I saw a thread on here about Cinder Block Speakers and am very intrigued.

The block I am thinking about using

I'm fairly new to this and could use some help

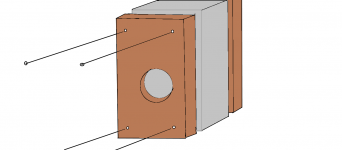

Here is what I have mocked up so far

Couple Questions and Facts

The ~sealed volume of each cavity is .217 ft cubed. Should I go for a sealed enclosure or a ported. Based on my research a sealed enclosure is both easier and more forgiving. Looking at the gif they have clearly made an effort to combine both cavities which seems like the best course of action for either sealed or ported

Based on the size of the cavities, I think it makes sense to have a 4" driver. The Dayton Audio one I have looked at have a sealed vol of .18ft cubed which means (if i understand) that this cavity is actually WAY too big for those drivers? It would be even more mismatched if you added both cavities to the sealed volume. Any suggested drivers.

Crossovers: I have tried to understand the ideal crossover point but I really am missing something here and could use some advice. I need a crossover for each driver right? This is the tweeter I think makes the most sense Frequency response is 1,600 to 20,000Hz so does that mean I want to get a crossover between 1500 or 2000hz

For additional parts that I need:

Speaker Terminal

Already have speaker cable (14 gauge monoprice)

Gasketing Tape to make seals

Glue to connect wood to cement when complete.

Am I missing anything here?

Any help would be much appreciated. I have tried to do a lot of my own research but i'm very new and don't know what I don't know

The block I am thinking about using

I'm fairly new to this and could use some help

Here is what I have mocked up so far

Couple Questions and Facts

The ~sealed volume of each cavity is .217 ft cubed. Should I go for a sealed enclosure or a ported. Based on my research a sealed enclosure is both easier and more forgiving. Looking at the gif they have clearly made an effort to combine both cavities which seems like the best course of action for either sealed or ported

Based on the size of the cavities, I think it makes sense to have a 4" driver. The Dayton Audio one I have looked at have a sealed vol of .18ft cubed which means (if i understand) that this cavity is actually WAY too big for those drivers? It would be even more mismatched if you added both cavities to the sealed volume. Any suggested drivers.

Crossovers: I have tried to understand the ideal crossover point but I really am missing something here and could use some advice. I need a crossover for each driver right? This is the tweeter I think makes the most sense Frequency response is 1,600 to 20,000Hz so does that mean I want to get a crossover between 1500 or 2000hz

For additional parts that I need:

Speaker Terminal

Already have speaker cable (14 gauge monoprice)

Gasketing Tape to make seals

Glue to connect wood to cement when complete.

Am I missing anything here?

Any help would be much appreciated. I have tried to do a lot of my own research but i'm very new and don't know what I don't know

Attachments

There's a thread on the topic already, which you should look at if you have not already seen it:

RE Cinder Block Kits

----

General noob tips:

If you want to simplify it right down, just use a full range driver.

e.g. 1 buy a pair of nice little drivers, like the Visaton B80.

Put them in sealed cabs. Play music. Done. Later on: add a subwoofer. This makes a "FAST" system (Fullrange And Subwoofer).

e.g. 2 copy a simple design that's already out there.

There are plenty of FAST examples you can copy, and other similarly simple builds.

e.g. 3 post 10 of this thread has a parts list for a build that might work well in a cinderblock:

Need help building open baffle/bass reflex hybrid

"Gasketing Tape to make seals"

For which part?

Most drivers already have a ring of foam / whatever for seals, and you can seal the speaker terminal in with glue.

"Glue to connect wood to cement when complete."

You'll need to fill in a bit of space to get a good seal between the concrete and wood, so use (a) lots of cheap gap-filling glue (the type that comes in a tube for use in glue guns), or (b) something like polyurethane, which expands a bit as it sets.

RE Cinder Block Kits

----

General noob tips:

If you want to simplify it right down, just use a full range driver.

e.g. 1 buy a pair of nice little drivers, like the Visaton B80.

Put them in sealed cabs. Play music. Done. Later on: add a subwoofer. This makes a "FAST" system (Fullrange And Subwoofer).

e.g. 2 copy a simple design that's already out there.

There are plenty of FAST examples you can copy, and other similarly simple builds.

e.g. 3 post 10 of this thread has a parts list for a build that might work well in a cinderblock:

Need help building open baffle/bass reflex hybrid

"Gasketing Tape to make seals"

For which part?

