...Generally loudspeakers distort less when driven from a very high impedance (current drive) than when driven from a very low impedance (voltage drive), because with current drive, you get rid of a couple of non-linear effects: signal-related changes in the voice coil temperature that change the voice coil resistance have no effect anymore on the current through the voice coil, and the same holds for variations of the voice coil self inductance with the position in the loudspeaker...

That is true and has been known for a long time and used several times. In the end its not as effective as constant voltage given that the distortion differences where not heard.

Thanks for the reply Mr. Geddes. If you are bored maybe you can give some insight into the topic of intensity?

How does this play into the experience? I feel like the higher sd systems have more intensity (at the listening position) than a smaller sd system playing at the same volume. Is that correct?

By definition, the intensity (I) of any wave is the time-averaged power (⟨P⟩) it transfers per area (A) through some region of space.

How does this play into the experience? I feel like the higher sd systems have more intensity (at the listening position) than a smaller sd system playing at the same volume. Is that correct?

Last edited:

How can one increase intensity at listener position without increasing spl....or did you just say literally, that intensity is unperceivable lol?

You are still thinking in perceptual terms - SPL and Intensity are basically the same thing, except one is a vector and is per unit area, i.e. Intensity = Pressure^2 / area (times some constants)

I thought I had found the aspect to describe something that I am not so sure is true, so I'll just ask....A large sd system creates more direct energy than a small sd system, while playing at the same volume...is that correct? If thats correct how does this affect our perception?

A tough question perhaps because "same volume" is not well defined.

The system with higher direct energy, i.e. higher DI, will have less early reflections which will strongly affect the perception of image. The reverse leads to more early reflections creating a more spacious sound, but poorer imaging. So yes the direct to reverberant energy, again related to DI, will have a fairly strong influence on perception.

The system with higher direct energy, i.e. higher DI, will have less early reflections which will strongly affect the perception of image. The reverse leads to more early reflections creating a more spacious sound, but poorer imaging. So yes the direct to reverberant energy, again related to DI, will have a fairly strong influence on perception.

OK, and thanks for that, I think I under-estimated the polar in that aspect.

Other random things;

I am trying to figure out how much dampening material I am going to need, wool and fiberglass are the contenders it seems. The design is supposed to be in the "heavily stuffed large seal box" category...In horn resp I used fr1 100 and Tal1 100

I have two (315.0578liter or 11.126161205cuft) and two (214liter or 7.55734cuft) boxes that need fr1 100 and Tal1 100 =)

How does one convert fr1=100 (mks rayles/m) to human language lol

Other random things;

I am trying to figure out how much dampening material I am going to need, wool and fiberglass are the contenders it seems. The design is supposed to be in the "heavily stuffed large seal box" category...In horn resp I used fr1 100 and Tal1 100

I have two (315.0578liter or 11.126161205cuft) and two (214liter or 7.55734cuft) boxes that need fr1 100 and Tal1 100 =)

How does one convert fr1=100 (mks rayles/m) to human language lol

Not very easily!!!

Based on experience fill the box totally without compressing any of the material. That maximizes the effect. What rayles/m this is I have no idea, but it doesn't matter because you can't get any more damping than what I expressed anyways, and you usually can't get as much as you want.

We found cotton batting worked best. Didn't try wool, but it should be very good. Fiberglass is much less effective. But then there is cost!

Based on experience fill the box totally without compressing any of the material. That maximizes the effect. What rayles/m this is I have no idea, but it doesn't matter because you can't get any more damping than what I expressed anyways, and you usually can't get as much as you want.

We found cotton batting worked best. Didn't try wool, but it should be very good. Fiberglass is much less effective. But then there is cost!

I thought I found a decent wook price but then shipping added on another 100 dollars some how...cotton batting, looks promising but I don't get how to keep installation uniform from top to bottom...

- I'll plan on applying this technique but in my minds eye, I envision staple/glue to sides... and then what? Hang the batting from the roof of he enclosure like curtains until the void is filled?Based on experience fill the box totally without compressing any of the material

rockwool can be used in a quite dense quality, fiberglass needs to be in half of that for same absorption. by using blocks of rockwool it is easy to fill a box and it will stays in place without any movements

Yeah I did this wierd circle where I was like rock wool is likely the best (for me), but then the fibers in the air might not be so good, then I thought wool/denim insulation but the price again, so fiberglass seems to be still used but once again I thought fibers in the air but the comment was made that I shouldn't have any issue with fibers....maybe I am being overly cautious? Rockwool cut into blocks that fit inside box sounds like a good way...anyone else use rockwool? or against it?

Gm just reminded me that poly-fil is a popular option...I would spring for polyester batting, but non the less..

