5. For tin/silver, I recommend using the tip to melt the solder FIRST...buildup a ball of liquid solder between the tip and the work where you want it to go, and when the work has reached the melt temp, the solder will wick to the work. Keep applying the solder to the tip/work interface. The most important aspect of this is, it does not overheat the work because the molten solder is at the melt temperature, which is 221C for tin/silver. You are heating the work using a 221 C source. This is exactly like melting chocolate by putting one pot inside another filled with water. As heat is applied, the inner pot cannot exceed the 100 C.

jn

To clarify:

The ‘solder blob’-‘water pot’ constant temperature analogy is valid only for the time span new solid solder is being introduced to the liquid blob (phase change from solid to liquid).

When blob is stopped been fed with new solder and all solder mass is in liquid state, it’s temperature will rise (if heat continues to be applied).

Is this correct?

George

Last edited:

Re-quote with hiliteI Googled, but didn't really find anything new.

This from Brigham Young University EET faculty sums it up for me:

When an alloy is heated it typically goes thorough multiple phases. It goes from a solid state to what is known as a pasty stage, sort of halfway between a liquid and a solid, and then to a liquid state. In soldering it is difficult to work with a substance that goes through a pasty stage. Eutectic solder is often used for this reason. A eutectic alloy is one that goes directly from a solid state to a liquid state without a pasty stage. The eutectic tin-lead alloy is made up of 63% tin and 37% lead. Eutectic tin-lead solder can be applied as a liquid just above the melting point, and then as it cools it will transform directly into a solid. This makes it possible to form solid solder joints very quickly. Sometimes a 60% tin and 40% lead alloy is used. This alloy exhibits a nearly eutectic change from solid state to a liquid state and can be produced at a lower cost [3].

They really need to get out in to the real world. Sigh, those academics....

No, it is NOT difficult to work with a substance that goes through a pasty stage. Clearly, none of them has ever done any plumbing. 50/50 was the standard, and it was because of the pasty range, not in spite of it. Even now, hydronic heating zone valves require 50/50 and NOT lead free solder, and it's only due to temp and ease of use. Lead free requires the flux remain active and non burned up to 221, while 50/50 wets the joint at 183, covering the base metal even as the temperature climbs. The flux should not be needed once the work has hit 183.

50/50 requires about 250 C in order to completely go liquid, but below that it is a slurry, more viscous and easier to keep where it needs to be. Great when your sweating 1.5 inch copper. The lead free stuff needs 221 C, but goes all limp instantly, tough to wipe, always dripping.. and it messes up visual inspection, as it's more difficult to get a clean external lead free fillet because of the higher temp required.

Given lead free plumbing vs shark bites....sigh...

jn

I went to an ACE HW to replace my mortising chisel Sunday. At the checkout they put a big "hand tools are not returnable" sticker over the "lifetime warranty". I went home and there was a big chipout in the middle of the blade that was hidden by the anti-theft wrapping.

That means they will exchange it for a new one.

I have my grandfathers socket chisels, they still work. (I also have my fathers and a few dozen I bought.)

I actually just bought a 1/2" shoulder plane as I needed one and did not have one. On Ebay folks were asking $250.00 for the same model Amazon sold me for under $70.00

After a quick hone it is working great on the rock maple floor I am putting in.

But quick question, which end of the chisel...

To clarify:

The ‘solder blob’-‘water pot’ constant temperature analogy is valid only for the time span new solid solder is being introduced to the liquid blob (phase change from solid to liquid).

When blob is stopped been fed with new solder and all solder mass is in liquid state, it’s temperature will rise (if heat continues to be applied).

Is this correct?

George

Yes, yes, yes. And when we feed solder in, do so as fast as it will melt. If you feed in too slow, the melt temp will go up.

This is especially important when working with parts that are sealed using plastics. I had one vendor using a very small tip controlled temp iron to put 24 awg wires on a small pushbutton switch. They went lead free, had the tip too hot to speed production, and the plastic holding the terminal went "plastic", expanded, and during cooldown pulled away from the terminal metal sufficiently so flux could wick into the body, coating the contacts.

