Hello All

I have been repairing Klipsch subwoofer amps for about 15 years as a hobby. I have decided to start blogging my repairs and eventually do videos of each one. This thread is intended to be a blog and a resource for information. I will try to answer repair questions as best I can. Comments and tips are also welcome, If you do not have the experience or the tools, PLEASE do not attempt any of these repairs. You will only end up damaging the board and it will end up costing more for a tech to repair the damage. If you do not have a high quality vacuum desoldering station (Hakko or Weller) and a current limited mains supply, you should not be working on these amps. These subwoofers do not have any user serviceable parts inside. If you open up the sub or attempt any repair you see in this thread, you are doing so at your own risk!!!

The PDC board 660038RA (main supply control) is almost always the main failure mode of these amps. The glue that was used becomes conductive and kills the board and the fets (planned obsolescence?). These boards are typically made in China and are super easy to damage. If you don't have a desoldering tool you MUST cut the board off and remove the legs from the thru holes one by one. Once the thru holes are damaged the repair becomes a difficult hack job unless you have a thru hole repair kit.

The other most frequent failures are the Bash control board and Q5. If Q5 is SOT-23, it needs to be replaced with a TO-92 2N4401. This mod was done on later revisions most likely due to warranty claims.

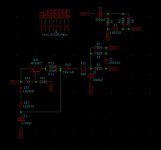

I have made a schematic of the PDC board and I also have made replacement boards (I do not sell or supply these boards). Sometimes they are so badly burnt, they have to just be replaced.

I have been repairing Klipsch subwoofer amps for about 15 years as a hobby. I have decided to start blogging my repairs and eventually do videos of each one. This thread is intended to be a blog and a resource for information. I will try to answer repair questions as best I can. Comments and tips are also welcome, If you do not have the experience or the tools, PLEASE do not attempt any of these repairs. You will only end up damaging the board and it will end up costing more for a tech to repair the damage. If you do not have a high quality vacuum desoldering station (Hakko or Weller) and a current limited mains supply, you should not be working on these amps. These subwoofers do not have any user serviceable parts inside. If you open up the sub or attempt any repair you see in this thread, you are doing so at your own risk!!!

The PDC board 660038RA (main supply control) is almost always the main failure mode of these amps. The glue that was used becomes conductive and kills the board and the fets (planned obsolescence?). These boards are typically made in China and are super easy to damage. If you don't have a desoldering tool you MUST cut the board off and remove the legs from the thru holes one by one. Once the thru holes are damaged the repair becomes a difficult hack job unless you have a thru hole repair kit.

The other most frequent failures are the Bash control board and Q5. If Q5 is SOT-23, it needs to be replaced with a TO-92 2N4401. This mod was done on later revisions most likely due to warranty claims.

I have made a schematic of the PDC board and I also have made replacement boards (I do not sell or supply these boards). Sometimes they are so badly burnt, they have to just be replaced.

Attachments

Last edited:

SUB-12 Plate serial number 06310349

This amp had no power. The PDC board was shorted, which blew the transformer drive fets and was causing the fuse to blow. The PDC was removed, cleaned and repaired. Q5 was upgraded to a 2N4401 and the amp was fully recapped with Nichicon caps. Gotta love those JUNFU capacitors. It's fun to say, but that't about the only good thing about them. The SUB-12 amp is my favorite BASH (Klipsch) amp, even with all the issues they have. They really put out a good amount of power. It is a good idea to silicone the replacement parts in place. You don't need to go crazy but it helps to have them secured.I use GE silicone 2. Q5 definitely needs to be secured at the head and also over the pads and solder joints. Epoxy over the solder joints would probably be better, but the silicone works just fine.

This amp had no power. The PDC board was shorted, which blew the transformer drive fets and was causing the fuse to blow. The PDC was removed, cleaned and repaired. Q5 was upgraded to a 2N4401 and the amp was fully recapped with Nichicon caps. Gotta love those JUNFU capacitors. It's fun to say, but that't about the only good thing about them. The SUB-12 amp is my favorite BASH (Klipsch) amp, even with all the issues they have. They really put out a good amount of power. It is a good idea to silicone the replacement parts in place. You don't need to go crazy but it helps to have them secured.I use GE silicone 2. Q5 definitely needs to be secured at the head and also over the pads and solder joints. Epoxy over the solder joints would probably be better, but the silicone works just fine.

Attachments

SUB-10 Plate serial number 06230172

This amp also power to the secondary side of the transformer. The +-15V supplies were stable, but the outputs did not have power. The BASH module was not working. At idle the rails should have around 5V across them with the volume at 0. Pin 5 of the bash module should have around 12V between pin 11. This module has the full ~90V rail voltage on it so don't poke around with the power on. Q5 was the issue and replaced with a TO-92 2N4401. From the heat generated the trace lifted of the board but I was able to carefully remove the part with hot air and epoxy the pad back down. This repair also got a blob of epoxy to secure the legs of the part from stressing the traces. A full recap of the power supply was done , also all the bad glue removed and it is good to go.

