Hello there,

I get that you use a TO3 insulating pad under a TO3 device so you don't short it out to a heat sink if it is mounted on top of one, but what insulators do you use around the leads/bolts passing through the heat sink?

What type of fasteners are commonly used?

What would be a a good "broad" insulator to use between the board the the heatsink?

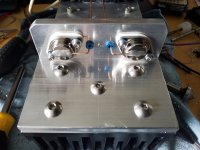

Here is an example of what I am talking about,

Thank you,

David.

I get that you use a TO3 insulating pad under a TO3 device so you don't short it out to a heat sink if it is mounted on top of one, but what insulators do you use around the leads/bolts passing through the heat sink?

What type of fasteners are commonly used?

What would be a a good "broad" insulator to use between the board the the heatsink?

Here is an example of what I am talking about,

Thank you,

David.

Attachments

Maybe your research will discover that products like these, might be suitable(?). Or maybe not.

Keystone 4725

link 2

link 3

Keystone 4725

link 2

link 3

A 6-32 screw is std for TO-3 mount down. I use brass screws for somewhat better electrical conductivity. There are also std shoulder washers for insulating the screws from the TO-3 case. As Mark has pointed out, if you pony up and buy the mounting kit/kits, you get all the pieces you need. though the screws will probably be steel. If you are outside the US, the M3 screw is about the same size as a 6-32 (a little smaller), and could be made to work. The bushings in the kits might be nylon, not the absolute best for high temperature work, esp. as they can get brittle over time, or just melt. A better alternative would be premium bushings made out of polyphenylene sulfide, a more durable, higher temperature alternative to nylon bushings - expect to pay more, but you get compensated in peace of mind, especially if you're running a hot Class A amplifier...

Last edited:

One 3mm bolt size fits virtually all semis. Just search "transistor insulating bush" either with your browser or at your favourite parts supplier's website for quality product but I've not had problems with buying really cheap stuff from platform sellers either. 200 bushes for a couple of dollars goes a long way, if the plastic grade is up to the task but if you build "hot box" amplifiers, and need more assurance, you'll find major parts suppliers also want most of their money just to count them out.

e.g: https://www.ebay.com.au/itm/184947482101?

e.g: https://www.ebay.com.au/itm/184947482101?

Last edited:

I haven't found the Keystone 4725 kit with ferrules screws nuts & solder tabs in stock anywhere in US. It has #6 screws which only fits TO3 (obsolete).

Newark/farnellUS has a multicomp kit with both mica insulator and the ferrules, https://www.newark.com/multicomp/mk3301-51/insulating-kit/dp/50P9587 $2.82 for pack of 10. Stock also in UK.

# 6 SS screw fits the TO3 package, which nobody(?) makes anymore. On semi makes TO-204AA package which only accepts #4 screw or 3 mm. I buy the SS screws in packs of 50 https://www.mcmaster.com/91735A113 or 100 from mcmaster.com https://www.mcmaster.com/91772A113

I use SS KL nuts with the built in serrated washer to touch the collector trace of Peavey pcbs. https://www.mcmaster.com/96278A005

For not touching a collector trace regular SS nuts will do https://www.mcmaster.com/90257A005

Newark sells screws & nuts but not SS and not as many lengths, nor KL nuts.

Newark/farnellUS has a multicomp kit with both mica insulator and the ferrules, https://www.newark.com/multicomp/mk3301-51/insulating-kit/dp/50P9587 $2.82 for pack of 10. Stock also in UK.

# 6 SS screw fits the TO3 package, which nobody(?) makes anymore. On semi makes TO-204AA package which only accepts #4 screw or 3 mm. I buy the SS screws in packs of 50 https://www.mcmaster.com/91735A113 or 100 from mcmaster.com https://www.mcmaster.com/91772A113

I use SS KL nuts with the built in serrated washer to touch the collector trace of Peavey pcbs. https://www.mcmaster.com/96278A005

For not touching a collector trace regular SS nuts will do https://www.mcmaster.com/90257A005

Newark sells screws & nuts but not SS and not as many lengths, nor KL nuts.

Last edited:

I have two amplifiers with TO3 output transistors. Currently the transistors (MJ15003/04 & MJ15024/25) are mounted on the heatsinks using M3 steel screws. I plan to replace that with brass or copper screws, nuts and washers. For the brass ones, I'm sure they are mechanically sound. I have no experience with copper screws and their mechanical properties. I'm worried that they won't loosen during tightening or later in operation, which would be disastrous. Has anyone used copper screws for TO3?

Attachments

If you're worried about the leads shorting you could always use a bit of small heat shrink tubing. 3/64" should fit perfectly.

Brass vs steel will make hardly any difference when there is an insulating bush in the TO-3 hole.I use brass screws for somewhat better electrical conductivity.

Take care to not over tighten the bolts or the insulating washer can fail.

I asked on a couple of forums, nobody seems to be using copper screws for this purpose. Since I'm a bit scared of their poor mechanical properties, I go with brass. I just want to remove the steel bolts from the signal path.

Copper and brass for bolts? I say way to soft, steel or stainless steel, the best method would probably be a sturdy spring or spring clamp, applying a constant continuous pressure, regardless of heat.

I can't solder anything to the collectors, I have plastic caps on the transistors. I think brass bolts can be used similarly to steel ones.

- Home

- Amplifiers

- Solid State

- Insulators for parts passing through aluminum heat sink? Bolts for TO3 devices?