Most drivers already have a ring of foam / whatever for seals, and you can seal the speaker terminal in with glue.

"Glue to connect wood to cement when complete."

You'll need to fill in a bit of space to get a good seal between the concrete and wood, so use (a) lots of cheap gap-filling glue (the type that comes in a tube for use in glue guns), or (b) something like polyurethane, which expands a bit as it sets.

Couple Questions and Facts

The ~sealed volume of each cavity is .217 ft cubed.

Based on the size of the cavities, I think it makes sense to have a 4" driver. Dayton Audio one I have looked at have a sealed vol of .18ft cubed which means (if i understand) that this cavity is actually WAY too big for those drivers? It would be even more mismatched if you added both cavities to the sealed volume. Any suggested drivers.

Sorry, don't keep up with what's available, just try to answer whatever tech Qs I have a clue about.

Actually, no since the popular 0.707 Qtc max flat sealed alignment requires ~0.71 ft^3 based on its Fs, Vas, Qts specs: Closed Sealed Subwoofer Box Equations Formulas Design Calculator Constant

a = 1.04 ft^3/0.217 = ~4.7926

Qtc = [4.7926+1]^0.5 * 0.66 = ~1.59 Qtc

P.E. 0.18 ft^3 = ~1.72 Qtc

From this, personally would open up the space and use all 0.434 ft^3 since the driver will take up some space and it's still a bit small for this driver's specs, especially since wiring losses will further increase the Qtc calcs:

[Qts']: [Qts] + any added series resistance [Rs]: Calculate new Qts with Series Resistor

[Rs] = 0.5 ohm minimum for wiring, so may be higher if a super small gauge is used as a series resistor plus any added resistance from an XO/whatever.

This chart gives an idea how much under-damped 'hump' is in these responses [attached]:

Attachments

This is super helpful and I really appreciate the response. Will dig in and make sure I fully understand before I ask any further questions

What hollowman said.

There are anumber of good FRs that will work in a sealed 6ish litre box. No 3” that i know of.

Mark Audio Pluvia 7HD would be my first suggestion ignoring budget.

dave

There are anumber of good FRs that will work in a sealed 6ish litre box. No 3” that i know of.

Mark Audio Pluvia 7HD would be my first suggestion ignoring budget.

dave

I feel like it will look unbalanced if there is only one driver. Thoughts?

I'm saving a ton on the enclosure so spending 50-90 dollars on a driver is fine.

I could use half a cinder block and make two speakers?

I'm saving a ton on the enclosure so spending 50-90 dollars on a driver is fine.

I could use half a cinder block and make two speakers?

Given one would cutout the divider section between the cavities, I get eight inches deep, eight and a half inches wide, & I'm guessing twelve and a half inches high. This comes out to 850 cubic inches, or 0.491 cubic foot, or 13.929 liters...The five inch fullrange Tangband driver, the W5-1611SAF wants 0.44 cubic feet interior volume with a port for an F3 of 56 hertz...now considering the volume is a little bit larger, retuning with the larger volume will probably get you a lower F3 extension...maybe 40-45 hertz?

___________________________________________________Rick...

___________________________________________________Rick...

Other than the plasticy sounding top a good driver.

13 litres does give a different set of drivers. Mark Audio Alpair 10.3/10p if you can find them.

dave

13 litres does give a different set of drivers. Mark Audio Alpair 10.3/10p if you can find them.

dave

By all means, get an ironclad volume value...and if one is up to the challenge, download some of the free simulation programs & go nuts!!!

Pull up the T/S parameters for bunches of drivers,,,six to ten choices should get you one that you like just fine. The fourteen or so liters worth should give you a wide variety.

Some good acoustic absorbing stuffing inside, maybe butcherblock wood panels front & back, or? A good adhesive bond wood to cinderbloack, there is plenty of surface area on the cinderblock for a good bond...maybe four long nut/bolt/washer assemblies to compress the two panels front to back with the adhesive. This will probably work fine & with some creative touches, you would have nice sounding & looking gear.

---------------------------------------------------------------------------Rick...

Pull up the T/S parameters for bunches of drivers,,,six to ten choices should get you one that you like just fine. The fourteen or so liters worth should give you a wide variety.

