About 18 months ago I purchased a pair of Jordan eikona 2 drivers. Just before I was about to start making some sawdust I had to move house which put the whole speaker project on hold. Fortunately for me my new house has something that I've never had before, a workshop. My original speaker plans had been for a pretty ordinary box as this was as much as I could manage with my old set up. With the space my new workshop offered I could get really creative. A complete redesign was required. The house move presented many other projects that needed to come before the speakers such as new equipment racks and wiring mains electricity to the workshop.

I have finally got to the point where I can start making the cabinets. I have the design sorted, and have made the jigs and tools that will be required and have received most of the materials.

I'm planning on splitting the thread into two parts. First off I'll describe my design decisions. Then I'll document the actual build.

My design goals are to achieve the best possible sound quality (of course) and to make something that visually wows, not by being over the top and garish but by being beautiful. I don't have the largest listening room so they are going to be stand mounted and reasonably compact.

I think my design should achieve these goals.

First installment to follow soon.

Niffy

I have finally got to the point where I can start making the cabinets. I have the design sorted, and have made the jigs and tools that will be required and have received most of the materials.

I'm planning on splitting the thread into two parts. First off I'll describe my design decisions. Then I'll document the actual build.

My design goals are to achieve the best possible sound quality (of course) and to make something that visually wows, not by being over the top and garish but by being beautiful. I don't have the largest listening room so they are going to be stand mounted and reasonably compact.

I think my design should achieve these goals.

First installment to follow soon.

Niffy

Why the Jordan Eikona 2.

I chose the eikona drive unit for several reasons some of which are specific to the Jordans and some to full range drivers in general.

I occasionally visit hifi shows. Every time I do I find that most of the systems that I really enjoy are either using full range drivers by themselves or with powered subwoofers. With virtually all of the multiway speakers I find the crossovers really obvious. I can usually pretty accurately state what the crossover frequency is with just a quick listen. The sound is nearly always disjointed.

Of the full range drivers that I've heard the two brands that have impressed me the most are Jordan and Voxative. The two brands definitely have different sounds. Overall I think I lean more towards the more neutral sound of the Jordans though I could happily live with either. I'm not that familiar the eikona, I mainly know the jx92s. The general consensus on line is that the eikona is better than the jx92 so I should be OK. The main advantage of the Jordan over the Voxative is the price. The Voxative drivers are massively more expensive than the Jordans.

This leads neatly into my next point.

Jordan drivers are insanely good value for money. The current price for a pair of Jordan drivers is £527. To build a two way you would need to buy a pair of mid bass units, a pair of tweeters and all the components for the crossover for the same price. (if you are new to speaker building you will probably also need to buy a calibrated microphone and design software. Without this your chances of getting the crossover to work is virtually zero). There is no way that you can buy all of this for £527 and make something that sounds better than the Jordans. One major reason for this is the midrange. If you were looking for the best midrange drivers for under a grand a pair the Jordans would have to be high on your list. The other main reason is that you still have the crossover messing things up.

More reasons to follow.

Niffy

I chose the eikona drive unit for several reasons some of which are specific to the Jordans and some to full range drivers in general.

I occasionally visit hifi shows. Every time I do I find that most of the systems that I really enjoy are either using full range drivers by themselves or with powered subwoofers. With virtually all of the multiway speakers I find the crossovers really obvious. I can usually pretty accurately state what the crossover frequency is with just a quick listen. The sound is nearly always disjointed.

Of the full range drivers that I've heard the two brands that have impressed me the most are Jordan and Voxative. The two brands definitely have different sounds. Overall I think I lean more towards the more neutral sound of the Jordans though I could happily live with either. I'm not that familiar the eikona, I mainly know the jx92s. The general consensus on line is that the eikona is better than the jx92 so I should be OK. The main advantage of the Jordan over the Voxative is the price. The Voxative drivers are massively more expensive than the Jordans.

This leads neatly into my next point.

