OK, I apologize for not being able to audition it on my rig. I'm just a prosumer with a round needle MC cart. Maybe not high- definition enough.

But do you know what Neumann used to control their cutting VMS cutting lathe? A round needle MC system.😉 But what did they know.

Indeed, the cutting head is driven by mobile coils (MC, but very bigs 😀 ) that cut a "mother" plate, which will serve a limited number of prints in the case of direct cutting discs, and there is a " back up ", a plate "father" to reprint new batches in the case of conventional discs.

But this has nothing to do with the shape of a cartridge's reproduction needle. Check your information on that Neumann cutter, give us the link, if you can. The cutting head is not spherical, elliptical, Shibata, Stereodrhon. etc, none of those geometries designed exclusively for reproduction. I do not know the exact shape, from what I could read in the attachments the material is sapphire and is cooled by helium, even so they can reach 200 degrees Celsius in temperature. .

The complete process is in the attachments, it is interesting to read them carefully.

The discussion here is not whether your TT system is so perfect that you don't listen to the IGD, congratulations on that, but the issue here is whether or not it exists:

"While we're on the curvature subject, it is necessary to explain one more thing. Ever wonder why outside diameter cuts on a record sound clearer and cleaner than inside ones? Unfortunately it's a fact. Why? ....... . "

Time to do homework, read!

Vinyl 101: How to Prepare Your Audio for Vinyl >> Furnace Record Pressing

The Limitation's of Vinyl Records

Attachments

Last edited:

Don't mean to offend you. Sorry if I did. I did reply before your edit. My point is there is consensus to the problems observable when auditioning the last track, "properly" aligned or not. You can "properly" align it twice and it will sound different both times. Better or worse? That is also a subjective question.Of course, not.

I laid out with some examples, that there aren't audible differences when playing an LP on a proper aligned system.

Do you hear differences in sound quality switching from the first track to the last one?

If you audition them, go and fix your player system.

Those discussions are the type of: My digital gear sounds better than my analog record player. If so and not the opposite way around, improve your player system, because it should sound better than digital. Thats the normal state of audio and thats how it should be. Anything else is some kind of misaligned/ low quality gear reason for the problem.

Btw, just answered a direct question from a forum member here with the post you quoted.

If I would listen to an opera, say a complete act on one side, and the sound quality of the voice would be noticeable be worsening during the playtime of an LP, I would go nuts. Maybe I would end up with digital audio. Thank god its not that way.

That the inner tracks are more demanding for a system to reproduce, no discussion about that. But on the other "problems", I don't see a consensus that they are relevant in practise.

They can be measured, of course. But irrelevant for the practical aproach of audio listening. End of discussion for me.

“Those are my principles, and if you don't like them...well I have others.”

― Groucho Marx

That the inner tracks are more demanding for a system to reproduce, no discussion about that. But on the other "problems", I don't see a consensus that they are relevant in practise.

They can be measured, of course. But irrelevant for the practical aproach of audio listening. End of discussion for me.

“Those are my principles, and if you don't like them...well I have others.”

― Groucho Marx

Last edited:

Indeed, the cutting head is driven by mobile coils (MC, but very bigs 😀 ) that cut a "mother" plate, which will serve a limited number of prints in the case of direct cutting discs, and there is a " back up ", a plate "father" to reprint new batches in the case of conventional discs.

But this has nothing to do with the shape of a cartridge's reproduction needle. Check your information on that Neumann cutter, give us the link, if you can. The cutting head is not spherical, elliptical, Shibata, Stereodrhon. etc, none of those geometries designed exclusively for reproduction. I do not know the exact shape, from what I could read in the attachments the material is sapphire and is cooled by helium, even so they can reach 200 degrees Celsius in temperature. .

The complete process is in the attachments, it is interesting to read them carefully.

The discussion here is not whether your TT system is so perfect that you don't listen to the IGD, congratulations on that, but the issue here is whether or not it exists:

"While we're on the curvature subject, it is necessary to explain one more thing. Ever wonder why outside diameter cuts on a record sound clearer and cleaner than inside ones? Unfortunately it's a fact. Why? ....... . "

Time to do homework, read!

Vinyl 101: How to Prepare Your Audio for Vinyl >> Furnace Record Pressing

The Limitation's of Vinyl Records

A misunderstanding or I made myself not clear enough.

I never wrote that Neumann used round needles for cutting the records.

