1audio said:

However there are now a number of good recordings at higher sample rates and greater bit depth, just not on CD. Most are only available as download.

Any links, or titles?

john curl said:Not in small values.

Hi John,

I think I agree with you on this one, but I'd like to study this more, particularly in regard to the iductance issue.

I would like to default to polystyrenes for compensation capacitors in the range of 2pF to 50pF. Maybe I haven't looked hard enough (probably), but I don't see much in the way of available polystyrenes in such small values of capacitance. Can you tell me where I can get polystyrenes in such small values?

I would then look at what the inductance on these really is and whether it matters in a typical compensation application.

I do not buy the argument that just because low inductance is important for power supply bypassing that it is equally important for compensation circuits, since the impedances involved are quite different.

I'm not making this post to disparage NPOs or Mica, I'm just interested in the polystyrene issue right now. I usually use silver Micas, but they are pretty expensive these days and I would love to explore the option of going to polystyrene instead.

Thanks,

Bob

1audio said:I use carefully trimmed pieces of old .031" teflon pcb material to make small caps. Stable, not too hard to make and works well.

I use 2 short lengths of teflon coated wire wrap, twisted and

trimmed to length in-circuit.

😎

Nelson Pass said:

I use 2 short lengths of teflon coated wire wrap, twisted and

trimmed to length in-circuit.

😎

That's an old RF trick named gimmick capacitor 😉

http://web.telia.com/~u85920178/begin/gimmik-0.htm

I don't think there are enough problems with wound caps to be worried about. All you really need to do is find where their self resonant frequency is to see if you're in trouble or not. Some even have the entire ends metalized, so not enough inductance to be concerned about.

Good NP0 / C0G caps can be fine. Some mica caps are fine. They are variable in quality, so that means you have to shop better manufacturers. $$ The cheaper parts have horrible D/A and poor tolerances. They are junk for almost everything.

The thing that often determines what cap I use (polystyrene or mica) is what I have on hand and whether the location is hot or not. I do measure D/A on all my caps before installing them. Mica caps I have do not have poor D/A values, and I measure them at 10KHz and 100 KHz. A high frequency LCR meter would be nice for this stuff.

Now, as for DVMs, the only handheld meter I would trust for cap measurements are the better Fluke models. They always seemed to be more accurate than they had any right to be. Most cheaper LCR meters do not measure very accurately compared to a good bench model. In fact, a Fluke DVM often out performs these even.

Like Nelson, I'll often use some networking cable to create caps that measure 5 pF or less. Beyond that they start becoming a bit long (or if you are brave, you can squish them flat). A little heat shrink keeps them from relaxing over time, that and a tight wrap to start.

-Chris

Good NP0 / C0G caps can be fine. Some mica caps are fine. They are variable in quality, so that means you have to shop better manufacturers. $$ The cheaper parts have horrible D/A and poor tolerances. They are junk for almost everything.

The thing that often determines what cap I use (polystyrene or mica) is what I have on hand and whether the location is hot or not. I do measure D/A on all my caps before installing them. Mica caps I have do not have poor D/A values, and I measure them at 10KHz and 100 KHz. A high frequency LCR meter would be nice for this stuff.

Now, as for DVMs, the only handheld meter I would trust for cap measurements are the better Fluke models. They always seemed to be more accurate than they had any right to be. Most cheaper LCR meters do not measure very accurately compared to a good bench model. In fact, a Fluke DVM often out performs these even.

Like Nelson, I'll often use some networking cable to create caps that measure 5 pF or less. Beyond that they start becoming a bit long (or if you are brave, you can squish them flat). A little heat shrink keeps them from relaxing over time, that and a tight wrap to start.

-Chris

OT, but what prize is being awarded to the millionth viewer of this thread? That's got to be coming up in the next day or two.😀 - Pat

Hi Pavel,

What are you measuring there? What does your test setup look like?

Multiple layer capacitors are obviously going to have lower inductance. In use, you may need to damp them as well.

Besides, I didn't comment on what were the best parts, just what is usable.

-Chris

What are you measuring there? What does your test setup look like?

Multiple layer capacitors are obviously going to have lower inductance. In use, you may need to damp them as well.

Besides, I didn't comment on what were the best parts, just what is usable.

-Chris

PMA said:Really?

I could be as laconic as yourself and use the BS flag, but I'm in a good mood today.

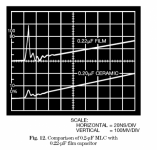

That's an unfair comparison, between foil caps and multilayer ceramic, showing nothing more than the obvious. 0.2uF MLC caps are ideal for decoupling, as they have fundamentally low ESL.

