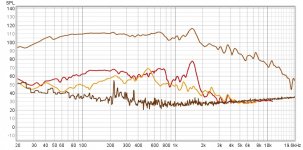

First of all, the measurent conditions have to be taken in context. To do this I will post an hd vs fundamental image of a Seas 10" subwoofer(Used in S.F. designs) measured by Vance Dickason, and taken at 10cm/110db

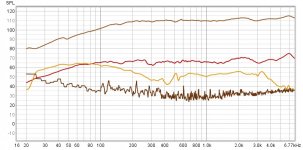

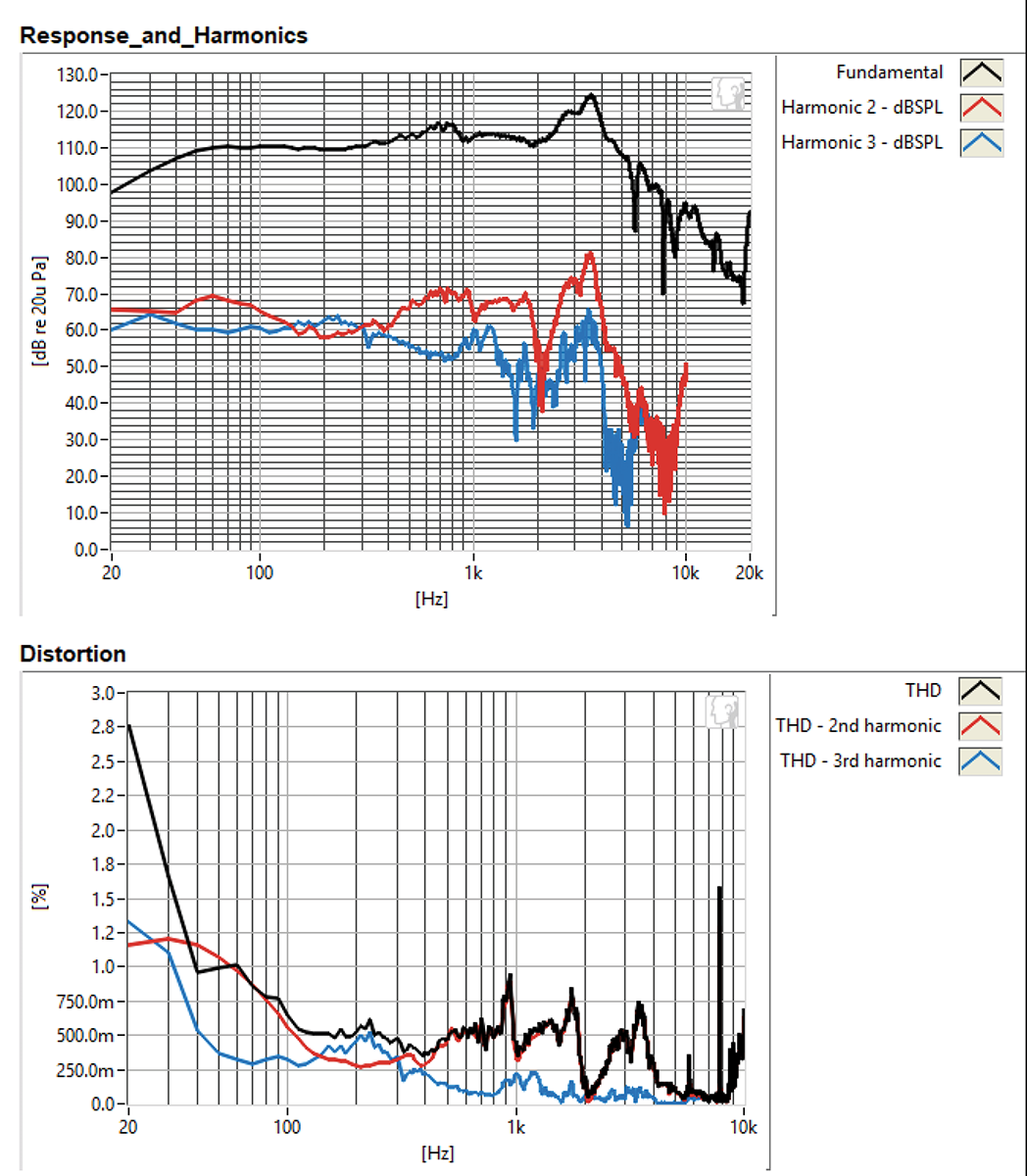

The next image is of my 10" Peerless XXLS subwoofer hd, taken 3ft off the floor at exactly 10cm/110db..

Maybe I'm wrong, but if the mic was broken, wouldn't the comparison of two excellent 10" subwoofers measured exatly the same way, be very different from one another? They look pretty similar to me.

The next image is of my 10" Peerless XXLS subwoofer hd, taken 3ft off the floor at exactly 10cm/110db..

Maybe I'm wrong, but if the mic was broken, wouldn't the comparison of two excellent 10" subwoofers measured exatly the same way, be very different from one another? They look pretty similar to me.