What I wrote was, that Neumann reproduced (controlled) the cutted records with a round needle and that was the Neumann DST pick up system. At least it was good enough for them to evaluate the quality that was cut into the grooves.

And whats the meaning of a "clean " sounding record? A better sounding one? I know of some records that sound ultra clean, but therefore not better to me.

And if that "clean" would be synonymous with "better", why do some 45 rpm records on LP actually don't sound better compared to some of my 33 rpm records?

You see, this is mostly a misuse of wrongly used terms or theoretical viewpoints on audio. In reality, the audio world is much more complex and leads towards different results for "clean sounding records" than whether its 33 or 45 rpm, outer or inner grooves.

Last edited:

Don't forget what the playback on the lathe was basically for was a mixture of:

Playing technical reference disks to provide a way to calibrate the metering, then playing a technical cut to make sure your levels were lined up. Yea, Buchmann-Meyer I know, but measuring that way is a pain in the ****.

Playing a test cutting to check for technical quality (or equivalently playing a test groove cut outside the finished diameter of the stamper for the same purpose). Cutting styli wear quickly (100 hours or so on a good day, less then 20 on a bad one), and there are a lot of ways for things to go sideways, everything from a particular batch of lacquers needing a different amount of stylus heat to mechanical issues with the head or suspension, it is wise to test.

Checking that a test cutting of actual material could be replayed on the sorts of gear the consumers had, you need to know that your pop record will at least sort of track on the crossley with the knackered ceramic stylus, and a spherical is much more likely to show tracking problems then a super elliptical or line contact stylus. This is about showing up problems, not doing the best possible playback.

You need this to show up what happens in a sort of worst case situation, not a best case one.

Interestingly the de-esser in the SAL74 did NOT track diameter when it came to the HF limiting thresholds, so the whole disk was cut with the same HF limit imposed by the inner groove limitations, it also in the standard rig (There were acres of modifications out there, mostly company secret sauce), not sensitive to speed, it imposed the same limiter settings at 45 as it did at 33, in spite of the 45 RPM format clearly being capable of significantly better high frequency performance.

Part of this is that there are very real thermal issues with cutting high frequency at high level, that ~40dB on the velocity between 50hZ and 20kHz has a lot to answer for, and force is proportional to current, so acceleration is proportional to current, which makes thing worse when you realise that drive coil heat goes as current squared, heat goes approximately as frequency^2 * velocity^2!

While I suspect that a late generation machine with helium and a cut at sane level could probably cut better better HF at 45 RPM, I don't know how many people ever did it.

Playing technical reference disks to provide a way to calibrate the metering, then playing a technical cut to make sure your levels were lined up. Yea, Buchmann-Meyer I know, but measuring that way is a pain in the ****.

Playing a test cutting to check for technical quality (or equivalently playing a test groove cut outside the finished diameter of the stamper for the same purpose). Cutting styli wear quickly (100 hours or so on a good day, less then 20 on a bad one), and there are a lot of ways for things to go sideways, everything from a particular batch of lacquers needing a different amount of stylus heat to mechanical issues with the head or suspension, it is wise to test.

Checking that a test cutting of actual material could be replayed on the sorts of gear the consumers had, you need to know that your pop record will at least sort of track on the crossley with the knackered ceramic stylus, and a spherical is much more likely to show tracking problems then a super elliptical or line contact stylus. This is about showing up problems, not doing the best possible playback.

You need this to show up what happens in a sort of worst case situation, not a best case one.

Interestingly the de-esser in the SAL74 did NOT track diameter when it came to the HF limiting thresholds, so the whole disk was cut with the same HF limit imposed by the inner groove limitations, it also in the standard rig (There were acres of modifications out there, mostly company secret sauce), not sensitive to speed, it imposed the same limiter settings at 45 as it did at 33, in spite of the 45 RPM format clearly being capable of significantly better high frequency performance.

Part of this is that there are very real thermal issues with cutting high frequency at high level, that ~40dB on the velocity between 50hZ and 20kHz has a lot to answer for, and force is proportional to current, so acceleration is proportional to current, which makes thing worse when you realise that drive coil heat goes as current squared, heat goes approximately as frequency^2 * velocity^2!

While I suspect that a late generation machine with helium and a cut at sane level could probably cut better better HF at 45 RPM, I don't know how many people ever did it.

That's a lot of "first water" information, thanks.

I'm afraid it's too much for me to process .....

Do you have a little info about the cutting head? A photograph of the morphology of it would be interesting ..........

I'm afraid it's too much for me to process .....

