I seen your listing on the internet. Can you explain what this type of horn is used for and why the other horns are not commonly found in these sizes? I know that this horn is made for a driver like the axi2050 but then why are so many people under the belief that no one wants to cross a horn so low? Obviously there's a market for it with the Sato style horn. Also, what are the short comings of bending the signal path? I assume there must be some type of drawback.

In the listing I see these are coming out of Germany. The shipping from Germany seems to be always cheaper vs the shipping from Poland, maybe this is the route for me....maybe.

Collegaues explained drawbacks. Just got many requests on Sato and said myself why not give it a try?

If you have a time can you simulate in Hirnresp JMLC 100Hz T=0 with Supravox 400 open baffle?

You guy seem to be a little bit positively crazy 😀

What you intend is something I would recall as trumpets of Jericho. But it has been written down it should happen so:

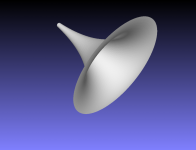

View attachment 794329

Of course we are going to attempt to simulate these and compare them to the other two 160hz spherical horns...right? I'm going to load these into fusion360 when I get a chance. How do you propose I simulate the response for comparison? The model looks like what I am going for. I seen a pair of concrete JMLC on ebay once that resemble this as well. They had equal length and width.

These GoodSoundClub - Romy the Cat's Audio Site - Manufacturing MDF tractrix horns have a longer length than width.

The 15" woofer isn't supposed to be covered from the mouth ?!

Is this a question or a statement?

Last edited:

Generally speaking'

Long horn.. 24" or deeper is better for bass , midbass and low midrange, say up to 800 cycles

Shorter horns 24" or shorter are better for upper midrange and treble. Say 500 cycles or higher.

Long horn.. 24" or deeper is better for bass , midbass and low midrange, say up to 800 cycles

Shorter horns 24" or shorter are better for upper midrange and treble. Say 500 cycles or higher.

@camplo

I have truncated the calculation a little because of your mouth size restrictions. We could ask DonVK to prepare an ABEC3 model for the last horn. He is the absolute export to simulate a freestanding horn. But I assume that it would beam substantially because of its length.

I have truncated the calculation a little because of your mouth size restrictions. We could ask DonVK to prepare an ABEC3 model for the last horn. He is the absolute export to simulate a freestanding horn. But I assume that it would beam substantially because of its length.

It would be no problem for me to create a ABEC model and simulate it. Just ask when you've narrowed it down to a few models.

P.S. more encouragement to complete that GEO script. 🙂

P.S. more encouragement to complete that GEO script. 🙂

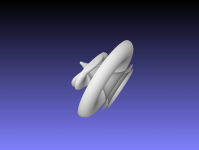

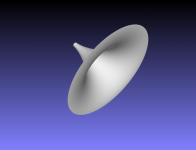

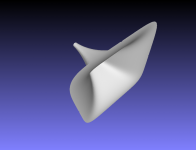

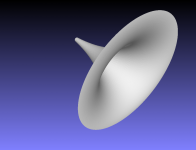

To make it easier for everyone to view these previous 8 horns. The first pic is an overlay of all 8 horns to show relative size.

Hover over the pic and its title will display.

Hover over the pic and its title will display.

Attachments

-

all_horns_overlay00.png50.1 KB · Views: 346

all_horns_overlay00.png50.1 KB · Views: 346 -

swh_rnd_160_pe04.png64.9 KB · Views: 92

swh_rnd_160_pe04.png64.9 KB · Views: 92 -

swh_sq_160_pe03.png69.8 KB · Views: 90

swh_sq_160_pe03.png69.8 KB · Views: 90 -

swh_ra_160_pe02.png69.8 KB · Views: 93

swh_ra_160_pe02.png69.8 KB · Views: 93 -

swh_rnd_160.png93.7 KB · Views: 93

swh_rnd_160.png93.7 KB · Views: 93 -

swh_160_t071_jericho01.png73.9 KB · Views: 348

swh_160_t071_jericho01.png73.9 KB · Views: 348 -

drba_250hz_pe07.png49.2 KB · Views: 354

drba_250hz_pe07.png49.2 KB · Views: 354 -

drba_250hz_pe_sq06.png47.2 KB · Views: 343

drba_250hz_pe_sq06.png47.2 KB · Views: 343 -

drba_120hz_pe08.png48.5 KB · Views: 351

drba_120hz_pe08.png48.5 KB · Views: 351

Last edited:

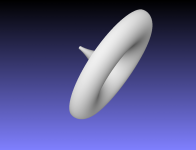

60cm mouth, 2inch throat, 130Hz. What if we load 2" compression driver back with this and front side with a waveguide?

Attachments

Last edited:

It seems like the exit wavefront would be tilted because the inside radius is shorter than the outside radius.

I'm hoping the square 160 Hz (the one I showed a pic of) will be a finalist...

the bounding box measurements are quite similar to the 'desired' dimensions, right?

the bounding box measurements are quite similar to the 'desired' dimensions, right?

I'm hoping the square 160 Hz (the one I showed a pic of) will be a finalist...

the bounding box measurements are quite similar to the 'desired' dimensions, right?

Well kind sir, what is it that you like about square horns? I can tell you that I favor round horns because no matter what angle the response is unanimous. I likle square/rectangle horns because you can create wide horizontal and narrow vertical polar...on that note Docali would you mind throwing a square Horn of Jerico?, Choose what you think would be the optimal vertical and horizontal angles.

This is way more support than I expected by the way...I am overly grateful for the participation!!! I hope some one else will create a loudspeaker that is similar to what my goal is, within this thread. So we can get some different iterations of what the ultimate "2 way" systems can look like, 2019 style. 😀

You got me hyped up! lol, I've been watching 3d printer videos to learn the ropes and at first I was reminded how ridiculously slow 3d printing is, a friend of mine warned me before but I forgot as I had let go of the idea a while ago. Now that I've actually done some more research, I see that it is possible to speed printing up several ways and it affects resolution but the detail those guys are going for completely unnecessary! They are printing detailed (and I do mean detailed!) miniatures, where as I need broad un-detailed, but rather flat gently curved and smooth surfaces. Building from the a vertical aspect with the horns opening faced down supports the option to print without a structure within so I can make completely hollow pieces without worry of bridging issues. PETG seems to be perfect for the task, as it doesn't have warp issues, and shrinkage is minimal. If I can get it down to like 6 days worth of printing or less, that would be awesome.

Last edited:

60cm mouth, 2inch throat, 130Hz. What if we load 2" compression driver back with this and front side with a waveguide?

Are you the guy I spoke with on the phone, of Autotech horns?

I've been told by those that have have them that the highs slide down the long side (IIRC). Can't verify that as I no longer have access to the large horns.It seems like the exit wavefront would be tilted because the inside radius is shorter than the outside radius.

Are you the guy I spoke with on the phone, of Autotech horns?