When it compromised the NC terminals, vibration due to fans would cause faults.

jn

I am using the AIM Glow core no clean solder for my hand smt work, it is nice to work with. Stock up, as we all know Pb is out.

13368 AIM | Mouser

13368 AIM | Mouser

I don't have a regular technician scheduled, but over the years, I have had a number of technicians that come in for a few hours when I have Vendetta or CTC Blowtorch repairs. The techs. unfortunately can try to cut too large a wire size or even sometimes a steel wire with the flush cutters. This will damage the working surface, so I tend to keep it mostly to myself, unless I am directly supervising.

Instead, I give them a variety of tools, made in the USA or elsewhere, to do essentially the same thing.

A good tool is a pleasure to work with, and I am hoping to share others experiences with their favorite tools.

Instead, I give them a variety of tools, made in the USA or elsewhere, to do essentially the same thing.

A good tool is a pleasure to work with, and I am hoping to share others experiences with their favorite tools.

Given lead free plumbing vs shark bites....sigh...

jn

Shark bites are awesome. At my offgrid place I dread sweating joints because if one has a pinhole I have to drain the entire system down and start over again. Last fall a friend thought they were doing me a favor by closing a gate valve that I never touch to stop a very slow drip trapping water in about a 4' verticle run. I closed down as usual and got a shower the next spring (yes the split was right at eye level aimed at the middle of the room).

Shark bites are awesome.

I love them for the radiant heat runs I installed on the ground floor. I did a nailup install between joists in the basement, so any shark I put in I have access to forever. The system is 15 PSI working, 150F temp set by tempering valve, and the relief is set to 30 PSI.

A friend of mine used one at the street feed coming in the house. A hammer pulse released the copper from the shark. Apparently it was caused by the water main being re-energized after street work. We don't have one ways from the street feed yet, so don't need an expansion tank on the domestic.

For domestic, I prefer using the crimp style on the PEX, I borrow the tool. But for now, I have oodles and oodles of copper fittings, an inheritance from dad..

jn

At my offgrid place I dread sweating joints because if one has a pinhole I have to drain the entire system down and start over again.

Well, that's a process problem. What you need to do is invite JC over whenever you need to sweat a fitting, and tell him to bring his knife..😀

jn

Well, that's a process problem. What you need to do is invite JC over whenever you need to sweat a fitting, and tell him to bring his knife..😀

jn

A bit snide. Just use one of the purpose made steel wire ring brushes.

Not at all. We're all having fun.. most here are mature adults. (me, who knows...)😱A bit snide.

If ya don't like it. Tough toodles. <=== see?

And, given your next sentence, what was meant was clearly understood by you. That being, it may have been the prep work that was the problem.

But as I pointed out earlier, I've had more than my share of flux tins that stopped working, as I don't use enough for quick stock rotation at home. Sometimes I feel like just buying a new one every time I have to sweat something, as it is a pita when the flux doesn't work right.

Just use one of the purpose made steel wire ring brushes.

The external ones don't last too long, I seem to always fold the bristles over eventually. The inners are great, they last a while. I always have a roll of the emery as well.

jn

I don't have a regular technician scheduled, but over the years, I have had a number of technicians that come in for a few hours when I have Vendetta or CTC Blowtorch repairs. The techs. unfortunately can try to cut too large a wire size or even sometimes a steel wire with the flush cutters. This will damage the working surface, so I tend to keep it mostly to myself, unless I am directly supervising.

Instead, I give them a variety of tools, made in the USA or elsewhere, to do essentially the same thing.

A good tool is a pleasure to work with, and I am hoping to share others experiences with their favorite tools.

Ah, ok.

Let's see, I guess one of my favorite tools are my Clauss (now made by Miller) No-Nik wire strippers.

se

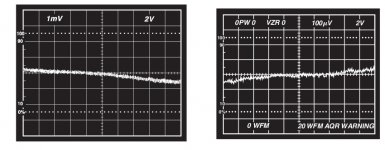

Here’s a little story about a -140dB distortion. When we released the AD620 there was an unexplained 50nV/V non-linearity in the gain (picture on left). It’s not like anyone cared but I had to figure it out. It turns out the 1% copper/99% aluminum metallization had a 200uV/C thermocouple potential to the contact metallurgy. The input devices were perfectly done to eliminate any thermal gradient (the part in the picture was only doing a peak power of 10mW anyway) but to reduce leakage the base contact was reduced to a dot in the corner and the dot worked better on one of 4 devices in a different corner. We only needed .0025 degrees C error in the symmetry and got it.

