How can I know? I haven't seen your DC voltage measurements yet (before LM317 and after).

Actual before measurement is around 14VAC. After rectifier is about 19VAC. Output of LM 317 is 12.6VDC.

If there's a really good argument supporting doublers in this application, I would sure like to hear it. A capacitor's life in one is hard enough, and they often die young -- even properly implemented.

Maybe you could run the filaments on AC, straight from the transformer. By removing that current draw from the LM317, it'll run a lot cooler and it won't need as big of an input capacitor. Since this is line-level, the AC on the filaments won't make a significant hum contribution. And the improved DC supply for the plate load and output is crucial -- nearly every bit of supply crud will find its way straight through to the headphones.

Cheers

Edit: Sorry if this has been covered in the last few posts -- it took me since PRR's #17 to put it together. 😱

Maybe you could run the filaments on AC, straight from the transformer. By removing that current draw from the LM317, it'll run a lot cooler and it won't need as big of an input capacitor. Since this is line-level, the AC on the filaments won't make a significant hum contribution. And the improved DC supply for the plate load and output is crucial -- nearly every bit of supply crud will find its way straight through to the headphones.

Cheers

Edit: Sorry if this has been covered in the last few posts -- it took me since PRR's #17 to put it together. 😱

Last edited:

Would this work with 3300 uF and no other adjustments?

Possibly, but depends on the transformer. Give it a try.

Post the input and output voltage measurements of the 317.

And if you don't have a 'scope to check the input to the 317, measure (and post 😉) both DC and AC voltages at the input. That'll often give enough insight to estimate whether the 317's minimum dropout spec is being violated.

Another good reason to run the filaments on transformer AC: They care a lot more about the voltage than does the rest of the circuit.

Another good reason to run the filaments on transformer AC: They care a lot more about the voltage than does the rest of the circuit.

Actual before measurement is around 14VAC. After rectifier is about 19VAC. Output of LM 317 is 12.6VDC.

AC or DC? Doesn't make sense. Did you set your meter to DC to measure the input and output of the 317? Then again, doublers are notorious for increasing sag and ripple. In an early post you mentioned that the buzz disappears when you feed the amp with a battery.

That's your issue right there: you have ripple and an amp with little ripple rejection.

You want to fix it? Get another proper transformer, like 15VAC secondary. Chuck the doubler. Done.

Jan

As it was said - rectifier gives us DC but not AC.Actual before measurement is around 14VAC. After rectifier is about 19VAC. Output of LM 317 is 12.6VDC.

As it was said - rectifier gives us DC but not AC.

After rectifier is 19VDC. That was a typo earlier.

Last edited:

AC or DC? Doesn't make sense. Did you set your meter to DC to measure the input and output of the 317? Then again, doublers are notorious for increasing sag and ripple. In an early post you mentioned that the buzz disappears when you feed the amp with a battery.

That's your issue right there: you have ripple and an amp with little ripple rejection.

You want to fix it? Get another proper transformer, like 15VAC secondary. Chuck the doubler. Done.

Jan

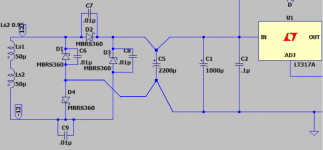

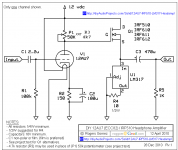

I am using a 12VAC transformer into a normal FWBR yielding 18VDC being fed into the lm317 set to output 12.6VDC and the measurements on the board confirmed these numbers. I posted the actual circuit I am using. I posted the wrong one by mistake earlier.

Possibly, but depends on the transformer. Give it a try.

Post the input and output voltage measurements of the 317.

As it was said - rectifier gives us DC but not AC.

12VAC from transformer. 19VDC after rectifier and into LM 317. Now getting 12.6VDC out.

AC or DC? Doesn't make sense. Did you set your meter to DC to measure the input and output of the 317? Then again, doublers are notorious for increasing sag and ripple. In an early post you mentioned that the buzz disappears when you feed the amp with a battery.

That's your issue right there: you have ripple and an amp with little ripple rejection.

You want to fix it? Get another proper transformer, like 15VAC secondary. Chuck the doubler. Done.

Jan

Would 12VAC not be able to handle this?

Possibly, but depends on the transformer. Give it a try.

Post the input and output voltage measurements of the 317.

Posted in this comment.

Now with Schottky diodes as proposed in another thread...

Attachments

Last edited:

18-19VDC is quite good. That means 18-12,6 - about 5,4 VDC (but we have to bear in mind a ripple). Shottky diodes raise that voltage drop.