Jordan drivers are insanely good value for money. The current price for a pair of Jordan drivers is £527. To build a two way you would need to buy a pair of mid bass units, a pair of tweeters and all the components for the crossover for the same price. (if you are new to speaker building you will probably also need to buy a calibrated microphone and design software. Without this your chances of getting the crossover to work is virtually zero). There is no way that you can buy all of this for £527 and make something that sounds better than the Jordans. One major reason for this is the midrange. If you were looking for the best midrange drivers for under a grand a pair the Jordans would have to be high on your list. The other main reason is that you still have the crossover messing things up.

More reasons to follow.

Niffy

Hi wesayso,

It was looking at your thread when you first started building the two towers that initially got me to join diyaudio all those years ago. You have been an inspiration. Your build embodies my design goals, great sound and beautiful aesthetics. As I am an analogue kind of guy your solution isn't quite right for me, plus I don't think I could get the idea of 7foot speakers past my wife. The use of translam is definitely inspired by you. Cheers.

Niffy

It was looking at your thread when you first started building the two towers that initially got me to join diyaudio all those years ago. You have been an inspiration. Your build embodies my design goals, great sound and beautiful aesthetics. As I am an analogue kind of guy your solution isn't quite right for me, plus I don't think I could get the idea of 7foot speakers past my wife. The use of translam is definitely inspired by you. Cheers.

Niffy

Why the Jordan Eikona 2.... 2

If I were to go down the separate mid-bass and tweeter approach I would have to mount one drive unit above the other. This will enviably result in a certain amount of vertical integration problems at the crossover frequency. A full range driver acts as a point source so won't have this problem and should result in better imaging. It is true that full range drivers can beam a bit at the top end. I've never noticed this being a problem with the jx92s so I doubt it will be with the eikona.

Having to shape the cabinet to accommodate the extra drive unit would complicate construction and compromise the clean lines I'm planning on, although I suppose I could have made a feature of it.

The use of a dual-concentric driver would address all of these issues but would reintroduce a crossover. Getting rid of the crossover is my single biggest reason for choosing the eikona.

If I were to go down the separate mid-bass and tweeter approach I would have to mount one drive unit above the other. This will enviably result in a certain amount of vertical integration problems at the crossover frequency. A full range driver acts as a point source so won't have this problem and should result in better imaging. It is true that full range drivers can beam a bit at the top end. I've never noticed this being a problem with the jx92s so I doubt it will be with the eikona.

Having to shape the cabinet to accommodate the extra drive unit would complicate construction and compromise the clean lines I'm planning on, although I suppose I could have made a feature of it.

The use of a dual-concentric driver would address all of these issues but would reintroduce a crossover. Getting rid of the crossover is my single biggest reason for choosing the eikona.

Internal Volume.

The most popular way of using the Jordan Eikona 2 drivers is in a transmission line. These can yield quite good low frequency output but seem to require more than one Eikona per cabinet to get truly impressive bass. This would both increase the cost and would move away from the point source ideal. The real strength of the Jordan is from the mid-bass and up. I will be using my Jordans in conjunction with a subwoofer (hopefully 2 in the future). As I don't need the Jordans to do deep bass I don't need to use ports or lines to extend their bottom end. My design is for a sealed box. In my experience sealed midrange enclosures always sound better than ported.

It is often recommended to set the Q of a sealed box to 0.707 as this gives the lowest - 3dB point. For the eikona this requires a box volume of 3.7 litres. I think that a Q of 0.707 is the absolute minimum volume and not the target. A Q of 0.707 can result in a tubby sound. In my opinion a much better value for Q is 0.65. Going much lower than this can result in an over taught sound. To achieve a Q of 0.65 requires a cabinet volume of 4.65 litres. The use of internal stuffing has the effect of making the cabinet appear slightly larger to the driver than it actually is. Taking this into consideration I have set the internal volume to 4.5 litres.