and you said "don't cut Quad 4 stack"? 🙂

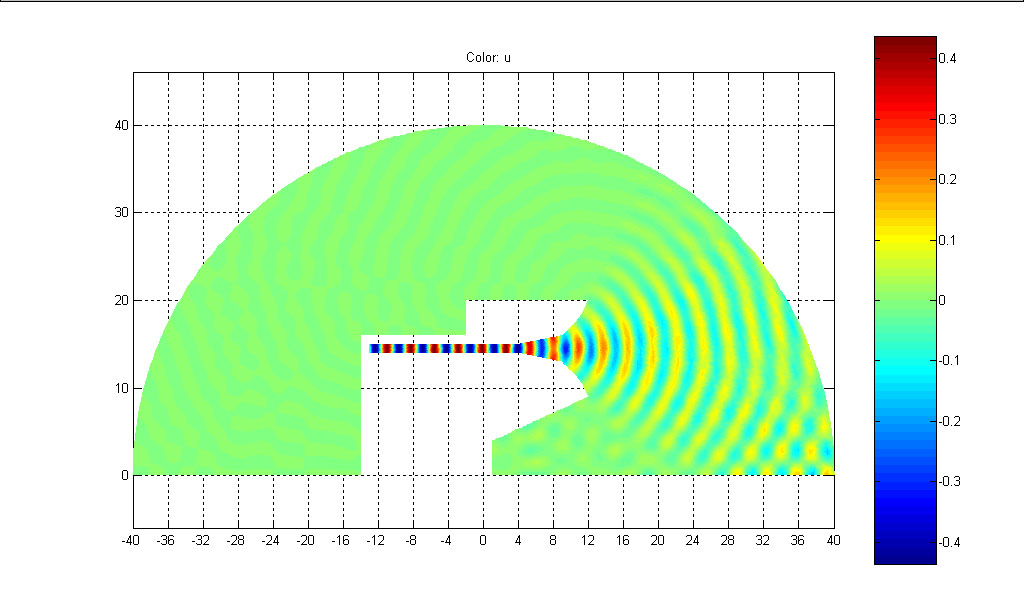

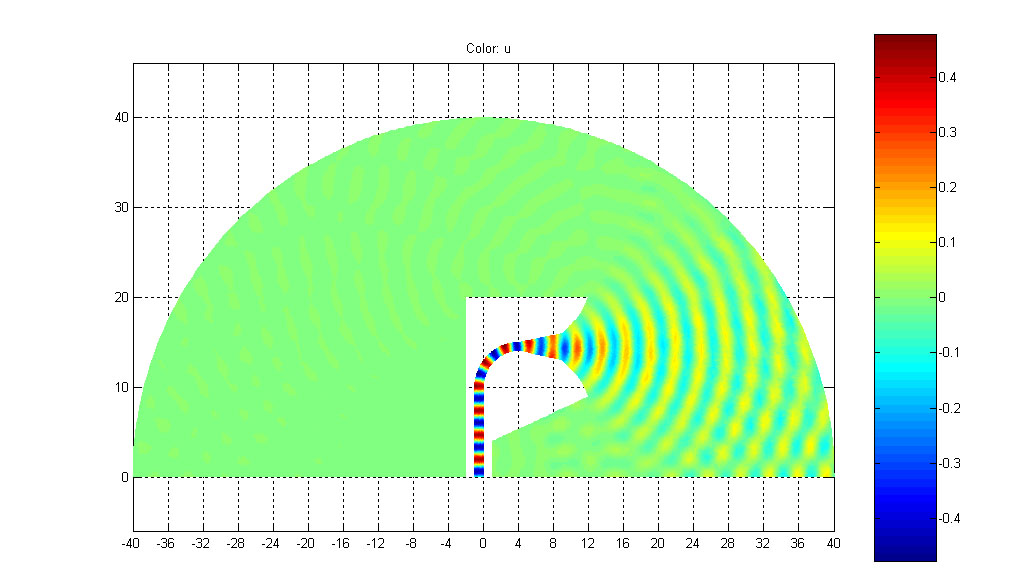

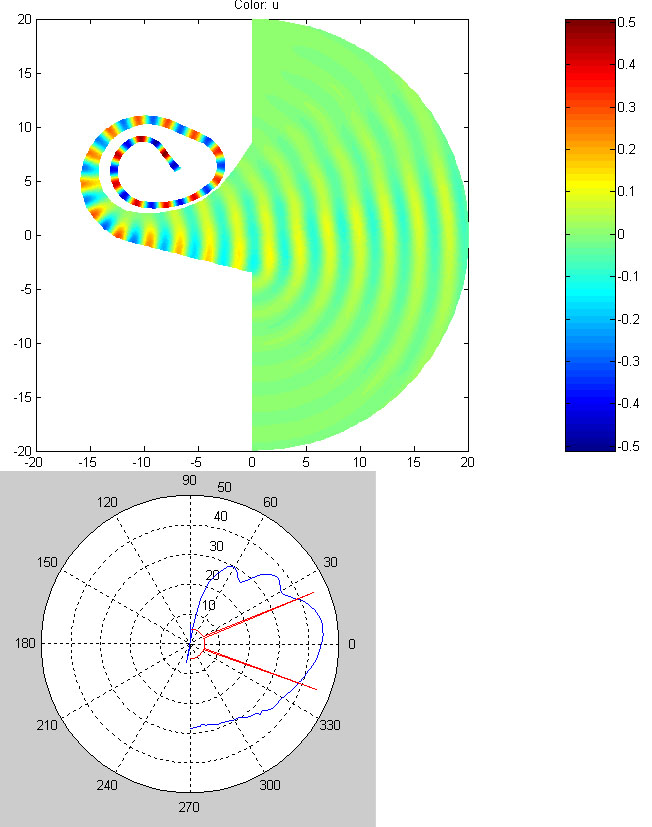

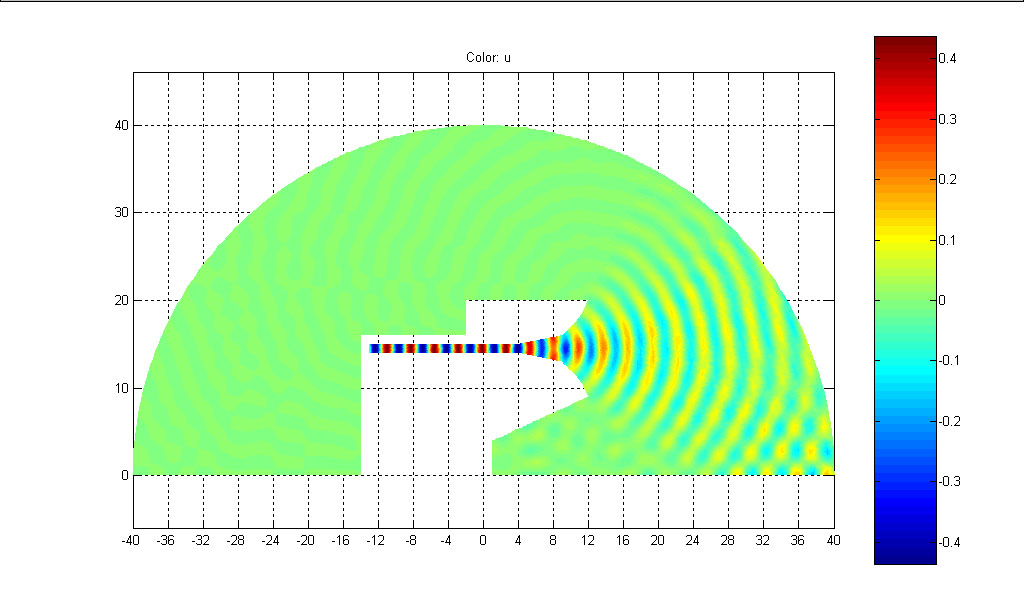

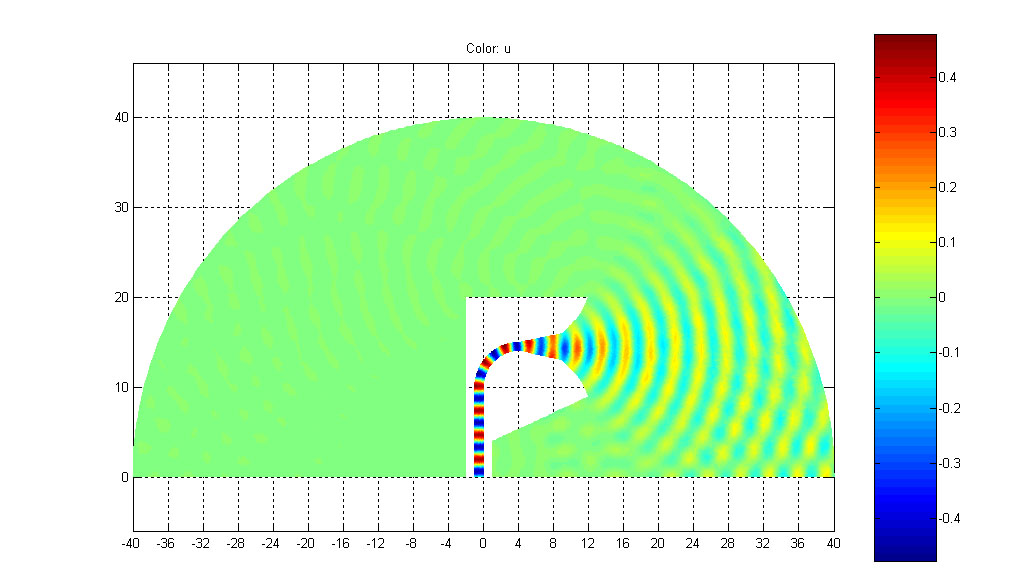

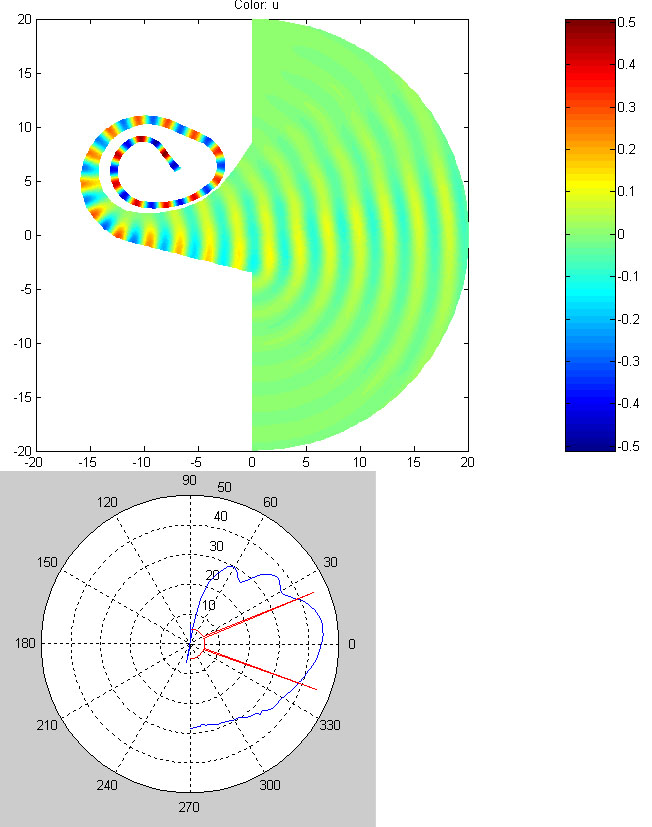

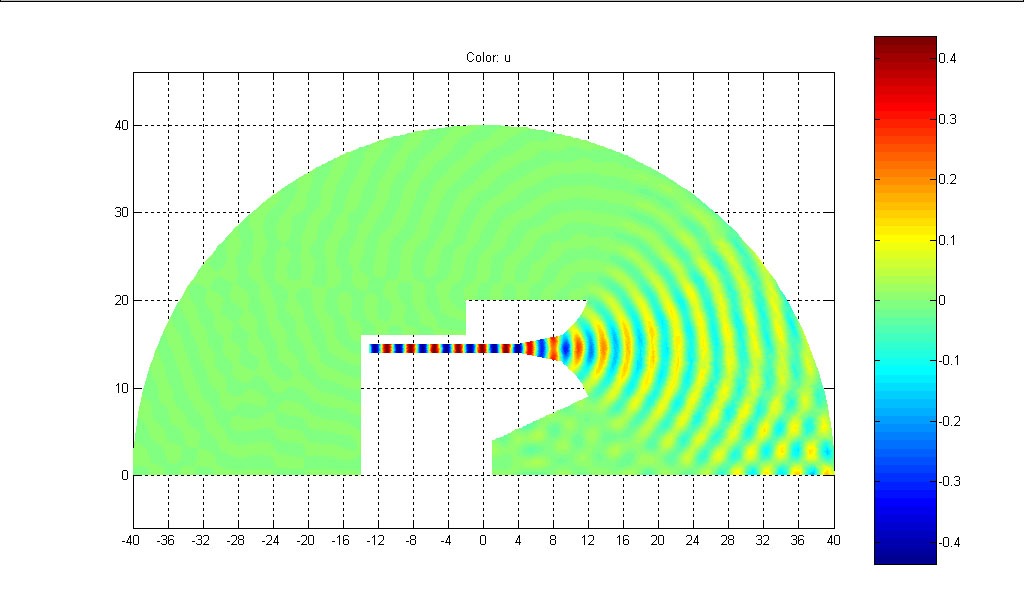