Such voltage drop means that LM317 works at its 100%.

Such voltage drop means that LM317 works at its 100%.

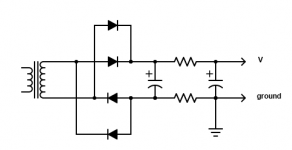

If you still have the buzz now, it must be a ground loop, etc. Then try something like this,

with each of the resistors having around 0.5VDC drop. The second capacitor is the same value

as the first. Use 2W resistors, since they also drop the ripple voltage.

with each of the resistors having around 0.5VDC drop. The second capacitor is the same value

as the first. Use 2W resistors, since they also drop the ripple voltage.

Attachments

Last edited:

As suggested, perhaps ground loop in which a ground loop breaker helps (a lot). But you still have issues with the poor PSRR of the 12AU7 amplifier, and the poor PSRR performance of the LM317.

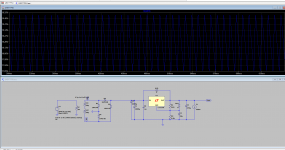

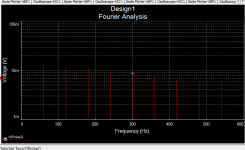

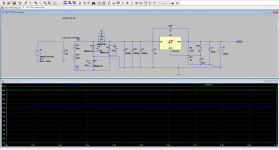

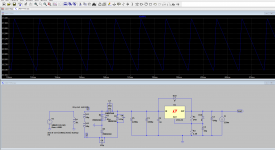

Fourier is easy in Multisim if you know the root frequency -- here's your problem:

Fourier is easy in Multisim if you know the root frequency -- here's your problem:

Attachments

If you still have the buzz now, it must be a ground loop, etc. Then try something like this,

with each of the resistors having around 0.5VDC drop. The second capacitor is the same value

as the first. Use 2W resistors, since they also drop the ripple voltage.

I tried all kinds of values and nothing seemed to help. Any ideas?

As suggested, perhaps ground loop in which a ground loop breaker helps (a lot). But you still have issues with the poor PSRR of the 12AU7 amplifier, and the poor PSRR performance of the LM317.

Fourier is easy in Multisim if you know the root frequency -- here's your problem:

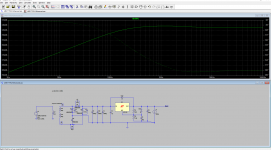

This is now my predicted response based on everybody's suggestions.

Attachments

I tried all kinds of values and nothing seemed to help. Any ideas?

Yes -- use one regulator for the filament, another for the B+, or use a regulator like the LT3081 which has 30dB more ripple rejection than the LM317.

Otherwise you're just batting your head against the wall. The ripple votlage is a linear function of the load current, and the LM317 isn't up to the task. If you use just one you've got a headache.

Ridiculous to try for the minimal benefit of Class-A amplification when you have this issue.

Another source of hum. Wrong ground connections.

Mona

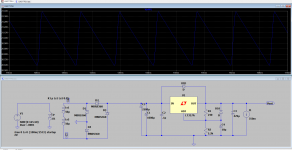

How does this look for a final design?

If you still have the buzz now, it must be a ground loop, etc. Then try something like this,

with each of the resistors having around 0.5VDC drop. The second capacitor is the same value

as the first. Use 2W resistors, since they also drop the ripple voltage.

I would love your thoughts on this as well. No resistors but this looks okay ish to me?

Attachments

Last edited:

> my latest design

You actually need THREE power supplies. While the original assumed you had a good clean 12V supply (not a hard thing to find or build), somehow you are stuck on it.

1) heater: does not need real-clean or regulated.

2) MOSFET: has huge PSRR so does not need real clean or regulated

3) 12AU7 plate has low PSRR. Its supply needs to be clean. It does NOT need to be regulated; and will work better at higher voltage. And this is a SMALL load. A simple RC will clean it slicker than Clorox hand-soak.

You actually need THREE power supplies. While the original assumed you had a good clean 12V supply (not a hard thing to find or build), somehow you are stuck on it.

1) heater: does not need real-clean or regulated.

2) MOSFET: has huge PSRR so does not need real clean or regulated

3) 12AU7 plate has low PSRR. Its supply needs to be clean. It does NOT need to be regulated; and will work better at higher voltage. And this is a SMALL load. A simple RC will clean it slicker than Clorox hand-soak.

Attachments

- Home

- Amplifiers

- Power Supplies

- LM 317 Buzz Issue/Design