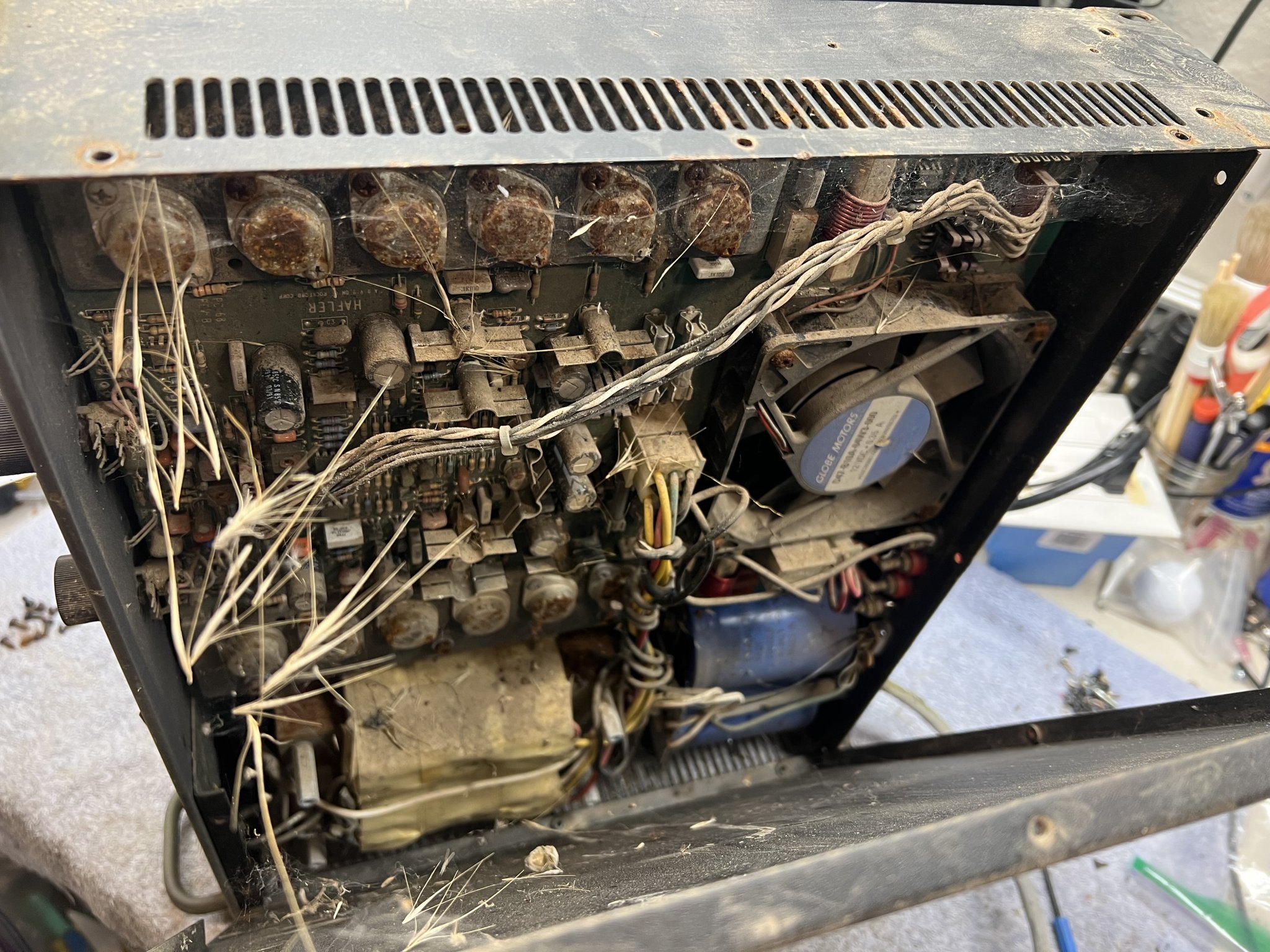

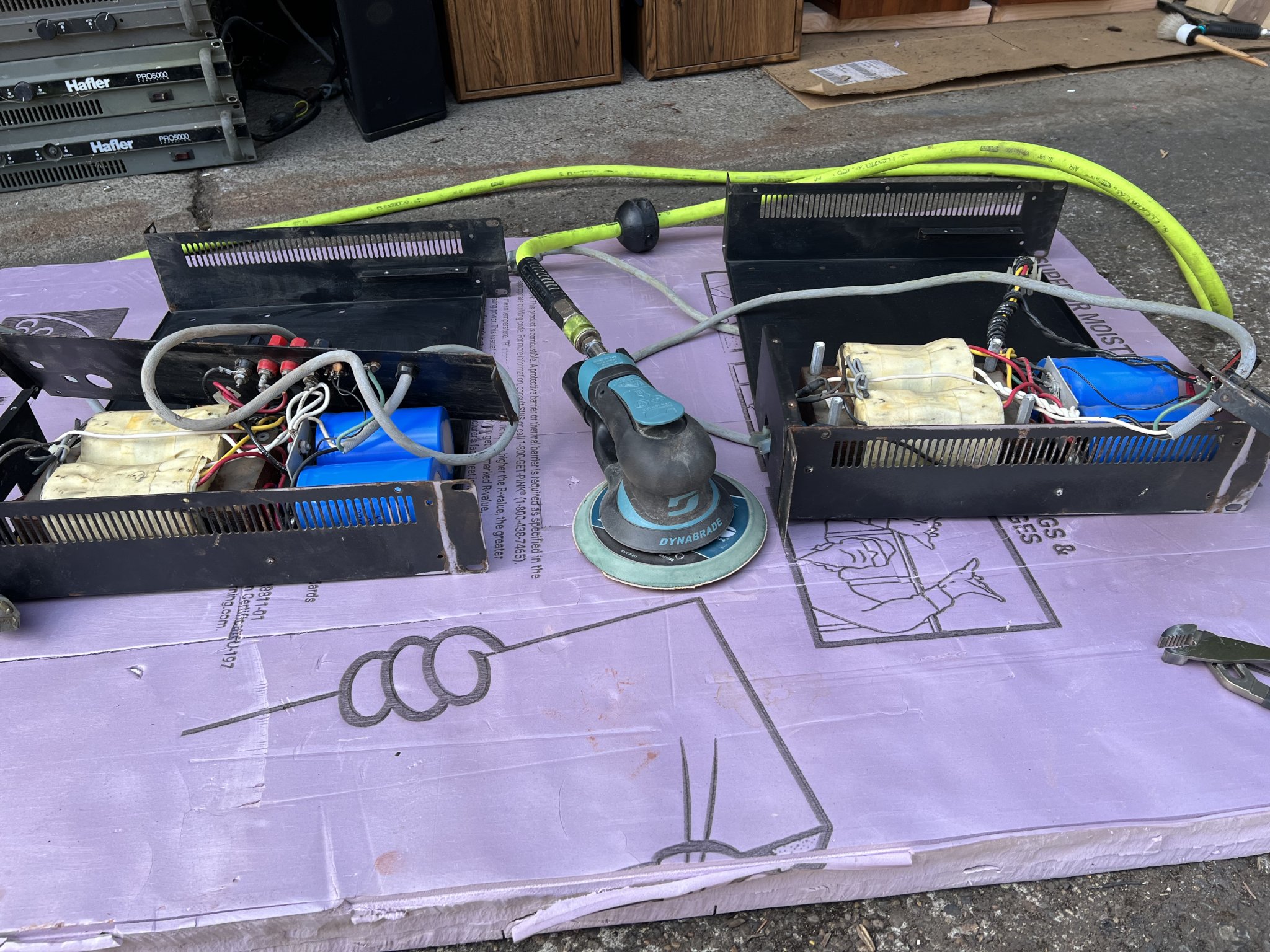

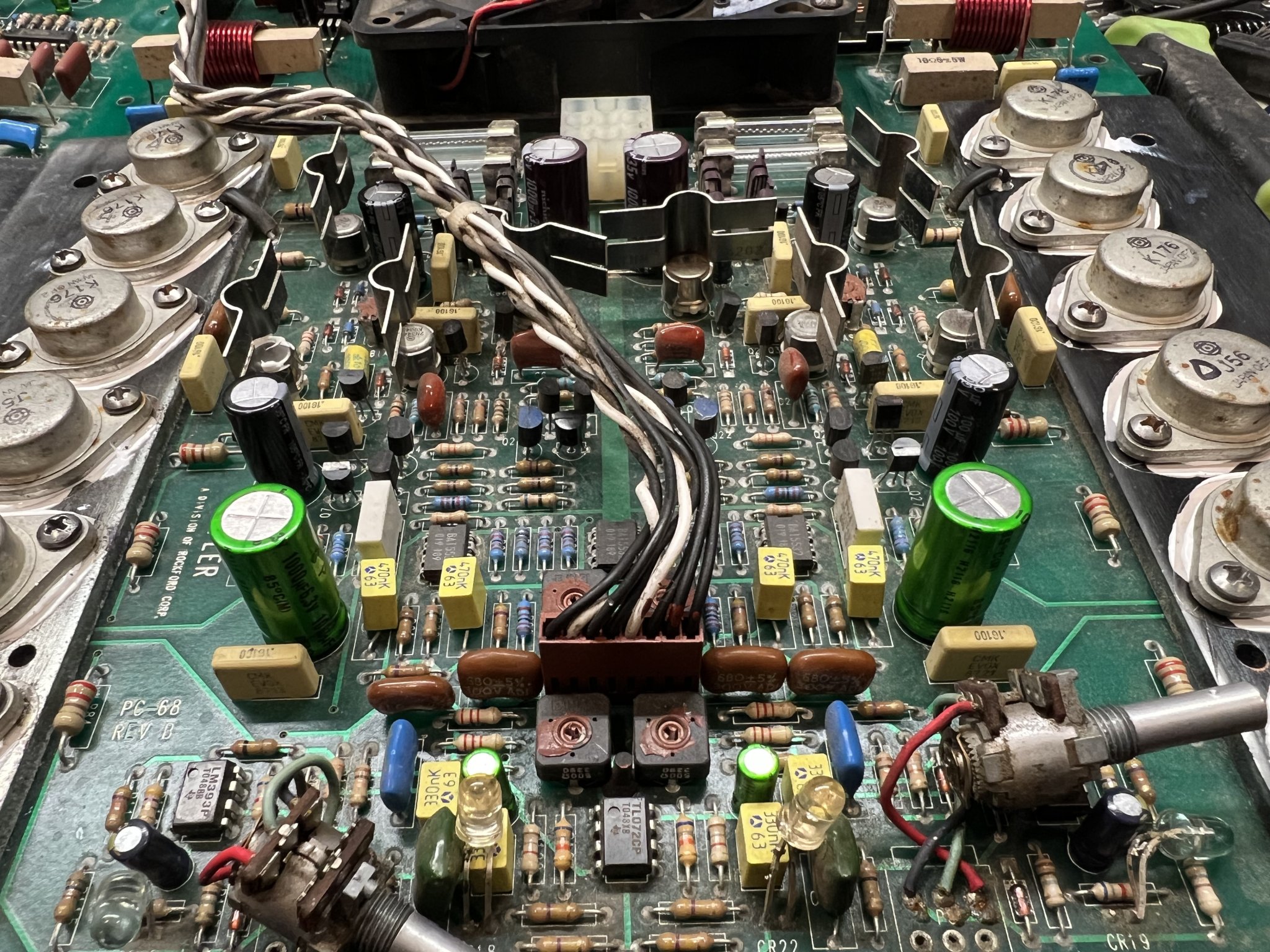

I have a thread over at Audiokarma, basically I was given a stack of ten Hafler Pro 5000 amplifiers that have been sitting outside in the elements for years, like over a decade. The guy took them to a couple of repair shops and was told they weren’t fixable as they couldn’t get parts for them, so they sat outside on the side of his house. In the PNW that means a lot of rain. With a lot of work I cleaned them up (first two only, working two at a time) made necessary repairs to the boards, recapped the boards, stripped the chassis and painted.

In one amp I had to replace a driver, a 2N5415 with a 2N5416. The other amp I only had to replace caps.