On the AD621 I made the change and the error disappeared (picture on right). I went to the library and found the guy who wrote the book on this stuff and called him. He had no idea on how to predict the Seebeck coefficients of inter-metallics or the effects of 30 microns of gold under a thermo-compression bond, etc. So beware solder joints and lead compositions in the presence of watts of power shuffling around can and do operate if you insist on fiddling around at the -140dB level.

BTW there is a built in offset of 3uV in the AD524 family due to the fact that on warm up the + and – leads are at different temperatures. This one gold over kovar (in the old days) to aluminum with 2% silicon. You should have seen me trying to make thermocouples out of 1mil gold and aluminum bond wires.

EDIT- Forgot to mention if you were measuring something that had comparably small distortion flipping things gave a different answer i.e. directionality. 😀

On the AD621 I made the change and the error disappeared (picture on right). I went to the library and found the guy who wrote the book on this stuff and called him. He had no idea on how to predict the Seebeck coefficients of inter-metallics or the effects of 30 microns of gold under a thermo-compression bond, etc. So beware solder joints and lead compositions in the presence of watts of power shuffling around can and do operate if you insist on fiddling around at the -140dB level.

BTW there is a built in offset of 3uV in the AD524 family due to the fact that on warm up the + and – leads are at different temperatures. This one gold over kovar (in the old days) to aluminum with 2% silicon. You should have seen me trying to make thermocouples out of 1mil gold and aluminum bond wires.

EDIT- Forgot to mention if you were measuring something that had comparably small distortion flipping things gave a different answer i.e. directionality. 😀

Attachments

Last edited:

Well, that's a process problem. What you need to do is invite JC over whenever you need to sweat a fitting, and tell him to bring his knife..😀

jn

You would be amazed at how much emery paper you need for pipe that has been 100' from ocean water for 25yr.

Interesting, SE.

Yeah, they're like razor blade guillotines with precisely milled holes in the middle. Need a stripper for each size and type of wire, but if you're regularly using a small number of different wires, they're the katana of wire strippers as opposed to Swiss Army knife strippers.

se

I always have a roll of the emery as well.

Well sure. Because you know, chicks really dig a guy who always has a roll of emery on him. 😛

se

This habituation will cause problems with ABX testing as well.Well, it doesn't have to be break-in (or run-in) at all. Whenever you change a component in your system it takes time for your ears to become familiar with the "new" sound. When you put a new component in your system, what do you know about it? How will it affect the sound? This starts a period of subconscious evaluation and how you respond to the sound can change day to day, until you've become familiar with it and formed beliefs about it. This is called habituation.

You will have an opinion of what the sound is stored in memory for months.

And a bias as to whether you like that sound or not

Your focus on transducer faults is, IMO, far more likely to be productive than the rut in which "high-end" electronics designers are stuck.

Yes, I understand you will see Jan shortly and if you NDA me I'd like him to explain to you what I'm up to. It involves plastics so there might be something we could do there.

I've had more than my share of flux tins that stopped working, as I don't use enough for quick stock rotation at home. Sometimes I feel like just buying a new one every time I have to sweat something, as it is a pita when the flux doesn't work right.

The external ones don't last too long, I seem to always fold the bristles over eventually. The inners are great, they last a while. I always have a roll of the emery as well.

jn

I had a nice coast to coast flight with a fellow who sold tools to the big box stores. Precision parts were made in Taiwan, plastic in the U.S. and lower tolerance parts in China. Clever design on his tools but not really aimed at the professional. Squarely aimed at the big box store customers.

So if the brush is wearing out, maybe you should cyro it first, clean it with magic stones, be sure to demagnetize it and rim it with green ink.

Or just buy tools at a real plumbing supply house, they usually carry better quality parts.

P.S. the brushes are directional you know!

Last edited:

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II