I would recomend that we try Victoria Magnetics to see what the price would be on a 1KVA with screens as Andrew mentioned. They are always LESS EXPENSIVE and of very high quality! Dr Leach specifies them for his students that are building his amps. I don't necessarily think it has to be in a can and potted though. Some of the finest amps being built today have standard open type toroids. A quality toroid will be virtually noiseless anyway. This should save considerable on the cost. Also is a toroid the best route or should we also consider an E-I type design.... both have their advantages.

I have e-mailed M&M for a quote on the heatsink extrusion and I should have that back in a day or two.

Mark

I have e-mailed M&M for a quote on the heatsink extrusion and I should have that back in a day or two.

Mark

If no one here has any objections in the next hour I am going to hijack the old KSA-50 1st board group buy WIKI and turn it into the KSA-100 board WIKI. This is the old original wiki located here and its long dead done and over with. This is not the KSA-50 technical WIKI and doing so will also help conserve server space.

Mark

Mark

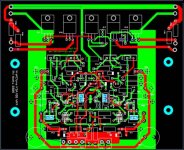

Okay, I've adapted the LTP pairs to be back-to-back, shifted the base pin for the few European types that have triangular pinouts, and added a fourth pin for 2SA/2SC types. Hope everybody is happy now. I had to use 0.5mm traces for a small portion but it will not be a problem.

I've also added the extra hole for triangular trimpots, thickened a few traces and holes, changed the footprints for the drivers to the flat-mounted TO220 package and added a jumper for shorting out the DC blocking feedback caps.

What I could NOT do was the diodes or bigger sized feedback electrolytics. Sorry. With a little ingenuity these can be soldered on the back for those who'd want to use them; I don't think they'd be popular enough to warrant serious adaptions to accommodate them. The driver part and all above it is still only preliminary, I'll make it prettier and more efficient and symmetrical later on. I'm also still pondering about where additional copper pours may be beneficial.

I'll try to see if I can adapt the board with the AAVID heatsinks for the predrivers.

There's only one big problem left: as it is now there is very little room left for the driver heatsink. Compared to the original, there's about 8mm less size for the driver heatsink, not a big difference, but the original already got way too hot. To fit flush with the top of the board, the maximum heatsink size is 25 x 120mm. The board and heatsink cannot be made longer as the clearance to the chassis lid is already very small. Wider will get in the way of the outgoing wire pads. Any increase can therefore only be in the z-axis, but cannot be too much or setting the bias will become difficult. The mounting holes can be shifted lower to make the whole thing lower and thus allow a taller board, but it all depends on the clearance to the chassis bottom.

Right now I cannot do much more until I have the details on what to do with this, how the predrivers should be sinked and what the exact board dimensions and location of terminals and mounting holes are.

Attached is a PDF with the the top and bottom side. I'll add the silkscreen layer etc. when the board is closer to being complete. Some of the stuff that appears to be overlapping would be the components that I made provision for different types i.e. only one will be used such as the MOSFET's. The silkscreen is also covered by the top layer in areas, but of course that will not be the case with the actual board.

Off-topic: Mark, even though I like the idea of my work potentially spreading like a ravaging virus into broken and serviced KSA100's 😉, are you sure that Krell will not have a problem with their designs being replaced with clones in repair shops? DIY stuff and servicing friends' amps on a personal level is one thing, but I'm just curious what the situation might be with something like this... given the sometimes rediculous extent of lawsuits in the USA.

Pierre

I've also added the extra hole for triangular trimpots, thickened a few traces and holes, changed the footprints for the drivers to the flat-mounted TO220 package and added a jumper for shorting out the DC blocking feedback caps.

What I could NOT do was the diodes or bigger sized feedback electrolytics. Sorry. With a little ingenuity these can be soldered on the back for those who'd want to use them; I don't think they'd be popular enough to warrant serious adaptions to accommodate them. The driver part and all above it is still only preliminary, I'll make it prettier and more efficient and symmetrical later on. I'm also still pondering about where additional copper pours may be beneficial.

I'll try to see if I can adapt the board with the AAVID heatsinks for the predrivers.

There's only one big problem left: as it is now there is very little room left for the driver heatsink. Compared to the original, there's about 8mm less size for the driver heatsink, not a big difference, but the original already got way too hot. To fit flush with the top of the board, the maximum heatsink size is 25 x 120mm. The board and heatsink cannot be made longer as the clearance to the chassis lid is already very small. Wider will get in the way of the outgoing wire pads. Any increase can therefore only be in the z-axis, but cannot be too much or setting the bias will become difficult. The mounting holes can be shifted lower to make the whole thing lower and thus allow a taller board, but it all depends on the clearance to the chassis bottom.

Right now I cannot do much more until I have the details on what to do with this, how the predrivers should be sinked and what the exact board dimensions and location of terminals and mounting holes are.