The discussion was about compensation caps and DA. While JC says NPO ceramic is bad and silver mica is good, other say that a) mica has more DA than NPO, b) there's no measurable DA difference between NPO and mica at the typical values around 100pF and c) polystyrene is not commonly available under 100pF.

BTW, I doubt the cap in the graph you posted is NPO. A 0.2uF NPO costs an arm and a leg, and I doubt any sane engineer would use such for decoupling.

In fact, you just proved that ceramics are beter for decoupling than whatever foil, another BS that JC was perpetrating around some time ago. Yes, those ceramics (not NPO) may have measurable DA, it doesn't matter, at least if the amp has what is commonly known as a decent PSRR. Add -40-60dB to the worst ceramic cap and you still got a decent decoupling.

i know the discussion was aimed towards amplifier frequency compensation caps i.e. less than 100 pF values.

i used silvered mica for years because that's what i could get.

started using polystyrene after i found some in small values, but they're tough to find again (i guess except for jacco)

i'm also curious about PMA's question.

assuming "good" quality parts, what's "best" in RIAA shaping networks - polystyrene, polypropylene, film-foil or metalized?

is the inductance enough of a factor (for a "good" quality part) in this application to worry about?

i've always been happy with a polypropylene film-foil and polystyrene across the cartridge if/when needed.

mlloyd1

sorry - i can't afford good teflon - gotta eat, too 🙂

i used silvered mica for years because that's what i could get.

started using polystyrene after i found some in small values, but they're tough to find again (i guess except for jacco)

i'm also curious about PMA's question.

assuming "good" quality parts, what's "best" in RIAA shaping networks - polystyrene, polypropylene, film-foil or metalized?

is the inductance enough of a factor (for a "good" quality part) in this application to worry about?

i've always been happy with a polypropylene film-foil and polystyrene across the cartridge if/when needed.

PMA said:Maybe in the RIAA equalization?

mlloyd1

sorry - i can't afford good teflon - gotta eat, too 🙂

mlloyd1 said:i know the discussion was aimed towards amplifier frequency compensation caps i.e. less than 100 pF values

i'm also curious about PMA's question.

assuming "good" quality parts, what's "best" in RIAA shaping networks - polystyrene, polypropylene, film-foil or metalized?

is the inductance enough of a factor (for a "good" quality part) in this application to worry about?

i've always been happy with a polypropylene film-foil and polystyrene across the cartridge if/when needed.

I'm using polypropilene (0.1uF) and/or styroflex (for the nF range) in all HPS version http://www.diyaudio.com/forums/showthread.php?s=&threadid=133136&highlight= and they work very good. I would not worry for the ESL in such applications.

Well, we at least, have an interesting and informative topic of discussion.

Why do I 'shirk' from ceramics in audio design?

I have been BURNED, big time, by assuming what is NOT on the cap data sheet won't hurt me.

This amounted to losing my job, one time. Another, making an UPGRADE that tended to grate on me, as I listened for awhile.

For the record, I did NOT discover the problems in CERAMICS. Tektronix did! They showed ME their test procedure, in 1974, some 35 years ago. I didn't have an easy way of measuring the problems, until then.

Up to 1974, we all used ceramics for many applications: Bypassing (sometimes still the best, when absolutely necessary), compensation, and even interstage coupling.

Of course, it was the interstage coupling, large value ceramics that stood out the most. Once you measure them, it is difficult to use them for anything in audio again. They have DA, harmonic and IM distortion, and 'non-return to zero' best described as a battery effect. They are also piezoelectric and have huge temperature drift. STILL, engineers often recommend them, because they are cheap and small, and 'Who cares about audio, anyway?'

Now what about smaller ceramic caps, below 1000pf, for example? Well, sometimes they are OK, and sometimes they are not, in the NON-linear distortion department.

It is often difficult to tell the difference at a glance between NPO and non-NPO caps at a glance, and they might be one or the other. I made some measurements with harmonic and IM and found distortion in some caps in the 500-1000 pf region. There was only a few pennies difference in cost between NPO and non-NPO in the same value, so one could be easily replaced for another, by accident, or by a 'bean counter'.

Also, they DO have about 10 times the DA as polyproplyene, polystyrene, or Teflon caps of the same value, so this is probably an inherent materials problem, rather than just size and quality of construction. Demian measured it, RECENTLY, and put the results on this thead.

NOW, what about mica? Mica also has DA, however I have never measured non-linear distortion of any significant amount, even with higher values, and I know it is NOT a non-NPO cap, so I tend to recommend it for very small values, unless polystyrene caps are available. That is what I use in my best Vendetta and CTC designs. I have my own personal stock, obtained more than a decade ago, when they were popular. I don't know how to replace them at this moment, any more than I can tell you how to replace the 2SK389's, 2SJ109's, 2SK146's, 2SJ73's, as my critics seem too cheap to buy small quantities from Erno Borbeley, who still sells them.

