why?

Big baffles don't fit in small places.

Japanese houses have small rooms.

can you show some examples?

This is the characteristic of ducted FH.

Unfortunately, there is no comparison video.

This is the characteristic of ducted FH.

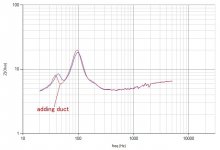

The rear mouth chart looks to me like there is significant drop (-5 db) in bass output below 200hz with the duct added.

What am I missing? It looks much worse to me. The sound was too "boomy" too much upper bass before the duct?

Nowadays much simpler than earlier thanks to both the Loudspeaker Wizard I posted a screenshot of and the much newer Input Wizards in the Help File that allows one to choose many different alignments + offset driver, vent, then it makes a demo that you can change to suit. Horn design has its own versions plus IIRC if you input a horn design it will reverse engineer the driver's optimal specs.Now I just gotta learn how to use HR

Really, not much need for the HELP file till getting into the myriad relatively recent multiple pipe alignments.

The rear mouth chart looks to me like there is significant drop (-5 db) in bass output below 200hz with the duct added.

What am I missing? It looks much worse to me. The sound was too "boomy" too much upper bass before the duct?

Please don't trust the words or graphs of others.

By all means, do your own follow-up tests.

Attachments

I think that if you examine carefully the drawing you will see that 26 slides over 12 as well as 28 slides over 21 to adjust the DACT AREAIt looks unnecessary complicated 12 and 26 could be replaced by an extension of 11 and 21 and 28 by an extension of 18.

Elias

Nandappe No 4 & No15 are forming triangle cavities ? From the videos you have uploaded to youtube the sound to my ears is clean and balanced . Not "bright" as with DDBH.This enclosure has a unique construction and does not use sound absorbing materials.

Compared to enclosures of other structures, it produces a unique sound.

The touching points between 2&3 , 8&9 (and some more) are left "just touching" and not airtight joined on purpose ?

(Maybe this is the floor stander I was(?) seeking for) 😉

What if the baffle and the rear panel will be real wood ? Also all these small pieces ? Hard wood or pine? Do we need a "live wood" or "a dead silent" material ?

Elias

Last edited:

Where in the states can this driver be purchased & at what cost? Sounds intriguing. Pun intended

Nandappe No 4 & No15 are forming triangle cavities ? From the videos you have uploaded to youtube the sound to my ears is clean and balanced . Not "bright" as with DDBH.

The touching points between 2&3 , 8&9 (and some more) are left "just touching" and not airtight joined on purpose ?

(Maybe this is the floor stander I was(?) seeking for) 😉

What if the baffle and the rear panel will be real wood ? Also all these small pieces ? Hard wood or pine? Do we need a "live wood" or "a dead silent" material ?

Parts 4 and 15 are for volume adjustment.

They are currently removed and adjust the volume of the back chamber.

In CHP-90, used two triangular block.

2 and 3, 8 and 9, and the other line adhesion, but it is not cut diagonally because it is troublesome.

If you use glue and screws together, I don't think there will be any gaps.

Please use any kind of wood you like.

Hard wood will sound hard and soft wood will sound soft.

Attachments

Elias

I get that about the adjustable ducts, but once decided for a specific driver they are not that useful. The 1 m response is OK but more usefull when testing the duct opening is to measure the response of the driver at very close distance. There will be dips in the frequency response at the driver corresponding to output from the pipe. Reducing the duct area should just lower the frequency of the dip until the area is substantially less than the cone area say 0.5-0.7 of cone area. Then losses will start to reduce the output.

The effective output is a bit more complicated due to phase differences in the outputs ducts and driver, vector additions anyone?

I get that about the adjustable ducts, but once decided for a specific driver they are not that useful. The 1 m response is OK but more usefull when testing the duct opening is to measure the response of the driver at very close distance. There will be dips in the frequency response at the driver corresponding to output from the pipe. Reducing the duct area should just lower the frequency of the dip until the area is substantially less than the cone area say 0.5-0.7 of cone area. Then losses will start to reduce the output.

The effective output is a bit more complicated due to phase differences in the outputs ducts and driver, vector additions anyone?

1 m response has less meaning for me.The effective output is a bit more complicated due to phase differences in the outputs ducts and driver, vector additions anyone?

The distance between the enclosures in my case is about 2,9 m and the distance between any of the enclosures and listening position is about 3,1 m (Behind the L.P. there is wall at a 0.6m covered with thick curtain) . The enclosures will placed close to room corners (lets say the front side of the driver if we consider it as "point source" will be at about 60cm from the sides of the corner) . Here starts the game of adjustments to the needs of the room in conjunction with my personal taste and as it is profound the need for sliding parts.

Elias

Soft can sounds maybe a little dull ?Please use any kind of wood you like.

Hard wood will sound hard and soft wood will sound soft.

I'm asking due to in Greece we make clarinets and flutes from olive tree wood and maybe I can source some (it is not extremely expensive) for internals (2, 3, 7, 8, 9, 13, 14, 16, 19, 20). Plywood is very easy material but... not for wooden musical instruments and "horn" looks to me like as such.