This amp also power to the secondary side of the transformer. The +-15V supplies were stable, but the outputs did not have power. The BASH module was not working. At idle the rails should have around 5V across them with the volume at 0. Pin 5 of the bash module should have around 12V between pin 11. This module has the full ~90V rail voltage on it so don't poke around with the power on. Q5 was the issue and replaced with a TO-92 2N4401. From the heat generated the trace lifted of the board but I was able to carefully remove the part with hot air and epoxy the pad back down. This repair also got a blob of epoxy to secure the legs of the part from stressing the traces. A full recap of the power supply was done , also all the bad glue removed and it is good to go.

Attachments

SYNERGY SUB-12 PLATE SERIAL 06230184

This amp was blowing fuses. The PDC control board failed and took out the mosfets. I had to clean and rebuild the PDC, replace the fets, replace Q5 and TH3. TH3 is almost always bad when fuses are blowing. After the board was working, a full recap was done on the amp.The active crossover was especially fun due to all the damn glue used.

This amp was blowing fuses. The PDC control board failed and took out the mosfets. I had to clean and rebuild the PDC, replace the fets, replace Q5 and TH3. TH3 is almost always bad when fuses are blowing. After the board was working, a full recap was done on the amp.The active crossover was especially fun due to all the damn glue used.

Attachments

SYNERGY SUB-10 PLATE SERIAL 05420831

This one looks a little brown and crispy. The back of the red film capacitors also has some nice black magic smoke on it. Q5 is turning brown from overheating. This will need a full recap, removal of all the glue, Q5 and fets replaced and rebuild of the PDC board.

This one looks a little brown and crispy. The back of the red film capacitors also has some nice black magic smoke on it. Q5 is turning brown from overheating. This will need a full recap, removal of all the glue, Q5 and fets replaced and rebuild of the PDC board.

Attachments

SYNERGY SUB-12 PLATE SERIAL Y9154604807

This is one of the nicest Sub-12 revisions that I have seen. It has all the updates and used a silicone based glue. This one died from a surge or spike. It will get a repair and recap.

This is one of the nicest Sub-12 revisions that I have seen. It has all the updates and used a silicone based glue. This one died from a surge or spike. It will get a repair and recap.

Attachments

SYNERGY SUB-10 PLATE SERIAL C707360626

SYNERGY SUB-12 PLATE SERIAL ?????

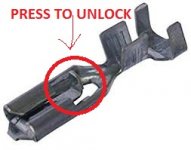

This set was sent in for me to go over. The Sub-12 looked like it was in a war. All of the wires were cut, the fuse holder was stuffed with aluminum foil and plenty of parts were deep fried and that is all after the failure from the glue monster. The Sub-10 was not in terrible shape, but it also good and crispy around the glue and PDC board. The owner couldn't figure out how to remove the speaker wire so why not just rip it out of the terminal. These terminals use locking tabs.

These are the before pictures

SYNERGY SUB-12 PLATE SERIAL ?????

This set was sent in for me to go over. The Sub-12 looked like it was in a war. All of the wires were cut, the fuse holder was stuffed with aluminum foil and plenty of parts were deep fried and that is all after the failure from the glue monster. The Sub-10 was not in terrible shape, but it also good and crispy around the glue and PDC board. The owner couldn't figure out how to remove the speaker wire so why not just rip it out of the terminal. These terminals use locking tabs.

These are the before pictures

Attachments

.........The owner couldn't figure out how to remove the speaker wire so why not just rip it out of the terminal. These terminals use locking tabs.

Congratulations, great work, thanks for sharing ! 🙂

Perhaps those terminals are also part of the programmed obsolescence, (the ones that are much more complicated are the terminals of car instruments, they are exasperating! )

OT, I'm sorry :

I had to repair the beacon switch of my car, it is located in the worst place imaginable and is part of a single large unit. I had to disassemble lights command keys, ABS system, everything! And each terminal had a different anchor system ....!

So I understand the user ....

Would you happen to know the trick to remove the amp assembly from the sub? I’ve got a Sub-10 that powers up but makes a weak, almost buzzing sound any time the bass hits. I was hoping to remove it and have a look since I’ve got some experience with electronics repair.

Klipsch/Bash sub 10

I have the exact same issue. speaker is good, board powers up and sound comes out but it is very low and buzzy but you can make out the music. replaced IFR530 mosfet that acted funny but to no avail. Dont really know if it worth it to cet another BASH amp for it. They have sooo many failures. I would get a BASH300s as a replacement but this one seems repairable.

I have the exact same issue. speaker is good, board powers up and sound comes out but it is very low and buzzy but you can make out the music. replaced IFR530 mosfet that acted funny but to no avail. Dont really know if it worth it to cet another BASH amp for it. They have sooo many failures. I would get a BASH300s as a replacement but this one seems repairable.

I have the exact same issue. speaker is good, board powers up and sound comes out but it is very low and buzzy but you can make out the music. replaced IFR530 mosfet that acted funny but to no avail. Dont really know if it worth it to cet another BASH amp for it. They have sooo many failures. I would get a BASH300s as a replacement but this one seems repairable.