Niffy

The most popular way of using the Jordan Eikona 2 drivers is in a transmission line. These can yield quite good low frequency output but seem to require more than one Eikona per cabinet to get truly impressive bass. This would both increase the cost and would move away from the point source ideal. The real strength of the Jordan is from the mid-bass and up. I will be using my Jordans in conjunction with a subwoofer (hopefully 2 in the future). As I don't need the Jordans to do deep bass I don't need to use ports or lines to extend their bottom end. My design is for a sealed box. In my experience sealed midrange enclosures always sound better than ported.

It is often recommended to set the Q of a sealed box to 0.707 as this gives the lowest - 3dB point. For the eikona this requires a box volume of 3.7 litres. I think that a Q of 0.707 is the absolute minimum volume and not the target. A Q of 0.707 can result in a tubby sound. In my opinion a much better value for Q is 0.65. Going much lower than this can result in an over taught sound. To achieve a Q of 0.65 requires a cabinet volume of 4.65 litres. The use of internal stuffing has the effect of making the cabinet appear slightly larger to the driver than it actually is. Taking this into consideration I have set the internal volume to 4.5 litres.

Niffy

Internal structure.

When a loudspeaker driver is operating it will have as much sound emanating from the rear of the cone into the cabinet as it has emanating from its front into the room. You only want to hear that from the front of the driver. The sound from the rear of the driver will tend to reflect from the inside panels and cabinet and come back out through the cone. The material of the cone has to be thin in order to make it lightweight. Being thin will make it acoustically transparent.

The sound inside of the cabinet will be changed by the shape and size of that cabinet. At certain frequencies, where the wavelength (or a multiple of the wavelength) of the sound is equal to a cabinet dimension, you will get standing waves form. These have nodes (minimum air movement) at the cabinet walls and antinodes (maximum air movement) in the centre of the cabinet. Standing waves will act to amplify the frequencies at which they occur resulting in sound that is reflected back through the driver being very peeky. The normal method of reducing the amount of reflected sound coming back through the driver is to line the inside of the cabinet with absorbent material, wadding, like foam or wool. There is a problem with this approach. Generally the minimum amount of air movement (nodes) are located at the cabinet walls and the maximum air movement (antinodes) is in the centre of the air volume. Putting the wadding where the air movement is at a minimum is very inefficient. Ideally you would like to put most of the wadding in the centre of the speaker.

Making the walls of the cabinet non-parallel can help to prevent the formation of standing waves and make the sound reflected back through the driver less peeky. Making the inner surface of the cabinet irregular can help to further break up the sound waves but this is only really effective at higher frequencies where the size of the irregularities are larger than the wavelength of the sound.

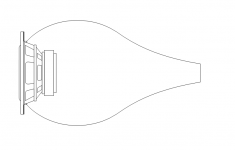

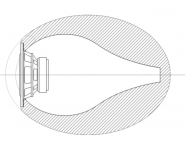

For my cabinet I have used a very different internal shape, a cross section of which is shown below.

Perpendicular to the axis shown the section is circular at all points. The internal volume is made of two intersecting shapes. The front section is an Ellipsoid that is 20% longer along its major axis. An Ellipsoid is used rather than a sphere as a sphere has all its dimensions the same in all directions which could cause a standing wave at one frequency. By using an Ellipsoid the formation of this standing wave is avoided. The rear section is a logarithmic cone that smoothly transitions from the front section. All sound waves emanating from the driver are reflected towards the rear of the cabinet. Apart from the small flat rear panel, which is only 32mm in diameter, there are no surfaces that can reflect sound back towards the driver. As sound waves travel towards the rear of the cabinet their amplitude will become greater. To promote the sound being reflected to the rear the inside surface will be as smooth as possible so that it acts as an acoustic mirror. The absorbant wadding will be inserted in such a way that there is an equal weight of wadding per unit length of the speaker. This means that the density of the wadding will increase exponentially towards the rear of the speaker. I have a couple of hundred grams of Mundorf elves hair which is recommended to be used at 10g/litre. As the cabinets will be 4.5 litres I'll start at 45g and experiment from there. I'll start the wadding from just behind the driver with it fluffed up as much as possible by the time it gets to the back it will be compressed to about 40 times this density. In order to reflect back through the driver a sound wave would have to make it all the way through the increasing density of wadding, then reflect off the tiny rear panel (which will have a 5mm felt disk attached) and then make it all the way back through the wadding. I think that the sound wave will be almost entirely absorbed by the time it reaches the felt disk so virtually nothing will reflect back as far as the driver.

