Originally posted by josephpo

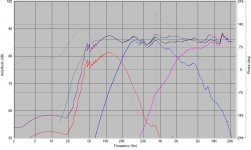

The crossover is based on manufacturer's data adjusted for baffle response using edge and floor reflection from the MJK paper. For this I used FRD consortium's spreadsheet and adjusted each driver's response and calculate phase information. Speaker workshop was used to do the crossover simulation.

I realise that the combined response can be futher smoothed especially the open baffle reversal just after 500 Hz. I don't really want to start tweaking on a simulated crossover, adding complexity to the network. I'll leave this for when I've got actual measurements taken...

I have attached the open baffle effect from edge for interest sake.

It is good to use baffle placement simulations to optimise driver placement and check floor bounce, etc. But your crossover design is best derived from the measured acoustic response and impedance (of course, after having done aforementioned optimisations).

Originally posted by josephpo

A pretty large inductor is needed for the woofers.

Then you should consider iron-core inductors to minimise resistance (unless you need it).

Originally posted by josephpo Good idea, I'll play around with a notch and see if it can smooth things a bit at the top.

Another option would be to change the mid/high crossover to a Butterworth or try to get to a 3'rd or 4' order LR crossover to get the mid to roll off quicker. The dip is measured 85 db (5.2 KHZ) while the peak is at 87.76. db (8.2 KHZ), this is within my +- 2 db goal.

The problem is that such peaks are usually indicators of cone breakup or other resonance. Leave them untreated and you might end up with a bright or honky sound, even though the summed response might look smooth. If you have not experienced this before, I'd recommend that you do a before/after comparison for tamed/untamed treatment. There's no substitute for actually hearing the effect.

Do you have a measurement mic?

Point made.

I am a believer of simplicity so I'd really like to first see the real measurements before adding these bells and whistles. But obviously won't help if the current design is flawed.

Attached a revised chart with the notch filter added to tame the mid's peak. The new combined output (black line) is compared with the previous crossover (purple line).

Since it's just an addition of a notch filter it's worth a listening test. It does seem to change the mid's character a bit bringing it down a 2 db's from 0.8KHz to 3KHz. I think this will suit the overall design better though.

I'm getting my test equipment together, just finished the Wallin Jig II and should be able to provide real measurements soon using speaker workshop. I've got an uncalibrated mic which should be fine for now.

It will take me a week or two to mount the drivers in a test baffle and build the crossover.

I am a believer of simplicity so I'd really like to first see the real measurements before adding these bells and whistles. But obviously won't help if the current design is flawed.

Attached a revised chart with the notch filter added to tame the mid's peak. The new combined output (black line) is compared with the previous crossover (purple line).

Since it's just an addition of a notch filter it's worth a listening test. It does seem to change the mid's character a bit bringing it down a 2 db's from 0.8KHz to 3KHz. I think this will suit the overall design better though.

I'm getting my test equipment together, just finished the Wallin Jig II and should be able to provide real measurements soon using speaker workshop. I've got an uncalibrated mic which should be fine for now.

It will take me a week or two to mount the drivers in a test baffle and build the crossover.

Attachments

Gosh, I can't believe a year has gone by.

I have been making a lot of progress the last few months, spending my time on building and listening. Even though modeling gives you a bit of a headstart I have learned that there is no replacement for actually listening to a design. I'll post my measurements and final crossover here in the next few days. Just doing some last tweaking before ordering proper components. Used cheap non-poparized caps and home-build inductors whilst testing different crossovers.

One fundamental question I'm struggling with is whether should copy the Jamo baffle or create something more unique. Although I've used the conceptual design (drivers, etc) it won't really be fair just to try and copy the look. Attached is CAD drawing for computer cut mdf boards.

I have been making a lot of progress the last few months, spending my time on building and listening. Even though modeling gives you a bit of a headstart I have learned that there is no replacement for actually listening to a design. I'll post my measurements and final crossover here in the next few days. Just doing some last tweaking before ordering proper components. Used cheap non-poparized caps and home-build inductors whilst testing different crossovers.

One fundamental question I'm struggling with is whether should copy the Jamo baffle or create something more unique. Although I've used the conceptual design (drivers, etc) it won't really be fair just to try and copy the look. Attached is CAD drawing for computer cut mdf boards.

Attachments

josephpo said:

One fundamental question I'm struggling with is whether ( I )

should copy the Jamo baffle or create something more unique ...

... it won't really be fair just to try and copy the look.

Hi, I cannot see the point of not copying it unless you think you can do better, 🙂/sreten.

Ok, here she is, old faithfull prototype. My wife's been very patient but understandably would like me to get rid of her 🙂

Thinking of bending the plywood at the base to form the base. It will create a curved single baffle using the Jamo shape.

My room is L shaped open plan with speakers in the dead end, 4.5 m wide and 10 m long, couch position 3 m in front of speakers.

Thinking of bending the plywood at the base to form the base. It will create a curved single baffle using the Jamo shape.

