Hello All,

My nearly useless experience is that it really doesn't matter which tool is use for scraping.

For me it is a matter of the force applied and duration of the scraping.

Oh, you are just being practical, again.

-RNM

My speak was about aluminum bonding pads on transistors and IC's, with pure gold wires.

jneutron

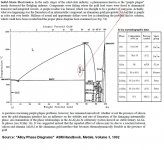

I was reading on alloy phase diagrams and I found this (attached jpeg).

I thought to send it to you

The key elements in the formation of Al2Au is composition and temperature (during bonding or later during service).

Did you do thermosonic bonding at that time?

George

Attachments

On the topic of D/A converters, I'm sure you'll find that BP's latest endeavors are (as always) quite interesting:

Mola-Mola Blog!

Mola-Mola Blog!

Interesting to see indeed - BP certainly does have a awful lot of faith in THD and SNR as the definitive figures of merit for a DAC.... 😛

I wondered how long it would be before he decided to make DACs. The last time I looked at the Grimm site he'd said he thought he would do more good coming up with superior ADCs.Interesting to see indeed - BP certainly does have a awful lot of faith in THD and SNR as the definitive figures of merit for a DAC.... 😛

Yes. Both thermocompression (T/C) and thermosonic (T/S).jneutron

I was reading on alloy phase diagrams and I found this (attached jpeg).

I thought to send it to you

The key elements in the formation of Al2Au is composition and temperature (during bonding or later during service).

Did you do thermosonic bonding at that time?

George

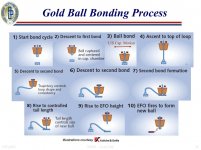

T/C uses compression and heat. T/S uses ultrasonic energy.

Also aluminum ultrasonic, 5 mil up to 25 mil

My responsibility was incoming electrical inspection of the silicon chips. We would sample manufactured lots using AQL, sampling a specific number to assemble, pass on one failure, reject on two. It was a stats thing.

The higher ups had determined that the good wirebonders were for production, and that the trainees would learn on my incoming samples. As a result, I learned all of the various ways chips could be damaged or destroyed by wirebonding. And there were lots of ways. Also, when the bonder wasn't working right, I had to learn how to troubleshoot and repair the bonders.

I also learned all about the physical structure of the chips, and how sensitive to physical damage they could be on the top.

jn

Interesting to see indeed - BP certainly does have a awful lot of faith in THD and SNR as the definitive figures of merit for a DAC.... 😛

Having read their philosophy on their site I imagine that their definition of "noise" might be somewhat more comprehesive than simple steady state noise.

Rather, they talk about removing everything that isn't the music.

This sounds like a very reasonable approach to producing very good sounding gear.

Someone else using Maxwell demons? Their pay rates will start rising, and soon they will form a union and demand larger offices and a retirement package.mikelm said:Rather, they talk about removing everything that isn't the music.

I'm sure having a few maxwell demons would be handy here n there but I'm happy to settle for managing the more mundane stuff.

Their pay rates will start rising, and soon they will form a union and demand larger offices and a retirement package.

I know you dont man it to the extream but extreame exists too;

there might be something to be said for working until you drop dead on the spot... forget unions and retirement plans; A couple years ago, I was in a Taxi in Nepal and by the curb side was dead body with a sheet over it. the person was outstretched arms and facing east....face down. he/she made it that far and dropped dead. Others along the roadway/curb were not even concerned.... but one person beside the covered person was very distrought but what could he do? [trust me, you dont want to know what they do with the body].

So, yes, lets all forget about a safety net et al... work 'til you drop... sounds third world to me.

-Richard

Last edited:

Someone else using Maxwell demons?

Not in this case- they're using solid engineering.

Yes.

Thank you.

I searched for this article that fits well to your job description

http://articles.adsabs.harvard.edu/cgi-bin/nph-iarticle_query?1997ESASP.395..411J&data_type=PDF_HIGH&whole_paper=YES&type=PRINTER&filetype=.pdf

(See the mention of temp of 125 d. C as a limit, above which Al-Au intermetallics can degrade the bond.

Notice also the positive comments on mass production and stats)

And here are some test data plots that warn against high operating temperatures which promote the formation of intermetallics. In combination with contaminations they cause bond failure

https://www.reliabilityanalysislab.com/IntermetallicsandWearout0302.html

George

Attachments

Rather, they talk about removing everything that isn't the music.

I read that too - however I wonder if they're really walking the talk. Removing everything that's not in the original bits would mean aiming for a null when playing music, not aiming for perfect THD playing out a sinewave.

Yes the engineering is good no doubt. But, it looks like BP is cast from the same mold then as DS. Only sub PPM will do. It's a pretty dimensionless view of things IMV. The result has been, and especially in the DIY community, all these frightfully convoluted designs to achieve sub ppm distortion in the simulator, most of which, because of their complexity, never get built.

Yes the engineering is good no doubt.

For me this depends on how 'engineering' is defined. If its only about making the product right, then I agree. However for me engineering also encompasses making the right product - an area which traditionally has gotten devolved to marketing.

As always, it will be about the implementation. The design may be brilliant, but if interference effects kill its real world performance then it won't make such a big splash. The trouble might be, that they will have to spend just as much money and effort chasing down and eliminating all the audible artifacts resulting from 'cross contamination' between electrical areas ...

Last edited:

I didn't see the word "grunt" anywhere...that, and gofer...😀Thank you.

I searched for this article that fits well to your job description

George

Kulicke and Soffa..whoa, names from the past.

The jpeg is thermosonic. Thermocompression is a tad diff..

Sigh..precap visual inspector.. I still have nightmares..😱

jn

As always, it will be about the implementation. The design may be brilliant, but if interference effects kill its real world performance then it won't make such a big splash. The trouble might be, that they will have to spend just as much money and effort chasing down and eliminating all the audible artifacts resulting from 'cross contamination' between electrical areas ...

I doubt BP will have any issues with getting things clean and quiet. It will probably sound quite good as well but I don't think that's necessarily because its low distortion. We will just have to wait and see how it's received and what people think about it.

My own experience with class D was with S and P in Japan, but it was very high volume consumer stuff - certainly not pitched where BP or Devaliet (sp?) are.

🙂😎

I ditto that. [Simplify where ever possible without material impact on final goal(s).]

-Richard

Last edited:

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II