It's like everyting, lifetime of the device will be disminished, but it should work for a period of time.That's good to know, I was 15 when I did it and I used an old top loaded freezer that had been previously used in a restaurant. It might have been a little beefier than a regular fridge...

I wish I were able to struggle with 4 blade servers and an SCSI array when I was 15. To what end it was for, if I may ask?

IRC server, various game servers (cs and quake mostly), ftp dump and online music library. I got my first PC when I was 6 and my mother banned Gaming consoles from my house, so the rest came naturally. The blades where spoils of her employer upgrading their server room, that's usually I got my equipment when I was younger.

Some developments.

I had two more pump failures with the submersible approach. They weren't due to electrical changes, but the seals had either separated or were never installed properly by the manufacturer. I have not given up on that setup, but will apparently need to shell out more than $8 to get something more reliable.

In the meantime, I went for the small $49 Danger Den external pump I have, which required a new reservoir design. It worked out great as it is less than 1/4 the size of the all-in-one. The two most important elements here are a small space for air bubbles to escape, and an air tight seal. With the vertical placement of the cooler, even the tiniest leak allowed the weight of the water to force it to the top of the reservoir and flow out of any small crack. Careful construction, liberal use of Teflon tape and air pressure testing solved the problem.

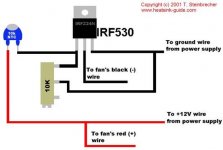

The next big development was applying the thermistor/regulator referenced by evanc over on the Pass Pictures thread. His suggestion was to use that circuit to increase the fan speed at higher temps. I built one and it worked as described (wire connections/junctions must be exactly as shown) However, slowing the water flow and holding it in the radiator longer is just as important. I discovered a PTC thermistor that works backward - increases resistance as temperature goes up. Replaced the standard thermistor with a PTC and it worked as I had hoped.

The tuning involves letting the amp reach it's highest temperature and then adjust the trimmer to run the pump at the lowest speed desired. This time I'm using a 9 volt wall wart to power both fan and pump, with the fan at full power. I did try to use both thermistors on one power supply - but the trimmers were too interactive to allow useful individual adjustments. The fan noise is still undetectable at 9 volts. The adjustment range is wide enough to allow safe start-up voltages and the low speed is protected by the pulsed voltage from the PTC chip. Here is a short video that shows the flow/temp relationship. Watch liquid activity in the reservoir.

Still need to tidy up and shorten the wires, install the 9V power inlet socket at the back of the chassis and start on the chassis cosmetics. The Burning Amp build is taking shape and will hopefully appear near the end of next week.

Thanks again evanc - you got the ball rolling.

I had two more pump failures with the submersible approach. They weren't due to electrical changes, but the seals had either separated or were never installed properly by the manufacturer. I have not given up on that setup, but will apparently need to shell out more than $8 to get something more reliable.

In the meantime, I went for the small $49 Danger Den external pump I have, which required a new reservoir design. It worked out great as it is less than 1/4 the size of the all-in-one. The two most important elements here are a small space for air bubbles to escape, and an air tight seal. With the vertical placement of the cooler, even the tiniest leak allowed the weight of the water to force it to the top of the reservoir and flow out of any small crack. Careful construction, liberal use of Teflon tape and air pressure testing solved the problem.

The next big development was applying the thermistor/regulator referenced by evanc over on the Pass Pictures thread. His suggestion was to use that circuit to increase the fan speed at higher temps. I built one and it worked as described (wire connections/junctions must be exactly as shown) However, slowing the water flow and holding it in the radiator longer is just as important. I discovered a PTC thermistor that works backward - increases resistance as temperature goes up. Replaced the standard thermistor with a PTC and it worked as I had hoped.

The tuning involves letting the amp reach it's highest temperature and then adjust the trimmer to run the pump at the lowest speed desired. This time I'm using a 9 volt wall wart to power both fan and pump, with the fan at full power. I did try to use both thermistors on one power supply - but the trimmers were too interactive to allow useful individual adjustments. The fan noise is still undetectable at 9 volts. The adjustment range is wide enough to allow safe start-up voltages and the low speed is protected by the pulsed voltage from the PTC chip. Here is a short video that shows the flow/temp relationship. Watch liquid activity in the reservoir.

Still need to tidy up and shorten the wires, install the 9V power inlet socket at the back of the chassis and start on the chassis cosmetics. The Burning Amp build is taking shape and will hopefully appear near the end of next week.

Thanks again evanc - you got the ball rolling.

