is that it is almost universally used for machine ways and bases, and just as in the example of the piano, it is not about strength, there are much better materials for that property. Cast iron dissipates 10x the vibration energy of steel. Any amount of natural harmonic resonance would be bad for a precision machine tool, or piano for that matter, at least within the audible range.

I think cast aluminum might be interesting as well (minimus 7?). As cast aluminum has a coarse grain structure, and tends to be more brittle, more like cast (gray) iron. It might tend to be more rigid than grain refined plate material.

Aluminum is roughly 30% the density of cast iron. I don't have the comparison to wood handy, but there's no doubt 1/2" of Al is more rigid than 3/4 ply, maybe 1" is equivalent? Point being the enclosure panels don't need to be nearly as thick (again minimus 7, I remember opening one up in high school) or clumsily braced. I think my Thiels are solid mdf. It is fairly trivial to cast in stiffening ribs, baffles, etc.

Sonicweld do a nice job of CNC machined aluminium enclosures;

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Casting requires expensive tooling and it is hard to get good cosmetics.

Many commercial speakers are more fancy furniture than physics

Many commercial speakers are more fancy furniture than physics

The high end brand Krell, better known for their amplifiers, made and still makes speakers with aluminum enclosures. These do look pretty good in my opinion.

Of course it was about strength, what else was available when they made the first piano's?

It's just tradition now.

It's just tradition now.

Doubting, they had cast bronze and wrought iron available as materials, both of which would be much stronger than cast iron, or at least much tougher. Bronze starts at 30,000 psi tensile and something like 20% to 30% elongation. Wrought iron is similiar to steel in properties as it is puddled iron worked to eliminate carbides and other brittle crystal structures to yield a material that has some ductility and high strength which was used as a structural material prior to the availability of modern bessemer process steel.

Gray iron, the technical grade comparable to cupola melted iron that would have been available in the late 1800's is rather brittle, although very strong in compression. A good analogy to gray iron is stone, or very strong stone. In a piano you can see a bridge like structure, rather thin and presumably with forces in tension as well as compression, if strength were the primary criteria other materials, historic and modern would be much better.

My suspicion, while possibly incorrect, is based on a pretty good understanding of the chemical and physical properties of cast metals and without a doubt, cast iron was NEVER selected for it's superior strength. It is however much cheaper than wrought iron or bronze to make and as mentioned before has unique resonant properties for metal, which is really the question at hand.

You asserted, rather stridently without any substantiation, that all metals act like a tuning fork or other purposely resonant object and wouldn't be good for driver enclosures. I think my initial proposition is valid that for example a gray iron piano frame is not resonant to the point of being deleterious to tonally correct sound reproduction and some analogies can be made.

For that matter, many old magnet frames for drivers were made from cast iron before being made from stamped steel.

But, really, Bob pretty much debunked the categorical rejection of metals for enclosures using much better reasoning, so maybe you could concede that you are mistaken about your unsubstantiated assertions?

Gray iron, the technical grade comparable to cupola melted iron that would have been available in the late 1800's is rather brittle, although very strong in compression. A good analogy to gray iron is stone, or very strong stone. In a piano you can see a bridge like structure, rather thin and presumably with forces in tension as well as compression, if strength were the primary criteria other materials, historic and modern would be much better.

My suspicion, while possibly incorrect, is based on a pretty good understanding of the chemical and physical properties of cast metals and without a doubt, cast iron was NEVER selected for it's superior strength. It is however much cheaper than wrought iron or bronze to make and as mentioned before has unique resonant properties for metal, which is really the question at hand.

You asserted, rather stridently without any substantiation, that all metals act like a tuning fork or other purposely resonant object and wouldn't be good for driver enclosures. I think my initial proposition is valid that for example a gray iron piano frame is not resonant to the point of being deleterious to tonally correct sound reproduction and some analogies can be made.

For that matter, many old magnet frames for drivers were made from cast iron before being made from stamped steel.

But, really, Bob pretty much debunked the categorical rejection of metals for enclosures using much better reasoning, so maybe you could concede that you are mistaken about your unsubstantiated assertions?

