What would be optimal - skin printed with harder TPU (polyurethane) and infill with softer TPE (ShoreA 40-80)?

The usual method is to vibrate a standard cantilever and from its resonance and decay you can calculate what you need. It's not a trivial exercise however.

I found a more accurate way to model my subs with Horn resp (offset horn)

The new Fr prediction has lost good usable signal territory centered around 300hz....

I kinda really want it back...lol, I also really want to keep output on the front baffle....

So I am entertaining solutions, Isobaric comes to mind....But I cannot decipher if that is a step backwards in sound quality or not.

I'm thinking a V shaped baffle might be solution but how can I model this? If Akabak will do this I will try... on second thought, that gets rid of the force cancelation. Maybe I just have to deal with issue, win some lose some...

I also consider that HornResp cannot fully Sim two drivers facing each other, but maybe theres a make shift way to see some predictions?

Last edited:

lol I know you are right, but for me, Horn Sim has been my prototype shop....

Maybe I can lean on your experience? Any suggestions?

I could ditch the whole idea and just make 4 separate subs......I knoooow some of you are thinking this...but whats the hook line and sinker on why?

In Vituix I modelled a WTMW but then I'd have a super heavy subbox in the air.....and we've already exposed my basement height issue.

with slot load vs isobaric.....one has more efficiency, and we have covered how basically efficiency is everything...Both configs lower system Fs....the slot stands to further dampen the woofer....the higher mass of isobaric would dampen as well I guess.... I'm just wondering within matched reasonable level, does one have higher SQ than the other?

This topic is ridiculous evading to research btw....SQ virtues of Isobaric vs PPSL that is....

Maybe I can lean on your experience? Any suggestions?

I could ditch the whole idea and just make 4 separate subs......I knoooow some of you are thinking this...but whats the hook line and sinker on why?

In Vituix I modelled a WTMW but then I'd have a super heavy subbox in the air.....and we've already exposed my basement height issue.

with slot load vs isobaric.....one has more efficiency, and we have covered how basically efficiency is everything...Both configs lower system Fs....the slot stands to further dampen the woofer....the higher mass of isobaric would dampen as well I guess.... I'm just wondering within matched reasonable level, does one have higher SQ than the other?

This topic is ridiculous evading to research btw....SQ virtues of Isobaric vs PPSL that is....

Last edited:

I don't have too many bass boxes under my belt but the few I have don't measure exactly to the simulation, and the room evaporates the rest of the design details 😀 I'd say go for a practical design (height/weight/difficulty) and if it is somehow sub par in performance, then build a more refined design what ever that might be. Point being, that a refined design needs the prototype before it 😉 I'd say a vibration cancelling arrangement is probably the way to go. If there are slots or cavities, try to keep their dimensions as small as possible to keep resonances above the crossover frequency as high as possible. Driver to the center of the box (or if multiple drivers, their acoustical center to the center of the box) to minimize the lowest standing waves inside a box. Have fun! 🙂

No, intensity is not a perceptual quantity ("I feel like ..."), it is purely objective.

My argument for the idea that it is, either perceptible, or has perceivable impacts downstream, is based on my conclusion that velocity/area is just another way to look at polar...

I have come to a round about in my studying that has lead me back to the belief that intensity is perceivable....what is our proof that it is not?

Last edited:

what is our proof that it is not?

Sigh.....

Our proof comes from actually building something, and then testing/measuring it.

My argument for the idea that it is, either perceptible, or has perceivable impacts downstream, is based on my conclusion that velocity/area is just another way to look at polar...

I have come to a round about in my studying that has lead me back to the belief that intensity is perceivable....what is our proof that it is not?

Of course "intensity" is perceivable it is the actual level of the sound (not exactly though) so you "perceive" the sound level. But intensity is a physical measurement - no humans involved - and you are using the word subjectively. One of us needs to change the terms we use because they mean different things.

OK I must of miss read, the initial response... What I am imagining is really just the affects of the polar...I keep visualizing taking an intensity measurement spanning a set width...between different systems....resulting in different measurements. Conceivably, doing so will result in different measurements, somehow that is significant to me... I think there is a connection between source size, intensity and the "seismic" affect of sound... I feel like a child trying to explain to "da da" in my big boy voice but it aint ready yet....lol!

In other news...

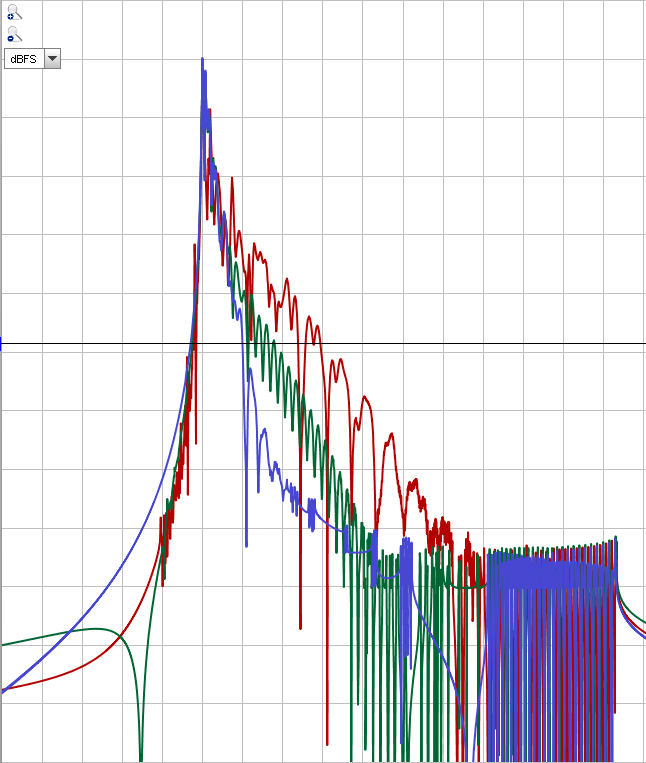

As I investigate enclosures with HR I thought this was notable

My woofer in a 3 different but same volume enclosures...Sealed slot load, Ported slot loaded, and a BR, both vented designs with the same port dimensions. The slot loaded ported seems to be better behaved than its non slotted cousin. The resistance of the slot must help to dampen the driver.

