Seems like it would be hard to smear silicone on evenly. I wouldn't even try it on anything other than a half roll fabric surround.

People used to use diluted acrylic latex plus silicone caulk. Cleans up with water. Cheap.

I've used liquid latex (for moldmaking) before. Works well.

People used to use diluted acrylic latex plus silicone caulk. Cleans up with water. Cheap.

I've used liquid latex (for moldmaking) before. Works well.

I'll have to measure my CHN70 - its character is nice enough for my tastes - Permatex might be good - could look ugly - silicone seems like something bad (?) Damar's aroma is heavenly 😀

Member

Joined 2009

Paid Member

On second thought, I'm wondering if it needs any treatment for peaks at the cone surround - isn't the issue more simply that this driver has been designed with an elevated response throughout the 'presence' region so it naturally sounds bright. The solution is a) pick a different driver if you don't like a strong presence region, b) apply some EQ in the signal domain ??

Dammar smells so good I went to bed last night with a bit smeared under my nose.

Just kidding. I think it smells bad did the work very near an open window.

Just kidding. I think it smells bad did the work very near an open window.

with a bit smeared under my nose.

That is gonna cause havok with your mustache 🙂

dave

can in some cases, damping a pleated spider do good? (or at least have a thin felt or foam shield between it and the cone's rear) - it would take someone who has a greater understanding than myself to diagnose.

Most of what I think folks are finding as issues with the CHN needing remediation could probably be better accomplished with treatment of the cone with selected materials. I'd treat very lightly with modification to the spider.

When room is sufficient, it probably can't hurt to try a thin layer of felt to the inside of basket support legs, but I think all of Mark's 70mm class models are rather sparse for clearance in that area.

I understand that part of the EnABL treatment includes pre-treatment / sealing of paper coned drivers , then the polka dots, followed by clear top coat(s). The number of coats of material at each stage, as well as the quantity & location of treatment rings vary with individual driver models.

When room is sufficient, it probably can't hurt to try a thin layer of felt to the inside of basket support legs, but I think all of Mark's 70mm class models are rather sparse for clearance in that area.

I understand that part of the EnABL treatment includes pre-treatment / sealing of paper coned drivers , then the polka dots, followed by clear top coat(s). The number of coats of material at each stage, as well as the quantity & location of treatment rings vary with individual driver models.

Last edited:

I understand that part of the EnABL treatment includes pre-treatment / sealing of paper coned drivers

Yes. This is not officially part of the EnBAL process, but i find it helps, and it helps (at least a bit) to recover from mistakes. Pretreatment is with thinned (not too much) ModPodge (PVA). I've been doing that to paper drivers since the late '70s.

dave

Member

Joined 2009

Paid Member

I'm not sure cone treatment is the answer, it doesn't look like errant resonances.

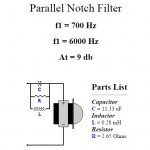

How about a simple EQ in series with the speaker ?

http://www.diyaudioandvideo.com/Calculator/ParallelNotchFilter/

or in parallel with the speaker

http://www.linkwitzlab.com/reference_earphones.htm

How about a simple EQ in series with the speaker ?

http://www.diyaudioandvideo.com/Calculator/ParallelNotchFilter/

or in parallel with the speaker

http://www.linkwitzlab.com/reference_earphones.htm

Attachments

Why electronics when my suggestion a few posts back is reversible, cheap and easy and has worked for a number of drivers for me?

mechanical is always an interesting alternative - for those of us challenged with visualizing from descriptions, would you have a sketch or photo handy?

Member

Joined 2009

Paid Member

Why electronics when my suggestion a few posts back is reversible, cheap and easy and has worked for a number of drivers for me?

Because I don't think it's an issue of peakiness at the top end. Based on the FR plots posted earlier it looks like there is a broad response between 600Hz and 7kHz that is raised higher and this makes the driver forward sounding. If it's not a peak, caused by resonance/cone break-up for example, then it needs a different solution. Do you think there is a mechanical solution that will work over the 600Hz to 7kHz range without messing up the behaviour elsewhere ?

I was thinking that if the FR was bothering you a broad shelving filter (similar to post 29, but i doubt it needs to be that deep) to bring down the offending range would be something to try.

dave

dave

you could take some cardboard + tape and try various width slot-lens adjusting for best overall effect - of course that can introduce cavity resonances and reflections but might sound ok

Because I don't think it's an issue of peakiness at the top end. Based on the FR plots posted earlier it looks like there is a broad response between 600Hz and 7kHz that is raised higher and this makes the driver forward sounding. If it's not a peak, caused by resonance/cone break-up for example, then it needs a different solution. Do you think there is a mechanical solution that will work over the 600Hz to 7kHz range without messing up the behaviour elsewhere ?

Bragg reflectors are among other techniques a way of doing bandpass in acoustic space.

Anyhow this is what I had in mind.

https://drive.google.com/open?id=0B-BwNQN626aZcW1lMldTbFBLMUU

Last edited:

Dammar or PVA or whatever cone doping method isn't going to correct or drastically alter frequency response. It is done to improve clarity and detail. With Fostex drivers, it's gets rid of the slight papery shimmery sound the tend to have, especially when brand new.

AFA mechanical fixes, yeah, some sort of bandpass filter is about the only way. This could be a BBC slot, or a horn. Also they could be upfired like in the microtower Castles previously posted. They'd probably balance out in a Karlsonator too.

The large treble plateau of the CHN70 obviously pleases its target market with no correction.

AFA mechanical fixes, yeah, some sort of bandpass filter is about the only way. This could be a BBC slot, or a horn. Also they could be upfired like in the microtower Castles previously posted. They'd probably balance out in a Karlsonator too.

The large treble plateau of the CHN70 obviously pleases its target market with no correction.

The large treble plateau of the CHN70 obviously pleases its target market with no correction.

bingo, methinks

Member

Joined 2009

Paid Member

Bragg reflectors are among other techniques a way of doing bandpass in acoustic space.

Anyhow this is what I had in mind.

https://drive.google.com/open?id=0B-BwNQN626aZcW1lMldTbFBLMUU

That looks really neat - an experimenters dream. However, it will certainly change the appearance of the speaker which I don't want to do.

you could take some cardboard + tape and try various width slot-lens adjusting for best overall effect - of course that can introduce cavity resonances and reflections but might sound ok

I could try a quick test by putting this in the Karlsonator designed for the RS 40-1197 to see the effect of the K aperture on the plateau from 600Hz to 6kHz. I think the cutouts are similar.

I could try a quick test by putting this in the Karlsonator designed for the RS 40-1197 to see the effect of the K aperture on the plateau from 600Hz to 6kHz. I think the cutouts are similar.

I for one would be interested in seeing how that works out. It does seem like the CHN-70 has an almost perfectly complementary frequency response.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- Improving the CHN-70