in case of Vol Pot moved back (using extending shaft and L mount), close to pads on pre pcb, you can use twisted triplet per channel, thinnest possible solid core or, if you insist, stranded

in case of arrangement shown by Jim, use 2+Screen coax per channel, again thinnest possible

in case of arrangement shown by Jim, use 2+Screen coax per channel, again thinnest possible

And I thought that you were going to just say, copper.

This manual is a great thing for reference. Glad that it has arrived.

This manual is a great thing for reference. Glad that it has arrived.

Mic cable. Not even the thick stuff. Specifically, in that build, it's Canare L-2B2AT https://www.redco.com/Canare-L-2B2AT.html

Panel to PCB is my favorite coax, Mogami 2330 https://www.redco.com/Mogami-W2330.html

But honestly, wire is wire. I judge it by how easy it is to work with. Mogami and Canare both make wonderful quality.

Panel to PCB is my favorite coax, Mogami 2330 https://www.redco.com/Mogami-W2330.html

But honestly, wire is wire. I judge it by how easy it is to work with. Mogami and Canare both make wonderful quality.

Last edited:

You said it about workability! I have tried several types of wire only find some of them are unimaginably unworkable. I tend to like 24-26 ga. solid core because it seems to stay put more easily than heavier gauges. Depends on what I am doing, power, or signal.

I want to add the question--- What are some of the worst choices to make with this Iron Pre concerning wire? It has already been stated to use a fine ga wire, but is there an electrical reason for this? And what if you went the other direction? I am not talking about the 'sound' of a wire, but mostly the workability. In this build, because of the number of wires needed to connect all 5 inputs (which in my build I will probably only use 4 of them), it can become a circus for the hands to get around these connections.

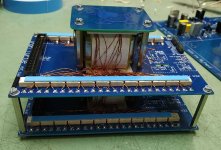

I've used some stranded solid core UTP cable, as you can see on the pic.

Just because these was in hand, and I was so impatient.

I was afraid because of noise issues, but there isn't any, even with that long wires from front panel pots to the panel.

Later I will move ALPS pots to the back.

Just because these was in hand, and I was so impatient.

I was afraid because of noise issues, but there isn't any, even with that long wires from front panel pots to the panel.

Later I will move ALPS pots to the back.

I don't remember if you were doing the SE or BAL.... or if you got the chassis.I want to add the question--- What are some of the worst choices to make with this Iron Pre concerning wire? It has already been stated to use a fine ga wire, but is there an electrical reason for this? And what if you went the other direction? I am not talking about the 'sound' of a wire, but mostly the workability. In this build, because of the number of wires needed to connect all 5 inputs (which in my build I will probably only use 4 of them), it can become a circus for the hands to get around these connections.

Either way (and this is not what you asked... but)... my biggest recommendation re: input wiring is to use the Neutrik jacks and mount them on the inside of the chassis (like 6L6 shows in the picture).

Why?

You can solder all the input wiring to the boards and to the jacks before you mount the jacks to the back panel. My preferred order is to solder the wire to the jack first. I can mount the jack in a helping hand or similar to keep it still and have a ton of freedom in it's orientation to solder it much more easily and cleanly. Then, I solder the two (or three) wires to the boards. Then, as almost the last step in a build.... I mount the jacks to the back panel before closing up the chassis. That makes my life 99% easier, but everyone has their own trips / tricks to make it a little easier. Mainly... it gives me a lot more room to work, and I don't have to worry much about yanking one of the potentially tiny wires while working on an adjacent input / output.

Meanwhile, back at the ranch, I am still curious about wiring in the Iron Pre or other applications as well. What wire that is and where. Not to mention why. I realize that a good bit of it is about the ability to carry current or have the proper insulation when needed.

What views would any of you have to use magnet wire for example in signal wiring?

What views would any of you have to use magnet wire for example in signal wiring?

do not overthink that

How to wire damn Iron Pre

- for primary - if you need to extend those from Donut, use similar wire as you already have on Donut primary, heatshrink connection points and doesn't hurt to heatshrink entire line additionally

- for secondaries wiring, if you need to extend those from Donut - just use similar and heatshrink connection points

for signal:

- pot on front panel, use thin coax (2+screen per channel)

- pot mounted back, use any thin wire which make your heart warm, twisted triple per channel

- for RCA inputs, use any thin wire which make your heart warm, twisted pair per input

- for RCA outputs, use any thin wire which make your heart warm, twisted pair per output

- for XLR inputs, use any thin wire which make your heart warm, twisted triple per input

- for XLR outputs, use any thin wire which make your heart warm, twisted triple per output

How to wire damn Iron Pre

- for primary - if you need to extend those from Donut, use similar wire as you already have on Donut primary, heatshrink connection points and doesn't hurt to heatshrink entire line additionally

- for secondaries wiring, if you need to extend those from Donut - just use similar and heatshrink connection points

for signal:

- pot on front panel, use thin coax (2+screen per channel)

- pot mounted back, use any thin wire which make your heart warm, twisted triple per channel

- for RCA inputs, use any thin wire which make your heart warm, twisted pair per input

- for RCA outputs, use any thin wire which make your heart warm, twisted pair per output

- for XLR inputs, use any thin wire which make your heart warm, twisted triple per input

- for XLR outputs, use any thin wire which make your heart warm, twisted triple per output

How to wire damn Iron Pre

^^Exactly this.

Patrick... Put a link to #2852 into the first post.

If thinner is better, then I think it's an excellent idea.Meanwhile, back at the ranch, I am still curious about wiring in the Iron Pre or other applications as well. What wire that is and where. Not to mention why. I realize that a good bit of it is about the ability to carry current or have the proper insulation when needed.

What views would any of you have to use magnet wire for example in signal wiring?

Now why didn't I think of that? I have lots of different sizes (down to 0.19mm) from my RC motor building days. It may not be practical for strength reasons. But twisted together as advised here, it could probably work. But would one hear the difference compared to more durable thicknesses?

Thanks for confirming ZM. I have 0.18mm (33 AWG) and 0.28mm (29 AWG) both copper. The latter is probably more practical and still quite thin. But I think one has to be realistic and not expect that a short length of very thin wire will make a difference to the sound while the tracks on the board and the interconnects are much thicker. The placebo effect would be strong, though. 😆

- Home

- Amplifiers

- Pass Labs

- Iron Pre Essentials Kits For The DIYA Store - Register Your Interest