Doubting, they had cast bronze and wrought iron available as materials, both of which would be much stronger than cast iron, or at least much tougher. Bronze starts at 30,000 psi tensile and something like 20% to 30% elongation. Wrought iron is similiar to steel in properties as it is puddled iron worked to eliminate carbides and other brittle crystal structures to yield a material that has some ductility and high strength which was used as a structural material prior to the availability of modern bessemer process steel.

Gray iron, the technical grade comparable to cupola melted iron that would have been available in the late 1800's is rather brittle, although very strong in compression. A good analogy to gray iron is stone, or very strong stone. In a piano you can see a bridge like structure, rather thin and presumably with forces in tension as well as compression, if strength were the primary criteria other materials, historic and modern would be much better.

My suspicion, while possibly incorrect, is based on a pretty good understanding of the chemical and physical properties of cast metals and without a doubt, cast iron was NEVER selected for it's superior strength. It is however much cheaper than wrought iron or bronze to make and as mentioned before has unique resonant properties for metal, which is really the question at hand.

You asserted, rather stridently without any substantiation, that all metals act like a tuning fork or other purposely resonant object and wouldn't be good for driver enclosures. I think my initial proposition is valid that for example a gray iron piano frame is not resonant to the point of being deleterious to tonally correct sound reproduction and some analogies can be made.

For that matter, many old magnet frames for drivers were made from cast iron before being made from stamped steel.

But, really, Bob pretty much debunked the categorical rejection of metals for enclosures using much better reasoning, so maybe you could concede that you are mistaken about your unsubstantiated assertions?

I'm not saying cast iron wasn't a good material from an acoustic point of view, just that that's not why they used it, they used to make everything out of cast iron because it was easy for them. The process originated in the USA mid 19th century, if you look at architecture of the day, much of what looks like stonework is in fact cast iron, it was everywhere, in Manhattan and elsewhere I'm sure, you see whole facades made from it. Forgive me for harping on, (and lets not digress to harps) I just enjoy a little intellectual fencing.

Let me clarify, I mean the process for modern piano manufacture not generally the casting of iron.

Doubting, please excuse my "harping". I too enjoy some fencing, and I'm a little too invested in the topic as my family has been making cast iron for about 100 years now (OK Foundry, Flexible Gray and Ductile Iron Casting.). I'm daily making engineering and architectural recommendations about the selection of materials between gray iron, ductile iron, and sometimes aluminum. (Hopefully correctly, but many times it is a bit subjective).

We are making restoration castings for many of those cast iron storefronts in NYC and one of the biggest challenges we face is educating Architect's that gray cast iron is NOT a structural material and we are often substituting ductile iron for that purpose either as part of the design or just to protect ourselves from the misuse of gray iron. There were a few bridges built in England and some buildings were built with gray iron used as structural supports, but it didn't take long for folks to figure out that gray iron fails catestrophically when overloaded. It essentially has no elastic to plastic yield point, and just breaks when overloaded.

Most of the columns and half columns used in buildings are really "faux" structural elements even from far back. It is mostly today's Architect's and builders that confuse purely decorative purpose with structural as the knowledge of how to use the material has been lost.

The key properties of gray iron are that it is the easiest of all metals to cast and it is cheap due to the abundance of iron and being easily cast. It is not very strong, but it is strong enough and is 3X as strong in compression than tension, AND it absorbs vibration.

Ultimately, I think cast aluminum may be the better material for an enclosure, but I wouldn't want my crusty, rusty friend gray iron ruled out for the wrong reasons (or ruled in).

It may be a silly pursuit to make a cast enclosure, but I have the means to do it, and if there's a couple of other people interested who have better enclosure/driver/crossover etc. design skills to help model the performance, I'd be interested in leveraging their contribution. For example, I think Metrenome is a very good candidate for several reasons and is already designed. And not the least attractive quality is that I think Metrenome would look fantastic with a black patina on a rough sand cast finish for a modern interior space. Or allowed to rust to a dark brown patina and then oiled or clear coated. I could never install a large front loaded horn in my house, but I don't think my wife would ban some iron Metrenome's from the living room (after all she married a foundryman) and I have some friends who'll help me carry them.