Do you have a little info about the cutting head? A photograph of the morphology of it would be interesting ..........

................

You see, this is mostly a misuse of wrongly used terms or theoretical viewpoints on audio. In reality, the audio world is much more complex and leads towards different results for "clean sounding records" than whether its 33 or 45 rpm, outer or inner grooves.

Yes, I see that beyond your good intentions, you are not in a position to solve my clicks and pops problems other than investing in Garrard / Ortofón. Thanks all the same.....😀

Calcium carbonate in record grooves

Last edited:

I'll tell you what I'm blathering about... I've got information man! New **** has come to light! I mean uh... hasn't that ever occurred to you, man? Sir?

I'm very sorry for your plastic record player system, plops and clicks included.

I'm very sorry for your plastic record player system, plops and clicks included.

I'll tell you what I'm blathering about... I've got information man!

I have not noticed that you have contributed much information that we say ... neither in this nor in the other post that I attached above ..

New **** has come to light! I mean uh... hasn't that ever occurred to you, man? Sir?

This phrase does not make much sense to me, so I completely overlook it .....

With all due respect, I think that you are one of those guys who in the XXI century are "flat-earthers", deniers of science.

Or maybe you have serious hearing problems, and consequently you think that your wonderful music reproduction system is immune to the real problems of 100% of those who listen to vinyl.

I have not noticed that you have contributed much information that we say ... neither in this nor in the other post that I attached above ..

New **** has come to light! I mean uh... hasn't that ever occurred to you, man? Sir?

This phrase does not make much sense to me, so I completely overlook it .....

With all due respect, I think that you are one of those guys who in the XXI century are "flat-earthers", deniers of science.

Or maybe you have serious hearing problems, and consequently you think that your wonderful music reproduction system is immune to the real problems of 100% of those who listen to vinyl.

About reducing or eliminating "inner groove distortion".........

The majority of the audiophile community, being of a certain "pedigree" or snobbishness, is devoid of practical and reasonable intelligence in many ways - I don't work well with those types.

My head's not in the clouds, nor do I practice the overly obsessive traits that they do.

Because they're just a bunch of nuts.

With that stated, I'll explain the inner-groove issues in my own way....

This of course is focused on both new, well-recorded LP's, as well as older, used, and sometimes worn ones.

First, with older, worn records, in a lot of cases you just have to accept that they're worn, and no amount of diddling around is going to eliminate IGD totally.

So get over it, the damage has been done.

The same goes for poorly pressed or recorded LP's - the distortion is already built in.

Secondly, the record groove itself, being an inward spiral of decreasing speed and diameter, is a constantly changing physical property as seen by the stylus.

At the beginning of the LP, the stylus is plowing along the groove at a fast pace, and high frequencies are much easier to cleanly negotiate, being more "stretched out" per inch/cm than at the end of the LP, where that same high frequency is is "tighter" modulations because of reduced rotational speed.

And this is where most distortion can happen, and is the most noticeable.

I'll note that on heavily played LP's, particularly ones played on a less-than-perfect machine, mistracking, stylus shape/wear, and tonearm friction, contribute to the wear and/or damage.

As to the audiophile's insistance of using a "two point" stylus alignment protractor, I don't go that route, because it goes against my learned experience of physics, it's just audiophile hype and written in "their" bible, not mine.

Because at the innermost grooves, at 2-3/8" or 6cm diameter, is where you really need the stylus aligned (90 degrees) for best performance.

To hell with that "outer" measurement that the snobs insist on.

Of course, linear tracking turntables are not part of this equasion, like my Kenwood.

On conventional pivoted tonearms, just align the stylus for 90 degrees at that 2-3/8 or 6cm diameter, where it matters most, particularly with non-conical styli.

At that point of the LP, the generator coils of the cartridge are also aligned with the stereo groove, providing the best high frequency left-right phase alignment, and far less prone to such distortions.

And no, I don't want to argue with or debate my beliefs and findings with the snobs, because it will not change things because of their insistance.

I've had that crap before on other sites, and I've had enough of their babbling.

The majority of the audiophile community, being of a certain "pedigree" or snobbishness, is devoid of practical and reasonable intelligence in many ways - I don't work well with those types.

My head's not in the clouds, nor do I practice the overly obsessive traits that they do.

Because they're just a bunch of nuts.

With that stated, I'll explain the inner-groove issues in my own way....

This of course is focused on both new, well-recorded LP's, as well as older, used, and sometimes worn ones.