My room is L shaped open plan with speakers in the dead end, 4.5 m wide and 10 m long, couch position 3 m in front of speakers.

Attachments

Was thinking of mounting on spikes, would this work?

Don't think I can improve on the Jamo baffle design, even the rough prototype has such a presence/personality no one walking into my house would be able to ignore them! They manage to turn what is usually a bulky clumsy big ... baffle into a sleek elegant shape.

Don't think I can improve on the Jamo baffle design, even the rough prototype has such a presence/personality no one walking into my house would be able to ignore them! They manage to turn what is usually a bulky clumsy big ... baffle into a sleek elegant shape.

josephpo said:Ok, here she is, old faithfull prototype. My wife's been very patient but understandably would like me to get rid of her 🙂

Thinking of bending the plywood at the base to form the base. It will create a curved single baffle using the Jamo shape.

My room is L shaped open plan with speakers in the dead end, 4.5 m wide and 10 m long, couch position 3 m in front of speakers.

Looks great. Is the panel really curved or is it lens distortion? If curved how did you do it ?

Glad if you can share us the xo too.... I've always liked active as it is easier (and cheaper if the amp is already owned) but curious if the passive xo is simple enough.

How is the bass is is deep enough ? 😎

The baffle is slightly bend, it is only a single 6mm mdf sheet strugling to carry the weight of all the drivers - no fancy construction technique 🙂. This instability does reflect in the measurements, also the tweeter is pointing about 30 deg off axis.

I'm going to build a jig to

introduce very subtle curves to 10 layers 4 mm ply. Once the glue set the curves will be permanent. I'm just wary of the effect on the tweeter, maybe Jamo used this technique bring down the top-end without using a resistor?

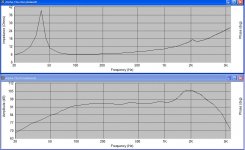

Attached measurement taken at 2 1/2 m distance at 1 m height.

I'm going to build a jig to

introduce very subtle curves to 10 layers 4 mm ply. Once the glue set the curves will be permanent. I'm just wary of the effect on the tweeter, maybe Jamo used this technique bring down the top-end without using a resistor?

Attached measurement taken at 2 1/2 m distance at 1 m height.

Attachments

Hi,

The components you chose are all of very good quality, however they are not very effcient, to get 88db at the same time driving the overall speakers using one amplifier is some thing which I don't agree.

Currently I am building something similar to your configuration, tweeter, midrange and twin woofer. The components I pick are:

tweeter: B&C DE10 and ME10 horn, 109dB

mid range: Hempcone, 8" full range, 95db to 250 Hz

woofer: 12" no brand, Fs=37 hz, in parallel 95-96db to

45hz, in U-frame.

x-over😀CX 2496

These are all the components left over from a no. of projects I am working on.

Tri amping. The speakers should be ready soon.

My suggest for your system is if you tri-amp or at least bi-amp(woofer and joint mid and tweeter) you should get very good sound.

The components you chose are all of very good quality, however they are not very effcient, to get 88db at the same time driving the overall speakers using one amplifier is some thing which I don't agree.

Currently I am building something similar to your configuration, tweeter, midrange and twin woofer. The components I pick are:

tweeter: B&C DE10 and ME10 horn, 109dB

mid range: Hempcone, 8" full range, 95db to 250 Hz

woofer: 12" no brand, Fs=37 hz, in parallel 95-96db to

45hz, in U-frame.

x-over😀CX 2496

These are all the components left over from a no. of projects I am working on.

Tri amping. The speakers should be ready soon.

My suggest for your system is if you tri-amp or at least bi-amp(woofer and joint mid and tweeter) you should get very good sound.

Output goal is 86 db, this is mostly limited by the SEAS excel driver with stated sensitivity at 85.5 db.

I do plan to play with active setup at some point but figured it would be interesting to compare with a passive design. I'll live with the passive crossover for a while before doing this.

Personally I like full range driver more for midrange...

I do plan to play with active setup at some point but figured it would be interesting to compare with a passive design. I'll live with the passive crossover for a while before doing this.

Personally I like full range driver more for midrange...

josephpo said:Output goal is 86 db, this is mostly limited by the SEAS excel driver with stated sensitivity at 85.5 db.

I do plan to play with active setup at some point but figured it would be interesting to compare with a passive design. I'll live with the passive crossover for a while before doing this.

Personally I like full range driver more for midrange...

You can stick with passive, but you can separate the terminals and drive them separately using separate or even diffrent amps say of different power ratings. you will find the soundstage improves dramatically, eg. Magnetar uses 4 amps in his "Stargate speaker"

I plan to move to passive once I finalise my speaker system. We are now in reverse row!

cheers.

Sounds easy enough to give it a try.

Here's the jig that will bend the baffle into shape whilst the glue dries. Learned the hard way that the ply direction is important. If use 3 ply, make sure that it is cut with single ply horizontal. This makes it easier to bend! Going to try again this weekend.