Although the castings and shipping wouldn't be cheap, once the foundry pattern is made (which I have people to make who I barter with) it would be easy for me to ship some rough castings to others in the community.

We are making restoration castings for many of those cast iron storefronts in NYC and one of the biggest challenges we face is educating Architect's that gray cast iron is NOT a structural material and we are often substituting ductile iron for that purpose either as part of the design or just to protect ourselves from the misuse of gray iron. There were a few bridges built in England and some buildings were built with gray iron used as structural supports, but it didn't take long for folks to figure out that gray iron fails catestrophically when overloaded. It essentially has no elastic to plastic yield point, and just breaks when overloaded.

Most of the columns and half columns used in buildings are really "faux" structural elements even from far back. It is mostly today's Architect's and builders that confuse purely decorative purpose with structural as the knowledge of how to use the material has been lost.

The key properties of gray iron are that it is the easiest of all metals to cast and it is cheap due to the abundance of iron and being easily cast. It is not very strong, but it is strong enough and is 3X as strong in compression than tension, AND it absorbs vibration.

Ultimately, I think cast aluminum may be the better material for an enclosure, but I wouldn't want my crusty, rusty friend gray iron ruled out for the wrong reasons (or ruled in).

It may be a silly pursuit to make a cast enclosure, but I have the means to do it, and if there's a couple of other people interested who have better enclosure/driver/crossover etc. design skills to help model the performance, I'd be interested in leveraging their contribution. For example, I think Metrenome is a very good candidate for several reasons and is already designed. And not the least attractive quality is that I think Metrenome would look fantastic with a black patina on a rough sand cast finish for a modern interior space. Or allowed to rust to a dark brown patina and then oiled or clear coated. I could never install a large front loaded horn in my house, but I don't think my wife would ban some iron Metrenome's from the living room (after all she married a foundryman) and I have some friends who'll help me carry them.

Although the castings and shipping wouldn't be cheap, once the foundry pattern is made (which I have people to make who I barter with) it would be easy for me to ship some rough castings to others in the community.

Sounds like you know what you're talking about. Concerning the use of cast iron in architecture, my point was simply that it was being used for everything because it was cheap, I know it's not a good material for structure, but I reckon it's good enough for a piano frame and at the time the easiest thing to use.

Good luck with the cabinets, I have an aesthetic soft spot for rust which horrifies some people so I'm sure they will look and sound amazing.

As for being a silly pursuit, that could be said of anything that whent beyond pure practicality.

I hace just built a pair of Woden Designs Vulcan horns which sound superb, I am waiting for a pair of Fostex Fe 203 en-s which should sound even better then the 206's I am currently using. I am lucky enough to have a wife who permits me a few indulgences.

Good luck with the cabinets, I have an aesthetic soft spot for rust which horrifies some people so I'm sure they will look and sound amazing.

As for being a silly pursuit, that could be said of anything that whent beyond pure practicality.

I hace just built a pair of Woden Designs Vulcan horns which sound superb, I am waiting for a pair of Fostex Fe 203 en-s which should sound even better then the 206's I am currently using. I am lucky enough to have a wife who permits me a few indulgences.

Yeah, iron doesn't really truly patina very well, some guys say they can do a blue black like forged metal but that's about it, so rust is one of the few natural color options. It can be polished to a degree and clear coated and when cast with a really rough finish the polished metal has some depth, almost like stone. (See the attached picture. All the metal is iron, worked a little and faux patina'd with pigment.)

I wish I could build a bigger horn, but I think I'll have better luck with "ugly" versus "big" in trying to bring in some speakers. My wife is very indulgent of my foundry work, not so much for big cabinets no matter how nice and certainly not on spendy equipment. So, an extravagent enclosure run through the foundry is lot easier to fund.

I guess it's really time for me to put up, or shut up. With all the work Dave and the other folks have done designing enclosures and matching drivers using the latest quarter wave, horn, and driver loading models, I guess I have all the potential enclosure designs I might need. I'm still liking the Metronome design, but now I can't find the plans.

It would be interesting to see some more organic shapes modeled that could be cast, but maybe I'll need to do that myself as until I do something, why should someone bother. Or I'll see if the for hire designers might help me with the modeling.

