I haven't used 60-40 (SN60) solder in more than 1/3 century. It is a STUPID ratio. It allows cold joints, and it higher temperature than necessary. SN63 is MUCH BETTER, but SN62 is WONDERFUL!

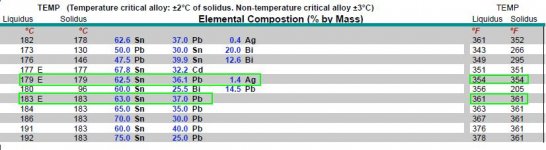

From the attached table, only two Sn/Pb compositions (framed in green) are truly eutectic (60/40 is not)

Otherwise, among these compositions, temperatures don’t deviate much.

Please define “stupid”

George

Attachments

Last edited:

From the attached table, only two Sn/Pb compositions (framed in green) are truly eutectic (60/40 is not)

Otherwise, among these compositions, temperatures don’t deviate much.

Please define “stupid”

He didn't say 60/40 was eutectic. He was saying that it isn't and further, it has a higher melting temperature than the eutectic 63/37. That's why he called 60/40 a "stupid" ratio. Did you misread his post?

se

My question is... is eutectic solder advantageous to the parts or the solderer?

I certainly think it is.

se

So you're answering, "both," to the question?

If both joints are soldered correctly, I don't see a difference.

If both joints are soldered correctly, I don't see a difference.

But you're less likely to screw up a joint with a eutectic. **** happens. Things move. Plus the parts are exposed to a lower temperature.

se

se

Sofaspud, you could learn something important here. I first learned about it 40 years ago, and it is about time, everybody did!

What, exactly?

Parts aren't automatically and necessarily exposed to a lower temp with 63/37.

Don't let parts move around when soldering, whatever solder is used.

Not that I can't be convinced, it's just that, well... it ain't happening yet.

Parts aren't automatically and necessarily exposed to a lower temp with 63/37.

Don't let parts move around when soldering, whatever solder is used.

Not that I can't be convinced, it's just that, well... it ain't happening yet.

You form a joint cleaner, quicker and with less chance of overheating the part or the joint.

Cleaner?

How so?

Quicker?

I'm not in that big a hurry.

Less chance?

The odds don't make it a mountain IMO. Burning up parts and boards isn't that commonplace 'round here.

How so?

Quicker?

I'm not in that big a hurry.

Less chance?

The odds don't make it a mountain IMO. Burning up parts and boards isn't that commonplace 'round here.

He didn't say 60/40 was eutectic. He was saying that it isn't and further, it has a higher melting temperature than the eutectic 63/37. That's why he called 60/40 a "stupid" ratio. Did you misread his post?

se

I don’t confront JC as a habit.

Among the words he used to characterise solders, “eutectic” was not included.

I showed some data by which he could make it more “technical”.😀

George

Gpapag, I consider quality solder as almost obvious, as I have used SN63 starting 40 years ago, BUT I used to use SN60 starting in 1959, when I made my first Heathkit. I even put together an oscilloscope (Eico) in 1962, and got many years of use out of it, but I was living in ignorance, AND I always had to worry about 'COLD JOINTS' and I got a few, over time.

My introduction to SN63 removed this problem, because the 'plastic region' as it was sometimes called, was virtually eliminated. It made quality soldering more reliable and faster, all for a 3% change in the tin-lead ratio.

What amazes me is WHY they made 60/40 solder in the first place?

SN62 solder adds further advantages, such as an even lower melting point, better wetting, and reduced absorption of gold or silver plated contacts into the solder, because it is already partially saturated with silver.

I have had a nearly 500 page book on soldering (Manko) for the last 30+ years, by my side or on my bookshelf. Photocopying it and displaying it here is a hassle, and I don't feel that I have to baby anyone here with this info directly from the book, since you are all grownups and can find answers for yourself.

What makes me laugh is when FINALLY, SE and I agree on something, it is resisted, or ignored by others. The reason WHY we agree on this is that we are both professionals in getting circuit boards soldered properly, and we have learned to use EUTECTIC solder from hard experience.

My introduction to SN63 removed this problem, because the 'plastic region' as it was sometimes called, was virtually eliminated. It made quality soldering more reliable and faster, all for a 3% change in the tin-lead ratio.

What amazes me is WHY they made 60/40 solder in the first place?

SN62 solder adds further advantages, such as an even lower melting point, better wetting, and reduced absorption of gold or silver plated contacts into the solder, because it is already partially saturated with silver.

I have had a nearly 500 page book on soldering (Manko) for the last 30+ years, by my side or on my bookshelf. Photocopying it and displaying it here is a hassle, and I don't feel that I have to baby anyone here with this info directly from the book, since you are all grownups and can find answers for yourself.

What makes me laugh is when FINALLY, SE and I agree on something, it is resisted, or ignored by others. The reason WHY we agree on this is that we are both professionals in getting circuit boards soldered properly, and we have learned to use EUTECTIC solder from hard experience.

Forgive me asking what must be a dumb question, but WHY are you scraping leads? If you keep your parts in sealed bags with dessicant, they should be 100% solderable after two years - which is what many semi companies spec them at and how they ship 'em also. Ditto passives. I have lots of precision resistors that still solder great after 4 years - no corrosion at all.

I haven't used 60-40 (SN60) solder in more than 1/3 century. It is a STUPID ratio.

That depends on the application. For things like tinning of leads (major pun involved there!), the 60/40 is superior because it lays down a thicker coat. For hand soldering, the 63/37 is easier to use to get a good joint. In wave solder operations, the thinner coating of 63/37 outweighs the higher per-pound cost.

Horses for courses, the Ersin and Kester people aren't stupid.

That depends on the application. For things like tinning of leads (major pun involved there!), the 60/40 is superior because it lays down a thicker coat. For hand soldering, the 63/37 is easier to use to get a good joint. In wave solder operations, the thinner coating of 63/37 outweighs the higher per-pound cost.

Horses for courses, the Ersin and Kester people aren't stupid.

What's the particular advantage of a thicker coat on leads?

se

That's apparently preferred for tinning in production situations, increasing solderability (according to my source). The technician-type hand soldering, i.e., the stuff that we all do, is a minuscule segment of the market.

Perhaps it's meant to foil people who insist on scraping leads. 😀

Perhaps it's meant to foil people who insist on scraping leads. 😀

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II