Well just one point - my floor is tiled directly onto a reinforced concrete slab 45cm thick. The speakers are on spikes not the tiles. We have rugs to absorb the reflections off of the floor but not under the speakers. Point is I can not imagine much vibration/ sound coming of a 45cm thick concrete slab.

Tried swapping the granite for a pair of bookshelf speakers.

Nothing like the same, all sorts of - well I carnt explain it really; confused is the best word.

I'll just say again - it is totally possible that it is just my speakers in my living room. And better be more specific as well. It is not more bass - it is the solidity and especially the attack of the bass that has improved not the quantity or how low it goes. The overall improvement is also in the attack but tiny details are better separated and not delivered as one combined background sound.

The best description is - it is as if you have tightened up a screw, everything is more solid.

Tried swapping the granite for a pair of bookshelf speakers.

Nothing like the same, all sorts of - well I carnt explain it really; confused is the best word.

I'll just say again - it is totally possible that it is just my speakers in my living room. And better be more specific as well. It is not more bass - it is the solidity and especially the attack of the bass that has improved not the quantity or how low it goes. The overall improvement is also in the attack but tiny details are better separated and not delivered as one combined background sound.

The best description is - it is as if you have tightened up a screw, everything is more solid.

Did you compare using the boxes against nothing on top? I think the suggested point was that bass and diffraction could each be contributing their own issue, although it seems you've shown one of these effects at least.

Were the bookshelf speakers facing front? With drivers in that could resonate from the sound field in the air? Try turning them to face side or rear, and see if that makes a different. Could also try shorting the connections on the bookshelf speakers, that could damp the woofer some.

Were the bookshelf speakers facing front? With drivers in that could resonate from the sound field in the air? Try turning them to face side or rear, and see if that makes a different. Could also try shorting the connections on the bookshelf speakers, that could damp the woofer some.

Tried them both ways round, results as follows:

Speakers as normal - Ill give an arbitrary 70/100

Bookshelf facing cone to front - not good - 60/100

Bookshelf side on - confused - 63/100

Speakers + Granite - Better attack, solidity and detail - 74/100

It does seem to keep improving the more weight I add but my desire not to have to buy new speakers after these crush under the weight prevented serious testing

There is another alternative - my tweeters are in a separate enclosure at the top - I could fill this with lead shot if i insulate the connectors.

Still guessing here, but could the added weight be putting the panels under strain, ie: indicating panel resonance concerns?

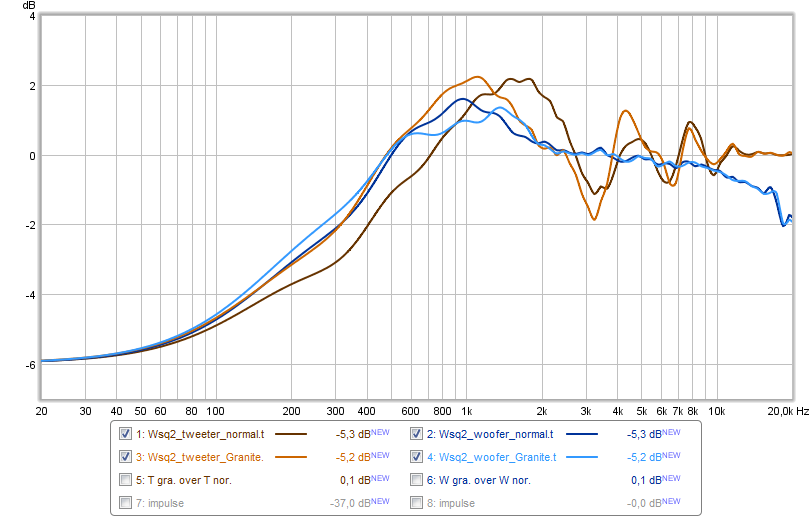

Did look bit into baffle and diffraction effects so we have some more data to look at in this regard to isolate from weight and tension talk, hope research data/math/methods used is right done and Stuck In Bulgaria can check if these settings is okay:

Normal baffle: 200mm x 975mm baffle with woofer piston 136mm (diameter middle of surround) at height 765mm, tweeter piston 25mm at height 912mm.

Baffle plus 125mm stacked granite at top: 200mm x 1100mm baffle with driver diameters and positions as above.

Started in The Edge make the two woofer and tweeter scenarios seen in attachment 1 plus two and exported those four responses as frd-files.

