Addition

I forgot to say that anyone who wanted the sound track from the video is very welcome I can send them an MP3 in exchange for a nice message.

Cheers

I forgot to say that anyone who wanted the sound track from the video is very welcome I can send them an MP3 in exchange for a nice message.

Cheers

I made myself a motorcar tax disc in an equivalent of Photoshop and thought I was doing good.

I thought I had some spare junction boxes to tidy the lighting circuits. Someone had modified the one in the loft with chocolate block connectors that don't seem right. Just as I got ready the JBs are nowhere to be found. I am not going to the shop for those.

I thought I had some spare junction boxes to tidy the lighting circuits. Someone had modified the one in the loft with chocolate block connectors that don't seem right. Just as I got ready the JBs are nowhere to be found. I am not going to the shop for those.

Yes, I agree that 0.5K/W is safe but still a bit hot for my liking and I wouldn't locate the amplifier in a cabinet, on close shelves etc. or lean over the amp whilst fiddling with connectors, as I do. If the amplifier is separate to the preamp as Hood's clearly was, it doesn't matter so much if it runs hot but I prefer to incorporate at least a volume control/preamp for simplified operation at home and heat doesn't mix with pots or any contacts and connectors, for that matter.

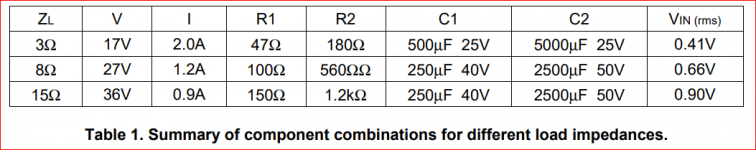

I'll dig out a bit more history by attaching Hood's table of parts and supply voltage combinations for different speaker loads and power output. First, we need to check that what we are using for speakers is really in the same ball-park as Hood was, 50 years ago, when impedances were nominated differently to today. Now, marketing drives what 8 ohms means and that's more likely a universal 6 ohms rating by 1969 standards.

In other words, don't be confused by old docs which recall past values and facts which may well be more correct but still at odds with today's audio babble, where technical terms seem to flip around willy-nilly from one ignorant user to another. Just use a little history to help clarify what nominal speaker impedance really means when you are looking at a speaker's impedance graph that only crosses the 8 ohms line at one point 😕

I'll dig out a bit more history by attaching Hood's table of parts and supply voltage combinations for different speaker loads and power output. First, we need to check that what we are using for speakers is really in the same ball-park as Hood was, 50 years ago, when impedances were nominated differently to today. Now, marketing drives what 8 ohms means and that's more likely a universal 6 ohms rating by 1969 standards.

In other words, don't be confused by old docs which recall past values and facts which may well be more correct but still at odds with today's audio babble, where technical terms seem to flip around willy-nilly from one ignorant user to another. Just use a little history to help clarify what nominal speaker impedance really means when you are looking at a speaker's impedance graph that only crosses the 8 ohms line at one point 😕

Attachments

Nice one Nigel,

You made a start with that image and with what you learnt you can go back to it later. I spent 13 years prevaricating before I threw everything else to one side concentrate on montage.

Something that has just occurred regarding you last but one post. I don't think Mr Hood had the heat transmitting paste that we now have, I suspect that he would have used something like petroleum jelly and mica washers.

Cheers

You made a start with that image and with what you learnt you can go back to it later. I spent 13 years prevaricating before I threw everything else to one side concentrate on montage.

Something that has just occurred regarding you last but one post. I don't think Mr Hood had the heat transmitting paste that we now have, I suspect that he would have used something like petroleum jelly and mica washers.

Cheers

Thanks for that Nigel.

Hello Ian,

Your quite right about the spread of knowledge, one person says something others repeat it and it becomes gospel, even though it is totally erroneous. I have experienced this many times, in photography, in model railways and in growing your own veggies.

I do two things, I teach myself and never say anything other than that which I done and proved for myself. So many people trust this false knowledge without going back to the original source and seeing and understanding what the person had at the time did with it and why.

And that is why I trust Mr Hood and his words, the way they are written speaks to me of a transparent honesty.

Cheers both

Hello Ian,

Your quite right about the spread of knowledge, one person says something others repeat it and it becomes gospel, even though it is totally erroneous. I have experienced this many times, in photography, in model railways and in growing your own veggies.

I do two things, I teach myself and never say anything other than that which I done and proved for myself. So many people trust this false knowledge without going back to the original source and seeing and understanding what the person had at the time did with it and why.

And that is why I trust Mr Hood and his words, the way they are written speaks to me of a transparent honesty.

