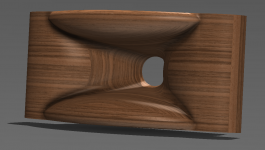

Thanks to a very fruitful cooperation with Dr. Bernd Ahlswede from www.sphericalhorns.net, I can introduce my second large 3D printed horn (the first being the multicell horn for JBL2445). It consists of 9 parts and almost 3 kg of PLA. The 62 cm wide horn was cut to fit my Flsun Super Racer printer, it took more than 60 hours of printing time.

It is glued with Mamut construction glue with a few M3 bolts and nuts for alignment. The inside is only roughly sanded, coated with photo resin and two layers of grey spray paint.

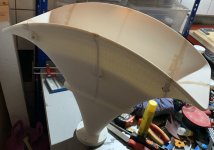

The pictures show the construction and building process. It is still work in progress, the prototype was put together as a feasibility test. It seems to resonate quite strongly, so I will try various ways of damping the horn walls and also second unit with added ribs was printed and is waiting for assembly.

It is intended for BC DCX464 coaxial driver.

It is glued with Mamut construction glue with a few M3 bolts and nuts for alignment. The inside is only roughly sanded, coated with photo resin and two layers of grey spray paint.

The pictures show the construction and building process. It is still work in progress, the prototype was put together as a feasibility test. It seems to resonate quite strongly, so I will try various ways of damping the horn walls and also second unit with added ribs was printed and is waiting for assembly.

It is intended for BC DCX464 coaxial driver.

Attachments

-

4FCB8CF2-1939-4919-94C1-70C4F3C07735.jpeg377.8 KB · Views: 356

4FCB8CF2-1939-4919-94C1-70C4F3C07735.jpeg377.8 KB · Views: 356 -

BB41AD1C-2081-4A1C-8AF7-E9B7CE02DD23.jpeg509.5 KB · Views: 352

BB41AD1C-2081-4A1C-8AF7-E9B7CE02DD23.jpeg509.5 KB · Views: 352 -

EAD0F6E0-C822-4C17-A785-C3AC79A28E70.jpeg349.1 KB · Views: 350

EAD0F6E0-C822-4C17-A785-C3AC79A28E70.jpeg349.1 KB · Views: 350 -

ADCFF771-EF3F-492F-A353-B844DDB09D26.jpeg400.5 KB · Views: 331

ADCFF771-EF3F-492F-A353-B844DDB09D26.jpeg400.5 KB · Views: 331 -

09D43C99-1081-4745-8D02-A688ADDC9D0D.jpeg260.4 KB · Views: 318

09D43C99-1081-4745-8D02-A688ADDC9D0D.jpeg260.4 KB · Views: 318 -

CB616918-1C59-408A-B4F4-94F25947A934.jpeg623 KB · Views: 324

CB616918-1C59-408A-B4F4-94F25947A934.jpeg623 KB · Views: 324 -

9CA3D9ED-3A5C-47FF-8D97-2B0AE906BCC8.jpeg479.7 KB · Views: 328

9CA3D9ED-3A5C-47FF-8D97-2B0AE906BCC8.jpeg479.7 KB · Views: 328 -

3DC2F2BC-F03C-4897-94B1-69AA9C95D445.jpeg892.1 KB · Views: 332

3DC2F2BC-F03C-4897-94B1-69AA9C95D445.jpeg892.1 KB · Views: 332

As far as I can tell, this is not really necessary. I built also a smaller one out of MDF for 1" driver, as mentioned in the recent article. That one has a bit more roundover, in my opinion that is all that is needed, but Bernd would definitely explain better.

Here is one more photo of the horn with a stand just printed.

Here is one more photo of the horn with a stand just printed.

Last edited by a moderator:

this horns very close to what I'm trying to do for a 2" midrange driver: https://www.diyaudio.com/community/...per-scripts-and-m200-fun.385493/#post-7003214 but my results are a bit rubbish in comparison!

The BEM model used had no roundover like DonVK created several times for my designs. Just a tiny one as existing for a real horn resolves most of the roughness you might see.I wonder if the horn could be further optimised with lecleach style roundovers on the edges, to possibly meld with a cabinet and reduce edge diffraction beyond 90°.