I've put a good amount of time into experimenting and am very close to some type of finish scheme

In other news...

As I investigate enclosures with HR I thought this was notable

My woofer in a 3 different but same volume enclosures...Sealed slot load, Ported slot loaded, and a BR, both vented designs with the same port dimensions. The slot loaded ported seems to be better behaved than its non slotted cousin. The resistance of the slot must help to dampen the driver.

I've put a good amount of time into experimenting and am very close to some type of finish scheme

Attachments

Last edited:

What are you guys using to mount the compression driver to the horn? The threads into the Axi are 4inches deep? The mounting plate on this horn is 2" thick.....I've found 70mm headless m6 screws....

Hi Camplo

Which ETC is which constellation ? My guess is that the blue one is slot loaded-closed, red is ported and green is ported-slot.loaded.

What was the stimulus ? Pulse or step ?

Regards

Charles

Which ETC is which constellation ? My guess is that the blue one is slot loaded-closed, red is ported and green is ported-slot.loaded.

What was the stimulus ? Pulse or step ?

Regards

Charles

Generally stainless steel mounting hardware is preferred to minimize disruption of the magnetic field.What are you guys using to mount the compression driver to the horn? The threads into the Axi are 4inches deep? The mounting plate on this horn is 2" thick.....I've found 70mm headless m6 screws....

For such long screws, you may need to source M6 threaded rod, then cut to length and put nuts on the horn flange side.

1/4"/20 SS threaded rod costs $5.55 for two feet from Grainger's, but I didn't see a M6 listing.

You can often get 1/4"/20 to thread a couple turns into M6 before it binds up permanently 😉

Happy hunting!

Art

What are you guys using to mount the compression driver to the horn? The threads into the Axi are 4inches deep? The mounting plate on this horn is 2" thick.....I've found 70mm headless m6 screws....

The Axi mounting info of 4.4" deep has to be for the entire driver, not the thread depth of the holes, doesn't it ????????

You have one right? How deep are the holes? (The 4" spec for mounting holes is a standard c-to-c spec for CDs.)

I can't imagine the thread depth is much over 1/4"....which is all that's needed...

I use these guys for stainless hardware... here's a M6 cap screw link

M6-1.00 Metric Stainless Steel Socket Head Cap Screws

Last edited:

Hi Camplo

Which ETC is which constellation ? My guess is that the blue one is slot loaded-closed, red is ported and green is ported-slot.loaded.

What was the stimulus ? Pulse or step ?

Regards

Charles

You nailed it....What I've learned is that a fully stuffed low tuned (15hz before stuffing) vent has characteristics that might be hard for one to differentiate from a stuffed sealed enclosure while still carrying an extra 2 db at 300hz...

The Axi mounting info of 4.4" deep has to be for the entire driver, not the thread depth of the holes, doesn't it ????????

You have one right? How deep are the holes? (The 4" spec for mounting holes is a standard c-to-c spec for CDs.)

I can't imagine the thread depth is much over 1/4"....which is all that's needed...

I use these guys for stainless hardware... here's a M6 cap screw link

M6-1.00 Metric Stainless Steel Socket Head Cap Screws

OK, at first I was looking at headless screws?...as long as these heads fit in the horns they look good too...thank you for the response.

Generally stainless steel mounting hardware is preferred to minimize disruption of the magnetic field.

For such long screws, you may need to source M6 threaded rod, then cut to length and put nuts on the horn flange side.

1/4"/20 SS threaded rod costs $5.55 for two feet from Grainger's, but I didn't see a M6 listing.

You can often get 1/4"/20 to thread a couple turns into M6 before it binds up permanently 😉

Happy hunting!

Art

I'm glad I asked.... I did not know this! ty =)

I found some SS m6 studs. Ordered a bunch of hardware to put this ol push push sub box together..... 12" threaded rod, you know, the usual...

Buy Stainless Steel Threaded Bars | Bespoke Threaded Bars | 500,000+ Components | Accu(R)

S6X65FSS - Full Stud Stainless [S6X65FSS] - $0.95 : Bel-Metric, Metric Hardware, Metric Fasteners, Metric Bolts, Metric Nuts & Time-Sert Thread Repair

Buy Stainless Steel Threaded Bars | Bespoke Threaded Bars | 500,000+ Components | Accu(R)

S6X65FSS - Full Stud Stainless [S6X65FSS] - $0.95 : Bel-Metric, Metric Hardware, Metric Fasteners, Metric Bolts, Metric Nuts & Time-Sert Thread Repair

- Home

- Loudspeakers

- Multi-Way

- Is it possible to cover the whole spectrum, high SPL, low distortion with a 2-way?