Attached is a PDF with the the top and bottom side. I'll add the silkscreen layer etc. when the board is closer to being complete. Some of the stuff that appears to be overlapping would be the components that I made provision for different types i.e. only one will be used such as the MOSFET's. The silkscreen is also covered by the top layer in areas, but of course that will not be the case with the actual board.

Off-topic: Mark, even though I like the idea of my work potentially spreading like a ravaging virus into broken and serviced KSA100's 😉, are you sure that Krell will not have a problem with their designs being replaced with clones in repair shops? DIY stuff and servicing friends' amps on a personal level is one thing, but I'm just curious what the situation might be with something like this... given the sometimes rediculous extent of lawsuits in the USA.

Pierre

Attachments

Mark A. Gulbrandsen said:...I am going to hijack the old KSA-50 1st board group buy WIKI and turn it into the KSA-100 board WIKI...

Good idea!

PWatts said:Attached is a PDF with three different parts: the top side, bottom side and top silkscreen.

I think you linked to the wrong file! 🙂

Ok, Its here

Also to those of you that are involvd in this if you want to add or change the WIKI around please feel free to do so. I only set it up as a very basic WIKI. I think this is going to b a more limited run than the KSA-50 WIKI was so we jut might want to place the technical stuff and amplifiers built there as well.

You can also click on the link under my name in each post I make.

Mark

Also to those of you that are involvd in this if you want to add or change the WIKI around please feel free to do so. I only set it up as a very basic WIKI. I think this is going to b a more limited run than the KSA-50 WIKI was so we jut might want to place the technical stuff and amplifiers built there as well.

You can also click on the link under my name in each post I make.

Mark

I doubt that many original KSA50 and/or KSA100 owners would have their amplifier repaired by a Krell distributor by now.

It would probably cost an arm and a leg, and more of these amplifers would end up in the scrapyard or as a case for a Leach or a chippy amp.

A board that can be used to rejuvenate one of these amplifiers will keep more of these classics alive.

Surely, if these boards do not lead to lost earnings for Krell dealers and keep more of the Krell heritage in one piece, Mr Krell can not object.

It would probably cost an arm and a leg, and more of these amplifers would end up in the scrapyard or as a case for a Leach or a chippy amp.

A board that can be used to rejuvenate one of these amplifiers will keep more of these classics alive.

Surely, if these boards do not lead to lost earnings for Krell dealers and keep more of the Krell heritage in one piece, Mr Krell can not object.

You may be trying to figure out that I changed the KSA-50 wiki and then changed it back. Either I accidentally created a new KSA-100 wiki or someone behind the scenes did it for me while I was attempting to change the KSA-50 header to the KSA-100.... Yes, I need the WIKI for dummies book!

A Question on the driver heatsink...

Do we all agree on #3 or #2. I asked for a quote on #3 because of its larger contact area.

PWatts.. What is the space between the C/L of the driver transistor mounting holes and the top edge of the board? I need to be sure this sink or #2 will work. I'm not worried about radiating area. Krell only had 3 fins on theirs and it was also quite thin. I think with either we will be in better shape thermally speaking. I just need to be sure that one or the other's mounting foot is going to fit between the top of the board and extend down to allow sufficient contact of the driver deices tabs. What color do you all want these sinks anodized? We have a local place thats reasonable and does very good work. Do we want to stick with the orignal blue color?

Mark

A Question on the driver heatsink...

Do we all agree on #3 or #2. I asked for a quote on #3 because of its larger contact area.

PWatts.. What is the space between the C/L of the driver transistor mounting holes and the top edge of the board? I need to be sure this sink or #2 will work. I'm not worried about radiating area. Krell only had 3 fins on theirs and it was also quite thin. I think with either we will be in better shape thermally speaking. I just need to be sure that one or the other's mounting foot is going to fit between the top of the board and extend down to allow sufficient contact of the driver deices tabs. What color do you all want these sinks anodized? We have a local place thats reasonable and does very good work. Do we want to stick with the orignal blue color?

Mark

The wiki is a strange and wonderful beast that doesn't always do exactly what you want it to, as I think you've found out as well, and changing the page link was the esiest way to get things sorted. 🙂

edit: I've changed the link in your earlier post, so that will work as well.

edit: I've changed the link in your earlier post, so that will work as well.

pinkmouse said:The wiki is a strange and wonderful beast

Makes you want to run to the shop to get one, Sir Al-lenborough.

OK, people need to realize the following: I cannot go further until I have someone providing me the exact board dimensions and relative positions of the mounting holes and wire pads. The current board is merely an extrapolation I did from pictures I had and literally measuring on my monitor with a ruler and using reference sizes in order to find the scale. Not terribly accurate but within a cm or so. That is unacceptable, so I'm halted for the time being. I have a Mk2 coming in for service in the near future but I'm not certain about the details.