Elias

Last edited:

Yes, it is very much about personal taste. Do you hear a different sound with different wood? Good luck!1 m response has less meaning for me.

The distance between the enclosures in my case is about 2,9 m and the distance between any of the enclosures and listening position is about 3,1 m (Behind the L.P. there is wall at a 0.6m covered with thick curtain) . The enclosures will placed close to room corners (lets say the front side of the driver if we consider it as "point source" will be at about 60cm from the sides of the corner) . Here starts the game of adjustments to the needs of the room in conjunction with my personal taste and as it is profound the need for sliding parts.

Elias

Woods treated differently behave differently. To be a little more specific. Wood treated with sheep milk behaves differently (moisture & temperature variations) from wood treated with melted beeswax or with paraffin oilYes, it is very much about personal taste. Do you hear a different sound with different wood? Good luck!

Elias

Last edited:

I have only used MDF. Maybe it sound different with wood. I dont know.Woods treated differently behave differently. To be a little more specific. Wood treated with sheep milk behaves differently from wood treated with melted beeswax or paraffin oil

Elias

Treated MDF I dont know if it make any different?

As two minor points:

-'Softwood' is not necessarily 'softer' than a hardwood (and visa versa). It depends on the wood species and the grain structure of the boards, and especially how well dried & sealed it is. I well recall GM describing building a box 20+ years ago out of pine boards that had been part of a 150 year-old barn in Georgia. The stiffness / weight ratio was roughly that of aluminum.

-A loudspeaker is not an instrument. It's a loudspeaker. Its job is to reproduce an electrical signal, which represents a recording of instruments, voices & the like. The original instruments etc. have already produced sound; if you want an accurate reproduction of that recorded signal, then the loudspeaker should not introduce colourations of its own devising. Speakers deliberately designed to produce colourations of their own from panel resonance etc. can sound enjoyable on certain material, which in itself is fair enough if that's what you like (this is a hobby after all) -but it's not technically accurate, and unlikely to be particularly flexible across all genres. A speaker designed to resonate like a cello may sound quite good when fed Bach's suites for unaccompanied cello (other cello music available), but probably not so hot when Coltrane lets rip on sax, or Rick Wakeman fires up the old MiniMoog.

-'Softwood' is not necessarily 'softer' than a hardwood (and visa versa). It depends on the wood species and the grain structure of the boards, and especially how well dried & sealed it is. I well recall GM describing building a box 20+ years ago out of pine boards that had been part of a 150 year-old barn in Georgia. The stiffness / weight ratio was roughly that of aluminum.

-A loudspeaker is not an instrument. It's a loudspeaker. Its job is to reproduce an electrical signal, which represents a recording of instruments, voices & the like. The original instruments etc. have already produced sound; if you want an accurate reproduction of that recorded signal, then the loudspeaker should not introduce colourations of its own devising. Speakers deliberately designed to produce colourations of their own from panel resonance etc. can sound enjoyable on certain material, which in itself is fair enough if that's what you like (this is a hobby after all) -but it's not technically accurate, and unlikely to be particularly flexible across all genres. A speaker designed to resonate like a cello may sound quite good when fed Bach's suites for unaccompanied cello (other cello music available), but probably not so hot when Coltrane lets rip on sax, or Rick Wakeman fires up the old MiniMoog.

But MDF it is already treated by its construction method (glue + wood "dust"). Doesn't absorbs (practically) moisture. Neither "chipboard" or OSBI have only used MDF. Maybe it sound different with wood. I dont know.

Treated MDF I dont know if it make any different?

Elias

😏 😏 🤔 In Greece they used to build parts of wooden roofs from mulberry wood. Today when we restore such old (older than 150 y.o.) houses often we get those woods to make the top cover for strings musical instruments and believe me they sounds GRATE no mater if they perform Dimitris Layos music or mid century's "madrigalia". I know that "musicality" - if I may use the term - is independent of the musical genre. (this is a hobby after all) Yes I do agree with you Scott and for this reason I try to explore 🤓(this is a hobby after all) ......... A speaker designed to resonate like a cello may sound quite good when fed Bach's suites for unaccompanied cello (other cello music available), but probably not so hot when Coltrane lets rip on sax, or Rick Wakeman fires up the old MiniMoog.

Elias

I'm sure it does sound great when used in musical instruments. As noted though -there is a fundamental difference between an instrument and a loudspeaker. Normally, we try to minimise audible panel resonances as they are ultimately just added colouration (i.e. they are not part of the recording). But, as I also said -this is just a hobby, so if you enjoy the effect, there's nothing wrong with that. And it's often fun to experiment with these things -it's a good way of learning how box construction can affect presentation in different ways for e.g.

- Home

- Loudspeakers

- Full Range

- MarkAudio CHP-90 mica + SDDBH-T13.5R-AD (Dual Back-loaded Horn adding adjustable Duct, no sound absorber)