Back at the front of the speaker, the internal angle of the cabinet where the driver is mounted is 45°. This will allow the rear of the cone lots of room to breath. There will be stanchions around the mounting hardware.

Hopefully these measures will totally eliminate the rear wave from the cone and prevent any of it reflecting back through into the room. Only time will tell.

Niffy

When a loudspeaker driver is operating it will have as much sound emanating from the rear of the cone into the cabinet as it has emanating from its front into the room. You only want to hear that from the front of the driver. The sound from the rear of the driver will tend to reflect from the inside panels and cabinet and come back out through the cone. The material of the cone has to be thin in order to make it lightweight. Being thin will make it acoustically transparent.

The sound inside of the cabinet will be changed by the shape and size of that cabinet. At certain frequencies, where the wavelength (or a multiple of the wavelength) of the sound is equal to a cabinet dimension, you will get standing waves form. These have nodes (minimum air movement) at the cabinet walls and antinodes (maximum air movement) in the centre of the cabinet. Standing waves will act to amplify the frequencies at which they occur resulting in sound that is reflected back through the driver being very peeky. The normal method of reducing the amount of reflected sound coming back through the driver is to line the inside of the cabinet with absorbent material, wadding, like foam or wool. There is a problem with this approach. Generally the minimum amount of air movement (nodes) are located at the cabinet walls and the maximum air movement (antinodes) is in the centre of the air volume. Putting the wadding where the air movement is at a minimum is very inefficient. Ideally you would like to put most of the wadding in the centre of the speaker.

Making the walls of the cabinet non-parallel can help to prevent the formation of standing waves and make the sound reflected back through the driver less peeky. Making the inner surface of the cabinet irregular can help to further break up the sound waves but this is only really effective at higher frequencies where the size of the irregularities are larger than the wavelength of the sound.

For my cabinet I have used a very different internal shape, a cross section of which is shown below.

Perpendicular to the axis shown the section is circular at all points. The internal volume is made of two intersecting shapes. The front section is an Ellipsoid that is 20% longer along its major axis. An Ellipsoid is used rather than a sphere as a sphere has all its dimensions the same in all directions which could cause a standing wave at one frequency. By using an Ellipsoid the formation of this standing wave is avoided. The rear section is a logarithmic cone that smoothly transitions from the front section. All sound waves emanating from the driver are reflected towards the rear of the cabinet. Apart from the small flat rear panel, which is only 32mm in diameter, there are no surfaces that can reflect sound back towards the driver. As sound waves travel towards the rear of the cabinet their amplitude will become greater. To promote the sound being reflected to the rear the inside surface will be as smooth as possible so that it acts as an acoustic mirror. The absorbant wadding will be inserted in such a way that there is an equal weight of wadding per unit length of the speaker. This means that the density of the wadding will increase exponentially towards the rear of the speaker. I have a couple of hundred grams of Mundorf elves hair which is recommended to be used at 10g/litre. As the cabinets will be 4.5 litres I'll start at 45g and experiment from there. I'll start the wadding from just behind the driver with it fluffed up as much as possible by the time it gets to the back it will be compressed to about 40 times this density. In order to reflect back through the driver a sound wave would have to make it all the way through the increasing density of wadding, then reflect off the tiny rear panel (which will have a 5mm felt disk attached) and then make it all the way back through the wadding. I think that the sound wave will be almost entirely absorbed by the time it reaches the felt disk so virtually nothing will reflect back as far as the driver.