Today I had the pleasure to meet Bernd in person. The suspected resonance was in fact a reflection interference, we did a few measurements together and the results are really exceptional performance. The improvements in stiffness of V2 will definitely not hurt, but were not really necessary. I will do some more measurements on V2 when it is finished. This horn is an ideal match to the DCX464. I am excited to make some listening tests in near future.

The pleasure was of course also my side! I will need some days to reflect with all these overwhelming impressions. And I have a prototype in my car for testing

The day was so dense that I forgot to take some photos. Especially the wood horns Jaroslav created catched my attention. This story is definitively going on!

And finally, many thanks for the hospitality!

The day was so dense that I forgot to take some photos. Especially the wood horns Jaroslav created catched my attention. This story is definitively going on!

And finally, many thanks for the hospitality!

They look d..n cool to say the least !

Which advantage do you expect from the DCX in a home setting compared to an ordinary modern high-quality driver ? Its tweeter section has more HD than many other 1.4" drivers. There is of course the IMD advantage of multiple ways but does it make an audible difference at home SPLs ? Did you have the possibility to compare ?

Sorry for OT.

Regards

Charles

Which advantage do you expect from the DCX in a home setting compared to an ordinary modern high-quality driver ? Its tweeter section has more HD than many other 1.4" drivers. There is of course the IMD advantage of multiple ways but does it make an audible difference at home SPLs ? Did you have the possibility to compare ?

Sorry for OT.

Regards

Charles

I wonder if the horn could be further optimised with lecleach style roundovers on the edges, to possibly meld with a cabinet and reduce edge diffraction beyond 90°.

I have a thread called "what do roundovers do?"

It basically came to the same conclusion as @pelanj and @bwaslo - the roundover is unnecessary if the waveguide is sufficiently large.

Roundovers ARE very useful when the waveguide is smaller than the largest wavelength that it radiates. For instance, if you have a 12.7cm waveguide that plays down to 1350Hz (34cm) you definitely want a roundover.

At the moment I'm designing a Joseph Crowe inspired horn for an SB26ADC tweeter, 3rd order cross at 1.8kHz with an SB15NBAC. I'm aiming to have an octave lower of loading to ensure a smooth transition, so the horn isn't likely large enough to not require the roundovers. I may keep them as it's meant to meld with the front baffle anyway.I have a thread called "what do roundovers do?"

It basically came to the same conclusion as @pelanj and @bwaslo - the roundover is unnecessary if the waveguide is sufficiently large.

Roundovers ARE very useful when the waveguide is smaller than the largest wavelength that it radiates. For instance, if you have a 12.7cm waveguide that plays down to 1350Hz (34cm) you definitely want a roundover.

Attachments

Last edited:

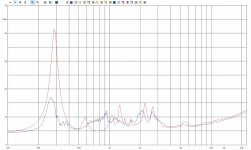

So here is impedance measurement (thanks to Bernd and his Clio Pocket) - free air (red) and on the horn (blue) - only the MF part, HF part shorted. FR measurements I have are not good at the low end, since they were taken in a small room and when gated properly, the low end resolution is really bad.

Attachments

Do you have any decay waterfall measurements to see if any of the impedance spikes result in resonance/horn reflection?So here is impedance measurement (thanks to Bernd and his Clio Pocket) - free air (red) and on the horn (blue) - only the MF part, HF part shorted. FR measurements I have are not good at the low end, since they were taken in a small room and when gated properly, the low end resolution is really bad.

I was just checking out that printer...looks very promising. but 60hours for such a small hornFlsun Super Racer printer, it took more than 60 hours of printing time.

@HEXAAA I need to finish the second prototype and bring it outside. Which peaks do you mean - at which frequency range? I can only do measurements in REW with UMIK-1. If you could give advice how to set up the waterfall view to show what you need, I will do so.

- Home

- Loudspeakers

- Multi-Way

- Large (350 Hz) 3D printed 1.4" William Neile ALO horn by sphericalhorns.net