They both run pretty warm, but the one with the replaced driver idles hotter. The idle current after warm up of the amp having the new driver is 2.4a which seems kind of high. The other amp with no new silicon idles at 2.14 amp. I didn’t touch any of the trimmers within either amp. They are covered with paint so I know they are in the same position as they were when they left the factory. Even though the trimmers are sealed, maybe being in the elements have changed their values. I did check the resistances of the bias trimmer settings and they were all within their 1kohm range.

There is no service manual and no bias instruction. So I don’t know if the 2.4A idle draw is normal or the 2.14 is. I’d like to have the 4 channels I have working so far the same. I’m worried that maybe the one channel I changed the driver in might be way out.

Dan

In one amp I had to replace a driver, a 2N5415 with a 2N5416. The other amp I only had to replace caps.

They both run pretty warm, but the one with the replaced driver idles hotter. The idle current after warm up of the amp having the new driver is 2.4a which seems kind of high. The other amp with no new silicon idles at 2.14 amp. I didn’t touch any of the trimmers within either amp. They are covered with paint so I know they are in the same position as they were when they left the factory. Even though the trimmers are sealed, maybe being in the elements have changed their values. I did check the resistances of the bias trimmer settings and they were all within their 1kohm range.

There is no service manual and no bias instruction. So I don’t know if the 2.4A idle draw is normal or the 2.14 is. I’d like to have the 4 channels I have working so far the same. I’m worried that maybe the one channel I changed the driver in might be way out.

