About to pull the trigger on a pair of the LASE drivers and get building.

From what I gathered, the LASE driver sims well for a budget driver but is currently untested? I don't think there's anything in that same cost bracket.

I have DATS v3 and would be willing to measure and post up findings. Just kind of concerned about getting unusable drivers.

From what I gathered, the LASE driver sims well for a budget driver but is currently untested? I don't think there's anything in that same cost bracket.

I have DATS v3 and would be willing to measure and post up findings. Just kind of concerned about getting unusable drivers.

Art,

The driver is ordered. When it arrives I'll measure it to see real world t/s specs as they seem questionable.

It's going to take a bit to build out the cabinet unfortunately. We did just print off some syntripp lenses to match. Can't wait to hear the combo in our normal party space!

The driver is ordered. When it arrives I'll measure it to see real world t/s specs as they seem questionable.

It's going to take a bit to build out the cabinet unfortunately. We did just print off some syntripp lenses to match. Can't wait to hear the combo in our normal party space!

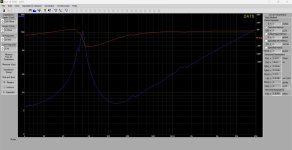

Hopefully the photo attached properly. This is a fresh Lase 18lf-3600 measured in free air with spacers under the magnet to allow the vents to be open. Leads on the Dats unit were calibrated before testing. Seems to be a lot of driver for the money, and the specs look to be close to what the manufacturer has listed for the NEW! model.

Attachments

Tooling up to build. I have access to a decent laser cutter and would like to design some templates to make the build easier. Is there a solid model for the keystone? I searched the thread and couldn't find it, just the 2d drawings.

I don't recall any shared solid models in this thread.

Tonefarm posted some 3D CAD photos 3/20/2020 post #1287:

https://www.diyaudio.com/community/...-12-inch-speakers.185588/page-65#post-6127960

Speetpeet printed a different version of the Keystone in 2021 post #1470:

https://www.diyaudio.com/community/threads/keystone-sub-using-18-15-12-inch-speakers.185588/page-74

Here's something in 3D Warehouse that says "Not finished yet!":

https://3dwarehouse.sketchup.com/mo...eystone-Subwoofer-Using-18-inch-speaker?hl=de

Tonefarm posted some 3D CAD photos 3/20/2020 post #1287:

https://www.diyaudio.com/community/...-12-inch-speakers.185588/page-65#post-6127960

Speetpeet printed a different version of the Keystone in 2021 post #1470:

https://www.diyaudio.com/community/threads/keystone-sub-using-18-15-12-inch-speakers.185588/page-74

Here's something in 3D Warehouse that says "Not finished yet!":

https://3dwarehouse.sketchup.com/mo...eystone-Subwoofer-Using-18-inch-speaker?hl=de

The 3d printed one really makes me wish we have a printer with that large of a bed as currently it's just big enough for syntripp lenses. Assuming the post linked in the OG post has the link to the correct plans (post 487) I'll make a quick model off those and host them as it might help other builders out. I do plan on designing templates for panels that have more going on, as this just makes building a fleet so much easier, and I'll post them also.

If the bed if your 3d printer is not big enough for what you want to fabricate, just print it in smaller pieces that you can glue with epoxy after, you can add dado like joints or some kind of holes on one piece and some pins on the other so it will mate perfectly and with epoxy or some other glue that the community recommends will make your lens or part indestructible!!

Unless it fall from a 15 feet scaldfold 🤪

Unless it fall from a 15 feet scaldfold 🤪

I was referring to the 3d printed keystone mentioned above, it's beautiful but printing on a small frame printer would be literal hell.

I've modeled up all of the main panels and just need to draw in the bracing. This is all done in fusion360 and I'll post a shared link soon.

What's the take on "speed holes" in the bracing? Are most people building with them? The braces themselves are rather small in area as designed (which is likely fine for 3/4 ply) so I'm unsure if it serves any purpose to add them.

I've modeled up all of the main panels and just need to draw in the bracing. This is all done in fusion360 and I'll post a shared link soon.

What's the take on "speed holes" in the bracing? Are most people building with them? The braces themselves are rather small in area as designed (which is likely fine for 3/4 ply) so I'm unsure if it serves any purpose to add them.

I don't recall any shared solid models in this thread.

Tonefarm posted some 3D CAD photos 3/20/2020 post #1287:

https://www.diyaudio.com/community/...-12-inch-speakers.185588/page-65#post-6127960

Speetpeet printed a different version of the Keystone in 2021 post #1470:

https://www.diyaudio.com/community/threads/keystone-sub-using-18-15-12-inch-speakers.185588/page-74

Here's something in 3D Warehouse that says "Not finished yet!":

https://3dwarehouse.sketchup.com/mo...eystone-Subwoofer-Using-18-inch-speaker?hl=de

I gotchu guy!

That interior plate covering half the driver cavity, is that supposed to be there? I'm not seeing it in and of the plans.

The photos of the cad do help with seeing how the braces around the G board work, it's not the clearest in the cut sheet/plan.

The photos of the cad do help with seeing how the braces around the G board work, it's not the clearest in the cut sheet/plan.

Speetpeet's construction, measured response, the holes in the braces and their placement and shape are all quite different than any other Keystone sub builds done according to my plans.What's the take on "speed holes" in the bracing? Are most people building with them?

The experiments I did with a plate covering a portion of the driver throat made the response worse than without.

I don't know what BP1Fanatic means by "I gotchu guy!", but the photos in post # 1671 are not representative of the Keystone Sub as I designed it.

Cheers,

Art

I was thinking speed holes in general, not in reference to any particular build.

Are they recommend for the build, or is solid the way to go? I'm used to BFM builds, but those required it mostly due to the this ply used, with much longer braces in general.

Are they recommend for the build, or is solid the way to go? I'm used to BFM builds, but those required it mostly due to the this ply used, with much longer braces in general.

The term is "lightening holes", they take longer to make 😉I was thinking speed holes in general, not in reference to any particular build.

If you look at the plans, you will see I did not use any, nor do I recommend them in the Keystone as designed.

Art

I've always called them speed holes, due to their likeness to motorsport bracing. I'll refrain from making the superleggera of cabs!

Yeah, the steel tubes used in superleggera (Italian for "superlight") construction don't lend themselves well to subwoofers the size of the Keystone 😎

I modeled it up. Should be pretty spot on from the cutsheet.

Both a fusion360 file and .step can be found here: https://drive.proton.me/urls/5RB4XDX5BG#6y9n3c47QMh1

Both a fusion360 file and .step can be found here: https://drive.proton.me/urls/5RB4XDX5BG#6y9n3c47QMh1

- Home

- Loudspeakers

- Subwoofers

- Keystone Sub Using 18, 15, & 12 Inch Speakers