Attachments

Last edited:

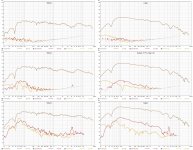

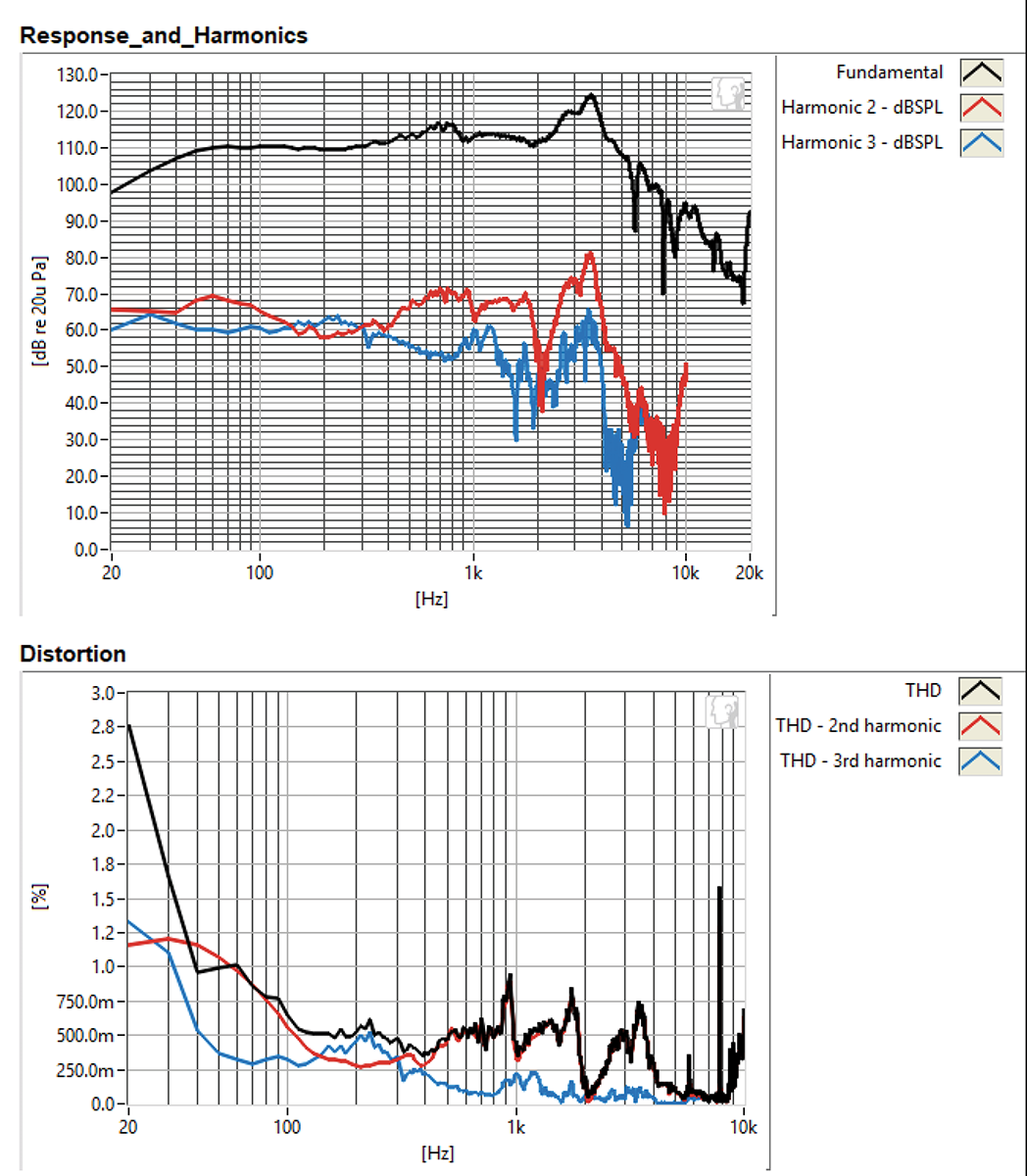

Actually I haven't done many nearield distortion tests. So, here a quickie with Adam T7V on "bedplane" At high spl 50cm furniture started rattling and woofer hit Xmax... It has about 20mm thick MDF baffle and thin-walled box. Not bad if we look at nearield distortion!

But my nearield mathces the pattern Remlab gets - pretty constant H2 distortion %

It is well known that distortion measurements are tricky to do at home. High spl is needed and easily we get artefacts from furniture, windows, doors etc. resonating!

But my nearield mathces the pattern Remlab gets - pretty constant H2 distortion %

It is well known that distortion measurements are tricky to do at home. High spl is needed and easily we get artefacts from furniture, windows, doors etc. resonating!

Attachments

Well, I think I can now safely say that the mic isn't malfunctioning and what was throwing people off was the 110db/10cm measurement distance that I've adapted from Voice Coil magazine's test bench protocol. It lowers the noise floor and influence of the room drastically compared to measuring further away. Voice coil magazine's measurement protocol is pretty much the standard for the industry when it comes to measuring individual drivers.

