So you mean mount DAC chips in the space between two parallel PCBs? Certainly that will allow air to both sides of the chip, improving the cooling but I'm a bit concerned how to decouple the power supplies as the + and - power supply pins will end up on different PCBs. Interesting idea though, thanks!

From the short time I did some research into fans, I found the attached document which has a lot of useful info.

From the short time I did some research into fans, I found the attached document which has a lot of useful info.

Attachments

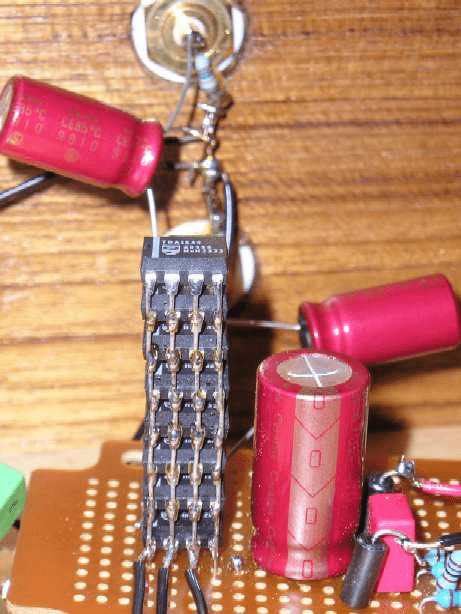

I thought it was simply a matter of piggybacking the chips. I saw somewhere someone selling a modular vertical stack of DAC chips but I can't find it anymore. The closest was this

Ah - that looks like it might be a stack of TDA1543 (dual in line package). Those chips do get seriously hot when stacked and run at maximum supply (around 8V if I remember right). I have tried stacking TDA1387 but being as its SMD, the legs aren't quite long enough to reach between chips. So I have tended to fill the gap between with solder - it works but has never been super-reliable. To get more reliability, I've soldered 30AWG wires between chips, its hard to get the result looking neat though and its jolly fiddly.

I was really looking for a way to arrange/stack PCBs holding chips rather than bare chips as I'd like it to be a bit less labour-intensive than building DAC skyscrapers.

I was really looking for a way to arrange/stack PCBs holding chips rather than bare chips as I'd like it to be a bit less labour-intensive than building DAC skyscrapers.

Can't disagree there Claude but I also have to have a way to keep wifey engaged in this project or no more PCBs will get laid out. The current edition is already the second revision of the original which she has patiently and diligently delivered. And I suspect 'chimney' might be a bridge too far (if you'll excuse the mixed metaphor) for her mechanical design skills...😈

LOL

Understand!

Well, do you really need all these chips then? That's the first necessity test...

If really yes, where does the heat concentrate? On the chips? Is there then a way to make simple provision (2 holes for screws?) for a small very flat metal bar acting as a radiator, with a long extension leading to a cooler area (outside of the board vertical projection) in hope the extra local metal surface and some heat being led away where it does less harm does the job?

Etc.

Just thinking out loud, sorry for the little help

Claude

Understand!

Well, do you really need all these chips then? That's the first necessity test...

If really yes, where does the heat concentrate? On the chips? Is there then a way to make simple provision (2 holes for screws?) for a small very flat metal bar acting as a radiator, with a long extension leading to a cooler area (outside of the board vertical projection) in hope the extra local metal surface and some heat being led away where it does less harm does the job?

Etc.

Just thinking out loud, sorry for the little help

Claude

The bottleneck in this design is the number of chips, so I'd say yes, if we want the performance then we have to swallow the sheer quantity of chips. That is of course conditional on choosing the 1387 as DAC in the first place - it only comes with 95dB SNR. I am getting good results using a DAC with better measurements (PCM56) so this design will probably be the end of the road for the 1387 in regards to getting ultimate performance as the 'hair shirt' is just getting too itchy.

The heat isn't really concentrated - sure the chips are warm but given there's quite a lot of copper in the PCB (its 4 layer) the spreading effect evens out the heat quite nicely. Just doesn't disperse it far enough. Could be just a metal plate on the back of each PCB extending beyond the edges will do enough, as you seem to suggest.

I've now made some measurements - the hottest spot I've been able to find with my thermocouple has been 62degrees C, this in an ambient of about 23degrees. Which is probably just about OK sat on my bench but inside a box the ambient will easily become 20oC higher...