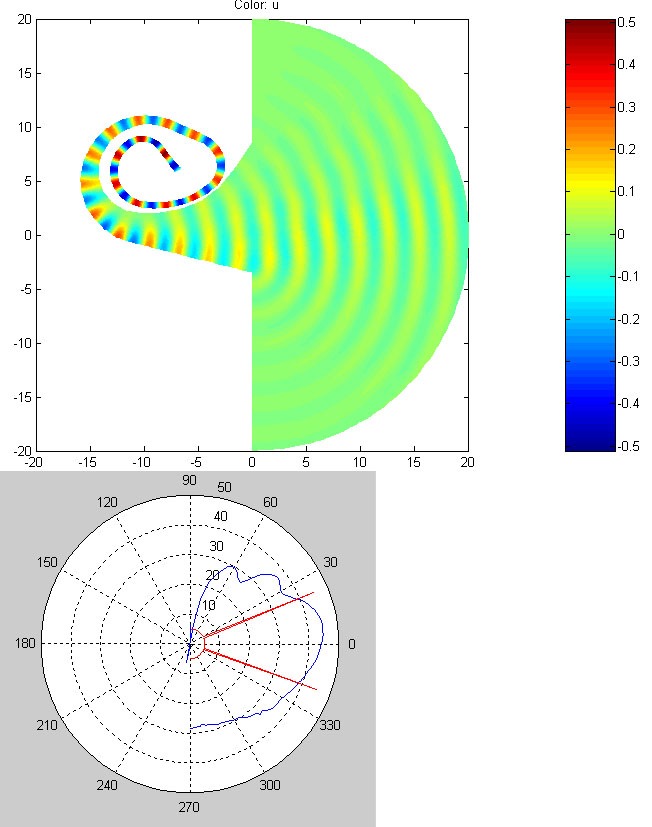

John Sheerin simulated several classic horns in ANSYS:

GOTO style straight horn at 5kHz:

90° bend at 5kHz:

WE30154 at 5kHz

This is the WE30154 in the flesh:

GOTO style straight horn at 5kHz:

90° bend at 5kHz:

WE30154 at 5kHz

This is the WE30154 in the flesh:

Last edited:

60cm mouth, 2inch throat, 130Hz. What if we load 2" compression driver back with this and front side with a waveguide?

I know that there are many friends in a german forum discussing about these Sato like horns but the common consense is that such horns cannot be used as 2-way. You cannot let travel several octaves through such an horn without "side effects".

John Sheerin ran sims in ANSYS of several classic horns:

GOTO style straight horn at 5kHz:

WE30154 at 5kHz

This is the WE30154 in the flesh:

just stick with the horn in the left lower corner 😎

Edit: foto with Selenium like horn disappeared!

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Is it possible to cover the whole spectrum, high SPL, low distortion with a 2-way?