First, with older, worn records, in a lot of cases you just have to accept that they're worn, and no amount of diddling around is going to eliminate IGD totally.

So get over it, the damage has been done.

The same goes for poorly pressed or recorded LP's - the distortion is already built in.

Secondly, the record groove itself, being an inward spiral of decreasing speed and diameter, is a constantly changing physical property as seen by the stylus.

At the beginning of the LP, the stylus is plowing along the groove at a fast pace, and high frequencies are much easier to cleanly negotiate, being more "stretched out" per inch/cm than at the end of the LP, where that same high frequency is is "tighter" modulations because of reduced rotational speed.

And this is where most distortion can happen, and is the most noticeable.

I'll note that on heavily played LP's, particularly ones played on a less-than-perfect machine, mistracking, stylus shape/wear, and tonearm friction, contribute to the wear and/or damage.

As to the audiophile's insistance of using a "two point" stylus alignment protractor, I don't go that route, because it goes against my learned experience of physics, it's just audiophile hype and written in "their" bible, not mine.

Because at the innermost grooves, at 2-3/8" or 6cm diameter, is where you really need the stylus aligned (90 degrees) for best performance.

To hell with that "outer" measurement that the snobs insist on.

Of course, linear tracking turntables are not part of this equasion, like my Kenwood.

On conventional pivoted tonearms, just align the stylus for 90 degrees at that 2-3/8 or 6cm diameter, where it matters most, particularly with non-conical styli.

At that point of the LP, the generator coils of the cartridge are also aligned with the stereo groove, providing the best high frequency left-right phase alignment, and far less prone to such distortions.

And no, I don't want to argue with or debate my beliefs and findings with the snobs, because it will not change things because of their insistance.

I've had that crap before on other sites, and I've had enough of their babbling.

Last edited:

Yes, all other audiophiles are just a bunch of nuts and you'r a little intolerant when it comes to different viewpoints. I made mine clear, but thats nothing you are able to tolerate.

Other viewpoints must be "just a bunch of nuts", but you little fascist are telling the absolute truth. Accepted.

Other viewpoints must be "just a bunch of nuts", but you little fascist are telling the absolute truth. Accepted.

Other viewpoints being noted, are fine for being laid on the table to discuss.

But that certainly doesn't mean anyone else has to abide by the rules presented forth, and in some cases are misconceptions generated over time.

I just know for a fact that what I presented earlier is worthy information, perhaps to wake some others up to a different meaningful perspective as to what can be done to help diminish the audible effects of inner groove distortions.

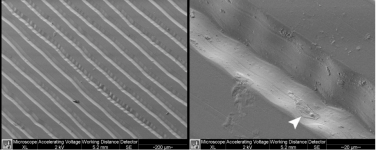

A microscopic inspection of a 10kHz modulation at the LP's outer edge, even halfway into the record, compared to the same 10kHz modulation at the end of an LP is clear evidence that that stylus alignment is substantially more critical at those inner grooves.

The general audio community talks about protractors, and stylus alignment - only.

What is never discussed is the actual generating coils up inside the cartridge itself, and their lateral alignment to the groove modulations.

That itself is why I brought up the phase alignment mention, because if say an elliptical stylus is retrieving information from both groove walls, but at an angle not being 90 degrees, the left/right modulations are out of sync, introducing some distortion.

And being at the innermost grooves is naturally more critical since those frequency modulations are far more compact.

But that certainly doesn't mean anyone else has to abide by the rules presented forth, and in some cases are misconceptions generated over time.

I just know for a fact that what I presented earlier is worthy information, perhaps to wake some others up to a different meaningful perspective as to what can be done to help diminish the audible effects of inner groove distortions.

A microscopic inspection of a 10kHz modulation at the LP's outer edge, even halfway into the record, compared to the same 10kHz modulation at the end of an LP is clear evidence that that stylus alignment is substantially more critical at those inner grooves.

The general audio community talks about protractors, and stylus alignment - only.

What is never discussed is the actual generating coils up inside the cartridge itself, and their lateral alignment to the groove modulations.

That itself is why I brought up the phase alignment mention, because if say an elliptical stylus is retrieving information from both groove walls, but at an angle not being 90 degrees, the left/right modulations are out of sync, introducing some distortion.

And being at the innermost grooves is naturally more critical since those frequency modulations are far more compact.