Attachments

-

20130712_220854.jpg115.1 KB · Views: 440

20130712_220854.jpg115.1 KB · Views: 440 -

20130712_223409.jpg243.4 KB · Views: 188

20130712_223409.jpg243.4 KB · Views: 188 -

20130712_223347.jpg190.9 KB · Views: 190

20130712_223347.jpg190.9 KB · Views: 190 -

20130712_221055.jpg628.7 KB · Views: 429

20130712_221055.jpg628.7 KB · Views: 429 -

20130712_221113.jpg98.7 KB · Views: 423

20130712_221113.jpg98.7 KB · Views: 423 -

20130712_220918.jpg108.6 KB · Views: 435

20130712_220918.jpg108.6 KB · Views: 435 -

20130712_220907.jpg92.9 KB · Views: 449

20130712_220907.jpg92.9 KB · Views: 449 -

control.jpg34.5 KB · Views: 222

control.jpg34.5 KB · Views: 222

I have been lurking around and thinking that, in order to avoid the hassle of building your own water block, there are good options all around that will allow to fit one, two or more ICs per block. I'd just make some kind of vice to hold them all:

MagiCool Black Butterfly CPU Liquid Cooling Copper Block - Universal Socket (MC-BLOCK-CPU II) - FrozenCPU.com

Bitspower MOS AMOSII ASUS X58 Type 1 MOSFET Liquid Cooling Block (BP-WBPAMOS2-BK) - FrozenCPU.com

Alphacool X2 D-RAM Liquid Cooling Block - Plexi - FrozenCPU.com

Magicool Hybrid Pro 3.5" HDD Water Block / Anti-Vibration Adapter (MC-BLOCK-HDD) - FrozenCPU.com

They are not that expensive if you account that you only need a few of them. For example, the last one I listed is a double block design, so you will only need one of them to cool an F5 or any other 4-6 mosfets design. And for 37$ is negligible accounting the total project cost.

A decent radiator, a pump, some fans and some tubing and you are ready to make a pretty compact setup.

MagiCool Black Butterfly CPU Liquid Cooling Copper Block - Universal Socket (MC-BLOCK-CPU II) - FrozenCPU.com

Bitspower MOS AMOSII ASUS X58 Type 1 MOSFET Liquid Cooling Block (BP-WBPAMOS2-BK) - FrozenCPU.com

Alphacool X2 D-RAM Liquid Cooling Block - Plexi - FrozenCPU.com

Magicool Hybrid Pro 3.5" HDD Water Block / Anti-Vibration Adapter (MC-BLOCK-HDD) - FrozenCPU.com

They are not that expensive if you account that you only need a few of them. For example, the last one I listed is a double block design, so you will only need one of them to cool an F5 or any other 4-6 mosfets design. And for 37$ is negligible accounting the total project cost.

A decent radiator, a pump, some fans and some tubing and you are ready to make a pretty compact setup.

By a vice I mean something like that, which will not damage your water block or anything:

http://www.shine7.com/audio/concentra-3.jpg

http://www.shine7.com/audio/concentra-3.jpg

Hey Reg,

I think some of those would be excellent for both the F5 and the ACA. I would encourage anyone to jump into the liquid cooling concept using whatever hardware they feel comfortable with. There are myriad devices in the PC cooling industry that can easily be re-purposed to audio.

I enjoy the fabrication process as much as the amp building itself. I was employed as a machinist for a period of my work history and it's fun to discover how much of that is still rattling around in this aged brain. 😉 Over the years I've collected a comfortable set of tools and small machines (drill press, band saw, sanders etc,) which may not be available to others. Not having those should not deter one from investigation the concept.

😉 Over the years I've collected a comfortable set of tools and small machines (drill press, band saw, sanders etc,) which may not be available to others. Not having those should not deter one from investigation the concept.

I might go back and try to modify the water block I used for a MyRef build to cool the F5. It is attached to a piece of 1/4" aluminum with an Arctic Silver two part thermal epoxy to avoid drilling. Simply making the slab a little longer should work. There are several items available from the vendor I used, so jump in if you feel the urge 😀

The clamping technique you mention is part of the BA-3 project. Selecting the appropriate radiator and fan size is the trial and error process I'm in currently. I've discovered there is a great difference in heat transfer efficiency depending whether the fan draws or pushes the air. Single fan at high speed vs. multiples at slower speeds effects overall system noise levels.

So - Come one, Come all - would love to see some other liquid cooling configurations.

I think some of those would be excellent for both the F5 and the ACA. I would encourage anyone to jump into the liquid cooling concept using whatever hardware they feel comfortable with. There are myriad devices in the PC cooling industry that can easily be re-purposed to audio.

I enjoy the fabrication process as much as the amp building itself. I was employed as a machinist for a period of my work history and it's fun to discover how much of that is still rattling around in this aged brain.

😉 Over the years I've collected a comfortable set of tools and small machines (drill press, band saw, sanders etc,) which may not be available to others. Not having those should not deter one from investigation the concept.

😉 Over the years I've collected a comfortable set of tools and small machines (drill press, band saw, sanders etc,) which may not be available to others. Not having those should not deter one from investigation the concept. I might go back and try to modify the water block I used for a MyRef build to cool the F5. It is attached to a piece of 1/4" aluminum with an Arctic Silver two part thermal epoxy to avoid drilling. Simply making the slab a little longer should work. There are several items available from the vendor I used, so jump in if you feel the urge 😀

The clamping technique you mention is part of the BA-3 project. Selecting the appropriate radiator and fan size is the trial and error process I'm in currently. I've discovered there is a great difference in heat transfer efficiency depending whether the fan draws or pushes the air. Single fan at high speed vs. multiples at slower speeds effects overall system noise levels.