Back at the front of the speaker, the internal angle of the cabinet where the driver is mounted is 45°. This will allow the rear of the cone lots of room to breath. There will be stanchions around the mounting hardware.

Hopefully these measures will totally eliminate the rear wave from the cone and prevent any of it reflecting back through into the room. Only time will tell.

Niffy

Sorry for my ignorance but what are the benefits of doing a full top to bottom translam cabinet compared to CNC'ing four or five formers and use flexiply sheet (possibly in 4 layer of 5mm ?) to cover it and get the same profile internal and external. Seems the latter is easier for the DIYer and has much less waste.

This is the stuff I am thinking about - no curfing etc. and bends to 10x the thickness in radius i.e. 5mm bends to 50mm radius. OK it is harwood finish so will need veneer/leather/paint but you could also laminate it with pre-curfed MDF or acoustic rubber sheet or bitumen sheet for added sound deadening.

Flexible Plywood Sheets - 5mm Flexi Ply Bendy Plywood Flexi Board Curved Plywood | eBay

Just curious and wanting to learn.

This is the stuff I am thinking about - no curfing etc. and bends to 10x the thickness in radius i.e. 5mm bends to 50mm radius. OK it is harwood finish so will need veneer/leather/paint but you could also laminate it with pre-curfed MDF or acoustic rubber sheet or bitumen sheet for added sound deadening.

Flexible Plywood Sheets - 5mm Flexi Ply Bendy Plywood Flexi Board Curved Plywood | eBay

Just curious and wanting to learn.

Hi Ugg,

The internal and external shapes are going to be quite different so if I could make them out of flexible ply I would need some sort of filler between the shells. CNC is not something that is available to me so I would have to make the formers by hand which would be as much work as making translam by itself. I did contemplate using glass fibre for the shells with a lightweight core like balsa or polyurethane foam, similar to that used by Vivid Audio. There is a problem with this approach for these speakers. The lightweight high rigidity approach is great for bass where you can push the first resonant mode out of the pass band. I'm using a full range driver so I can't push the resonant modes out of the pass band. A cabinet for a full ranger still needs to be very rigid but it also needs to be well damped in order to control the resonant modes. A heavier material will also be more acoustically opaque so there will be less "leakage" of sound through the cabinet walls.

Both the internal and external shapes are curved in two directions, flexible ply can only curve in one direction at a time. I don't think it would be possible to use this material for my application.

My next couple of posts will be looking at the external shape of the cabinets and the use of materials.

One major factor in choosing translam is that, if done right, it looks gorgeous.

Niffy

The internal and external shapes are going to be quite different so if I could make them out of flexible ply I would need some sort of filler between the shells. CNC is not something that is available to me so I would have to make the formers by hand which would be as much work as making translam by itself. I did contemplate using glass fibre for the shells with a lightweight core like balsa or polyurethane foam, similar to that used by Vivid Audio. There is a problem with this approach for these speakers. The lightweight high rigidity approach is great for bass where you can push the first resonant mode out of the pass band. I'm using a full range driver so I can't push the resonant modes out of the pass band. A cabinet for a full ranger still needs to be very rigid but it also needs to be well damped in order to control the resonant modes. A heavier material will also be more acoustically opaque so there will be less "leakage" of sound through the cabinet walls.

Both the internal and external shapes are curved in two directions, flexible ply can only curve in one direction at a time. I don't think it would be possible to use this material for my application.

My next couple of posts will be looking at the external shape of the cabinets and the use of materials.

One major factor in choosing translam is that, if done right, it looks gorgeous.

Niffy

One major factor in choosing translam is that, if done right, it looks gorgeous.

The only asset of translam is the ability to make a complex shape fairly easy. It has a large waste of material and does not make for the best structural assemblege.

dave

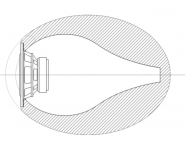

External Shape

Many of you are probably aware of the study by Harry Olson into the effects of cabinet shape on diffraction. This chart is very often quoted by manufacturers. I saw it being used by two different manufacturers at this years Bristol hifi show.