Let me know what you find out! I would really rather not have to replace the amp since all the components on the board are pretty inexpensive. It's a matter of figuring out which is the culprit...

Would you happen to know the trick to remove the amp assembly from the sub? I’ve got a Sub-10 that powers up but makes a weak, almost buzzing sound any time the bass hits. I was hoping to remove it and have a look since I’ve got some experience with electronics repair.

Remove the perimeter screws and pop it out with a butter knife. The seal is sometimes sticky.

I have the exact same issue. speaker is good, board powers up and sound comes out but it is very low and buzzy but you can make out the music. replaced IFR530 mosfet that acted funny but to no avail. Dont really know if it worth it to cet another BASH amp for it. They have sooo many failures. I would get a BASH300s as a replacement but this one seems repairable.

They can all be fixed. The 300S is the exact same amp but the plate is a different size I believe. The IRF530 fets never go bad in these. In the many amps I have worked on the only reason I ever saw a blown 530 was from someone messing around and causing it to blow. Be careful removing parts the plated holes tear out very easy and are not cheap to replace.

Haha. I tore out the eyelets/vias when removing the mosfets from my sub amp. And yes, they're a pain in the a$$ to repair.

IIRC these amps are similar to the ones used in Mirage subs. I just repaired my Mirage Omni S10 which has an indigo/BASH amplifier. Replaced the two mosfets, inrush current limiter, and the fuse and its back in action.

SVS sub Indigo board repair

IIRC these amps are similar to the ones used in Mirage subs. I just repaired my Mirage Omni S10 which has an indigo/BASH amplifier. Replaced the two mosfets, inrush current limiter, and the fuse and its back in action.

SVS sub Indigo board repair

Haha. I tore out the eyelets/vias when removing the mosfets from my sub amp. And yes, they're a pain in the a$$ to repair.

IIRC these amps are similar to the ones used in Mirage subs. I just repaired my Mirage Omni S10 which has an indigo/BASH amplifier. Replaced the two mosfets, inrush current limiter, and the fuse and its back in action.

SVS sub Indigo board repair

Many different subs use BASH amps and they all have the same failure modes. BAD GLUE & CHINESE CAPS

Many different subs use BASH amps and they all have the same failure modes. BAD GLUE & CHINESE CAPS

How can you tell if the problem is the glue? My caps all look good. Not expanded or leaking at least. Would glue problems cause the low buzzing sound? My Q5 leads look a little discolored. Would you suggest doing the upgrade and see if that fixes the issue?

How can you tell if the problem is the glue? My caps all look good. Not expanded or leaking at least. Would glue problems cause the low buzzing sound? My Q5 leads look a little discolored. Would you suggest doing the upgrade and see if that fixes the issue?

Make sure you have the skill and the tools. If you don't you will be sending it to a tech and paying extra to repair the damage. If you tear out a thru hole, stop and send it out. Hack jobs can cause fires and other failures. Have the plated holes replaced and start over.

The glue causes shorts all over the amp and needs to be fully removed anywhere it touches the board. The capacitors are all at end of life and should all be replaced regardless of how they look. 2000 hours on a Chinese capacitor is a blessing anything over that is a time bomb. 99% of the owners of these never turn the switch off. That means in 2 YEARS the capacitors have used a good part of their life, the glue has heated and started turning brown and conductive and the amp needs to be serviced. They will eventually dry up or leak and cause even more damage. STANDBY MODE DOES NOT POWER THE SUPPLIES OFF FULLY!!!!!!!

The only proper way to service the amp is to do a full restoration/upgrade. Remove all the glue, replace ALL the caps, repair any damaged parts, fets or PDC board and upgrade Q5. The Q5 upgrade is very difficult and I almost always lift a pad.

Last edited:

Make sure you have the skill and the tools. If you don't you will be sending it to a tech and paying extra to repair the damage. If you tear out a thru hole, stop and send it out. Hack jobs can cause fires and other failures. Have the plated holes replaced and start over.

The glue causes shorts all over the amp and needs to be fully removed anywhere it touches the board. The capacitors are all at end of life and should all be replaced regardless of how they look. 2000 hours on a Chinese capacitor is a blessing anything over that is a time bomb. 99% of the owners of these never turn the switch off. That means in 2 YEARS the capacitors have used a good part of their life, the glue has heated and started turning brown and conductive and the amp needs to be serviced. They will eventually dry up or leak and cause even more damage. STANDBY MODE DOES NOT POWER THE SUPPLIES OFF FULLY!!!!!!!

The only proper way to service the amp is to do a full restoration/upgrade. Remove all the glue, replace ALL the caps, repair any damaged parts, fets or PDC board and upgrade Q5. The Q5 upgrade is very difficult and I almost always lift a pad.

Would you happen to have a recommended parts list for the replacement parts/upgrades? I can check the number on each cap, but curious if there is a brand you suggest since you have lots of experience with these exact boards

- Home

- Loudspeakers

- Subwoofers

- Klipsch Sub-10 / Sub-12 / RPW-10 Repair Blog