If we're doing a redesign let's get rid of that big protection resistor on the inputs when the diodes start to conduct, adds about 6-8db of Johnson noise at least.

If we're doing a redesign let's get rid of that big protection resistor on the inputs when the diodes start to conduct, adds about 6-8db of Johnson noise at least.

That big resistor is what gives you overvoltage protection. Without it, and apply an overvoltage, and it goes pop.

There may be some lower noise alternatives using FETs, I haven't looked at it yet.

Surface mount parts?

What are peoples feelings about building with (at least some) surface mount parts?

It is getting very difficult to source through-hole ICs, so much so that the design would probably be compromised by not using some SMT parts.

As I see it there are three categories of SMT with regards to home assembly:

Easy - 0.05" pitch parts like SOICs (most opamps are in this catagory)

Intermediate - Finer pitch, down to 0.5mm, but still with exposed leads that can be soldered with an iron. TSSOP packages and the like.

Advanced - Packages that have pads that really need to be soldered with reflow, either hot a air gun or "toaster oven". This includes packages like QFNs.

Can most people at least deal with "easy" parts?

Pete

What are peoples feelings about building with (at least some) surface mount parts?

It is getting very difficult to source through-hole ICs, so much so that the design would probably be compromised by not using some SMT parts.

As I see it there are three categories of SMT with regards to home assembly:

Easy - 0.05" pitch parts like SOICs (most opamps are in this catagory)

Intermediate - Finer pitch, down to 0.5mm, but still with exposed leads that can be soldered with an iron. TSSOP packages and the like.

Advanced - Packages that have pads that really need to be soldered with reflow, either hot a air gun or "toaster oven". This includes packages like QFNs.

Can most people at least deal with "easy" parts?

Pete

There may be some lower noise alternatives using FETs, I haven't looked at it yet.

That's exactly what I was think of, not doing away with the function, just using something else to provide it, something depletion mode perhaps?

The easy should be no problem for most, i'd think. You don't need any special tools. (Maybe a few people don't have a fine enough iron tip)

Intermediate can be frustrating, but w/ the help of solder wick and a magnifying glass, are do-able.

#3 I’ve done a few times to fix broken electronics/pc's, but it takes some supplies and tools many hobbyists probably don't have yet.

If people haven't done the easy category yet, they need to learn.. I'd say go for the surface mount components.

Intermediate can be frustrating, but w/ the help of solder wick and a magnifying glass, are do-able.

#3 I’ve done a few times to fix broken electronics/pc's, but it takes some supplies and tools many hobbyists probably don't have yet.

If people haven't done the easy category yet, they need to learn.. I'd say go for the surface mount components.

What are peoples feelings about building with (at least some) surface mount parts?

It is getting very difficult to source through-hole ICs, so much so that the design would probably be compromised by not using some SMT parts.

As I see it there are three categories of SMT with regards to home assembly:

Easy - 0.05" pitch parts like SOICs (most opamps are in this catagory)

Intermediate - Finer pitch, down to 0.5mm, but still with exposed leads that can be soldered with an iron. TSSOP packages and the like.

Advanced - Packages that have pads that really need to be soldered with reflow, either hot a air gun or "toaster oven". This includes packages like QFNs.

Can most people at least deal with "easy" parts?

Pete

If you choose the parts that are as large as possible you will win over more people.

And as Jan says, most of us can with some effort get to the second level.

A toaster oven with a convection setting, some patience and good lighting gets you one level more. So some of this is doable if there is some instruction.

But it will seperate out people that are really interested from people slightly interested.

What are peoples feelings about building with (at least some) surface mount parts?

It is getting very difficult to source through-hole ICs, so much so that the design would probably be compromised by not using some SMT parts.

As I see it there are three categories of SMT with regards to home assembly:

Easy - 0.05" pitch parts like SOICs (most opamps are in this catagory)

Intermediate - Finer pitch, down to 0.5mm, but still with exposed leads that can be soldered with an iron. TSSOP packages and the like.

Advanced - Packages that have pads that really need to be soldered with reflow, either hot a air gun or "toaster oven". This includes packages like QFNs.

Can most people at least deal with "easy" parts?

Pete

Yes, even my tri-focaled, superannuated eyes can work with small components down to about 0.05" pitch, SOT23, 0603 (at least 0805) but it takes patience and practice. Beyond that it becomes more frustration rather than fun.If you choose the parts that are as large as possible you will win over more people. . . .

Yeah, it takes some instruction, some practice, and some outlay of money and bench space that I'd rather devote more directly to the goal of precise measurements.And as Jan says, most of us can with some effort get to the second level.

A toaster oven with a convection setting, some patience and good lighting gets you one level more. So some of this is doable if there is some instruction.

You didn't mean it that way, but this statement sounds a little elitist. Let's keep this as a hobby - a recreational activity - not a contest or competition to see who can do quality work with the smallest components. Even professional manufacturers don't try to work the small packages with human hands. Some may take it on as a challenge, or a source of pride and feeling of accomplishment to master the skills, but most of us are "really interested" in the performance of the electronics, not our personal performance in the areas of visual acuity and manual dexterity.But it will seperate out people that are really interested from people slightly interested.

Dale

Quote:

But it will seperate out people that are really interested from people slightly interested.