I wish I could build a bigger horn, but I think I'll have better luck with "ugly" versus "big" in trying to bring in some speakers. My wife is very indulgent of my foundry work, not so much for big cabinets no matter how nice and certainly not on spendy equipment. So, an extravagent enclosure run through the foundry is lot easier to fund.

I guess it's really time for me to put up, or shut up. With all the work Dave and the other folks have done designing enclosures and matching drivers using the latest quarter wave, horn, and driver loading models, I guess I have all the potential enclosure designs I might need. I'm still liking the Metronome design, but now I can't find the plans.

It would be interesting to see some more organic shapes modeled that could be cast, but maybe I'll need to do that myself as until I do something, why should someone bother. Or I'll see if the for hire designers might help me with the modeling.

Attachments

Doubting, please excuse my "harping". I too enjoy some fencing, and I'm a little too invested in the topic as my family has been making cast iron for about 100 years now (OK Foundry, Flexible Gray and Ductile Iron Casting.). I'm daily making engineering and architectural recommendations about the selection of materials between gray iron, ductile iron, and sometimes aluminum.

Sounds like you have the knowledge & access to facilities to make a 1st class metal loudspeaker. Metal can have properties that let you make a really good box.

If you want to expand on what Bob said, the tenents outlined in this thread are all applicable, http://www.diyaudio.com/forums/cons...ussion-what-materials-build-speakers-out.html, and will give you some criteria to follow when it comes to design decisions.

dave

I'm still liking the Metronome design, but now I can't find the plans.

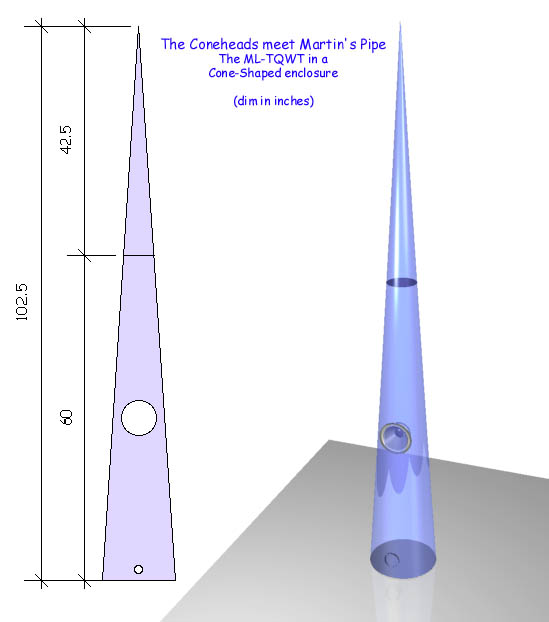

I can probably help there... and working in metal you would have the opportunity to do a conehead variation.

(illustration dimensioned for RS 40-1354 IIRC or maybe FE164)

dave

Yeah, iron doesn't really truly patina very well, some guys say they can do a blue black like forged metal but that's about it, so rust is one of the few natural color options. It can be polished to a degree and clear coated and when cast with a really rough finish the polished metal has some depth, almost like stone. (See the attached picture. All the metal is iron, worked a little and faux patina'd with pigment.)

I wish I could build a bigger horn, but I think I'll have better luck with "ugly" versus "big" in trying to bring in some speakers. My wife is very indulgent of my foundry work, not so much for big cabinets no matter how nice and certainly not on spendy equipment. So, an extravagent enclosure run through the foundry is lot easier to fund.

I guess it's really time for me to put up, or shut up. With all the work Dave and the other folks have done designing enclosures and matching drivers using the latest quarter wave, horn, and driver loading models, I guess I have all the potential enclosure designs I might need. I'm still liking the Metronome design, but now I can't find the plans.

It would be interesting to see some more organic shapes modeled that could be cast, but maybe I'll need to do that myself as until I do something, why should someone bother. Or I'll see if the for hire designers might help me with the modeling.

Go for it, I'd be amazed if someone didn't want to help with the design, they could be in on something historic, the pictured sculpture is very cool. has anyone ever built a cast iron speaker?

- Home

- Loudspeakers

- Full Range

- Metal Speaker Enclosures ? A bad idea ?