Cheers both

If you study heat transfer the big problem is the washer. Arcam had very good anodising on the A60 heatsink. They did away with the washer and just used the heat transfer compound. Whilst I couldn't believe it I never knew it fail. From memory a very good T03 washer is 0.3 degrees per watt. That's a massive problem.

Almost right with what JLH would have used. Around 1969, I was using clear silicone grease with sheet mica for a 2N3055 based amplifier, much the same compound as used in my company's chemistry lab for sealing ground glass jointed laboratory glassware. This differs from today's thermal paste compounds only in that it was thickened with aerogel silicon dioxide rather than powdered alumina or similar ceramic filler, which renders it white and is claimed to improve heat conductivity.

Last edited:

The problem with electrical insulation is it also is thermal insulation. This.is all connected with conduction, semiconductors and ultimately insulation. The free electrons come into it. The electrical insulation washer has to pretend to be a thermal conductor. As far as I know thermal powders are mixed with a rubber like compounds to make the washer. Free electrons are equally associated with heat and electrical conductivity. A heat transfer washer is a bit remarkable.

The surface finish of the transistor is a factor. The rubber conforms to the surface to assist. Thermal paste the same. Conduction and free electrons a fascinating subject. Aluminium is on its own with that, it resembles a metaloid. Silver is a superb electrical and thermal conductor. Mica a very good insulator and can be made thin. Some still prefer it.

The surface finish of the transistor is a factor. The rubber conforms to the surface to assist. Thermal paste the same. Conduction and free electrons a fascinating subject. Aluminium is on its own with that, it resembles a metaloid. Silver is a superb electrical and thermal conductor. Mica a very good insulator and can be made thin. Some still prefer it.

Hello and thanks for all the information.

Thinking about suitable transistors and the heat transmission through mating surfaces I would be grateful for some suggestions for flat TO220 varieties, the only one I know of is TIP3055. I have tried a search for TO220 but sadly it doesn't reveal anything concrete.

Cheers

Thinking about suitable transistors and the heat transmission through mating surfaces I would be grateful for some suggestions for flat TO220 varieties, the only one I know of is TIP3055. I have tried a search for TO220 but sadly it doesn't reveal anything concrete.

Cheers

TIP3055 was Arcam's choice in T03P or T0247. The T0220 is a bit small to shed the heat. TIP3055 is a slightly faster device and very nice. I have seen the T0220 version.

Hello Nigel,

I'll stick to that and make a start soon.

As soon as I hear anything from my speakers I'll let you know.

Thanks and cheers take care all of you.

Byeeeeeeeeeeeeeeeeeeeee 🙂

I'll stick to that and make a start soon.

As soon as I hear anything from my speakers I'll let you know.

Thanks and cheers take care all of you.

Byeeeeeeeeeeeeeeeeeeeee 🙂

I think you mean TO218, the precursor of TO247 outline, rather than TO3P. My experience is that that these are (or perhaps were) inconsistent from one manufacturer to another. Some are just repackaged 2N3055/MJ2955, others are different chips that probably fit the broad specs of 90W general purpose power transistors. YMMV regarding hFE, Ft and linearity there, even though the datasheet specs are comfortably met......TIP3055 was Arcam's choice in T03P or T0247. The T0220 is a bit small to shed the heat. TIP3055 is a slightly faster device and very nice. I have seen the T0220 version....

https://www.onsemi.com/pub/Collateral/TIP3055-D.PDF

ST Micro still supplies the TIP types and I was given a large quantity of them, still in their boxes and the Ft was comparable with 4Mz semis. I have also encountered original TI product that didn't even make 1Mhz and sounded very poor in my P3 amplifiers long ago. I went over the same ground only a year ago with ST Micro's versions and had a pleasant surprise though. So, I wonder what chips ST will be using now that the ancient TO3 outline has finally bitten the dust?

ST don't make many high power BJTs now, only 4 TIP types and surprise, surprise, a version of 2SD1047 in the TO3P package. Rotel has been associated with the 2SD1047/2SB817 pair in all their top range amplifiers from low power to monsters, over decades. Methinks it would make a great, economical but at least genuine 15MHz power transistor for Quasi-complementary designs such as small Naim clones and several Naim wannabes that were popular but manufacturers couldn't survive in business. That one's on the 'must try' list for a JLH'69 too 🙂

Farnell list T0247 from On semiconductors. Main thing is not the rarer T0220 type that I once saw listed. On list SOT93 T0218 and T0247.

Well, Farnell's list is wrong - no sorry, its right for the G suffix if you check On Semi's website too. In reply to an earlier question though, anyone searching for T0220 versions of TIP3055/2955 etc, should look for MJE3055/2955 or MJE3055T/2955T rather than TI's brand prefix. For Audio applications, I wouldn't consider these unless you are only trying to get up to 25W in class AB or maybe 8W in class A in the smallest possible space, since there are better transistors that won't cost much more.

