Good day everyone,

I am building a 2 way speaker with a 8" Fenton Midbass driver and a viper dome tweeter. I have managed to get a decently flat frequency response using Xsim software for the crossover design.

The issue that I have now is that we do not have any localy manufactured crossover components and importing such components from the US (Parts express) is extremely expensive.

Is there anyone that can assist me with the equipment and or aids required to wind your own inductors? Resistors and capacitors I have already procured and is not an issue.

I have also obtained the enameled copper wire required but the plastic coil formers and bobbins are an issue. I also require a 5.5mH inductor for the midbass driver which might require an iron core of some sort.

Please help 😕

I am building a 2 way speaker with a 8" Fenton Midbass driver and a viper dome tweeter. I have managed to get a decently flat frequency response using Xsim software for the crossover design.

The issue that I have now is that we do not have any localy manufactured crossover components and importing such components from the US (Parts express) is extremely expensive.

Is there anyone that can assist me with the equipment and or aids required to wind your own inductors? Resistors and capacitors I have already procured and is not an issue.

I have also obtained the enameled copper wire required but the plastic coil formers and bobbins are an issue. I also require a 5.5mH inductor for the midbass driver which might require an iron core of some sort.

Please help 😕

You don’t need a former to wind the coil. Just use a wooden round dowel and wrap around that. Put plastic around the wood to make it easy to slide the coil off when done. The larger coil is not too big to make air core. Finding a iron core is not easy or really needed. Once off the wooden former use zip ties to hold the coil together or drip varnish on the coil while on the former and let it dry. The plastic will allow you to take it off. Try it it’s easy. Overwind the coil so if it changes when you slide it off you can unwind it to the correct value.

Low ESR ferrite core Jantzen Audio 000-5401

Search | Hifi Collective

Low ESR air core Jantzen Audio 000-0038

Search | Hifi Collective

Parts Express has the most outrageous freight charges I have ever come across, apart from eBay's global shipping program! HiFi Collective's are much, much cheaper.

Search | Hifi Collective

Low ESR air core Jantzen Audio 000-0038

Search | Hifi Collective

Parts Express has the most outrageous freight charges I have ever come across, apart from eBay's global shipping program! HiFi Collective's are much, much cheaper.

Winding your own air cored crossover inductors is straight forward if you have the wire and a round bit of broom handle. It helps enormously if you have a DMM that measures inductance. I have wound 4.5 MH that way while listening to Classic FM in about an hour. It helps to calculate the diameter required as a guide (online calculator) and measure when around the mark for accuracy. My inductors for the bass-mid speaker are 13 awg enameled copper wire.

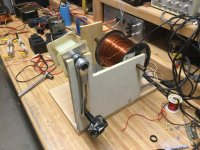

It’s fairly easy to put together a hand crank to make transformers and speaker inductors. Saves a lot of wear and tear on your fingers. You can make your own bobbins out of a piece of PVC pipe and a couple pieces of 1/8” wood/fiberboard if you don’t need to fit transformer laminations in them. While getting relatively orderly rows of turns isn’t critical, it helps get the most turns with the minimum length wire.

Attachments

It’s fairly easy to put together a hand crank to make transformers and speaker inductors. Saves a lot of wear and tear on your fingers. You can make your own bobbins out of a piece of PVC pipe and a couple pieces of 1/8” wood/fiberboard if you don’t need to fit transformer laminations in them. While getting relatively orderly rows of turns isn’t critical, it helps get the most turns with the minimum length wire.

That is a great idea. Click your foot on and you have two free hands for guiding the wire.

It’s fairly easy to put together a hand crank to make transformers and speaker inductors. Saves a lot of wear and tear on your fingers.

Cheap chinese winders are available complete with conical pieces for locating various sizes of former and with turn-counting mechanism.

When I made mine, I wound them on a lathe using a wooden former and side cheeks. Take it carefully and don't get caught in the wire. (unlike my hair when I was twisting the strands together initially!). This one is 2.2mh, I made 4.

Though if doing a few, the cheap winders might be a better idea.

Though if doing a few, the cheap winders might be a better idea.

Attachments

Last edited:

- Home

- Design & Build

- Parts

- Making your own crossover inductors