Pavel,

Sorry I forgot you. Your bridge would be a steel truss design! 🙂

ES

Oh Yeah Demian I can see yours as a cable design mono pole!

Sorry I forgot you. Your bridge would be a steel truss design! 🙂

ES

Oh Yeah Demian I can see yours as a cable design mono pole!

Demian's bridge I see as a complex construction with lots of gauges and controls, to measure parameters then adjust them according to load and weather conditions. 😀

Jfets are OK. They are NOT as good as tubes, part for part, in linearity.

Wow, revival for non-audio application . . .

Return of the Vacuum Tube "estimate that their nano vacuum tube operates at frequencies up to 0.46 terahertz—some 10 times faster than the best silicon transistors."

An externally hosted image should be here but it was not working when we last tested it.

.

Last edited:

Digital microtubes. They have in common with tubes that we use no more than pipes in toilet do.

Actually Demian's would be a collection of rebuilt bridges!

Reduce, Reuse, Recycle

I'm from California. . . The gauges are necessary to prevent it from collapsing since its all recycled stuff (like everything here. . .)

Even when we agree, we don't! I pick on 16 bits as that is perfect audio reproduction forever as CD's often mention. 🙂

What that means is that audio equipment that uses carbon comp. resistors as an absolute reference (As in a heavy feedback circuit) will be limited to performance less than the digital processes.

Now as you know those designs were done with hard well defined All the way back to Wheatstone and Heaviside using strain gauges to design bridges!

ES

Ed, I have a new bridge to sell you after I test it out. I think I can do the -150 db with a sound card.

As for the 16bits, a typical modern CD player has no AC signals over about 2V rms so no resistors over a K Ohm see more than 4mW. Yes fine you can measure distortion at significant fractions of rating at <2% of rating I don't see it mattering (remember these things scale as V squared).

BTW I was thinking of you. I had the tech replace all the external resistors in that diff amp with series and parallel (in turn) combinations of SMT components, no difference in THD not even a fraction of a dB.

Last edited:

Scott,

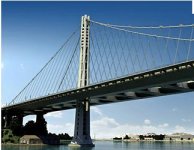

Here is a picture of the bridge we are loading today!

Yes low level resistors don't have much thermal distortion. As has been mentioned to Curldum is that it is the power amp feedback resistors that matter most. However the carbon composition resistors do have more noise when a voltage is applied than most other types.

Interesting thing about excited excess noise, when you excite with lower frequencies you get more overall noise in many (but not all) cases. Next thing you know we will confirm the big bang theory.

Here is a picture of the bridge we are loading today!

Yes low level resistors don't have much thermal distortion. As has been mentioned to Curldum is that it is the power amp feedback resistors that matter most. However the carbon composition resistors do have more noise when a voltage is applied than most other types.

Interesting thing about excited excess noise, when you excite with lower frequencies you get more overall noise in many (but not all) cases. Next thing you know we will confirm the big bang theory.

Attachments

Well, 'bridgebuilders', have we established our respective personalities?

Ever onward.

I have been at a loss to talk about any subject here that has already been 'reviewed' a number of times. Something has come up that leads me to talk about something else.

This is the difference between making 'good sound' or making 'good specs.' or the most features.

I am at such a crossroad:

Now why is there a difference? Well, better specs. usually means more stage complication and MORE global negative feedback. More features can lead to more complexity, as well, often compromising the passive components because so many extra features means so much more money for really good parts, or we have to normally listen through cheap, common parts.

Now I realize that some people here could care less, but they are not the people I am addressing here.

This IS the reason that mid-fi usually has a kinds of 'bells and whistles' and something like the CTC Blowtorch doesn't even have an LED to show that it is on.

The conflict arises when 'marketing' insists that 'engineering' meets a set of arbitrary specs. often taken from competitors data sheets.

The reasons why this becomes a conflict, I will try to show by examples, in future inputs.

Ever onward.

I have been at a loss to talk about any subject here that has already been 'reviewed' a number of times. Something has come up that leads me to talk about something else.

This is the difference between making 'good sound' or making 'good specs.' or the most features.