Last edited:

So why do you think that is? What kind of distortion do you think is generated by a misaligned stylus? How many of us here do you think have experimented in placing the nulls of the cart? They are placed where they are because that's the best compromise available to the design vis a vis tracking ability vs alignment. It isn't the sheep that came up with this arrangement, it was the technical experts. The sheep simply followed the shepherd. If anyone cares to take the status quo to task, they can easily reveal the the imposters by following your formula. The difference in sq is quite remarkable, generally dark, distant, rolled off. But hey, you've got best inner groove tracking, eh. Yea, that's what we should want.🙄The general audio community talks about protractors, and stylus alignment - only.

What is never discussed is the actual generating coils up inside the cartridge itself, and their lateral alignment to the groove modulations.

..........

I'm very sorry for your plastic record player system, plops and clicks included.

Your interest here is just to show off your dream turntable, you've shown it to death. And in your stubbornness, you disqualify what others have been able to acquire with much effort and patience. Are you a rich man, very wealthy? Well, that would not give you the right to despise what others have. My TT and arm are not plastic, - I have already told you with hair and signs - and if they were, I would never write such nonsense, out of respect for others ..

So, try to "fascists" those who think differently than you is a lot like a "projection", in terms of psychology.

Micro Seiki DQ-43 2-Speed Direct-Drive Turntable Manual | Vinyl Engine

Micro Seiki MA-707 Dynamic-Balance Gimbal Bearing Tonearm Manual | Vinyl Engine

Last edited:

Some updates from my side as starting this theme... Cartridge was changed some time ago with a red Ortophone 2M. It seems that the old one was somehow damaged - Ortophone OM Pro. Now is completely different, only very rare vinyls can sound a bit distorted on the last tracks. My plans are to buy the black Ortophone cartridge, it is quite expensive, what do you think?

Some updates from my side as starting this theme... Cartridge was changed some time ago with a red Ortophone 2M. It seems that the old one was somehow damaged - Ortophone OM Pro. Now is completely different, only very rare vinyls can sound a bit distorted on the last tracks. My plans are to buy the black Ortophone cartridge, it is quite expensive, what do you think?

https://www.amazon.com/s?k=denon+dl103&crid=1ID1L3JUVXSI0&sprefix=denon+dl103,aps,215&ref=nb_sb_ss_ts-doa-p_1_11

https://www.ortofon.com/ortofon-2m-black-p-329-n-1579

Last edited:

Maybe you could change the needle for the Black model. Some Orthophone models allow it, and the manufacturer recommends it, when the body and the set of coils are the same. Check the official page.

That said, I have seen on the Ortofon website that this model is worth 630 Euros.

My last acquisition was to buy the very famous Denon DL103. (it's a low output MC, you need an MC pre-phone or step-up transformer, the classic model is $350) The sound it delivers is amazing, the most natural and musical I've ever heard. The only "extra" condition is that for maximum performance the arm must be of medium to high mass. There is a lot of information about it on the web.

Wow, now I understand the reason for his fame!

At some point they stopped making it, its production started in 1962, so hurry up if you decide, I'm about to buy one more spare cartridge. For my "common" recordings I have two Ortofon 2M Red cartridges, (one of them was an Ortofon/Needle Doctor service because the model I received was defective) and for silent recordings in "excellent" condition I use the Denon. Well, the resulting sound is like comparing a Ford T with a Ferrari, and I say that I don't like these analogies, but I don't want to go into technical details.

I'll avoid future controversies here, send me a private message if you want details.

That said, I have seen on the Ortofon website that this model is worth 630 Euros.

My last acquisition was to buy the very famous Denon DL103. (it's a low output MC, you need an MC pre-phone or step-up transformer, the classic model is $350) The sound it delivers is amazing, the most natural and musical I've ever heard. The only "extra" condition is that for maximum performance the arm must be of medium to high mass. There is a lot of information about it on the web.

Wow, now I understand the reason for his fame!

At some point they stopped making it, its production started in 1962, so hurry up if you decide, I'm about to buy one more spare cartridge. For my "common" recordings I have two Ortofon 2M Red cartridges, (one of them was an Ortofon/Needle Doctor service because the model I received was defective) and for silent recordings in "excellent" condition I use the Denon. Well, the resulting sound is like comparing a Ford T with a Ferrari, and I say that I don't like these analogies, but I don't want to go into technical details.

I'll avoid future controversies here, send me a private message if you want details.

Last edited:

- Home

- Source & Line

- Analogue Source

- Last tracks sounds distorted on vinyl

This thread is open again.

This thread is open again.