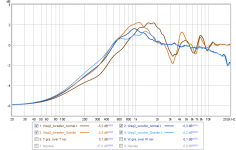

Imported files to REW to later do some math here is overlay of them four ones:

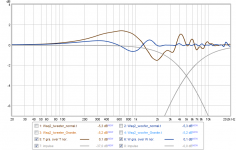

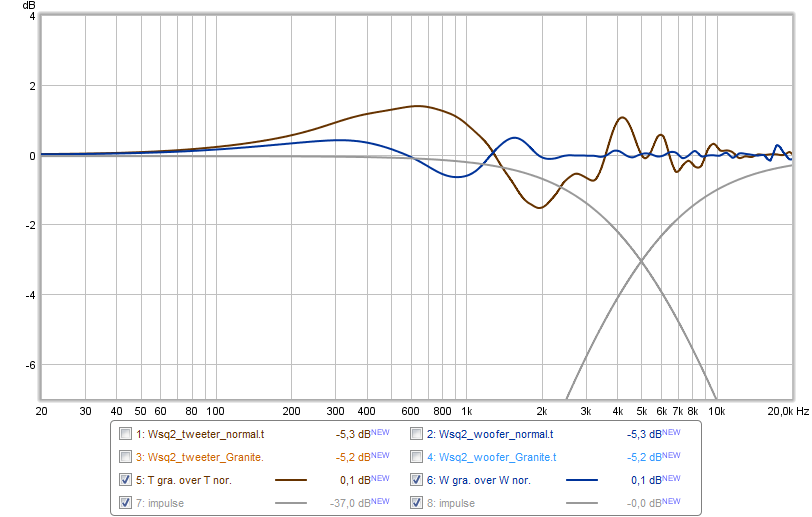

This plot should be the exiting one and tell difference for response with baffle set 125mm higher verse normal.

Math used was let REW output (Granite / Normal) for tweeter (Brown) and woofer (Blue) and we now see that

isolated response change and as help to mind added the 1st order 5kHz XO point. Think about what we don't know

is how real response was with normal baffle in situation for particular living room but below should tell the new EQ

corrected response:

Normal baffle: 200mm x 975mm baffle with woofer piston 136mm (diameter middle of surround) at height 765mm, tweeter piston 25mm at height 912mm.

Baffle plus 125mm stacked granite at top: 200mm x 1100mm baffle with driver diameters and positions as above.

Started in The Edge make the two woofer and tweeter scenarios seen in attachment 1 plus two and exported those four responses as frd-files.

Imported files to REW to later do some math here is overlay of them four ones:

This plot should be the exiting one and tell difference for response with baffle set 125mm higher verse normal.

Math used was let REW output (Granite / Normal) for tweeter (Brown) and woofer (Blue) and we now see that

isolated response change and as help to mind added the 1st order 5kHz XO point. Think about what we don't know

is how real response was with normal baffle in situation for particular living room but below should tell the new EQ

corrected response:

Attachments

Last edited:

Ok - having done a lot of messing around with different topographies and weights i came to the conclusion (based purely on listening tests) that it is indeed a number of factors making up the difference.

I stood one granite tile on its end at the front so as to have a set baffle extension and then i altered the number behind. More weight = better sound in many respects.

No weight apart from the one tile extending the baffle v no tile. Yes big difference but mostly in the treble.

Weight positioned further back on the speaker top have less effect on the baffle - some improvement.

Then i started to conciser the construction of the speakers.

the WB Sq2's have a well made very rigid cabinet that is bolted with 4 x 8mm bolts to the plinth. 4 x 2mm washer spacing and this allows bottom venting through the floor of the actual cabinet.

However - and this has always been my gripe with them - the plinth is 40mm mdf below that is a 4mm steel plate the spikes screw into and the heads of the bolts rest upon washers that in turn rest on the steel plate. So its a sandwich of bolt head, washer, steel, MDF, washer, wood and nut. Plus the spike locations are say 130mm from the bolts and the steel plate is effectively "free floating" at that point. I always suspected this arrangement was allowing a LOT of flex.

So thinking about this i concluded a good deal of the improvement may be from forcing the speaker harder down on to the steel plate allowing less movement.

Fast Forwards

I now have the speakers directly bolted to a (god knows how many kg’s - not easily liftable on your own for sure) marble plinth 750mm x 450mm x 60mm. I further upgraded the fixings inside the cabinet and the torque holding the cabinet to the marble base is as much as i dare put on 4 8mm stainless bolts.

BIG BIG difference - can not easily quantify it, but serious difference.

NEXT - and i was so convinced this was going to do nothing at best or possibly make things worse - i got 4 of those super bouncy balls, crazy balls i think they are called? Cut them in half to make 8 very elastic but dense feet to replace the spikes.

HUGE DIFFERENCE - COLOSSAL - £4k upgrade in speakers kind of difference.