So, anybody have access Mk1 or Mk2 PCB?

Mark, if I assume the current board dimensions to be correct, there is about 14mm between the top of the board and the driver transistor mounting holes' centre (I assume that's what C/L stands for). Of course the heatsink extends down to about midway of the package, so the total length would of the sink would be around 22mm. When I have the correct dimensions I can give more accurate figures; these can easily be up to 30% off.

Is everybody OK about the predrivers? I tried the AAVID heatsinks Floedstroem suggested, but that would really screw up everything and seriously hamper the efficiency of the layout. According to my simulations the sinks can be fairly small, about 2W in total for all four. However, before people send the KKK to burn down my house if they do indeed get to hot, I suggest somebody build a prototype on a cheap dual-side board before having the group buy done. I would have volunteered but I just do not have the time.

If the predrivers are acceptable and I have the final board spacing sorted out, the design would be pretty much finished. I have to remention that somebody should PLEASE double-check both the diagram, routing, components, pad/hole sizes etc.

So, anybody have access Mk1 or Mk2 PCB?

Mark, if I assume the current board dimensions to be correct, there is about 14mm between the top of the board and the driver transistor mounting holes' centre (I assume that's what C/L stands for). Of course the heatsink extends down to about midway of the package, so the total length would of the sink would be around 22mm. When I have the correct dimensions I can give more accurate figures; these can easily be up to 30% off.

Is everybody OK about the predrivers? I tried the AAVID heatsinks Floedstroem suggested, but that would really screw up everything and seriously hamper the efficiency of the layout. According to my simulations the sinks can be fairly small, about 2W in total for all four. However, before people send the KKK to burn down my house if they do indeed get to hot, I suggest somebody build a prototype on a cheap dual-side board before having the group buy done. I would have volunteered but I just do not have the time.

If the predrivers are acceptable and I have the final board spacing sorted out, the design would be pretty much finished. I have to remention that somebody should PLEASE double-check both the diagram, routing, components, pad/hole sizes etc.

Power supply?

Hi

Is there anybody out there having a reference/Link to the DATE for the main transformer (for the KSA 100mkII)?

I need data specifications (winding-voltage + VA) or a model number (for the transformer, not the amp). I can have the Avel Lindberg to wind exactly the same original transformer and I would like to investigate pricing (price breakes etc...) for a small production run for a GB.

Regards 😎

Hi

Is there anybody out there having a reference/Link to the DATE for the main transformer (for the KSA 100mkII)?

I need data specifications (winding-voltage + VA) or a model number (for the transformer, not the amp). I can have the Avel Lindberg to wind exactly the same original transformer and I would like to investigate pricing (price breakes etc...) for a small production run for a GB.

Regards 😎

Hi Floedstrom,

good idea about the GB of transformers, but would the freight not be prohibitive?

good idea about the GB of transformers, but would the freight not be prohibitive?

Luke,

Depends of-course on your location or wether you choose to ship it surface or by air, especially by whom. There is always a research to do.

Recently I organized a GB for big heat sinks from Australia (Conrads Heat Sinks). the freight costs became very low due to the quantity ordered. Big heat sinks are heavy.

Because there is so many different parts to check, design and order (especially PCB´s) including chassis work to order or build, because of that reason surface freight, 8-12 weeks is not prohibitive for me.

is not prohibitive for me.

Any tip to this thread for cheap freight will be appreciated.

Regards 😎

Depends of-course on your location or wether you choose to ship it surface or by air, especially by whom. There is always a research to do.

Recently I organized a GB for big heat sinks from Australia (Conrads Heat Sinks). the freight costs became very low due to the quantity ordered. Big heat sinks are heavy.

Because there is so many different parts to check, design and order (especially PCB´s) including chassis work to order or build, because of that reason surface freight, 8-12 weeks

is not prohibitive for me.

is not prohibitive for me. Any tip to this thread for cheap freight will be appreciated.

Regards 😎

Flodstroem said:have Avel Lindberg wind exactly the same original transformer

Hate to dissapoint you, i believe the MKII had 700VA toroids.

Of course, the 3d stage KSA, the fan-less KSA100EUR overhere, had Holden& Fisher transformers.

Those have/had nice smooth rounded edges, still no idea what kind of core was used by H&F. I'm certainly not going to unwind one to find out.

How's about a nice MK-I transformer ? 😀 =>

(excuse me for cutting those bad French fans off the pic. Speaking of fans, any idea how much capacitor life/cash is saved by using a fan instead of passive cooling ?)