You didn't mean it that way, but this statement sounds a little elitist. Let's keep this as a hobby - a recreational activity - not a contest or competition to see who can do quality work with the smallest components. Even professional manufacturers don't try to work the small packages with human hands. Some may take it on as a challenge, or a source of pride and feeling of accomplishment to master the skills, but most of us are "really interested" in the performance of the electronics, not our personal performance in the areas of visual acuity and manual dexterity.

Dale

Your right, I didn't mean it that way.

Never even thought about it that way.

What I meant was simple. If this is going to really push the boundaries out to where it makes quite a difference, I will be willing to pop 40 or 50 dollars on an oven and take a whack at the smaller packages. I have a surface mount microscope and it helps, but some of the packages are pushing the limits of even that.

The over idea may well be the way to go. It can work rather well.

Some of us are getting "long of tooth" so to speak, and getting visual and mechanically challenged.

I can handle 0603s, but 0402 are right out.

No need of an oven for 0.5mm packages if you develop the technique.

Over solder and remove the excess with solder wick.

The loss of TH parts is going to be a challenge for a lot of young people growing up.

I can handle 0603s, but 0402 are right out.

No need of an oven for 0.5mm packages if you develop the technique.

Over solder and remove the excess with solder wick.

The loss of TH parts is going to be a challenge for a lot of young people growing up.

Can we add an "easiest" aka "lazy-a$$" option? A pre-stuffed PCB with whichever SMT parts best suited for the new design.

Overvoltage protection

Well, I've investigated a few possible overvoltage protection schemes. They all have issues.

Using FETs will lower the noise, but will increase the distortion (at least according to simulation). So far I cannot find any solution that is better than a resistor.

Perhaps I can make the resistor smaller, and beef up the clamps. And maybe even add a fuse as a last resort protection for a long-term overvoltage (the HP8903 does this - and I've blown it once!)

Anybody have any brilliant ideas?

Pete

Well, I've investigated a few possible overvoltage protection schemes. They all have issues.

Using FETs will lower the noise, but will increase the distortion (at least according to simulation). So far I cannot find any solution that is better than a resistor.

Perhaps I can make the resistor smaller, and beef up the clamps. And maybe even add a fuse as a last resort protection for a long-term overvoltage (the HP8903 does this - and I've blown it once!)

Anybody have any brilliant ideas?

Pete

Boonton uses a fuse and a small inductor - the Tektronix differential amp has a "Pre-Charge" button which assumes that everyone knows how to use it.

Using FETs will lower the noise, but will increase the distortion (at least according to simulation). So far I cannot find any solution that is better than a resistor.

Perhaps I can make the resistor smaller, and beef up the clamps. And maybe even add a fuse as a last resort protection for a long-term overvoltage (the HP8903 does this - and I've blown it once!)

Anybody have any brilliant ideas?

Noise of resistors is overestimated compared to other components, keep them as is. Anyone who don't like them can solder something else, there is a plenty of space (Pete, you can leave extra room on PCB for tweakers).

As somewhat improved variant - what about Vishay low TCR thin film (made with passivated nichrome) or Vishay bulk metal foil (Z-foil) resistors? I think the last would be the best choice, please correct me if I'm wrong here.

Look at through-hole resistors of series S102C/Y0007, S104D/Y0011, S105D/Y0012, S106D/Y0013, resistance range 0.5 Ohm - 1M. Price is enormously high for just a resistor - $23/pc.

Last edited:

Well, I've investigated a few possible overvoltage protection schemes. They all have issues.

Using FETs will lower the noise, but will increase the distortion (at least according to simulation). So far I cannot find any solution that is better than a resistor.

Pete

The idea should work, which ones did you try, how were they wired?

Andrew

I built one of the originals straight away. I found it to be too noisy and incompatible with balanced connections. I tried using a VXPocket card and it wasn't at all usable in this configuration. So mine has only collected dust since completion.

So my input would be for balanced I/O, a PCB that is designed to fit the Hammond 1455 series of extruded alloy cases, front/rear panels to match and a less noisy power supply.

Regards, KM

So my input would be for balanced I/O, a PCB that is designed to fit the Hammond 1455 series of extruded alloy cases, front/rear panels to match and a less noisy power supply.

Regards, KM

The idea should work, which ones did you try, how were they wired?

Andrew

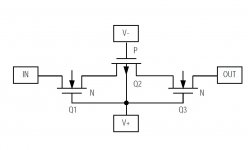

I was looking at circuits like this. I tried various MOSFETs - need at least 100V VDS to be worthwhile. The problem is that the rds(on) increases as the signal voltage deviates from zero. We are shooting for very low distortion (<.001% contribution from this, I would say) and I was not getting there.

Attachments

My preference as well along with balanced inputs, galvanic isolation, 20mV range, and brighter display.Can we add an "easiest" aka "lazy-a$$" option? A pre-stuffed PCB with whichever SMT parts best suited for the new design.

So my input would be for balanced I/O, a PCB that is designed to fit the Hammond 1455 series of extruded alloy cases, front/rear panels to match and a less noisy power supply.

Regards, KM

Those improvements are definitely on the list. A full metal case, larger to get some physical separation from the power supply, and no DC/DC converter module - instead, probably a flyback running at >250kHz with post-LDO regulators.

And balanced in and out.

BTW, the sound card side on the original is already balanced.

- Status

- Not open for further replies.

- Home

- Design & Build

- Equipment & Tools

- Improved Sound Card Interface - Ideas and Suggestions?