The problem is that ONsemi and Fairchild have integrated their past catalogues and some are only recent additions to the ON catalogue.

The problem is that ONsemi and Fairchild have integrated their past catalogues and some are only recent additions to the ON catalogue.

Last edited:

Bloomberg say Australia is trying BCE vaccine to help boost immunity. Whilst it's a long shot well done Australia. It's an old vaccine for tuberculosis. I recommended HIV drugs to my surgery and perhaps similar drugs. Anti malaria drugs might work.

Nigel, for as long as I can remember and probably previous generations can, we have had a hyperactive, government sponsored serum development culture here. Once, many immigrants brought both common and rare diseases from their long voyages here and whole shiploads were often held onboard or in a prison-like remote quarantine station for weeks and months, awaiting tests, vaccines or just "wait and see" treatment. It wasn't good for a resentful population that wanted the disease risks gone.

Another factor is our involvement in the South Sea Islands, Papua New Guinea and our own tropical North where there are lots of remote communities spread thinly over vast areas of barren land, islands and swamps, without goods or health services that Europeans and Brits have enjoyed for centuries.

Put that together with plenty of bright medical scientists who are keen to crack life's big mysteries on a commensurate salary and you would have some good results in a lot of countries, I suspect 😉

Another factor is our involvement in the South Sea Islands, Papua New Guinea and our own tropical North where there are lots of remote communities spread thinly over vast areas of barren land, islands and swamps, without goods or health services that Europeans and Brits have enjoyed for centuries.

Put that together with plenty of bright medical scientists who are keen to crack life's big mysteries on a commensurate salary and you would have some good results in a lot of countries, I suspect 😉

Now we are unchained from EU rules I hope that the commonwealth grows. My grandfather had polio. I believe it was an Australian nurse who worked against authority and found a way to get victims walking. My neighbour in Woodstock UK was the last official victim in the UK. Only in her 60s. She was days away from her vaccination.

BCE would ramp up the production of antibodies. This would put new defences on the starting blocks. That's a brilliant speculation. I suspect that the risks are minimal.

One way to do a vaccine is to genetically engineer a fraction of the virus. Just enough to alert the immune system. Alas testing would prevent it.

The commonwealth is how the world should be. Just friends. Countries who were not in the empire can join. No one needs Draconian rules to be friends. Doubtless the commonwealth is less than perfect it wouldn't be humans if it were. Perfect shouldn't be the enemy of good. JLH is nearer perfect than good.

BCE would ramp up the production of antibodies. This would put new defences on the starting blocks. That's a brilliant speculation. I suspect that the risks are minimal.

One way to do a vaccine is to genetically engineer a fraction of the virus. Just enough to alert the immune system. Alas testing would prevent it.

The commonwealth is how the world should be. Just friends. Countries who were not in the empire can join. No one needs Draconian rules to be friends. Doubtless the commonwealth is less than perfect it wouldn't be humans if it were. Perfect shouldn't be the enemy of good. JLH is nearer perfect than good.

I just had an unusual thought in thermodynamics. We could eliminate the heat washers all together. The positive rail transistor could be 2N3055H or better. The bottom BUZ900 enhancement mode MOSFET. These come on much like a bipolar so should be possible. The advantage is Collector and Source to the casework. That means the two left right top transistors on on heatsink and left right MOSFETS to another. No compromise and using the ideal device where best. I would estimate a 30% smaller heatsinking possible it the fit very flat. It's not the heatsink temperature, it's the transistor. If the PSU has over current protection it should be ok exposed. Capacitor coupling preferable. Transistors make ideal current amplifiers, MOSFETs ideal voltage amps. Superficially that is what we would have. No idea how easy it would be to do. Not all FET are source ( emitter ) to case. Exicon make suitable FET.

You could adapt this idea to the JLH using all NPN devices. Make the 0V devices fitted to a 30 % larger heatsink with washers the others on a positive rail no washers. For this PNP slightly preferred.

I just made some hand steriliser. 80% pure isopropanol and 20% E45 cream. The cream helps it stick whilst being gentle.

You could adapt this idea to the JLH using all NPN devices. Make the 0V devices fitted to a 30 % larger heatsink with washers the others on a positive rail no washers. For this PNP slightly preferred.

I just made some hand steriliser. 80% pure isopropanol and 20% E45 cream. The cream helps it stick whilst being gentle.

- Home

- Amplifiers

- Solid State

- JLH 10 Watt class A amplifier