So - Come one, Come all - would love to see some other liquid cooling configurations.

Attachments

There is a pretty extensive research regarding liquid cooling on computer overclocking forums and websites, it bited me some time ago and I read a lot about it. They make tons of charts and graphics experimenting with water flow, radiator size, fan models/speed (there are noisier ones that pull out massive amounts of air at the cost of nosie)...

I don't mean to derail the thread in any way, but speaking of pc cooling methods being applied to audio electronics, what about passive cooling with mineral oil (no pumps or fans)? Would that be a bad idea?

Last edited:

you will probably find mineral oil is a bit too viscous to thermally pump itself around the loop unless you use really large pipes.

Thermosiphoning needs large channels to work.

Thermosiphoning needs large channels to work.

you will probably find mineral oil is a bit too viscous to thermally pump itself around the loop unless you use really large pipes.

Thermosiphoning needs large channels to work.

He said passive....I'm guessing he means submerge everything in oil. A lot of oil.

Last edited:

bcmbob - very sweet looking amp ! where do the hoses and such plug into that ?

Or is that it - all in one small chasis ??

Or is that it - all in one small chasis ??

Hi kasey, It is self-contained. There are a few picture here that give a better understanding of the setup.

You will end up with a very nice sounding deep frier, how would you cool down that oil?I don't mean to derail the thread in any way, but speaking of pc cooling methods being applied to audio electronics, what about passive cooling with mineral oil (no pumps or fans)? Would that be a bad idea?

Look here... It has been years that they have been doing it.

Custom PC; Mineral Oil Submerged Computer

Thx

Do

Custom PC; Mineral Oil Submerged Computer

Thx

Do

With pump and oil radiator is is not much more then a simple water cooler.

There are passive water coolers where the water flows because of the hot water need of going up. That would also work with amp.

There are passive water coolers where the water flows because of the hot water need of going up. That would also work with amp.

Took a look at the site -interesting, fun and novel. Guaranteed to be a conversation piece.

The focus of my projects it still to reduce the overall bulk of the heat management equipment. The aquarium pushes that in the opposite direction. I have to always keep in mind that thousands of high power/high heat amps are operating perfectly with simple metal heat sinks. You know - "if it aint broke, don't fix it".🙄

If anyone adopts the ideas presented here, I believe the attraction would be based primarily on reducing the total build size. At this point I'm trying to discover the base requirements - and once determined, attempt to further reduce bulk and maintain simplicity.

Again, I'd encourage anyone to do a practical application of the oil and/or any other approach. They sound like fun, and we all would be very interested to hear about the results.

The focus of my projects it still to reduce the overall bulk of the heat management equipment. The aquarium pushes that in the opposite direction. I have to always keep in mind that thousands of high power/high heat amps are operating perfectly with simple metal heat sinks. You know - "if it aint broke, don't fix it".🙄

If anyone adopts the ideas presented here, I believe the attraction would be based primarily on reducing the total build size. At this point I'm trying to discover the base requirements - and once determined, attempt to further reduce bulk and maintain simplicity.

Again, I'd encourage anyone to do a practical application of the oil and/or any other approach. They sound like fun, and we all would be very interested to hear about the results.

I think the main advantage of remote cooling is that the electronics package can be made more compact, without the risk of overheating the electronics package.

Splish Splash

Hi Bob,

That's me jumping in the pool. You are right, the water is fine.

I've been catching up on your adventures and reading about commercially available computer cooling products.

I really like your tube in a tube heat exchanger. One of the things like the most is that all of the liquid connections are below the electronics, so if you did have a leak, risk of fire and shock is reduced. I would be curious about your reaction to the following idea.

What if you extended the top of your heat exchanger, leaving the inner tube at the same height. The volume above the inner tube could become the reservoir with, perhaps, a small vent and overflow tube out the top. The advantage that I see to this approach is that it reduces the number of liquid connections and might even allow the pump to be mounted below the heat exchanger.

Now, gettin a little crazy. All we need is a switch with a float on it and you could shut everything down if the water got too high.

Any thoughts?

Jac

Hi Bob,

That's me jumping in the pool. You are right, the water is fine.

I've been catching up on your adventures and reading about commercially available computer cooling products.

I really like your tube in a tube heat exchanger. One of the things like the most is that all of the liquid connections are below the electronics, so if you did have a leak, risk of fire and shock is reduced. I would be curious about your reaction to the following idea.

What if you extended the top of your heat exchanger, leaving the inner tube at the same height. The volume above the inner tube could become the reservoir with, perhaps, a small vent and overflow tube out the top. The advantage that I see to this approach is that it reduces the number of liquid connections and might even allow the pump to be mounted below the heat exchanger.

Now, gettin a little crazy. All we need is a switch with a float on it and you could shut everything down if the water got too high.

Any thoughts?

Jac

- Status

- Not open for further replies.

- Home

- Amplifiers

- Chip Amps

- Liquid Cooling Build