Attachments

I do need the exact dimensions..... If you've ever seen where the die is located inside those TO-220 packages... right in the center of the square part... you would want the heatsink to extend all the way down the length package for best heat transfer which is what I'm aiming for. For now I will use the 14mm dimension since I can refer back to a TO-220 drawing and calculate how far above and below the hole the sink needs to extend for complete contact. I never did like Krell's layout and the lack of contact at the lower part of the devices. It may have been that it was the only off the shelf sink they cold get at the time. As you can see in the photo Alex provided us the internal die in each device is right at the lower edge of the sink...stupid!

As far as boards go I can get protos made up and build them. This was S.O.P. with the KSA-50 board runs to be sure they worked. It adds some time to the actual run but might reveal a serious problem. I could also send a pair of boards to someone else willing to build and test. The smallest quantity run is 5 proto boards. These don't have the silkscreen and are but half oz copper but they are fairly inexpensive and the proto cost can sometimes even be wavered if the boardhouse does a large enough final board run. Send me the files and I can get the whole thing priced out....but..... we still have to decide on.....

What thickness? Gold plated? Color, Teflon or G-10? I am going to do 2 oz copper irregardless since it holds up much better and will sink heat better for certain small devices.

As for transformers in the U.S. I will stick with either Victoria Magnetics or Plitron since shipping in the US would be far less expensive and there would be no duties to pay. Nelson Pass says Plitron is by far the best toroid made today. Also the Avel in the A-40 that Mike W sent me has a nasty buzz so I'm not so sure about Avel's quality.

Mark

As far as boards go I can get protos made up and build them. This was S.O.P. with the KSA-50 board runs to be sure they worked. It adds some time to the actual run but might reveal a serious problem. I could also send a pair of boards to someone else willing to build and test. The smallest quantity run is 5 proto boards. These don't have the silkscreen and are but half oz copper but they are fairly inexpensive and the proto cost can sometimes even be wavered if the boardhouse does a large enough final board run. Send me the files and I can get the whole thing priced out....but..... we still have to decide on.....

What thickness? Gold plated? Color, Teflon or G-10? I am going to do 2 oz copper irregardless since it holds up much better and will sink heat better for certain small devices.

As for transformers in the U.S. I will stick with either Victoria Magnetics or Plitron since shipping in the US would be far less expensive and there would be no duties to pay. Nelson Pass says Plitron is by far the best toroid made today. Also the Avel in the A-40 that Mike W sent me has a nasty buzz so I'm not so sure about Avel's quality.

Mark

Plitron hm..............

I have no confidence in a cheap Plitron. Got a quotation from them and it was far more expensive to buy a series produced Audio-model from Plitron than let have to wind a custom design in Europe.

Also, I think they demanded $ 200 freight charge (dont remember if freight charge was for UPS or FeDex) .

.

This is very sad though I also know their audio power transformers are excellent.

Its a matter of fakts: now we have the opportunity for to order Krell originals!!??

Ok, you could save a couple of bucks by not to use an audio-transformer, but to what price (after month of work you throw in a cheap transformer @ $ 100 and it starts to buzz a week or so later).

The iron core is different for those used in an audio-transformers compared to the standard commercials.

Mark:

Are you sure this was a transformer ordered as a custom design for audio, specified for to be dead-silent?

All of the commercial transformer I have used (regardless of brands) for class-A amp was buzzing and noising to much. I would newer use a cheap "Standard Mains/Power Transformer" for a Krell Clone amp, Its to much job for to build and it should be built of best available products and components But this is only my thoughts

But this is only my thoughts

Regards 😎

I have no confidence in a cheap Plitron. Got a quotation from them and it was far more expensive to buy a series produced Audio-model from Plitron than let have to wind a custom design in Europe.

Also, I think they demanded $ 200 freight charge (dont remember if freight charge was for UPS or FeDex)

.

.This is very sad though I also know their audio power transformers are excellent.

Its a matter of fakts: now we have the opportunity for to order Krell originals!!??

Ok, you could save a couple of bucks by not to use an audio-transformer, but to what price (after month of work you throw in a cheap transformer @ $ 100 and it starts to buzz a week or so later).

The iron core is different for those used in an audio-transformers compared to the standard commercials.

Mark:

As for transformers in the U.S. I will stick with either Victoria Magnetics or Plitron since shipping in the US would be far less expensive and there would be no duties to pay. Nelson Pass says Plitron is by far the best toroid made today. Also the Avel in the A-40 that Mike W sent me has a nasty buzz so I'm not so sure about Avel's quality.

Are you sure this was a transformer ordered as a custom design for audio, specified for to be dead-silent?

All of the commercial transformer I have used (regardless of brands) for class-A amp was buzzing and noising to much. I would newer use a cheap "Standard Mains/Power Transformer" for a Krell Clone amp, Its to much job for to build and it should be built of best available products and components

But this is only my thoughts

But this is only my thoughtsRegards 😎

- Home

- Amplifiers

- Solid State

- Krell KSA 100mkII Clone