Last edited:

So, here a quickie with Adam T7V on "bedplane"

Could you show a picture of the "bedplane" setup?

I looked at those Magico speakers; Weight: 390 lbs. (177kg). I wonder, is that for one or a pair? In any case, that's some mass for the drivers to push against; it aint going nowhere! Compared to an ordinary speaker, that is...

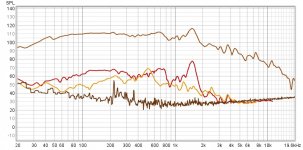

Now once again, 4" driver vs the 10" sub at 110db/10cm

Attachments

Last edited:

Actually I haven't done many nearield distortion tests. So, here a quickie with Adam T7V on "bedplane" At high spl 50cm furniture started rattling and woofer hit Xmax... It has about 20mm thick MDF baffle and thin-walled box. Not bad if we look at nearield distortion!

But my nearield mathces the pattern Remlab gets - pretty constant H2 distortion %

It is well known that distortion measurements are tricky to do at home. High spl is needed and easily we get artefacts from furniture, windows, doors etc. resonating!

Juhazi

That powered Adam monitor is a very good speaker for the $500US a pair. It's amazing that pro sector companies can do this, even with chinese manufacturing. The JBL's you have are also amazing for the price🙂

"Bedplane" means speaker and mic were laying on our twinbed, instead of on solid ground "groundplane" Outdoors we have 20cm snow and temp is - 10C...

Ultimately, when it comes to the 4" driver, this hd exercise is purely academic, becuse I would never use it below 200hz anyway. If it does work though, it could hopefully be adapted to larger drivers that would be used in a strict 2 way. But that's a big "if"Now once again, 4" driver vs the 10" sub at 110db/10cm

Last edited:

Update..

I finally filled the tweeter and 5.25" holes in my old 1" mdf baffles. After they harden fully, I'll cut the 4" midrange holes and chamfer the back, similarly to my aluminum, sorbothane cld baffles that are also 1" thick. When the hd comparison test is eventually made, I want everything to be as identical as possible. The relative comparison under otherwise identical conditions should help bare things out.

I finally filled the tweeter and 5.25" holes in my old 1" mdf baffles. After they harden fully, I'll cut the 4" midrange holes and chamfer the back, similarly to my aluminum, sorbothane cld baffles that are also 1" thick. When the hd comparison test is eventually made, I want everything to be as identical as possible. The relative comparison under otherwise identical conditions should help bare things out.

Last edited:

Do I think it's going to work? No. It has to be an artifact of something else somewhere. It's easy enough to do a comparison, and the baffle is different enough a design to at least investigate this a little further.

The reason I chose a several layer cld baffle construction instead of just the typical three, was based on the intuition that if a high amplitude resonance does happen to fight it's way through one cld layer, it should be completely dissipated in the second. And if it made it through that layer(highly unlikely), it would have to get through a final 1/8" thick, sorbothane "cld"(Kind of. It is a constrained layer🙂) gasket between the baffle and the enclosure. A "black hole" for mechanical resonances, so to speak. It makes sense that it would work, but of course it would be very hard to validate beyond a reasonable doubt. An accelerometer placed on the last aluminum layer (while mounted)perhaps?

Last edited:

I just purchased two plastic tape accelerometers of the type that John Atkinson uses. I'll see if I can rig them up for an inside the cabinet, baffle accelerometer reading. It may or may not work. There are some "kinks" I would need to iron out first🙂

10 times the output voltage of a typical piezo contact mic? Wow! I may be able to hook it up directly to my usb a/d converter.

Attachments

Last edited:

Yes, I've read about those but the documentation was confusing as to levels, impedance, noise and so on. Worth a shot, tho.

I also purchased a preamp to get the levels up. The contact mic works but its impedance is

so high, that it's acting like a high pass filter at around 400hz when fed directly into the usb a/d converter

As far as plastic tape accelerometers go, they produce no self resonating characteristics like traditional contact mics. That in itself is a profound difference.

so high, that it's acting like a high pass filter at around 400hz when fed directly into the usb a/d converter

As far as plastic tape accelerometers go, they produce no self resonating characteristics like traditional contact mics. That in itself is a profound difference.

Last edited:

If I can get this accelerometer/ preamp setup to work well, it will have a total cost of about $35. Add the usb a/d converter and it will be about $50.

By attaching the accelerometer to the concrete slab floor while playing a sweep through the speaker, I can compare it to a normal piezo contact mic under the same conditions. Unlike the piezo contact mic, if it's not picking up any airborne vibrations, the tape accelerometer fr should be very flat and should also be below the noise floor. Here is the piezo attached to the concrete slab floor. Ignore what's happening below 200hz(Impedance mismatch). Above that must be the sound it's picking up from the air..

Attachments

- Home

- Loudspeakers

- Multi-Way

- Is the cld baffle construction canceling out the 4" midbass HD? t