The funny thing is that it is actually a really old study carried out in1950 without the benefit of modern equipment. The cabinets used were also enormous, 2 feet in diameter, and the driver quite small. The driver in the study would have acted more like a point relative to the size of the cabinets (which were made of pressed steel). I definitely don't have room for speakers this size. My cabinets are 280mm in diameter and the frame of the driver is 149mm so the attachment is going to be somewhere between a sphere and a cone. Funny how the manufacturers don't mention this. Regardless, a basically spherical shape is still going to give the best diffraction characteristics.

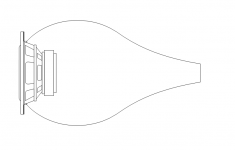

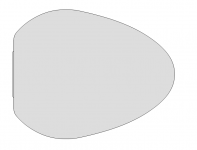

For domestic harmony I set my maximum cabinet size at 300mm high and wide and 350mm deep. I started by making the front spherical and transitioning into a parabolic rear end. Reducing the maximum diameter to 280mm improved the appearance. I still found that this looked too pointy at the back. I tried making the rear elliptical which worked better but still didn't look right.

More playing with shapes and it struck me to not use a composite shape but to go for a more simple shape and so I went for a single elliptical Cross section, an Ellipsoid.

This looks much more organic, more balanced. I really like this shape.

Niffy

Many of you are probably aware of the study by Harry Olson into the effects of cabinet shape on diffraction. This chart is very often quoted by manufacturers. I saw it being used by two different manufacturers at this years Bristol hifi show.

The funny thing is that it is actually a really old study carried out in1950 without the benefit of modern equipment. The cabinets used were also enormous, 2 feet in diameter, and the driver quite small. The driver in the study would have acted more like a point relative to the size of the cabinets (which were made of pressed steel). I definitely don't have room for speakers this size. My cabinets are 280mm in diameter and the frame of the driver is 149mm so the attachment is going to be somewhere between a sphere and a cone. Funny how the manufacturers don't mention this. Regardless, a basically spherical shape is still going to give the best diffraction characteristics.

For domestic harmony I set my maximum cabinet size at 300mm high and wide and 350mm deep. I started by making the front spherical and transitioning into a parabolic rear end. Reducing the maximum diameter to 280mm improved the appearance. I still found that this looked too pointy at the back. I tried making the rear elliptical which worked better but still didn't look right.

More playing with shapes and it struck me to not use a composite shape but to go for a more simple shape and so I went for a single elliptical Cross section, an Ellipsoid.

This looks much more organic, more balanced. I really like this shape.

Niffy

The only asset of translam is the ability to make a complex shape fairly easy. It has a large waste of material and does not make for the best structural assemblege.

dave

Hi Dave,

You're definitely right about the waste of materials, these are going to need almost 2 whole sheets of 12mm ply. I don't think that the structural assemblage will be a problem with this design. Watch this space.

Niffy

Many of you are probably aware of the study by Harry Olson...

Indeed. I was the one who scanned that chart.

Probably the most well researched shape for both inside & outside issues, you should look to the shape of the B&W nautilus mid enclosure.

An externally hosted image should be here but it was not working when we last tested it.

Our trapezoidal miniOnkens mimic this shape in the plan view.

dave

Construction.

The combination of the inner and outer parts of the cabinet.

The wall thickness varies from about 40mm at the front to a maximum of about 100mm near the rear. OK, the very back is only 24mm thick but this is only 32mm in diameter and surrounded by much thicker walls. The rear section is almost a solid block. The outer volume of the speaker is about 2.5 times the internal. The speaker will be mainly cabinet.