If you are really amateurs in the audio game, why not go the extra distance? If you are a competitor here, well chose what you want, but please don't bother me about it, if it doesn't get the same appreciation in the marketplace as some other products.

Why do I 'shirk' from ceramics in audio design?

I have been BURNED, big time, by assuming what is NOT on the cap data sheet won't hurt me.

This amounted to losing my job, one time. Another, making an UPGRADE that tended to grate on me, as I listened for awhile.

For the record, I did NOT discover the problems in CERAMICS. Tektronix did! They showed ME their test procedure, in 1974, some 35 years ago. I didn't have an easy way of measuring the problems, until then.

Up to 1974, we all used ceramics for many applications: Bypassing (sometimes still the best, when absolutely necessary), compensation, and even interstage coupling.

Of course, it was the interstage coupling, large value ceramics that stood out the most. Once you measure them, it is difficult to use them for anything in audio again. They have DA, harmonic and IM distortion, and 'non-return to zero' best described as a battery effect. They are also piezoelectric and have huge temperature drift. STILL, engineers often recommend them, because they are cheap and small, and 'Who cares about audio, anyway?'

Now what about smaller ceramic caps, below 1000pf, for example? Well, sometimes they are OK, and sometimes they are not, in the NON-linear distortion department.

It is often difficult to tell the difference at a glance between NPO and non-NPO caps at a glance, and they might be one or the other. I made some measurements with harmonic and IM and found distortion in some caps in the 500-1000 pf region. There was only a few pennies difference in cost between NPO and non-NPO in the same value, so one could be easily replaced for another, by accident, or by a 'bean counter'.

Also, they DO have about 10 times the DA as polyproplyene, polystyrene, or Teflon caps of the same value, so this is probably an inherent materials problem, rather than just size and quality of construction. Demian measured it, RECENTLY, and put the results on this thead.

NOW, what about mica? Mica also has DA, however I have never measured non-linear distortion of any significant amount, even with higher values, and I know it is NOT a non-NPO cap, so I tend to recommend it for very small values, unless polystyrene caps are available. That is what I use in my best Vendetta and CTC designs. I have my own personal stock, obtained more than a decade ago, when they were popular. I don't know how to replace them at this moment, any more than I can tell you how to replace the 2SK389's, 2SJ109's, 2SK146's, 2SJ73's, as my critics seem too cheap to buy small quantities from Erno Borbeley, who still sells them.

If you are really amateurs in the audio game, why not go the extra distance? If you are a competitor here, well chose what you want, but please don't bother me about it, if it doesn't get the same appreciation in the marketplace as some other products.

I should also offer that Scott Wurcer (remember him?) recommended to me, Erie RED CAPS, an RF ceramic, 25 years ago, that worked very well in the 30MHz power amp that I was designing at the time. Thanks again, Scott!

PMA said:Right you are, syn08.

What's up PMA, now that you are done with the Dispre II, are you back in the engineering team?

john curl said:It is often difficult to tell the difference at a glance between NPO and non-NPO caps at a glance, and they might be one or the other. I made some measurements with harmonic and IM and found distortion in some caps in the 500-1000 pf region. There was only a few pennies difference in cost between NPO and non-NPO in the same value, so one could be easily replaced for another, by accident, or by a 'bean counter'.

Also, they DO have about 10 times the DA as polyproplyene, polystyrene, or Teflon caps of the same value, so this is probably an inherent materials problem, rather than just size and quality of construction. Demian measured it, RECENTLY, and put the results on this thead.

NOW, what about mica? Mica also has DA, however I have never measured non-linear distortion of any significant amount, even with higher values, and I know it is NOT a non-NPO cap, so I tend to recommend it for very small values, unless polystyrene caps are available. That is what I use in my best Vendetta and CTC designs. I have my own personal stock, obtained more than a decade ago, when they were popular. I don't know how to replace them at this moment, any more than I can tell you how to replace the 2SK389's, 2SJ109's, 2SK146's, 2SJ73's, as my critics seem too cheap to buy small quantities from Erno Borbeley, who still sells them.

Cyril Bateman's articles on capacitors showed extensive measurements. NP0/C0G caps were one of the lowest distortion caps. Didn't do any tests on piezo properties, but NG0/C0G caps are not made of the same piezo ceramic as lower class ceramics are made of. His articles are posted on his web site:

capacitor sounds articles

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- John Curl's Blowtorch preamplifier