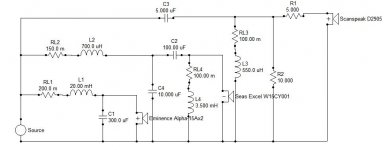

Here's parts list from Madisound. Still contemplating replacing C3 with a Mundorf Supreme cap!

Low

C1 300 uF Bennic 280 mfd Electrolytic

L1 20 mH Sledgehammer 20.0mH 15AWG Steel Laminate

Mid

L2 0.7 mH Sidewinder 0.7mH 16AWG

C2 100 uF 100 mfd Solen Fast Cap 400V

C4 10 uF 10ìF PX Range Polypropylene Capacitors

L4 3.5 mH Sidewinder 3.5mH 16AWG

High

C3 5 uF 4.7ìF SA Range Polypropylene Capacitors

L3 0.55 mH Sidewinder 0.5mH 16AWG

Here's the jig that will bend the baffle into shape whilst the glue dries. Learned the hard way that the ply direction is important. If use 3 ply, make sure that it is cut with single ply horizontal. This makes it easier to bend! Going to try again this weekend.

Here's parts list from Madisound. Still contemplating replacing C3 with a Mundorf Supreme cap!

Low

C1 300 uF Bennic 280 mfd Electrolytic

L1 20 mH Sledgehammer 20.0mH 15AWG Steel Laminate

Mid

L2 0.7 mH Sidewinder 0.7mH 16AWG

C2 100 uF 100 mfd Solen Fast Cap 400V

C4 10 uF 10ìF PX Range Polypropylene Capacitors

L4 3.5 mH Sidewinder 3.5mH 16AWG

High

C3 5 uF 4.7ìF SA Range Polypropylene Capacitors

L3 0.55 mH Sidewinder 0.5mH 16AWG

Attachments

Interesting jig; looks promising! You say that you are going to use ten layers of 4mm ply? How are you planning on bending and joining them all? My first thought is to glue two boards together in the jig at once. Hopefully the dried baffle will then be rigid in the final shape. Then if you glue copies of the same shape together, maybe in the jig under light pressure. Or is the jig strong enough to bend ten layers of ply at once? I'm guessing that might be tricky, taking into account having glue in there as well and getting all the layers to line up while bringing up to tension.

Have you thought about using a non-hardening adhesive between the panels - the so called constrained layer damping approach? Of course this might well add extra problems to shaping the baffle!

I take it your plywood is void-free as well? Apparently quite a lot isn't void free, and if there are loose knots and things rattling around in the inner plies, that can be very annoying! If you're going to so much trouble with your baffle it might be worth using top grade wood.

Have you considered finishing off the baffle edges with some half-rounds of hardwood? Then it wont look like the baffle's plywood either.

For what it's worth I'm also in the process of building an open baffle speaker. I have used Edge (software) to design a flat baffle, but am now stressing over the materials and building technique!

-Martin

Have you thought about using a non-hardening adhesive between the panels - the so called constrained layer damping approach? Of course this might well add extra problems to shaping the baffle!

I take it your plywood is void-free as well? Apparently quite a lot isn't void free, and if there are loose knots and things rattling around in the inner plies, that can be very annoying! If you're going to so much trouble with your baffle it might be worth using top grade wood.

Have you considered finishing off the baffle edges with some half-rounds of hardwood? Then it wont look like the baffle's plywood either.

For what it's worth I'm also in the process of building an open baffle speaker. I have used Edge (software) to design a flat baffle, but am now stressing over the materials and building technique!

-Martin

The key to bending the 10 ply's together is to cut the ply so that the strong side is vertical with the weak side horizontal. Since it is only 3 ply only a single layer would be against the grain in the horisontal plane. This makes bending much easier, almost like wiggly wood. It should be strong enough to hold all 10 layers together, if not, your suggestion sounds good!

The jig would have probably worked better with mdf, but I don't like mdf from a wood working view.

The key to the jig is symmetry and identical curves, otherwise the end result won't look right.

I'm planning to route the edges smooth and then use some sort of filler to smooth the rough edges. Finally a glossy piano black finish. My friend is planning to make his Ferrari Red. Did I mention we're building 2 pairs! Thats 8 X 15" Alphas in my garage!

If the jig does not give good result plan B is to use square baffle from with classy veneer finish. Much easier and less time consuming.

The jig would have probably worked better with mdf, but I don't like mdf from a wood working view.

The key to the jig is symmetry and identical curves, otherwise the end result won't look right.

I'm planning to route the edges smooth and then use some sort of filler to smooth the rough edges. Finally a glossy piano black finish. My friend is planning to make his Ferrari Red. Did I mention we're building 2 pairs! Thats 8 X 15" Alphas in my garage!

If the jig does not give good result plan B is to use square baffle from with classy veneer finish. Much easier and less time consuming.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Jamo R909 Passive Open Baffle Project