I was not prepared for this. I was convinced there was no way my speakers were making this solid concrete floor move a micron. I have literally never had a component upgrade (amp, speakers, DAC) make as much difference as swapping the factory spiked sandwich of a plinth for 2 paving slabs of marble and 4 crazy balls - £16 total expenditure.

I have not had a chance to play with the granite up top since this change but I'll update as i can.

What i was wondering - if BYRTT or anyone else with knowledge / software could work out a baffle extension left side, up and right that would further improve issues Id be very grateful.

Im assuming the front baffle is not perfect or all speaker manufacturers would use that configuration - i can not easily make it smaller but ordering a pice of granite cut to size and shape is easy enough. I can also have the edges rounded or sloped, tapered etc.

[EDIT]

Thinking about it - as granite is so cheep here (£20 - £60 m2) and labor is also cheep - i could easily have the entire cabinets replicated in granite for id guess £200 the pair - is there any mileage in that? Granite is a fairly rigid and "dead" material - my first impression is it would make good cabinets.

I stood one granite tile on its end at the front so as to have a set baffle extension and then i altered the number behind. More weight = better sound in many respects.

No weight apart from the one tile extending the baffle v no tile. Yes big difference but mostly in the treble.

Weight positioned further back on the speaker top have less effect on the baffle - some improvement.

Then i started to conciser the construction of the speakers.

the WB Sq2's have a well made very rigid cabinet that is bolted with 4 x 8mm bolts to the plinth. 4 x 2mm washer spacing and this allows bottom venting through the floor of the actual cabinet.

However - and this has always been my gripe with them - the plinth is 40mm mdf below that is a 4mm steel plate the spikes screw into and the heads of the bolts rest upon washers that in turn rest on the steel plate. So its a sandwich of bolt head, washer, steel, MDF, washer, wood and nut. Plus the spike locations are say 130mm from the bolts and the steel plate is effectively "free floating" at that point. I always suspected this arrangement was allowing a LOT of flex.

So thinking about this i concluded a good deal of the improvement may be from forcing the speaker harder down on to the steel plate allowing less movement.

Fast Forwards

I now have the speakers directly bolted to a (god knows how many kg’s - not easily liftable on your own for sure) marble plinth 750mm x 450mm x 60mm. I further upgraded the fixings inside the cabinet and the torque holding the cabinet to the marble base is as much as i dare put on 4 8mm stainless bolts.

BIG BIG difference - can not easily quantify it, but serious difference.

NEXT - and i was so convinced this was going to do nothing at best or possibly make things worse - i got 4 of those super bouncy balls, crazy balls i think they are called? Cut them in half to make 8 very elastic but dense feet to replace the spikes.

HUGE DIFFERENCE - COLOSSAL - £4k upgrade in speakers kind of difference.

I was not prepared for this. I was convinced there was no way my speakers were making this solid concrete floor move a micron. I have literally never had a component upgrade (amp, speakers, DAC) make as much difference as swapping the factory spiked sandwich of a plinth for 2 paving slabs of marble and 4 crazy balls - £16 total expenditure.

I have not had a chance to play with the granite up top since this change but I'll update as i can.

What i was wondering - if BYRTT or anyone else with knowledge / software could work out a baffle extension left side, up and right that would further improve issues Id be very grateful.

Im assuming the front baffle is not perfect or all speaker manufacturers would use that configuration - i can not easily make it smaller but ordering a pice of granite cut to size and shape is easy enough. I can also have the edges rounded or sloped, tapered etc.

[EDIT]

Thinking about it - as granite is so cheep here (£20 - £60 m2) and labor is also cheep - i could easily have the entire cabinets replicated in granite for id guess £200 the pair - is there any mileage in that? Granite is a fairly rigid and "dead" material - my first impression is it would make good cabinets.

Last edited:

Are you referring to the nature of panel excitation due to the placement of the finite mounting surface, or to resonance due to the magnet mass coupled to the cabinet through a compliant basket?but the structural vibrations that get into the cabinet walls through the frame of the driver - mostly by the reactive force of the magnet against the voice coil.

...

For example, I saw a large improvement in my speaker responses when I used a low mass woofer (neo.) The cone mass did not change, but the magnets reactive force on the cabinet through the frame would have been substantially reduced.

Within the last couple of days I read a post by Patrick Bateman (John) where he held down some subs he put together and found one type of sub he'd always disliked just had issues with bouncing up and down. Weight on top took care of the problem.

I also read his post on the sonotube sub that committed suicide by jumping off what sounded like a second story deck. Just about p***ed myself reading that post.