Gm just reminded me that poly-fil is a popular option...I would spring for polyester batting, but non the less..

Rockwool with cotton cloth protecting the woofer worked for me - but that was a sealed box. I had some commercial boxes open which were lined with rockwool. For some BR boxes, I used rockwool coverer with cloth, vacuumed after installation. I never noticed any small praticles coming out of the boxes, maybe they are too small to see?

MKS Rayls are the measure of Gas flow resistivity.How does one convert fr1=100 (mks rayles/m) to human language lol

There is a thread here that lists a lot of numbers for different materials.

Common Gas Flow Resistivity numbers. - Gearslutz

I have used fairly lightweight fibreglass with a layer of felt in front of it. I find this to be a good and cheap combination.

The felt I used was called underfelt and is used in auto soundproofing and under carpets. Looks like this

Attachments

Thanks for the link Fluid, good to see you. After i got tired of rummaging around in 2011 (lol) I clicked on the last thread page and was fortunate to find

RockBoard® 40 & FabRock™ LT would have similar air flow resistivity to the AFB® product [~15,000 – 20,000 mks rayls/m]

- RockBoard® 60 will have an expected air flow resistivity of ~32,000 – 46,000 mks rayls/m

- RockBoard® 80 is expected to have an air flow resistivity of ~53,000 – 57,000 mks rayls/m – also Comfortboard™80

Luckily its the cheapest thing I've found after polyfil....The tal variable in HR says it represents CM and percent....So for example....my Midbox...I changed the fr to 53000....dropped back tal to reach optimal impedance peak...tal=18....I need 18% rockwool 80 inside the box? Like 18% of the internal volume? 18% of 230.314liters? Maybe 18cm is less confusing...Line the walls with 18cm of rockboard 80? I hope its that simple.

ps - I have my Dats3 waiting

RockBoard® 40 & FabRock™ LT would have similar air flow resistivity to the AFB® product [~15,000 – 20,000 mks rayls/m]

- RockBoard® 60 will have an expected air flow resistivity of ~32,000 – 46,000 mks rayls/m

- RockBoard® 80 is expected to have an air flow resistivity of ~53,000 – 57,000 mks rayls/m – also Comfortboard™80

Luckily its the cheapest thing I've found after polyfil....The tal variable in HR says it represents CM and percent....So for example....my Midbox...I changed the fr to 53000....dropped back tal to reach optimal impedance peak...tal=18....I need 18% rockwool 80 inside the box? Like 18% of the internal volume? 18% of 230.314liters? Maybe 18cm is less confusing...Line the walls with 18cm of rockboard 80? I hope its that simple.

ps - I have my Dats3 waiting

Last edited:

I don't think it will be quite that simple but it might help you to get in the ballpark. An actual impedance measurement on the finished box will tell you a lot.

There are two separate functions for fill, one to deal with cabinet wall reflections and the backwave in general the other other is for making the box appear bigger than it really is. The only real reason for the second is because you want to make the physical box smaller. Polyfil will help with the box size but I found it next to useless in helping to deal with the cabinet.

This isn't something that is very easy to model to a great level of accuracy some practical test are usually needed.

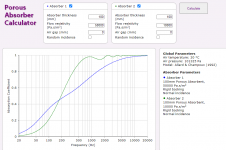

I think more cheap fibreglass in greater thickness is a better choice (when paired with felt). To get a feel for how the GFR numbers work in an absorber, try the porous absorber calculator.

Porous Absorber Calculator

I've attached a screenshot of 50000 vs 10000 in the same thickness I'll let you decide which you think is better

There are two separate functions for fill, one to deal with cabinet wall reflections and the backwave in general the other other is for making the box appear bigger than it really is. The only real reason for the second is because you want to make the physical box smaller. Polyfil will help with the box size but I found it next to useless in helping to deal with the cabinet.

This isn't something that is very easy to model to a great level of accuracy some practical test are usually needed.

I think more cheap fibreglass in greater thickness is a better choice (when paired with felt). To get a feel for how the GFR numbers work in an absorber, try the porous absorber calculator.

Porous Absorber Calculator

I've attached a screenshot of 50000 vs 10000 in the same thickness I'll let you decide which you think is better

Attachments

Insulation Wool 0 to 1200 Degrees F cheapest I've found so far.

This is actually cheaper than fiberglass when you wager efficacy. The only issue is I have no idea how much of it I need...even though I can plug the numbers into HR....that 18%/18cm....maybe I should go post in the hornresp thread...

- Home

- Loudspeakers

- Multi-Way

- Is it possible to cover the whole spectrum, high SPL, low distortion with a 2-way?