Some good acoustic absorbing stuffing inside, maybe butcherblock wood panels front & back, or? A good adhesive bond wood to cinderbloack, there is plenty of surface area on the cinderblock for a good bond...maybe four long nut/bolt/washer assemblies to compress the two panels front to back with the adhesive. This will probably work fine & with some creative touches, you would have nice sounding & looking gear.

---------------------------------------------------------------------------Rick...

Given one would cutout the divider section between the cavities

Oops! I Forgot to factor in the divider's approximate volume. 🙁

As for sealed Vs vented, guess it depends on what he wants to do with them, but I too would go vented now that there's such a wide range of small drivers with reflex friendly specs.

Dave’s mark audio driver recommendation is a good shout. Pulvia 7.2 drives works surprisingly well in a small cabinet. No crossover needed and a good curve of frequency response for a little full range. Graph in the document is a simulation

6L Diy of mine, made 2 pairs they are great speakers, sub gives them a boost but they don’t need it in a small room.

6L Diy of mine, made 2 pairs they are great speakers, sub gives them a boost but they don’t need it in a small room.

Attachments

I've made a few speakers where I've used two full range drivers together, wired in series with a 1.5 uf cap in parallel with the lower driver to bias treble in the top driver. I also used a separate front baffle held on with tension springs against a foam gasket. You could use a similar idea with a breeze block, sorry cinder block, using tension springs going all the way through, holding both the front and back panels on. Note that I also use a baffle with holes in it, mounted about an inch from the rear panel to absorb the rear wave from the driver.

This is a ruff idea of what you'd end up with. This would mean that you would be using the whole of the internal volume for bass, without the need to remove the centre section from the block.

Cinder blocks aren't air tight. The speakers do not have to be absolutely air tight, but for a sealed enclosure it's recommended to get only little leaking. Why cinder blocks are probably not the best idea for speakers, you can see the visible reason here (YouTube).

You could of course treat the surface outside and inside, fill the pores (ie with epoxy) but the overall effort just to get closer to a particle board let it seem completely unattractive. To make things worse, boring holes close to the edge lead (like the needed mounting holes for the drivers) in the most cases to something breaking off, either at boring or at tightening the screws in a dovel.

If you want a hard material which is also nice to look at, you could consider ceramics or the classic wood in good quality surprisingly (if not laughably) cheap. The Baffle can easily be made with a routing circle or with a flush trim router bit. You can find bigger wall thickness of both in home improvement stores, furniture and gardening shops, these were just suggestions of the principle.

You could of course treat the surface outside and inside, fill the pores (ie with epoxy) but the overall effort just to get closer to a particle board let it seem completely unattractive. To make things worse, boring holes close to the edge lead (like the needed mounting holes for the drivers) in the most cases to something breaking off, either at boring or at tightening the screws in a dovel.

If you want a hard material which is also nice to look at, you could consider ceramics or the classic wood in good quality surprisingly (if not laughably) cheap. The Baffle can easily be made with a routing circle or with a flush trim router bit. You can find bigger wall thickness of both in home improvement stores, furniture and gardening shops, these were just suggestions of the principle.

Cinder blocks aren't air tight.

Sure, but neither are most drivers.

...and for a 3" or 4" driver in a simple box, there's not much going to be much bass either way.

My guess is that the difference between a perfectly sealed box and a (very slightly) leaky / aperiodic box will be minute.

To make things worse, boring holes close to the edge lead (like the needed mounting holes for the drivers) in the most cases to something breaking off, either at boring or at tightening the screws in a dovel.

?

The design uses plates of ply or foamcore or whatever for the front and back. All the cutting / drilling is done in these plates, not in the cement.

+1

Ikea have several containers which are essentially prebuilt speaker boxes.

I've pictured a build using one of these.

Speaker made with Ikea cutting board + box - Imgur

The Baffle can easily be made with a routing circle or with a flush trim router bit. You can find bigger wall thickness of both in home improvement stores, furniture and gardening shops, these were just suggestions of the principle.

If the OP is a noob, who doesn't want to buy tools they may only use once, here are two no budget options:

- use foamcore as the front baffle. Can be cut with a scalpel or retractable knife.

- use thin (3mm) mdf. Cut a neat circle by putting 2 screws through a wood scrap to make a "compass". Use this to "draw" a circle repeatedly, and the screw point will cut out your circle.

Either option can be braced & strengthened multiple ways.

The simplest is probably to thicken up the baffle plate, by laminating a couple of extra layers / scraps to the inside surface.

- Home

- Loudspeakers

- Multi-Way

- Making a Cinder Block Speaker