If you have speakers with less resonance in the cabinet weight on top would make less of a difference. This "fix" is probably better for some speakers than others. The volume you play music at would also have a lot to do with needing more weight on the speaker.

Grant.

I also read his post on the sonotube sub that committed suicide by jumping off what sounded like a second story deck. Just about p***ed myself reading that post.

If you have speakers with less resonance in the cabinet weight on top would make less of a difference. This "fix" is probably better for some speakers than others. The volume you play music at would also have a lot to do with needing more weight on the speaker.

Grant.

I've had some time with RBH Status Granite speakers. Pretty good sounding, how much of that was due to the solid granite cabinet.... I'll never know🙂. I've heard other speakers from the same manufacturer made from MDF that sounded good too.....

Are you referring to the nature of panel excitation due to the placement of the finite mounting surface, or to resonance due to the magnet mass coupled to the cabinet through a compliant basket?

The magnet mass resonance against the basket. This causes a dip in the response at that frequency that I have seen in every woofer that I have looked at with a ceramic magnet.

Pilover - there does tend to be a liberal use of the volume.

HOWEVER....... since the "improvement" i dont feel i have to crank it up as much

HOWEVER....... since the "improvement" i dont feel i have to crank it up as much

The way I noticed quality improvement is realizing that I listened at way louder levels than I thought I was. Only noticing it trying to start a conversation 😉.

I have a SPL meter handy ever since, and put the volume on a fixed level trying to avoid listening way too loud. Letting my software player (JRiver) handle the average listening levels to keep it sane. Listening levels do have quite an effect on (my perceived) imaging though.

I have a SPL meter handy ever since, and put the volume on a fixed level trying to avoid listening way too loud. Letting my software player (JRiver) handle the average listening levels to keep it sane. Listening levels do have quite an effect on (my perceived) imaging though.

Id agree with you there wesayso - after i wrote that last night I thougt, actually that is not quite right. You first started off after the improvement with the dial way higher than you used to have it. NOW you have it much lower - the reason being it is actually a lot harder to discern the "volume level".

To enjoy the music previously there was a tenancy to crank it up - that no longer seems as necessary.

To enjoy the music previously there was a tenancy to crank it up - that no longer seems as necessary.

Here's my solution for the floor coupling:

(nut missing in this pic)

I bet it's working pretty similar to your super bouncy balls 😀.

(nut missing in this pic)

I bet it's working pretty similar to your super bouncy balls 😀.

Last edited:

wesayso just pointed me to this thread.

I am in the process of making 2 boxes of marble, one for a full range W8-1772.and another for the W8-740Q.

They should carry some weight. I am thinking of 1.5cm for the sides, and 2cm for the baffle. They will be backed with plywood, epoxy from the inside.

I initially though about using urethane disks between the support and also in between the two boxes.

It will be an ongoing process...

I am in the process of making 2 boxes of marble, one for a full range W8-1772.and another for the W8-740Q.

They should carry some weight. I am thinking of 1.5cm for the sides, and 2cm for the baffle. They will be backed with plywood, epoxy from the inside.

I initially though about using urethane disks between the support and also in between the two boxes.

It will be an ongoing process...

A few (haha) years ago I was in Lima, Ohio and Bruce Edgar did us the favor of giving a talk on horns. In it he mentioned how he found resonance in the cabinet. If memory serves he lay the speaker on it's side and spread a thin layer of sand on it an looked at what bounced.

That sounded like an interesting way to find resonance points.

Grant.

That sounded like an interesting way to find resonance points.

Grant.

I am thinking of 1.5cm for the sides, and 2cm for the baffle. They will be backed with plywood, epoxy from the inside.

.

Marble does not have a great shear strength and 1.5cm is actually very thin for marble. The guys i get my stuff of don't even like handling 2cm - you have to remember is is a sedimentary rock laid down in layers. They have a tendency to brake along these lines. Granite is igneous and has an interlinked crystalline structure which gives it far grater strength.

I am just worried that all your hard work could easily be ruined in the future by a small accident cracking one of the panels.

As far as the isolation goes - super bouncy balls rock. Literally. The one downer is the only place i can find them is a bubble gum type vending machine in the sea gardens. There are the super bouncy one that are great for this job and solid rubber ones that are US. The ratio of rubber to super is about 6 to 1 against - so i now have a huge collection of 1" solid rubber balls. Everyone who visits HAS to bounce the ***** and inevitably looses them. Then my dog keeps finding them and choking on them.

Listening levels do have quite an effect on (my perceived) imaging though.

If I needed to increase volume to high levels to get imaging I'd be wondering if I was listening to reflections to get the image.

Grant.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- MASS - Can It Realy Be That Easy To Upgrade?