Dan

Here is the amp drawing 2.4 A after several hours of playing music and not a very loud level. Even with no music playing the temps seems to be the same.

Those are the air intakes. The exhausts are much warmer.

The side of the cabinet metal

Puts out full power and clips symmetrically.

This is roughly the 325w and this is right before clipping.

Dan

Those are the air intakes. The exhausts are much warmer.

The side of the cabinet metal

Puts out full power and clips symmetrically.

This is roughly the 325w and this is right before clipping.

Dan

This thread may help. https://www.diyaudio.com/community/threads/hafler-p500-need-schematic-manual-and-some-help.54319/

And yes those lateral mosfets liked some bias current.

Bias may be 100 ma per device or 300ma measured at he rail fuses.

And yes those lateral mosfets liked some bias current.

Bias may be 100 ma per device or 300ma measured at he rail fuses.

Thank you! If I don’t have some many of them to do I would have probably stripped the chassis, sand blasted and then powder coated, or at least used my HVLP sprayer, but rattle cans seemed a lot easier and came out really nice.

I appreciate the manual, I do have it, but I don’t see anything about biasing.

This thread may help. https://www.diyaudio.com/community/threads/hafler-p500-need-schematic-manual-and-some-help.54319/

And yes those lateral mosfets liked some bias current.

Bias may be 100 ma per device or 300ma measured at he rail fuses.

Awesome, I will take a look at that thread. I figured they did like some bias as every other MOSFET amplifier I have runs pretty warm. Going off of this information that you just mentioned here I went ahead and measured the current at the positive rail fuse on each channel. Thinking that it was possibly 300 mA I went ahead and use the 400 mA section of the meters. Quickly turn the amp off when I realized it was going over 400.

This is how I have it setup, no input and no load.

Please excuse the mess, once I’m finished with a piece I completely clean my bench and then the next piece gets it dirty all over again lol.

After warm up I had about 440 mA on channel A

And about 470 mA on channel B

Does the cooler amp seem like it might be biased high? I don’t know this circuitry all that well but I’m guessing it’s pretty good at pulling current equally from both the positive and negative rails. Meaning that the negative rail was probably at 440 mA and 470 mA respectively. Should I turn those down closer to 300 mA so that they get about 100 per device? I’ll go ahead and take a look at that thread, it might have the answer for me. Another question I have, which also may be in the thread is about offset. The manual just states that if the offset gets high to contact the manufacture. There for other trimmers in the circuit, other than the bias in the gain.

There is P3/P4 and P7/P8. It looks like P3/P4 would be used to balance the output of an opamp in the input stage.

So my guess is those would be the trimmers I’d want to use. The offset is not horrible, about 30 mV on each channel. Nothing to worry about, but if I can get it closer to zero, why not. Thank you so much for the help this far.

Dan

Last edited:

Look for a trimmer marked P1 or P2 depending on the channel. Going to be closer to the output mosfets. Near Q31 and Q32.

This thread may help. https://www.diyaudio.com/community/threads/hafler-p500-need-schematic-manual-and-some-help.54319/

And yes those lateral mosfets liked some bias current.

Bias may be 100 ma per device or 300ma measured at he rail fuses.

Yes, thank you, very informative. Even though it isn’t my amp it looks like the rule of thumb is 100 mA and for the 6 devices that would be 300 mA for each rail. They also said to add 50 mA for the front end making it 350 mA.

One gentleman said he called the factory and they told him 450 mA. Odd that the amp I have which is factory other than the electrolytics on the board is measuring 430 and 470, maybe it did come from the factory set at 450. He did say when he turned it down the fan quieted, but that isn’t really an issue for me. Maybe go 400? I think 350 would be as low as I’d go, not really sure what the front end needs, maybe 50 mA is enough.

Dan

Look for a trimmer marked P1 or P2 depending on the channel. Going to be closer to the output mosfets. Near Q31 and Q32.

Well P1 and P2 are your bias. Were you answering my questions about which trimmer for offset? The bias trimmers are actually marked with “bias” on the board so I have those. Thank you very much though.

Dan

P1(P2) adjust the idle current.

P3(P4) trim common-mode rejection balance of the input stage.

P7(P8) set threshold of the clipping detector.

Of course P5(P6) are gain.

I believe there are no offset trims. It would be possible to improve offset with a pot and fixed resistor on each channel, but probably fine as is.

P3(P4) trim common-mode rejection balance of the input stage.

P7(P8) set threshold of the clipping detector.

Of course P5(P6) are gain.

I believe there are no offset trims. It would be possible to improve offset with a pot and fixed resistor on each channel, but probably fine as is.