The cabinet will be made from 29 layers of 12mm baltic birch plywood. The cabinet will be constructed from disks cut with a router and glued together. This will give a stepped profile. The steps will be smoothed using flap sanders. I anticipate that this will make a lot of dust. When gluing the layers together each layer will be rotated by 45° relative to the previous. This will give the cabinet a more homogeneous rigidity. I could have used thinner ply. This would have required more layers but less sanding. It would also mix the 0° and 45° layers more making it more homogeneous. I could have used thicker ply. This would require less layers but would need more sanding. The main reason I went for 12mm is that I already have 3/4 of a sheet.

Another advantage of making the cabinets spherical is that a sphere is an inherently rigid shape. Even if you consider that the cabinet is a more conical shape where the driver mounts, a cone is also an inherently rigid shape. It's why speakers drivers are made from domes and cones. I think that the combination of the rigidity of the shape and that the speaker will have no baffle to talk of will more than compensate for any deficiencies that translam may have. Add to this the thickness of the material used and that translam should have better damping. A large ply panel, even well braced, is going to have a more resonant character.

Having such a thick wall will make the cabinet acoustically opaque.

I have seen quite a few translam builds where the layers are stacked horizontally and quite a few where the layers are stacked vertically left to right. So far I haven't seen any where the layers are stacked vertically front to back. I hope there isn't a reason for this that I have overlooked.

Niffy

The combination of the inner and outer parts of the cabinet.

The wall thickness varies from about 40mm at the front to a maximum of about 100mm near the rear. OK, the very back is only 24mm thick but this is only 32mm in diameter and surrounded by much thicker walls. The rear section is almost a solid block. The outer volume of the speaker is about 2.5 times the internal. The speaker will be mainly cabinet.

The cabinet will be made from 29 layers of 12mm baltic birch plywood. The cabinet will be constructed from disks cut with a router and glued together. This will give a stepped profile. The steps will be smoothed using flap sanders. I anticipate that this will make a lot of dust. When gluing the layers together each layer will be rotated by 45° relative to the previous. This will give the cabinet a more homogeneous rigidity. I could have used thinner ply. This would have required more layers but less sanding. It would also mix the 0° and 45° layers more making it more homogeneous. I could have used thicker ply. This would require less layers but would need more sanding. The main reason I went for 12mm is that I already have 3/4 of a sheet.

Another advantage of making the cabinets spherical is that a sphere is an inherently rigid shape. Even if you consider that the cabinet is a more conical shape where the driver mounts, a cone is also an inherently rigid shape. It's why speakers drivers are made from domes and cones. I think that the combination of the rigidity of the shape and that the speaker will have no baffle to talk of will more than compensate for any deficiencies that translam may have. Add to this the thickness of the material used and that translam should have better damping. A large ply panel, even well braced, is going to have a more resonant character.

Having such a thick wall will make the cabinet acoustically opaque.

I have seen quite a few translam builds where the layers are stacked horizontally and quite a few where the layers are stacked vertically left to right. So far I haven't seen any where the layers are stacked vertically front to back. I hope there isn't a reason for this that I have overlooked.

Niffy

...the rigidity of the shape and that the speaker will have no baffle to talk of will more than compensate for any deficiencies that translam may have. Add to this the thickness of the material used and that translam should have better damping

The rididity will be affected by the construction (reducing it), but the wall thickness should compensate. Divide wall thicknesses by about 2 to get the eqivalent of what the sheet used in the intended direction will be. In the thick parts you could also add a cavity to be filled with something other than wood.

I see no reason to make the assumption about damping.

dave

Hi Dave,

Lawrence Dickie is my hero. The current B&W turbine head is based on the work he did when he worked for them. This design is heavily influenced by him. The main difference is that he is into MULTI way loudspeakers. I'm trying to adapt his approach for a full ranger.

Niffy

Lawrence Dickie is my hero. The current B&W turbine head is based on the work he did when he worked for them. This design is heavily influenced by him. The main difference is that he is into MULTI way loudspeakers. I'm trying to adapt his approach for a full ranger.

Niffy

I doI see no reason to make the assumption about damping.

- Home

- Loudspeakers

- Full Range

- Jordan Eikona Translam Ellipsoid