I am at such a crossroad:

Now why is there a difference? Well, better specs. usually means more stage complication and MORE global negative feedback. More features can lead to more complexity, as well, often compromising the passive components because so many extra features means so much more money for really good parts, or we have to normally listen through cheap, common parts.

Now I realize that some people here could care less, but they are not the people I am addressing here.

This IS the reason that mid-fi usually has a kinds of 'bells and whistles' and something like the CTC Blowtorch doesn't even have an LED to show that it is on.

The conflict arises when 'marketing' insists that 'engineering' meets a set of arbitrary specs. often taken from competitors data sheets.

The reasons why this becomes a conflict, I will try to show by examples, in future inputs.

If you give in to the LED, they will start asking for an on/off switch.😀

Best not to get started down that road though, otherwise the next thing you know, there's a fancy fluorescent display and a microcontroller on board, which really can mess with the audio signal (and the budget).

I actually wonder how John copes with that sort of thing with his commercial design work. As I understand it, he designs the core audio circuits, but the peripheral (or supporting) circuitry is left to others. I'd expect there are cases where the peripheral stuff hurts the performance of the core circuit.

Best not to get started down that road though, otherwise the next thing you know, there's a fancy fluorescent display and a microcontroller on board, which really can mess with the audio signal (and the budget).

I actually wonder how John copes with that sort of thing with his commercial design work. As I understand it, he designs the core audio circuits, but the peripheral (or supporting) circuitry is left to others. I'd expect there are cases where the peripheral stuff hurts the performance of the core circuit.

Do you suppose it would not sound as good with a LED?

😎

As that "a LED" or "an L.E.D.?"

Has anyone done a noise spectrum of L.E.D.s?

Has anyone done a noise spectrum of L.E.D.s?

Yes, quite a few people have. Note that I use LEDs effectively in series with the signal in my MC preamp and the signal to noise performance of the preamp is close to the theoretical maximum. Typical red LEDs are 0.4nV/rt Hz with noise corners below 100 Hz.

Leaving indicators off a preamp is performance art, not performance.

All I found was this Low-frequency noise used as a lifetime test of LEDs - Abstract - Semiconductor Science and Technology - IOPscience

Which is why I asked.

You are aware that L.E.D.s are photovoltaic?

Which is why I asked.

You are aware that L.E.D.s are photovoltaic?

Last edited:

Oh Yeah Demian I can see yours as a cable design mono pole!

This?

Attachments

All I found was this Low-frequency noise used as a lifetime test of LEDs - Abstract - Semiconductor Science and Technology - IOPscience

Which is why I asked.

You are aware that L.E.D.s are photovoltaic?

Red LEDs are not too terrible as photodiodes and I've played around with them for optocoupling where I wanted a big separation of emitter and detector. I tested shorter-wavelength parts and found very low photoelectric sensitivity. However I'm not sure if the latter are as good a tempco match to silicon Vbe.

I recently made a low battery detector using an LED-biased I source as the reference. The accuracy requirements are minimal. But I was pleased to get useful functionality with only 4uA of drain at 9V. This is for an apartment security system and one of the requirements was building it entirely out of parts I already had around 😀

Too far afield to recapitulate, but somewhere in one of the threads I told the story of using an LED to bias a common-base stage for an automotive amp, and the disasterous results of manufacturing's forcing the leads into the wrong holes on the PCB before wavesoldering.

If you give in to the LED, they will start asking for an on/off switch.😀

Best not to get started down that road though, otherwise the next thing you know, there's a fancy fluorescent display and a microcontroller on board, which really can mess with the audio signal (and the budget).

I actually wonder how John copes with that sort of thing with his commercial design work. As I understand it, he designs the core audio circuits, but the peripheral (or supporting) circuitry is left to others. I'd expect there are cases where the peripheral stuff hurts the performance of the core circuit.

This is a very serious problem of course. At least LCDs are low power, and there's e-ink now that is even static for a steady display. And don't even get started on wireless this and wireless that.

Nelson may remember or be alluding above to one of the British mags from many years ago (was it What HiFi? ?) that had someone saying "You're not going to like this", and then proceeding to describe how the sound of a component changed when he disabled the power indicator LED. A bit far-fetched, but then one could imagine a way in which the change in current could have a tiny effect on a poorly-designed circuit.

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II