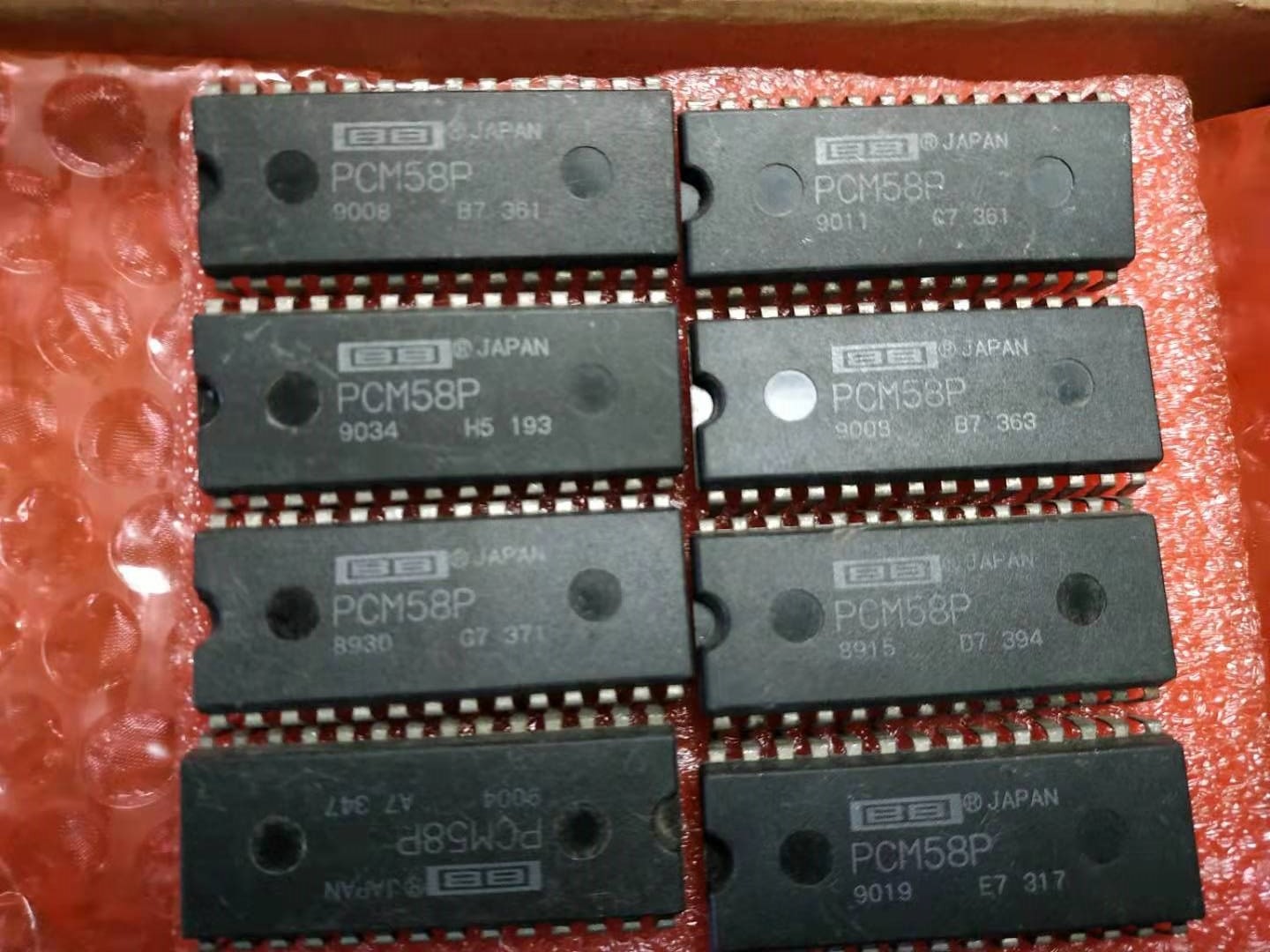

P.S. on the topic of lower noise chips, on paper these PCM58s which arrived yesterday look very good :

The heat isn't really concentrated - sure the chips are warm but given there's quite a lot of copper in the PCB (its 4 layer) the spreading effect evens out the heat quite nicely. Just doesn't disperse it far enough. Could be just a metal plate on the back of each PCB extending beyond the edges will do enough, as you seem to suggest.

I've now made some measurements - the hottest spot I've been able to find with my thermocouple has been 62degrees C, this in an ambient of about 23degrees. Which is probably just about OK sat on my bench but inside a box the ambient will easily become 20oC higher...

P.S. on the topic of lower noise chips, on paper these PCM58s which arrived yesterday look very good :

Last edited:

Could be just a metal plate on the back of each PCB extending beyond the edges will do enough, as you seem to suggest.

=> That was the idea indeed

Whatever the DAC and its specs, the number of chips, as of me at the end it is really sound quality that matters... if another chip is the answer, then so be it 🙂

Will look at the specs sheet tonight

Thanks for all this

Claude

=> That was the idea indeed

Whatever the DAC and its specs, the number of chips, as of me at the end it is really sound quality that matters... if another chip is the answer, then so be it 🙂

Will look at the specs sheet tonight

Thanks for all this

Claude

As a guy with a lot of class A amps I know that a fan can be your friend. There are a lot of quiet small computer fans available that might fit the bill. That way you can move forward with your existing design development without worrying about cooking everything.