My worry is you're reusing transformer windings that have been out in the rain for a decade. How can you be sure there isn't moisture trapped which will lead to future failure? Or did you bake them?

50mA to 100mA per MOSFET is a reasonable bias level for many lateral MOSFETs - lower will run cooler, higher may be slightly less cross-over gain wobble. Don't change the bias with speakers attached as severe underbias can cause instability at high frequency - I'd monitor with the 'scope to gain confidence its not oscillating at bias levels to either side of the bias level you set, nor at full signal amplitude.

50mA to 100mA per MOSFET is a reasonable bias level for many lateral MOSFETs - lower will run cooler, higher may be slightly less cross-over gain wobble. Don't change the bias with speakers attached as severe underbias can cause instability at high frequency - I'd monitor with the 'scope to gain confidence its not oscillating at bias levels to either side of the bias level you set, nor at full signal amplitude.

I set the first amp this morning, the one that was running cooler. Set each channel to 350 mA total draw on the positive rail which is what was recommended in the thread linked and seems to be what most people agree on, 100 per device and 50 for the front end.

The current draw of the amp dropped from 2.14A to 1.8A at idle. Which seems maybe a bit more in line??? My brothers Ashley FTX-2001 which comparable-ish power wise is 1.5A at idle.

The amplifier that runs quite a bit warmer and draws 2.4A has a current of 510 mA on the positive rail of channel A and 470 mA of channel. I got both channels lowered to 350 mA and the current draw is 1.98A.

What would account for the nearly 200 mA higher current draw from the wall if they’re biased equally? One fan less efficient? Difference in voltage at the wall (meaning fluctuations causing one amp to a couple extra volts)?

After setting bias I didn’t see any weird anomaly on the scope. I guess I’ll run it like this and see how it goes. I still have 8 more of these amps to rebuild and it would be interesting to see if they all have bias in the 450 mA range across the rail fuse.

Any thoughts on the extra current draw of the amp?

As for moisture in the transformers, I don’t think it’s going to be a problem. While these did see a lot of rain, they have been sitting in my garage for quite a while, several months. The last few months it’s gotten very hot in the garage and when I opened up these two amplifiers, I didn’t see any hints of moisture. plus both of these amps are running for longer than a straight 24 hour period where the inside of the amp had to have been at least 130° or 140° F inside. The cloth that the transformer is wrapped up in, feels like it was soaked in some type of resin, so hopefully it kept most moisture out of it, so far it hasn’t been a problem.

Dan

The current draw of the amp dropped from 2.14A to 1.8A at idle. Which seems maybe a bit more in line??? My brothers Ashley FTX-2001 which comparable-ish power wise is 1.5A at idle.

The amplifier that runs quite a bit warmer and draws 2.4A has a current of 510 mA on the positive rail of channel A and 470 mA of channel. I got both channels lowered to 350 mA and the current draw is 1.98A.

What would account for the nearly 200 mA higher current draw from the wall if they’re biased equally? One fan less efficient? Difference in voltage at the wall (meaning fluctuations causing one amp to a couple extra volts)?

After setting bias I didn’t see any weird anomaly on the scope. I guess I’ll run it like this and see how it goes. I still have 8 more of these amps to rebuild and it would be interesting to see if they all have bias in the 450 mA range across the rail fuse.

Any thoughts on the extra current draw of the amp?

As for moisture in the transformers, I don’t think it’s going to be a problem. While these did see a lot of rain, they have been sitting in my garage for quite a while, several months. The last few months it’s gotten very hot in the garage and when I opened up these two amplifiers, I didn’t see any hints of moisture. plus both of these amps are running for longer than a straight 24 hour period where the inside of the amp had to have been at least 130° or 140° F inside. The cloth that the transformer is wrapped up in, feels like it was soaked in some type of resin, so hopefully it kept most moisture out of it, so far it hasn’t been a problem.

Dan

Is this current drawn on the mains side of the transformer? That's dominated by inductance and leakage inductance of the transformer at light load, gradually transfering to being dominated by the load power draw at higher powers as the power factor of the transformer tends to 1. At no load or light load the transformer will have a low power factor. What makes the two units different I've no idea, but magnetics are less than ideal components and might well be different enough to explain this.

Is the pro 5000 pretty much the same amp as the xl-600 ?

I can find a pro 5000 under $200, the Xl-600 is way more expensive.

What are the differences ?

I can find a pro 5000 under $200, the Xl-600 is way more expensive.

What are the differences ?

- Home

- Amplifiers

- Solid State

- Looking for help bias/idle current draw on Hafler lateral mosfet amplifiers.