I tend to agree with PJN, small Noctua fans are almost inaudible. The level of background noise in my home far exceeds that of a cooling fan 🤣.

A very small amount of air movement is all you probably need for this application.

A very small amount of air movement is all you probably need for this application.

Thanks a bunch for all your input guys, I'll carry on the investigation into fans. And yes @Vunce the amount of air movement necessary is going to be very small, I suspect even a 6cm fan running at 300rpm will be overkill. I'll crank up a Taobao order or two and get the ball rolling...

I thought it was simply a matter of piggybacking the chips. I saw somewhere someone selling a modular vertical stack of DAC chips but I can't find it anymore. The closest was this

View attachment 1108019

http://www.dddac.com/sales_1543.html

I also like the idea of using a quiet fan as a simple solution...maybe the simplest solution. I have used Noctua, BeQuiet, and some other brand (can't remember the name right now) and they are slow, very quiet (have to put my ear next to them to hear), and move plenty of air. As I understand them, it is not so much slowing down a regular fan as it is designing blades that minimize noise-producing turbulence. I would think you could find a inexpensive quiet fan locally to try on your prototype. At first, I suggest using a separate power supply for the fan, just in case, until you can verify it does not affect the circuit electrically. I also agree that excess heat, and thermal cycling will affect reliability, so it is worth the effort to avoid thermal rise. Keep up the good work. This is an exciting project to watch.

Vertical stacking inevitably create thermal gradients btn devices to be cooled.

Horizontal placement and cooling with a low rpm fan is better technically (remains the problem of long term dust accumulation).

Maybe Abrax wants to try some Peltier cooling plates, they are cheap on ebay.

George

Horizontal placement and cooling with a low rpm fan is better technically (remains the problem of long term dust accumulation).

Maybe Abrax wants to try some Peltier cooling plates, they are cheap on ebay.

George

Thanks for the suggestion George, I hadn't realized that Peltier devices had gotten so cheap. In this instance though they don't look as suitable as a fan and they draw so much current that the PSU for them will probably need a fan (or yet another Peltier) to cool it....

Dust accumulation is indeed an issue, we have so much dust in the air here I keep an old toothbrush handy to get rid of it from boards that have been sitting on my desk for more than a couple of weeks. I think its less of an issue though if the fan merely circulates air within a sealed enclosure which is probably all we'll need.

Dust accumulation is indeed an issue, we have so much dust in the air here I keep an old toothbrush handy to get rid of it from boards that have been sitting on my desk for more than a couple of weeks. I think its less of an issue though if the fan merely circulates air within a sealed enclosure which is probably all we'll need.

Plenty of cheap PWM fan controllers out there to regulate the speed. Or Mark Johnson posted a schematic for a discrete fan controller if you were averse to PWM!

https://www.diyaudio.com/community/...-temperature-controlled-analog-no-pwm.336346/

https://www.diyaudio.com/community/...-temperature-controlled-analog-no-pwm.336346/

Thanks for that link Jim, I've now got a 12V 60mm PWM fan but no controller board yet (its on the way). I'm trying out running the fan on reduced DC voltage to see how slow and quiet it will go. At 4V it doesn't always start up but its effectively silent and still seems to be moving enough air.

Just one thing I remember reading with the Chinese PWM modules, atleast the one I ordered, they put out to the fan whatever voltage is input, there is no onboard regulation.

This looks fun.

Sounds like the fan is a good idea.

Plenty of options available and many people use them already right?

Sounds like it needs so little, it could be kind of put next to something else that already has a fan.

I have an urge to make as many things as possible fanless, but I suspect it will be a long time before I get round to it.

But I fancy experimenting with convection airflow. But I will need a fan until I have worked that out.

I might use a single fan for a number of components in a sort of tower or something. (one day, maybe maybe).

Think I have a noctua spare actually......

As to aesthetic, I rather like the more ummmmm industrial look.

It would be invisible anyway so it doesn't matter.

Sounds like the fan is a good idea.

Plenty of options available and many people use them already right?

Sounds like it needs so little, it could be kind of put next to something else that already has a fan.

I have an urge to make as many things as possible fanless, but I suspect it will be a long time before I get round to it.

But I fancy experimenting with convection airflow. But I will need a fan until I have worked that out.

I might use a single fan for a number of components in a sort of tower or something. (one day, maybe maybe).

Think I have a noctua spare actually......

As to aesthetic, I rather like the more ummmmm industrial look.

It would be invisible anyway so it doesn't matter.

Yep thats the one. But did you see the 120 chip version?

- Home

- Source & Line

- Digital Line Level

- lingDAC - cost effective RBCD multibit DAC design